Professional Documents

Culture Documents

Novo EP-Crystal

Uploaded by

Sherif Hadi0 ratings0% found this document useful (0 votes)

2 views2 pagesOriginal Title

Novo_EP-Crystal

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views2 pagesNovo EP-Crystal

Uploaded by

Sherif HadiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

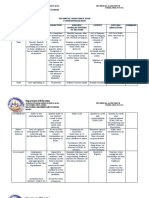

NOVO EP - CRYSTAL

Last update: - 24 / 06 / 2021 (2)

Two components, High Mechanical and Chemical Resistance, Transparent

Epoxy.

DEFINITION Mechanical properties for mortar

Novo EP- CRYSTAL is two components, solvent • Density 1.11 kg/l

free, non-pigmented liquid epoxy resin • Compressive strength 500 - 1000 kg/cm2

• It is used as a coating where outstanding • Flexural strength 200 - 400 kg/cm2

chemical resistance and mechanical stresses • Tensile strength 150 - 250 kg/cm2

are major Requirements. • Bond strength > concrete

• It can also be mixed with considerable • Abrasion resistance 15 mg

amounts of mineral aggregates to produce, Chemical Resistance

non-shrink, multi - purpose epoxy mortar with

high mechanical and chemical properties. Sulphuric acid 50% ex

• It can be used in drinking - water tanks and Hydrochloric acid 20% ex

food stores. Phosphoric acid 50% good

FIELDS OF USE Nitric acid 10% ex

Novo EP- CRYSTAL Used as: Acetic acid 5% ex

• A protective coating for concrete floorings Sodium hydroxide 50% ex

subject to chemical attack and high mechanical Potassium hydroxide 50% ex

stresses. Ammonium nitrate ex

• Can be used as screed for industrial floors. Fuels Petrol ex

• Repairing mortar for concrete structure. Benzene good

• Filling of concrete cracks. DIRECTIONS FOR USE

• Bonding mortar for most of the building (A) SURFACE PREPARATION

materials and fixing dowels. • The substrate must be capable of resisting the

ADVANTAGES intended mechanical stresses (C28>250

• It is high resistance against mechanical kg/cm2).

stresses and chemical effects. • The concrete surface must be dry (dampness

• Ready to use after mixing the 2 components. not more than 4 %). Free of dust and laitance,

• Adding fillers to Novo EP- CRYSTAL, oil, grease and other impurities which can

enables producing variety of epoxy mortars in affect the adhesion.

different consistencies according to the (B) MIXING

quantity of added fillers. • Component B (hardener) should be added to

PHYSICAL PROPERTIES @ 25 C° component A (resin) and mixed together

using a suitable mechanical mixer for a

DESCRIPTION RESULT

period of 3 minutes. The velocity of the

Color Transparent mixer must not exceed 300 r.p.m.

Solid content (by weight) 100 % • In the case of mortar, the filling material is

Density 1.11 ±0.02 kg/l

Mixing ratio A: B by weight 2: 1

added to the mixture and mixed again for a

Pot life 30 minutes period of 3 minutes.

application temperature 5°C -45 °C

• The mixture is then transferred to a larger

clean vessel; all materials stacked to the

Initial setting time 8 hours

walls of the original container must be

Final setting time 24 hours

Full hardness 7 days

scraped off with a knife and added and

Recoating time 18-24 hours renewed stirring.

ISSUE DATE/REV: - 1/5/2021 ISSUE REV NO: - 2/1 FP-14-07/EN

RATE OF CONSUMPTION

• 0.50 kg/m2 for the primer coat.

• 1.5kg/m²/mm thickness for topping

layer.

STORAGE

12 months under national regulations (dry,

cool, and far from heat and ignition).

PRECAUTIONS

• This product is for professional use only.

The applicators and operators shall be

trained, experienced and have the capability

and equipment to mix/stir and apply the

coatings correctly and according to technical

Documentation. Applicators and operators

shall use appropriate personal protection

equipment when using this product. This

guideline is given based on the current

knowledge of the product. Any suggested

deviation to suit the site conditions shall be

forwarded to the responsible representative

for approval before work.

HEALTH AND SAFETY

• Please observe the precautionary notices

displayed on the container. Use under well

ventilated conditions. Do not inhale spray

mist. Avoid skin contact. Spillage on the

skin should immediately be removed with

suitable cleanser, soap and water. Eyes

should be well flushed with water and

medical attention sought immediately.

ISSUE DATE/REV: - 1/5/2021 ISSUE REV NO: - 2/1 FP-14-07/EN

You might also like

- TDS - PPro Concrete Epoxy LV - 051520 PDFDocument3 pagesTDS - PPro Concrete Epoxy LV - 051520 PDFAllan James Anticamara Fernandez75% (8)

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- QMC® EPO-MASTER 50 - English - v1.0.0Document4 pagesQMC® EPO-MASTER 50 - English - v1.0.0Ahmed TahaNo ratings yet

- Epoxy Floor Coating: Description FeaturesDocument2 pagesEpoxy Floor Coating: Description FeaturesRayon 9No ratings yet

- Ep 150 PDS EngDocument4 pagesEp 150 PDS EngMajdi ShannibNo ratings yet

- Masterprotect 1825 TdsDocument3 pagesMasterprotect 1825 TdsYudhaNo ratings yet

- Aqua Epoxy PDFDocument2 pagesAqua Epoxy PDFAhKimNo ratings yet

- Tds Floor PatchDocument2 pagesTds Floor PatchDivyanshu GuptaNo ratings yet

- Pentens E-501LN Data SheetDocument2 pagesPentens E-501LN Data Sheetamelinda jocelinNo ratings yet

- Strongcoat Epoxy FDocument4 pagesStrongcoat Epoxy Fosama mohNo ratings yet

- Masterprotect 1825 TdsDocument3 pagesMasterprotect 1825 TdsSHAIK ASIMUDDINNo ratings yet

- Technical Data Sheet THC4001L (Rev01)Document3 pagesTechnical Data Sheet THC4001L (Rev01)romanuNo ratings yet

- Pentaline 2000 F17Document4 pagesPentaline 2000 F17Vineet KhanduriNo ratings yet

- Florgard SL: Self Levelling Epoxy Based FlooringDocument3 pagesFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNo ratings yet

- PC-7320 (Polypoxy) - TDSDocument2 pagesPC-7320 (Polypoxy) - TDSedwin cNo ratings yet

- Kemapoxy 150Document2 pagesKemapoxy 150Mosaad KeshkNo ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsrayNo ratings yet

- Mastertop 1705 TdsDocument3 pagesMastertop 1705 TdsrenandiaNo ratings yet

- TDS - PPro Concrete Epoxy HV - 022019Document2 pagesTDS - PPro Concrete Epoxy HV - 022019Jerome Li100% (1)

- Quito Epoxy TDSDocument2 pagesQuito Epoxy TDSNader ToutounjiNo ratings yet

- Arocoat - Repair Paint Data SheetDocument3 pagesArocoat - Repair Paint Data SheetIsboNo ratings yet

- PDS - Moisture SealDocument2 pagesPDS - Moisture Sealjasondouglas1810workNo ratings yet

- Thor EfccDocument2 pagesThor Efccazam RazzaqNo ratings yet

- Hi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFDocument5 pagesHi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFPushpendraNo ratings yet

- Strongcoat PE350Document48 pagesStrongcoat PE350Ahmad ElghazolyNo ratings yet

- Epoxy Coating Solvent Free TDSDocument3 pagesEpoxy Coating Solvent Free TDSMohamed MagdiNo ratings yet

- X-Tech Primer FillerDocument2 pagesX-Tech Primer FillersamerNo ratings yet

- SpECtite HP600Document3 pagesSpECtite HP600ahmed hamedNo ratings yet

- Nitocote EpswDocument4 pagesNitocote EpswmohamedbossilyNo ratings yet

- Sealbond 218 P Pressure Injection EpoxyDocument1 pageSealbond 218 P Pressure Injection EpoxyLeoven Jef Suzara Lorin0% (1)

- Aquatec Red Oxide Primer: Technical Data SheetDocument2 pagesAquatec Red Oxide Primer: Technical Data SheetLai Teo KuanNo ratings yet

- Weberep Epo 412 CRY PLUSDocument2 pagesWeberep Epo 412 CRY PLUSFaysal MadiNo ratings yet

- DS - 426 - Epilux Solvent Free Novalac Epoxy CoatingDocument2 pagesDS - 426 - Epilux Solvent Free Novalac Epoxy CoatingRatish NairNo ratings yet

- HB Epoxy Zinc Rich Primer - TDSDocument2 pagesHB Epoxy Zinc Rich Primer - TDSazam RazzaqNo ratings yet

- 2 Ton Epoxy: Technical Data SheetDocument2 pages2 Ton Epoxy: Technical Data SheetLeomar TorrealbaNo ratings yet

- Epocoat FCDocument1 pageEpocoat FCRafael ObusanNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Technical Data Sheet Masterbrace 2200Document2 pagesTechnical Data Sheet Masterbrace 2200Avinash PrajapatiNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Ac Epoxy Joint GroutDocument2 pagesAc Epoxy Joint GroutbhagwatpatilNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- My T Bond Fast and Clear Epoxy TDSDocument2 pagesMy T Bond Fast and Clear Epoxy TDSChetan MahajanNo ratings yet

- Kemapoxy 151 EDocument2 pagesKemapoxy 151 Ekozima1223No ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELMansoor AliNo ratings yet

- EnamopxyDocument5 pagesEnamopxyTawfiq ZidanNo ratings yet

- Datasheet Epidermix 344Document2 pagesDatasheet Epidermix 344Vicky MunienNo ratings yet

- Ds Medapoxy RepDocument2 pagesDs Medapoxy RepfaridNo ratings yet

- Dural Epoxy PrimerDocument3 pagesDural Epoxy PrimershinellajohnsonNo ratings yet

- Epoxy - Resin-51 For Swimming PoolsDocument2 pagesEpoxy - Resin-51 For Swimming PoolsalanNo ratings yet

- Floor Patch Fast CureDocument2 pagesFloor Patch Fast CureStevenFerrelNo ratings yet

- Strongcoat HB400Document53 pagesStrongcoat HB400irfan shafiqueNo ratings yet

- Ep 280 WHG PDS EngDocument5 pagesEp 280 WHG PDS EngMajdi ShannibNo ratings yet

- MS JDB 007 - Annexure 2 - ABE Epidermix 344Document2 pagesMS JDB 007 - Annexure 2 - ABE Epidermix 344Ben WalkerNo ratings yet

- TDS Fosroc Nitocote EP405 SEADocument4 pagesTDS Fosroc Nitocote EP405 SEAPT PP BIH SanurNo ratings yet

- MX-99-2K MP SB: Multipurpose Epoxy CoatinglDocument2 pagesMX-99-2K MP SB: Multipurpose Epoxy CoatinglGo Joko AriefNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- Brochure - FluidAbrasionWear. 200 Series - rv3.31072019Document20 pagesBrochure - FluidAbrasionWear. 200 Series - rv3.31072019voronwe5No ratings yet

- Weber - Joint Epo WBDocument2 pagesWeber - Joint Epo WBPCWizNo ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Ass AsDocument1 pageAss AsMukesh BishtNo ratings yet

- Trauma Informed Care Information From Allison Sampson Jackson PDFDocument14 pagesTrauma Informed Care Information From Allison Sampson Jackson PDFMirjana StevanovicNo ratings yet

- Stephen Spender Selected PoemsDocument28 pagesStephen Spender Selected PoemsWriting Hub100% (1)

- Camy Plants: RT Offer LetterDocument1 pageCamy Plants: RT Offer LetterShailesh DeshmukhNo ratings yet

- Captopril (Drug Study)Document3 pagesCaptopril (Drug Study)Franz.thenurse6888100% (3)

- Method Used For The Prevention of RustingDocument9 pagesMethod Used For The Prevention of RustingSaadiah MohammadNo ratings yet

- Bio 11.1 LE 2 NotesDocument7 pagesBio 11.1 LE 2 NotesCode BlueNo ratings yet

- Till Saxby Electric Pallet Truck Egv 10-12-0240 0242 0300 0302 Workshop ManualDocument22 pagesTill Saxby Electric Pallet Truck Egv 10-12-0240 0242 0300 0302 Workshop Manualmichaelfisher030690fgaNo ratings yet

- Iso Iec 13335-1-Information Technology-Concepts and Models For It SecurityDocument27 pagesIso Iec 13335-1-Information Technology-Concepts and Models For It SecurityPablo MarajNo ratings yet

- OS Prosthetics Orthotics, L3, L4 & L5Document144 pagesOS Prosthetics Orthotics, L3, L4 & L5MaxNo ratings yet

- Dt. NestleDocument9 pagesDt. NestleQytyku BoranaNo ratings yet

- Profit and Loss Statement TemplateDocument2 pagesProfit and Loss Statement TemplateAlisa VisanNo ratings yet

- Enmienda IFRS 17 IFRS2020 PDFDocument140 pagesEnmienda IFRS 17 IFRS2020 PDFOmarNo ratings yet

- Nitrox Tablice!Document6 pagesNitrox Tablice!Frane AsanovićNo ratings yet

- Chapter 1 HRMDocument31 pagesChapter 1 HRMABDULLAH MUHAMMAD RAFIQ ANWARNo ratings yet

- Icp-Aes S1Document57 pagesIcp-Aes S1fitriana dewi kurniawatiNo ratings yet

- Mech Seal VISPACDocument2 pagesMech Seal VISPACJamesNo ratings yet

- IcdDocument111 pagesIcdMedical Record RSFMNo ratings yet

- Question Epidmiolgy PDFDocument7 pagesQuestion Epidmiolgy PDFzkalel_mNo ratings yet

- System 4 Med G 7831 - PG 85362Document76 pagesSystem 4 Med G 7831 - PG 85362jerimiah_manzonNo ratings yet

- MSDS Hemolok GelDocument5 pagesMSDS Hemolok GelReniNo ratings yet

- Water Demand All SlidesDocument23 pagesWater Demand All Slidesrajat debnathNo ratings yet

- Short Tricks To Remember GK EasilyDocument3 pagesShort Tricks To Remember GK EasilyManoj KiningeNo ratings yet

- Food WebDocument12 pagesFood WebShaurya ChauhanNo ratings yet

- E25 - Lyn Joy v. Mendoza - Technical Assistance ContextualizationDocument3 pagesE25 - Lyn Joy v. Mendoza - Technical Assistance Contextualizationlyn joyNo ratings yet

- Water PotentialDocument2 pagesWater PotentialsmellybottomNo ratings yet

- Lymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsDocument2 pagesLymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsKaren ParraNo ratings yet

- 20mpe18 Aeor Assignment 3Document9 pages20mpe18 Aeor Assignment 3Shrinath JaniNo ratings yet

- ASEAN Cosmetic Labeling Requirements DOCSDocument1 pageASEAN Cosmetic Labeling Requirements DOCSmilkymilkyNo ratings yet

- Athletic Code of Conduct REVISED 020717Document6 pagesAthletic Code of Conduct REVISED 020717NewsChannel 9No ratings yet