Professional Documents

Culture Documents

Ds sp6002 en Co

Ds sp6002 en Co

Uploaded by

Janaka GunawardhanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds sp6002 en Co

Ds sp6002 en Co

Uploaded by

Janaka GunawardhanaCopyright:

Available Formats

SF₆ gas solutions

Gas density monitor

With optional calibration valve for recalibration

Model GDM-100

WIKA data sheet SP 60.02

Applications

■ Medium and high-voltage equipment

■ Gas density monitoring of closed SF6 gas tanks

■ Raising an alarm when defined limit values have been

reached

Special features

■ On-site display with switch contact

■ Temperature-compensated and hermetically sealed,

therefore no influence of temperature fluctuations,

differences in level and atmospheric pressure fluctuations

■ Compensation possible for gas mixtures

■ Functional check or recalibration possible without

Gas density monitor with calibration valve,

dismounting, in accordance with EU regulation no. model GDM-100

517/2014 on fluorinated greenhouse gases

■ Test connection is welded to prevent leakage

Description

The WIKA gas density measuring instruments provide With the help of the firmly welded calibration valve, the

reliable warnings against dangerously low gas levels, even gas density monitor can be shut off from the process and

under extreme ambient conditions. Electrical switch contacts recalibrated without having to disassemble it. This not only

warn the plant operator when the gas density drops below reduces maintenance time but also minimises the risks of SF₆

defined levels due to leakage. gas emissions and potential leakages during recommissioning.

Via the on-site display, the pressure based on 20 °C [68 °F] When connecting a recalibration instrument (e.g. model

can be read directly on the instrument. ACS-10 or model BCS-10) to the recalibration valve, the

gas density monitor is automatically disconnected from the

With regard to switchgear safety, asset protection and gas compartment and a recalibration can be performed.

environmental protection, it is common to perform functional Following the recalibration process, the recalibration

checks on a regular basis. Article 5 of EU regulation no. instrument can then be disconnected from the recalibration

517/2014 on fluorinated greenhouse gases, provides for valve and the connection to the gas compartment is

checking of the leakage detection system at least every 6 years re-established automatically.

if it contains > 22 kg SF₆ gas and the plant was commissioned

after 01 January 2017. The recalibration valve is also available as a retrofit solution

for gas density monitors already installed in the field, as

model GLTC-CV, and can be mounted between the gas

compartment and gas density monitor.

WIKA data sheet SP 60.02 ∙ 05/2021 Page 1 of 5

Data sheets showing similar products:

Recalibration valve for retrofitting to gas density monitors and other leakage detection systems; model GLTC-CV; see data sheet SP 61.16

Gas density monitor Window

Selectable versions

Nominal size

Option 1 Laminated safety glass

100

Option 2 Clear non-splintering plastic

Calibration pressure PE

To customer specification Ring

Bayonet ring, stainless steel, secured by means of 3 welding

Accuracy specifications spots

■ ±1 % at an ambient temperature of +20 °C [68 °F]

■ ±2.5 % at an ambient temperature of -20 … +60 °C Permissible air humidity

[-4 ... +140 °F] and with calibration pressure in accordance ≤ 90 % r. h. (non-condensing)

with reference isochore (reference diagram KALI-Chemie

AG, Hanover, prepared by Dr. Döring 1979) Ingress protection

IP65 per IEC/EN 60529

Scale range

Vacuum and overpressure range with measuring span of Weight

1.6 ... 25 bar (at an ambient temperature of 20 °C [68 °F] and With gas filling: approx. 0.8 kg

gaseous phase) With fill fluid: approx. 1.2 kg

Permissible ambient temperature High-voltage test 100 %

Operation: -20 ... +60 °C [-4 ... +140 °F], gaseous phase 2 kV, 50 Hz, 1 s

Storage: -50 ... +60 °C [-58 ... +140 °F]

Process connection Switch contacts

G ½ B per EN 837, lower mount

Stainless steel, spanner flats 22 mm Electrical connection

Cable socket with compression fitting M20 x 1.5

Other connections and connection locations on request. Wire cross-section max. 2.5 mm²

Pressure element Number of switch contacts

Stainless steel, welded

Gas-tight: Leakage rate ≤ 1 · 10-8 mbar · l / s Selectable versions

Test method: Helium mass spectrometry Option 1 1 magnetic snap-action contact

Option 2 2 magnetic snap-action contacts

Movement Option 3 3 magnetic snap-action contacts

Stainless steel

Bimetal link (temperature compensation)

Switching directions

Dial Selectable versions

Aluminium Option 1 Falling pressure

The scale range is subdivided into red, yellow and green

Option 2 Rising pressure

ranges

Pointer Switching functions

Aluminium, black Selectable versions

Option 1 Normally open

Case

Option 2 Normally closed

Selectable versions Option 3 Change-over contact (max. 2 switch points)

Option 1 Stainless steel, with gas filling

Option 2 Stainless steel, with fill fluid Circuits

Selectable versions

Gas-tight: Leakage rate ≤ 1 · 10-5 mbar · l / s

Option 1 Galvanically connected (not for change-over

contact)

Option 2 Galvanically isolated

WIKA data sheet SP 60.02 ∙ 05/2021 Page 2 of 5

Switching accuracy

Switch point = calibration pressure PE: See accuracy specifications

Switch point ≠ calibration pressure PE: Parallel to the reference isochore of the calibration pressure

Max. switching voltage

AC 250 V

Switching power

With gas filling: 30 W / 50 VA, max. 1 A

With fill fluid: 20 W / 20 VA, max. 1 A

Material of switch contacts

80 % Ag / 20 % Ni, gold-plated

Further information on magnetic snap-action contacts in data sheet AC 08.01

Calibration valve

All weld seams are qualified in accordance with DIN EN ISO 15613 in combination with DIN EN ISO 15614-1 and DIN EN ISO

15614-12 by the notified body TÜV Süd.

Tightening torque, test connection: 40 Nm ±10 %

Gas-tight: Leakage rate ≤ 1 · 10-8 mbar · l/s

Dimensions in mm

Version without calibration valve

WIKA data sheet SP 60.02 ∙ 05/2021 Page 3 of 5

Version with calibration valve

Any arrangement of the test valve possible

Other process connections on request approx. 88

approx. 94

approx. 131.5

approx. 57 incl. protective cap

approx. 88

approx. 94

approx. 103

approx. 57 incl. protective cap

WIKA data sheet SP 60.02 ∙ 05/2021 Page 4 of 5

Approvals

Logo Description Country

EU declaration of conformity European Union

Low voltage directive

Manufacturer‘s information and certificates

Logo Description

- China RoHS directive

→ Approvals and certificates, see website

Accessories for version with calibration valve

Description Order number

Recalibration valve for retrofitting to gas density monitors and other leakage 14484687

detection systems already installed in the field, model GLTC-CV See WIKA data sheet

Any arrangement of the test valve possible SP 61.16

Other process connections on request

Adapter from test connection (M26 x 1.5) to quick coupling 14146937

Protective cap for test connection (M26 x 1.5) 14193772

Calibration system for SF₆ gas density measuring instruments See WIKA data sheet

SP 60.08

Ordering information

Model / Process connection / Pressure unit / Measuring range / Filling pressure / Switch configuration / Gas mixture / Options /

Accessories

© 2015 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

05/2021 EN

WIKA data sheet SP 60.02 ∙ 05/2021 Page 5 of 5

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.com

www.wika.com

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Gas Metering System-Woodward - SwiftDocument4 pagesGas Metering System-Woodward - Swiftkats2404No ratings yet

- Double or Bifid Zygomaticus Major Muscle: Anatomy,: Incidence, and Clinical CorrelationDocument4 pagesDouble or Bifid Zygomaticus Major Muscle: Anatomy,: Incidence, and Clinical CorrelationBrijesh MaskeyNo ratings yet

- DM - Model GDM-100-TADocument5 pagesDM - Model GDM-100-TAvladaemsNo ratings yet

- Ds sp6005 Archived en CoDocument5 pagesDs sp6005 Archived en CoJanaka GunawardhanaNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAdenny yusufNo ratings yet

- Gas Density Monitor Model GDM-100: ApplicationsDocument4 pagesGas Density Monitor Model GDM-100: Applicationsdenny yusufNo ratings yet

- Attachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFDocument17 pagesAttachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFIbrahim Ben AmeurNo ratings yet

- Gas Density Monitor Model 233.52.063, With Gas Filling: ApplicationsDocument3 pagesGas Density Monitor Model 233.52.063, With Gas Filling: Applicationsdenny yusufNo ratings yet

- Sampling ProbeDocument5 pagesSampling Probetriminhdang_phar6701No ratings yet

- Pressure Switch Catalog Letest-91-109Document18 pagesPressure Switch Catalog Letest-91-109SUSOVAN BISWASNo ratings yet

- K-Gas Metering SystemDocument4 pagesK-Gas Metering SystemmohamadziNo ratings yet

- Pressure Sensors XM - ADW5M129012Document2 pagesPressure Sensors XM - ADW5M129012Carlos RodriguezNo ratings yet

- Kion C11 / Kion C22: Evacuation & Refrigerant Charging Equipment For Flammable GasesDocument6 pagesKion C11 / Kion C22: Evacuation & Refrigerant Charging Equipment For Flammable GasesSylvain AguedaNo ratings yet

- G65 and G100: Diaphragm MetersDocument4 pagesG65 and G100: Diaphragm MetersMiguel Angel Morales CastroNo ratings yet

- Ap B14 02L 01e - Akm - 38750 PDFDocument4 pagesAp B14 02L 01e - Akm - 38750 PDFsamsungloverNo ratings yet

- Condumax II Transportable 97149 US Datasheet-V1Document4 pagesCondumax II Transportable 97149 US Datasheet-V1MuhammadUmairNo ratings yet

- Catalog Zenner GasDocument24 pagesCatalog Zenner GasRan-Ran YTNo ratings yet

- En Aalborg EM201610 GFCDocument5 pagesEn Aalborg EM201610 GFCNguyen Van NangNo ratings yet

- Clause 7.2.8. Enclosure Tightness Test at Ambient TemperatureDocument1 pageClause 7.2.8. Enclosure Tightness Test at Ambient Temperaturelnhoang.fgroupNo ratings yet

- Gas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionDocument12 pagesGas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionchauNo ratings yet

- Gas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TADocument4 pagesGas Density Monitor (GDM) With Attached Gas Density Transmitter Model 233.52.100 TAbehnamatgNo ratings yet

- Differential Pressure DetectorsDocument4 pagesDifferential Pressure Detectorskdp_806212786No ratings yet

- ACD G10 G16 EnglishDocument4 pagesACD G10 G16 Englishnavivoc270No ratings yet

- MT - Incubadora de CO2 SanyoDocument187 pagesMT - Incubadora de CO2 SanyoRenato MouraNo ratings yet

- Catalog Chandler Engineering - ETA.0215Document3 pagesCatalog Chandler Engineering - ETA.0215José RodriguezNo ratings yet

- Gas CoolerDocument9 pagesGas CoolerKHANNNNo ratings yet

- s1gb - KDF KDG 9Document4 pagess1gb - KDF KDG 9fcordNo ratings yet

- Pressure Switch CatalogueDocument0 pagesPressure Switch CatalogueMilosglNo ratings yet

- SF6 Meter DatasheetDocument3 pagesSF6 Meter DatasheetHaider-e-KararNo ratings yet

- Bosch Afs Maf SensorDocument4 pagesBosch Afs Maf SensorAndo Tamkõrv100% (1)

- Model 2331D FDocument2 pagesModel 2331D FhopkhtnNo ratings yet

- Series AR712/722 Gas Chromatograph: Analysis of Impurities in ArgonDocument2 pagesSeries AR712/722 Gas Chromatograph: Analysis of Impurities in ArgonZaid MajedNo ratings yet

- Burgmann Ts2000eDocument4 pagesBurgmann Ts2000edeyoooooNo ratings yet

- Emerson TGU-53 LNG TanksDocument8 pagesEmerson TGU-53 LNG Tankssaid250009250No ratings yet

- 123 and 245 KV Instrument Transformers With G: Technical DataDocument1 page123 and 245 KV Instrument Transformers With G: Technical DataKennedy Alves VieiraNo ratings yet

- Proportion Air Flow Controller ManualDocument8 pagesProportion Air Flow Controller ManualRakesh RanjanNo ratings yet

- Mmy 30Document2 pagesMmy 30docrafiNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- Binder 8Document3 pagesBinder 8Hema S rashidNo ratings yet

- DS8681 Standard EU ENDocument12 pagesDS8681 Standard EU ENMauricioNo ratings yet

- TecJet 50 Plus Precision FlowDocument4 pagesTecJet 50 Plus Precision FlowMuhammad Talha MalikNo ratings yet

- Density Controller: GMDX95Document6 pagesDensity Controller: GMDX95Yasith Chinthaka50% (2)

- Vemmtec-IGTM-Turbine MeterDocument12 pagesVemmtec-IGTM-Turbine MeterErwan Omar Mukhtar100% (1)

- Ol715eng 2Document1 pageOl715eng 2Omar SaaedNo ratings yet

- Operation ManualDocument12 pagesOperation ManualSeaze RooNo ratings yet

- CO2 System PresentationDocument23 pagesCO2 System PresentationPankaj PandeyNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Bosch HFM 5 Sensors - Airmass PDFDocument3 pagesBosch HFM 5 Sensors - Airmass PDFLaurentiu79No ratings yet

- Pressure Switches BrochureDocument38 pagesPressure Switches BrochurearavindNo ratings yet

- MICROMOTION Gas-Specific-Gravity-MetersDocument20 pagesMICROMOTION Gas-Specific-Gravity-MetersseenubalaNo ratings yet

- GIR 3000 Eng ManualDocument31 pagesGIR 3000 Eng ManualsahilmetroNo ratings yet

- Dungs GW 50 A5 ManualDocument5 pagesDungs GW 50 A5 ManualMazhar IqbalNo ratings yet

- Transformer TestsDocument54 pagesTransformer TestsMohammedSaadaniHassani75% (4)

- Pressure Switch Bourdon 931Document4 pagesPressure Switch Bourdon 931tpchowoNo ratings yet

- 100 HP DatasheetDocument6 pages100 HP DatasheetPUNiiZIHIEIRNo ratings yet

- CIL Rotameters CBGN 2016Document8 pagesCIL Rotameters CBGN 2016Hisham ABD ALRASOULNo ratings yet

- Data Sheet CON300-FL v1Document3 pagesData Sheet CON300-FL v1claudia.metrokalNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Ip-Q24-05l-01e Informa PMD ADocument8 pagesIp-Q24-05l-01e Informa PMD AJanaka GunawardhanaNo ratings yet

- Catalog SF6 Valves and ConnectionsDocument148 pagesCatalog SF6 Valves and ConnectionsJanaka GunawardhanaNo ratings yet

- Power Supplies For Industrial Use - Rail Mounting - ABLM1A24025Document11 pagesPower Supplies For Industrial Use - Rail Mounting - ABLM1A24025Janaka GunawardhanaNo ratings yet

- Grade 5 Scholarship Paper Marking Scheme 2021Document6 pagesGrade 5 Scholarship Paper Marking Scheme 2021Janaka GunawardhanaNo ratings yet

- 20230726155048Document1 page20230726155048Janaka GunawardhanaNo ratings yet

- Correlation of Accountancy StudentsDocument10 pagesCorrelation of Accountancy StudentsAngelica Magdaraog100% (1)

- Sephora Facebook Ad Case StudyDocument3 pagesSephora Facebook Ad Case StudySocial Fresh ConferenceNo ratings yet

- Research-L11 Quantitative Research DesignDocument21 pagesResearch-L11 Quantitative Research DesignVevienne Canta100% (1)

- Stage 1 Academic Appeal FormDocument5 pagesStage 1 Academic Appeal FormNareinthirran KirushiraamNo ratings yet

- Sistema 2000-09Document52 pagesSistema 2000-09Dave ChecaNo ratings yet

- 1 - 4 Introduction To QualityDocument87 pages1 - 4 Introduction To Qualityjunita guiNo ratings yet

- Medical AbbreviationsDocument5 pagesMedical AbbreviationsJumar RanasNo ratings yet

- (123doc) - Tong-Hop-8-De-Thi-Ket-Thuc-Hoc-Phan-Tieng-Anh-2Document34 pages(123doc) - Tong-Hop-8-De-Thi-Ket-Thuc-Hoc-Phan-Tieng-Anh-2Lục Sĩ Thành ĐạtNo ratings yet

- Use of Medicinal Plants in The South-Eastern Area of The Partenio Regional Park (Campania, Southern Italy)Document11 pagesUse of Medicinal Plants in The South-Eastern Area of The Partenio Regional Park (Campania, Southern Italy)Rigotti BrNo ratings yet

- Feedback Activities - Second Term - First YearDocument8 pagesFeedback Activities - Second Term - First YearEmily PradoNo ratings yet

- Catalogue ParafoudresDocument15 pagesCatalogue ParafoudresKDANo ratings yet

- Final Revision System 22Document124 pagesFinal Revision System 22Ricson BondadNo ratings yet

- CBasicDocument37 pagesCBasicRobert EvansNo ratings yet

- Reciprocal Teaching of Comprehension Strategies Improves EFL Learners' Writing AbilityDocument14 pagesReciprocal Teaching of Comprehension Strategies Improves EFL Learners' Writing AbilityEVELYN GUISELLE CASTILLO ZHAMUNGUINo ratings yet

- Lab 1 (Barometer)Document8 pagesLab 1 (Barometer)hanif274No ratings yet

- 6 Stylistic Syntax of The English Language Stylistic Devices ofDocument19 pages6 Stylistic Syntax of The English Language Stylistic Devices ofKaterina AndreevaNo ratings yet

- Old - CALYPSO AFS - Electrical ManualDocument299 pagesOld - CALYPSO AFS - Electrical ManualTarik SendroNo ratings yet

- Profibus-According To Iec 61158en 50170Document58 pagesProfibus-According To Iec 61158en 50170mohammedrezaeeNo ratings yet

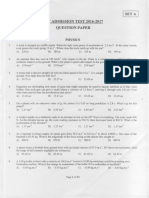

- Iut Admission Test 2016.2017 Question Paper: PhysicsDocument13 pagesIut Admission Test 2016.2017 Question Paper: PhysicsAhsan Habib TanimNo ratings yet

- How To Land A Post-Baccalaureate Research ExperienceDocument5 pagesHow To Land A Post-Baccalaureate Research ExperienceBizoy RahmanNo ratings yet

- Ifu Euroline Atopy IgeDocument12 pagesIfu Euroline Atopy IgeDwitaRiadiniNo ratings yet

- AnnuallyDocument70 pagesAnnuallyFloreidNo ratings yet

- Translation Literature in India: January 2012Document9 pagesTranslation Literature in India: January 2012Yukta NaudiyalNo ratings yet

- Poly (Meth) Acrylate Based CoatingsDocument9 pagesPoly (Meth) Acrylate Based CoatingssuryaprakashreddycNo ratings yet

- Jenga : Urizwick TDocument4 pagesJenga : Urizwick TSurya Dharma Ali MaheswaraNo ratings yet

- 8051 TMOD RegisterDocument4 pages8051 TMOD RegisterakshayNo ratings yet

- Ratio Analysis of InterloopDocument9 pagesRatio Analysis of InterloopSyed Usarim Ali ShahNo ratings yet

- Chapter 3.2Document63 pagesChapter 3.2SIDDHARTH KUMARNo ratings yet

- Class 9 BiologyDocument32 pagesClass 9 BiologyAbinaya ParthasarathyNo ratings yet