0% found this document useful (0 votes)

997 views6 pagesColumns and Beam Steel Notes

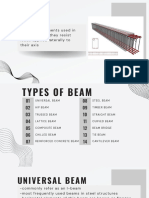

The document discusses different types of steel columns and beams used in construction including I-beams, H-beams, and W-beams. It describes their properties, typical applications, advantages, and differences. Steel pedestals are also covered as reinforced concrete blocks used to support steel columns.

Uploaded by

Kenneth Ignacio ArcillaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

997 views6 pagesColumns and Beam Steel Notes

The document discusses different types of steel columns and beams used in construction including I-beams, H-beams, and W-beams. It describes their properties, typical applications, advantages, and differences. Steel pedestals are also covered as reinforced concrete blocks used to support steel columns.

Uploaded by

Kenneth Ignacio ArcillaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Steel Columns and Beam: Introduction to different steel beam types such as standard I-beams, narrow flange, and wide flange beams.

- Comparison: I-Beam vs H-Beam: Detailed comparison of I-Beams and H-Beams including differences in design, application, and structural benefits.

- W-Beams Overview: Describes the purpose, design, and application of W-Beams in construction.

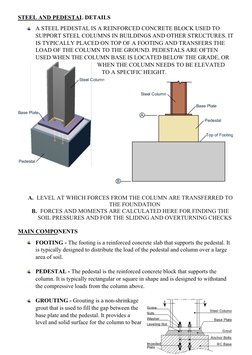

- Steel and Pedestal Details: Provides details on steel pedestals used in construction, their components, and the forces involved.