Professional Documents

Culture Documents

3305fb 3134731

3305fb 3134731

Uploaded by

VanBelkumWOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3305fb 3134731

3305fb 3134731

Uploaded by

VanBelkumWCopyright:

Available Formats

LTC3305

Lead-Acid Battery Balancer

FEATURES DESCRIPTION

n Single IC Balances Up to Four 12V Lead-Acid The LTC®3305 balances up to 4 lead-acid batteries

Batteries in Series connected in series. It is intended to be used in conjunction

n All NFET Design with a separate pre-existing battery charger as part of a

n Stackable to Balance Larger Series Battery Packs high performance battery system. All voltage monitoring,

n Standalone Balancing Operation: Requires No gate drive, and fault detection circuitry is integrated.

External μP or Additional Control Circuitry

The LTC3305 employs an auxiliary battery or an alternative

n Balancing Current Limited by External PTC Thermistor

storage cell to transfer charge to or from each individual

n Continuous Mode and Timer Mode

battery in the stack. A mode pin provides two operating

n Programmable UV and OV Fault Thresholds

modes, timer mode and continuous mode. In timer mode,

n Programmable Termination Time and Termination

once the balancing operation is completed, the LTC3305

Voltage

goes into a low power state for a programmed time and then

n Thermally Enhanced 38-Lead TSSOP Package

periodically rebalances the batteries. In continuous mode,

APPLICATIONS the balancing operation continues even after the batteries

are balanced to their programmed termination voltage.

n Telecom Backup Systems

The LTC3305 is available in a thermally enhanced 38-lead

n Home Battery Powered Backup Systems

TSSOP package.

n Industrial Electric Vehicles

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks of Linear

n Energy Storage Systems (ESS) Technology Corporation. All other trademarks are the property of their respective owners.

n Medical Equipment

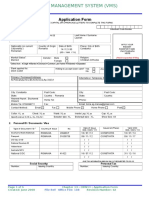

TYPICAL APPLICATION

4-Battery Balancer with Programmed High and Low Battery Voltage Faults

10µF

25V

CHARGER

VREG CM CP 1.33k SUPPLY

EN1 249Ω NGATE5

1µF

EN2

MODE

BOOST

10µF

6.04k ICHARGE

BATTERY

STACK

Battery Voltages Converge

6V TERM1

V4

25V CHARGER Over Time

TERM2 NGATE4

+

10µF 6.04k BAT4 16

UVFLT 25V

OVFLT

DONE V3

14

100k EACH BAL NGATE3 +

PTCFLT 10µF 3.01k BAT3 12

BATTERY VOLTAGE (V)

BATX 25V

BATY 10

V2

CTON LTC3305 NGATE2

10nF 10µF + 8

6.04k BAT2

25V

CTOFF 6

100nF V1

10µF NGATE6 NGATE1 4 BATTERY 1

+

CTBAT 25V 6.04k 6.04k BAT1 BATTERY 2

10nF 2 BATTERY 3

9 BATTERY 4

NGATE1-9 NGATE7

VL 0

27.4k 6.04k TIME

PTC

3305 TA01a

AUXP +

VH 10µF AUX

42.2k 25V

AUXN 6.04k

ISET NGATE8

GND

12.1k

3305 TA01 6.04k

NGATE9

3305fb

For more information www.linear.com/LTC3305 1

LTC3305

ABSOLUTE MAXIMUM RATINGS PIN CONFIGURATION

(Note 1)

TOP VIEW

Stack Voltage, V4 to GND..........................................68V

Battery Voltages, V4 to V3, V3 to V2, V2 to V1, BOOST 1 38 CM

V1 to GND................................................... –0.3V to 20V V4 2 37 CP

V3 3 36 NC

Auxiliary Cell Voltage, AUXP to AUXN......... –0.3V to 20V

AUXP 4 35 MODE

VREG Voltage................................................. –0.3V to 6V

AUXN 5 34 EN1

VH, VL Voltage...... –0.3V to Lesser of 6V or (VREG+0.3V) V2 6 33 EN2

UVFLT, OVFLT, PTCFLT, BAL, DONE, BATX, V1 7 32 TERM1

BATY Voltage................................................ –0.3V to 6V NGATE1 8 31 TERM2

EN1, EN2, MODE, TERM1, TERM2 NGATE2 9 30 VREG

Voltage................. –0.3V to Lesser of 6V or (VREG+0.3V) NGATE3 10 39 29 ISET

NGATE1, NGATE2, NGATE3, NGATE4, NGATE8, NGATE9 NGATE4 11

GND

28 VH

Voltage............... –0.3V to Lesser of 68V or (V4+0.3V) NGATE5 12 27 VL

NGATE5, NGATE6, NGATE7 NGATE6 13 26 CTBAT

Voltage............... (Greater of –0.3V or BOOST–68V) to NGATE7 14 25 CTON

(BOOST+0.3V)* NGATE8 15 24 CTOFF

UVFLT, OVFLT, PTCFLT, BAL, DONE, BATX, NGATE9 16 23 PTCFLT

BATX 17 22 DONE

BATY Current..........................................................10mA

BATY 18 21 BAL

ISET Current...............................................................1mA

OVFLT 19 20 UVFLT

CP, CM Current.......................................................50mA

Operating Junction Temperature Range FE PACKAGE

38-LEAD PLASTIC TSSOP

(Notes 2, 3)............................................. –40°C to 125°C θJA = 28°C/W

Storage Temperature Range................... –65°C to 150°C EXPOSED PAD (PIN 39) IS GND, MUST BE SOLDERED TO PCB

NC = No Connect

Lead Temperature (Soldering, 10 sec).................... 300°C

*The BOOST voltage is generated by the LTC3305 and is typically 8.45V higher than V4.

ORDER INFORMATION

(http://www.linear.com/product/LTC3305#orderinfo)

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC3305EFE#PBF LTC3305EFE#TRPBF LTC3305 FE 38-Lead Plastic TSSOP –40ºC to 125°C

LTC3305IFE#PBF LTC3305IFE#TRPBF LTC3305 FE 38-Lead Plastic TSSOP –40ºC to 125°C

Consult LTC Marketing for parts specified with wider operating temperature ranges. *The temperature grade is identified by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/. Some packages are available in 500 unit reels through

designated sales channels with #TRMPBF suffix.

3305fb

2 For more information www.linear.com/LTC3305

LTC3305

ELECTRICAL CHARACTERISTICS The l denotes the specifications which apply over the specified operating

junction temperature range, otherwise specifications are at TA = 25°C. (Note 2) V1 = 13.2V, V2 = 26.4V, V3 = 39.6V, V4 = 52.8V,

AUXP - AUXN = 13.2V, RISET = 12.1kΩ

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VBAT Individual Battery Voltage l 4 16 V

V4 Voltage at the Top of the Battery Stack l 12 64 V

VREG Regulator Output Voltage IVREG = 200µA l 2.4 2.5 2.6 V

VREG,UV Regulator Undervoltage Threshold Regulator Voltage Falling l 1.7 2.1 V

Hysteresis 125 mV

Maximum Guaranteed Load Current VREG > VREG,UV l 3 mA

Regulator Short Circuit Current Limit VREG = 0V 8 15 22 mA

Shutdown Current Measured at V4, BOOST-V4 = 0V 16 33 50 µA

Measured at V3, V2, V1, AUXP, BOOST l 0 1 µA

Supply Current While Balancing Battery 1 Measured at V4 900 1350 µA

(Notes 4, 5) Measured at V3 0 1 µA

Measured at V2 0 1 µA

Measured at V1 150 225 µA

Supply Current While Balancing Battery 2 Measured at V4 900 1350 µA

(Notes 4, 5) Measured at V3 0 1 µA

Measured at V2 150 225 µA

Measured at V1 –70 –45 µA

Supply Current While Balancing Battery 3 Measured at V4 900 1350 µA

(Notes 4, 5) Measured at V3 150 225 µA

Measured at V2 –70 –45 µA

Measured at V1 0 1 µA

Supply Current While Balancing Battery 4 Measured at V4 1050 1575 µA

(Notes 4, 5) Measured at V3 –70 –45 µA

Measured at V2 0 1 µA

Measured at V1 0 1 µA

Supply Current While Balancing any Battery Measured at AUXP 165 245 µA

Measured at AUXN –195 –130 µA

Supply Current in OFF State (MODE = 0) Measured at V4, BOOST-V4 = 0V 100 150 µA

Measured at V3, V2, V1, AUXP, BOOST 0 1 µA

Boost Pin Current While Balancing any Battery 220 330 µA

(Notes 4, 5)

VISET ISET Servo Voltage 50µA< IISET< 150µA l 1.18 1.2 1.22 V

IVH, IVL Current Out of VH and VL Pins IISET = 100µA l 31.3 33.3 35.3 µA

INGATE Current For External NMOS Turn On (Note 5) NGATE3 Current, IISET = 100µA l 2.0 2.2 2.4 mA

All Other NGATE Currents, IISET = 100µA l 1.0 1.1 1.2 mA

Leakage Current in Shutdown EN1 = EN2 = 0 l –2 2 µA

Current Programmable Range NGATE3 Current l 1 3 mA

All Other NGATE Currents l 0.5 1.5 mA

VBAT,UV Undervoltage Falling Battery Threshold (Note 6) VL = 0.4V l 3.9 4 4.1 V

VL = 1.6V l 15.6 16 16.4 V

Undervoltage Hysteresis 120 mV

Undervoltage Falling Programmable Range l 4 16 V

VBAT,OV Overvoltage Rising Battery Threshold (Note 6) VH = 0.4V l 3.9 4 4.1 V

VH = 1.6V l 15.6 16 16.4 V

Overvoltage Hysteresis 150 mV

Overvoltage Rising Programmable Range l 4 16 V

3305fb

For more information www.linear.com/LTC3305 3

LTC3305

ELECTRICAL CHARACTERISTICS The l denotes the specifications which apply over the specified operating

junction temperature range, otherwise specifications are at TA = 25°C. (Note 2) V1 = 13.2V, V2 = 26.4V, V3 = 39.6V, V4 = 52.8V,

AUXP - AUXN = 13.2V, RISET = 12.1kΩ

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

PTC Fault Threshold |BAT-AUXP| Falling 0.8 1 1.2 V

Hysteresis 100 mV

VTERMINATE |BAT-AUXP| for Which Balancing Is Terminated TERM2 = 0, TERM1 = 0 l 5.0 12.5 20.0 mV

TERM2 = 0, TERM1 = 1 l 17.5 25 32.5 mV

TERM2 = 1, TERM1 = 0 l 40 50 60 mV

TERM2 = 1, TERM1 = 1 l 85 100 115 mV

Minimum (BOOST-V4) Voltage for Operation l 6.7 6.95 7.2 V

Hysteresis 180 mV

Maximum (BOOST-V4) Voltage Regulated l 8.45 8.75 V

Hysteresis 200 mV

RNMOS Charge Pump NMOS Switch ON Resistance Measured at 10mA 20 Ω

RPMOS Charge Pump PMOS Switch ON Resistance Measured at 10mA 55 Ω

tBAT Maximum Time a Single Battery Stays CTBAT = 10nF 4.5 5 5.5 sec

Connected to the Auxiliary Battery

tON Maximum Stack Balancing Termination Time MODE = 0, CTON = 10nF 0.43 0.48 0.53 hrs

tOFF Off Time After Stack Balance Termination MODE = 0, DONE = 0, CTOFF = 10nF 0.43 0.48 0.53 hrs

VIH Digital Input High Voltage EN1, EN2, MODE, TERM1, TERM2 Pins l 1.2 V

VIL Digital Input Low Voltage EN1, EN2, MODE, TERM1, TERM2 Pins l 0.4 V

IIH, IIL Leakage Current EN1, EN2, MODE, TERM1, TERM2 Pins; l –1 1 µA

2.5V at Pin

VOL Output Low Voltage BATX, BATY, BAL, DONE, l 27.5 150 mV

UVFLT, OVFLT, PTCFLT Pins; 3mA Into Pin

IOH Output High Leakage Current BATX, BATY, BAL, DONE, 1 µA

UVFLT, OVFLT, PTCFLT Pins; 6V at Pin

Thermal Shutdown Threshold (Note 7) Rising Temperature 155 °C

Thermal Shutdown Hysteresis 10 °C

Note 1. Stresses beyond those listed under Absolute Maximum Ratings Note 3. Continuous operation above the specified maximum operating

may cause permanent damage to the device. Exposure to any Absolute junction temperature may result in device degradation or failure.

Maximum Rating condition for extended periods may affect device Note 4. The NGATE pin currents are not included in this number.

reliability and lifetime. Note 5. The NGATE5, NGATE6, NGATE7 pin currents are drawn from the

Note 2. The LTC3305 is tested under pulsed load conditions such that TJ BOOST pin. All other NGATE pin currents are drawn from the V4 pin. The

≈ TA. The LTC3305E is guaranteed to meet specifications from 0ºC to 85ºC NGATE pin currents add to the currents drawn by V4 and BOOST.

junction temperature. Specifications over the –40ºC to 125ºC operating Note 6. The voltage programmed at the VH and VL pins are gained up to

junction temperature range are assured by design, characterization and set the undervoltage and overvoltage thresholds of each battery.

correlation with statistical process controls. The LTC3305I is guaranteed

Note 7: This IC includes overtemperature protection intended to protect

over the –40°C to 125°C operating junction temperature range. Note that

the device during momentary overload conditions. The maximum junction

the maximum ambient temperature consistent with these specifications

temperature may be exceeded when overtemperature protection is active.

is determined by specific operating conditions in conjunction with board

Continuous operation above the specified maximum operating junction

layout, the rated package thermal impedance, and other environmental

temperature may result in device degradation or failure.

factors. The junction temperature (TJ, in °C) is calculated from the ambient

temperature (TA, in °C) and power dissipation (PD, in Watts) according

to the formula: TJ = TA + (PD • θJA), where θJA (in °C/W) is the package

thermal impedance.

3305fb

4 For more information www.linear.com/LTC3305

LTC3305

TYPICAL PERFORMANCE CHARACTERISTICS TA = 25°C, unless otherwise noted.

VREG Line and Load Regulation VREG vs Temperature VREG,UV vs Temperature

3.0 2.55 2.5

2.8 2.50 2.4

2.6

2.45 RISING

2.4 2.3

2.2 2.40

2.2

2.0 2.35

1.8 2.1

VREG,UV (V)

FALLING

VREG (V)

2.30

VREG (V)

1.6

2.0

1.4 2.25

1.2 V4 = 12V 2.20 1.9

1.0

2.15 1.8

0.8

0.6 2.10 IVREG = 0.2mA, V4 = 52.8V 1.7

0.4 V4 = 52.8V IVREG = 1mA, V4 = 52.8V

2.05 1.6

0.2 IVREG = 3mA, V4 = 12V

0.0 2.00 1.5

0 3 6 9 12 15 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

CURRENT (mA) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G01 3305 G02 3305 G03

Shutdown Current vs Temperature OFF State Current vs Temperature VISET vs Temperature

55 125 1.220

120 1.215

50

115

45 1.210

V4 = 64V 110 V4 = 64V

40 105 VISET (V) 1.205

IV4 (µA)

IV4 (µA)

100 V4 = 52.8V 1.200

35

V4 = 52.8V

95 1.195

30 V4 = 12V

V4 = 12V 90

25 1.190

85

20 80 1.185

15 75 1.180

–55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G04 3305 G05 3305 G06

INGATE vs IISET INGATE vs Temperature UV Threshold vs Temperature

1.8 1.20 5.25

RISET = 12.1k

1.7 ALL NGATE PIN CURRENTS ALL NGATE PIN CURRENTS

5.20 RVL = 15k

1.18 AND NGATE3 CURRENT

1.6 AND NGATE3 CURRENT

2 2 5.15

1.5 1.16

V4 = 52.8V, VNGATE = 0V, RISET = 12kΩ

1.4 V4 = 52.8V, VNGATE = 0V

BATTERY VOLTAGE (V)

1.14 5.10 RISING

1.3

5.05

INGATE (mA)

1.12

INGATE (mA)

1.2

1.1 1.10 5.00

1.0 4.95

1.08 FALLING

0.9

0.8 1.06 4.90

0.7 1.04 4.85

0.6

1.02 4.80

0.5

0.4 1.00 4.75

50 60 70 80 90 100 110 120 130 140 150 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

IISET (µA) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G07 3305 G08 3305 G09

3305fb

For more information www.linear.com/LTC3305 5

LTC3305

TYPICAL PERFORMANCE CHARACTERISTICS TA = 25°C, unless otherwise noted.

UV Threshold vs Temperature OV Threshold vs Temperature OV Threshold vs Temperature

10.5 7.70 15.4

RISET = 12.1k RISET = 12.1k RISET = 12.1k

10.4 RVL = 30.1k 7.65 RVH = 22.6k 15.3 RVH = 45.3k

10.3 7.60 15.2

BATTERY VOLTAGE (V)

BATTERY VOLTAGE (V)

10.2 15.1

BATTERY VOLTAGE (V)

7.55 RISING RISING

10.1 RISING 7.50 15.0

10.0 7.45 14.9

9.9 FALLING 7.40 14.8 FALLING

FALLING

9.8 7.35 14.7

9.7 7.30 14.6

9.6 7.25 14.5

9.5 7.20 14.4

–55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G10 3305 G11 3305 G12

PTC Fault Threshold Maximum Battery Current During

UV and OV Programming Gain vs Temperature PTC Fault Condition

10.5 1200 525

V1 = 13.2V, AUXN = GND V1 = 13.2V, AUXN = AUXP = GND

10.4 1175 515

1150

10.3 505

VBAT,UV/VL or VBAT,OV/VH (V/V)

1125

10.2 RISING 495

1100

|V1-AUXP| (mV)

10.1 UV GAIN 1075 485

IV1 (µA)

10.0 1050 475

9.9 1025 465

OV GAIN FALLING

1000

9.8 455

975

9.7 445

950

9.6 925 435

9.5 900 425

0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

VL OR VH (V) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G13 3305 G14 3305 G15

12.5mV Termination Threshold 25mV Termination Threshold 50mV Termination Threshold

vs Temperature vs Temperature vs Temperature

22.5 35 60

20.5 33 58

18.5 31 56

16.5 29 54

VTERMINATE (mV)

VTERMINATE (mV)

VTERMINATE (mV)

14.5 27 52

12.5 25 50

10.5 23 48

8.5 21 46

6.5 19 44

4.5 17 42

2.5 15 40

–55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G16 3305 G17 3305 G18

3305fb

6 For more information www.linear.com/LTC3305

LTC3305

TYPICAL PERFORMANCE CHARACTERISTICS TA = 25°C, unless otherwise noted.

100mV Termination Threshold Minimum Boost Voltage

vs Temperature vs Temperature tON, tOFF vs Temperature

110 7.2 0.510

V4 = 52.8V

108 0.505 CTON = CTOFF = 10nF (COG)

7.1 0.500

106

0.495

104 7.0 RISING 0.490

VTERMINATE (mV)

TIME (HOURS)

VBOOST-V4 (V)

102 0.485

6.9

100 0.480

98 6.8 0.475

FALLING 0.470

96 6.7

0.465

94

0.460

6.6

92 0.455

90 6.5 0.450

–55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

TEMPERATURE (°C) TEMPERATURE (°C) TEMPERATURE (°C)

3305 G19 3305 G20 3305 G21

tBAT vs Temperature VOL vs Temperature

5.5 45.0

CTBAT = 10nF (COG) I = 3mA

5.4 42.5

40.0

5.3

37.5

5.2

35.0

TIME (SECONDS)

5.1 32.5

VOL (mV)

5.0 30.0

4.9 27.5

25.0

4.8

22.5

4.7

20.0

4.6 17.5

4.5 15.0

–55 –35 –15 5 25 45 65 85 105 125 –55 –35 –15 5 25 45 65 85 105 125

TEMPERATURE (°C) TEMPERATURE (°C)

3305 G22 3305 G23

VREG Start-Up Boost Charge Pump Start-Up

CVREG = 2.2µF

VOLTAGE ACROSS CBOOST

CH2, 0V

5V/DIV

500mV/

DIV

VOLTAGE ACROSS CFLY

0V

CH1, 0V

3305 G24 2V/DIV 3305 G25

100µs/DIV 5ms/DIV

3305fb

For more information www.linear.com/LTC3305 7

LTC3305

PIN FUNCTIONS

BOOST (Pin 1): Charge Pump Output. Decouple with a BATX (Pin 17): This pin along with BATY indicates which

10µF capacitor to V4. battery in the stack is currently being balanced and to

V4 (Pin 2): Positive terminal of Battery 4 connects to this which the fault outputs apply. Open Drain Output.

pin. Battery 4 is connected between V4 and V3. Decouple BATY (Pin 18): This pin along with BATX indicates which

with at least a 10µF capacitor to V3. battery in the stack is currently being balanced and to

V3 (Pin 3): Positive terminal of Battery 3 connects to this which the fault outputs apply. Open Drain Output.

pin. Battery 3 is connected between V3 and V2. Decouple OVFLT (Pin 19): Overvoltage Fault. This pin is pulled low

with at least a 10µF capacitor to V2. when an overvoltage fault condition is detected on a bat-

AUXP (Pin 4): Positive terminal of the auxiliary cell con- tery. Open Drain Output.

nects to this pin. Decouple with at least a 10µF capacitor UVFLT (Pin 20): Undervoltage Fault. This pin is pulled

to AUXN. low when an undervoltage fault condition is detected on

AUXN (Pin 5): Negative Terminal of the auxiliary cell con- a battery. Open Drain Output.

nects to this pin. BAL (Pin 21): Balancing Indicator. This pin is pulled low

V2 (Pin 6): Positive terminal of Battery 2 connects to this while the balancing operation is being performed and is

pin. Battery 2 is connected between V2 and V1. Decouple in its high impedance state when the part is disabled or

with at least a 10µF capacitor to V1. the part is in the sleep state. Open Drain Output.

V1 (Pin 7): Positive terminal of Battery 1 connects to this DONE (Pin 22): Done Indicator. This pin is pulled low when

pin. Battery 1 is connected between V1 and GND. Decouple all the batteries in the stack are balanced. This pin is in its

with at least a 10µF capacitor to GND. high impedance state in shutdown. Open Drain Output.

NGATE1 (Pin 8): NMOS1 Gate. Connect to the gate terminal PTCFLT (Pin 23): PTC Fault. This pin is pulled low when the

of external NMOS switch. voltage across the PTC thermistor exceeds 1V. It is in its

high impedance state at all other times. Open Drain Output.

NGATE2 (Pin 9): NMOS2 Gate. Connect to the gate terminal

of external NMOS switch. CTOFF (Pin 24): A capacitor from this pin to GND programs

the retry time in timer mode. Connect to GND if MODE = 1.

NGATE3 (Pin 10): NMOS3 Gate. Connect to the gate ter-

minal of external NMOS switch. CTON (Pin 25): A capacitor from this pin to GND programs

the maximum time for the balancing operation in timer

NGATE4 (Pin 11): NMOS4 Gate. Connect to the gate ter- mode. Connect to GND if MODE = 1.

minal of external NMOS switch.

CTBAT (Pin 26): A capacitor from this pin to GND programs

NGATE5 (Pin 12): NMOS5 Gate. Connect to the gate ter- the maximum time an individual battery in the stack is con-

minal of external NMOS switch. nected to the auxiliary cell during the balancing operation.

NGATE6 (Pin 13): NMOS6 Gate. Connect to the gate ter- VL (Pin 27): Low Voltage Fault Threshold. A resistor from

minal of external NMOS switch. this pin to GND programs the low voltage fault threshold

NGATE7 (Pin 14): NMOS7 Gate. Connect to the gate ter- for each battery in the series stack. Works in conjunction

minal of external NMOS switch. with the ISET pin.

NGATE8 (Pin 15): NMOS8 Gate. Connect to the gate ter- VH (Pin 28): High Voltage Fault Threshold. A resistor from

minal of external NMOS switch. this pin to GND programs the high voltage fault threshold

for each battery in the series stack. Works in conjunction

NGATE9 (Pin 16): NMOS9 Gate. Connect to the gate ter- with the ISET pin.

minal of external NMOS switch.

3305fb

8 For more information www.linear.com/LTC3305

LTC3305

PIN FUNCTIONS

ISET (Pin 29): Reference Current Pin that Servos to 1.2V. EN1 (Pin 34): Enable Input. The state of the EN1 and EN2

A resistor from this pin to GND programs the gate charge pins is used to indicate the number of batteries in the stack.

current for the external NMOS switches. The reference With both pins at GND, the part is in shutdown. High input

current is also used to program the undervoltage and impedance pin, do not float.

overvoltage thresholds.

MODE (Pin 35): Mode Select. When held high, continuous

VREG (Pin 30): Low Voltage Regulated Output. An inter- mode is selected. When held low, timer mode is selected.

nally generated voltage of 2.5V is always present at this High input impedance pin, do not float.

pin. The voltage at this pin may be overdriven by a higher

No Connect (Pin 36): This pin is not connected internally.

external voltage up to 5.5V. This pin has limited current

Solder this pin to a pad electrically isolated from all other

sink capability and will not pull down a higher externally

circuit nodes.

applied voltage. All logic input pins must be referenced to

this pin. Decouple with a 1µF capacitor to GND. CP (Pin 37): Positive Terminal of Charge Pump Flying

Capacitor. Connect a 10µF capacitor from this pin to CM

TERM2 (Pin 31): Termination Threshold Select. This pin

for charge pump operation.

along with TERM1 is used to set the voltage difference

between the battery and auxiliary cell at which a battery is CM (Pin 38): Negative Terminal of Charge Pump Flying

deemed balanced. High input impedance pin, do not float. Capacitor. Connect a 10µF capacitor from this pin to CP

for charge pump operation.

TERM1 (Pin 32): Termination Threshold Select. This pin

along with TERM2 is used to set the voltage difference GND (Pin 39): The exposed pad is ground and must be

between the battery and auxiliary cell at which a battery is soldered to PCB ground for electrical connectivity and

deemed balanced. High input impedance pin, do not float. rated thermal performance.

EN2 (Pin 33): Enable Input. The state of the EN1 and EN2

pins is used to indicate the number of batteries in the stack.

With both pins at GND, the part is in shutdown. High input

impedance pin, do not float.

3305fb

For more information www.linear.com/LTC3305 9

LTC3305

BLOCK DIAGRAM

BOOST

1

GATE DRIVE NO CONNECT 36

CP

CHARGE 37

PUMP CM

38

NGATE1

8

NGATE2

9

MUX NGATE3

10

V4

2 NGATE4

11

V3 NGATE5

3 12

NGATE6

V2 13

6

NGATE7

14

V1

7 NGATE8

15

NGATE9

16

MIRROR V4

LOW VREG

VOLTAGE 30

BANDGAP REGULATOR

1.2V +

REFERENCE

–

ISET

29

EN2

33

EN1

34

VH

28 MODE

UV/OV 35

VL

27 BATX

17

TERM2 BATY

31 18

TERMINATION CONTROL

TERM1 SENSE LOGIC

32 OVFLT

COMPARATOR 19

AUXP

4

UVFLT

AUXN 20

5

CTOFF BAL

24 21

CTON DONE

25 TIMERS 22

CTBAT

26 PTCFLT

23

THERMAL

SHUTDOWN OT

39

3305 BD

GND

3305fb

10 For more information www.linear.com/LTC3305

LTC3305

OPERATION

The LTC3305 balancer is intended to be used in conjunc- NGATE5

tion with a separate pre-existing battery stack charger as 9

part of a high performance battery system. The balancing NGATE1-9

operation itself is stand-alone and can operate independent N5

NGATE4 +

of whether the battery stack is being charged, discharged, NGATE6 BAT4

or both. That being said, because the LTC3305 balances

voltages, it works best if the voltage readings are stable, LTC3305

N4

NGATE3

N6 +

which is more true when the battery stack is not being NGATE7 BAT3

charged or discharged. Nevertheless, it will properly bal-

N3A N3B

ance the battery voltages when the stack is being concur- PTC NGATE2

N7 +

rently charged and/or discharged, since the voltage across AUXP +

BAT2

the batteries will average out over time as the LTC3305 AUX N8

AUXN N2

repeatedly cycles through them. Like all balancers, the

LTC3305 will slightly net-discharge the stack in the absence NGATE8 NGATE1 +

of a separate charger. N9 BAT1

The LTC3305 balances batteries using an auxiliary cell or an N1

NGATE9

alternate storage cell as a charge reservoir. External NMOS

switches are controlled in a preprogrammed sequence

3305 F01

to connect each battery in the stack to an auxiliary cell. Figure 1. External Switch Arrangement

Charge is transferred to or from the auxiliary cell when it for a 4- Battery Balancing Application

is connected to a battery.

The LTC3305 can operate in one of two modes program- The balancing operation begins with the negative terminal

mable via the MODE pin. of the auxiliary cell connected to the negative terminal of

BAT1, the lowest battery in the stack. Referring to Figure 1,

Timer Mode (MODE = 0) the bottom switches N1 and N9 that connect the negative

The balancing operation begins once the CBOOST capacitor terminal of BAT1 to the auxiliary cell’s negative terminal are

is charged to at least 6.95V. The BAL pin is pulled low, first turned on. To turn on an external NMOS switch, the

indicating that the part is enabled and balancing the bat- current source at the NGATE pin connected to the gate of

tery stack. the external NMOS is turned on and a gate source voltage

is developed across an external resistor.

The termination voltage, VTERMINATE, is the difference in

voltage between the auxiliary cell and the battery connected After an internally set delay of 35ms, the voltages across

to the auxiliary cell for which a battery is considered to the auxiliary cell and BAT1 are compared by the termina-

be balanced. VTERMINATE is programmed via the TERM1 tion sense comparator.

and TERM2 pins to one of four preset voltages as shown If the voltage difference between the auxiliary cell and BAT1

in Table 1. is less than the selected termination voltage, the battery

Table 1. Termination Voltages is deemed to be balanced with respect to the auxiliary cell

TERM1 TERM2 VTERMINATE and the bottom switches are turned off by turning off the

0 0 ±12.5mV corresponding NGATE pin currents. The next battery in

1 0 ±25mV the stack is then connected to the auxiliary cell.

0 1 ±50mV

1 1 ±100mV

3305fb

For more information www.linear.com/LTC3305 11

LTC3305

OPERATION

If the voltage difference between the auxiliary cell and In this fashion each battery in the stack is connected to the

BAT1 is greater than the selected termination voltage, the auxiliary cell and the batteries in the stack will be balanced.

top NMOS switches N2 and N7 that connect the positive

An internal clamp circuit protects the LTC3305 when the

terminal of BAT1 to the auxiliary cell’s positive terminal

voltage difference between the battery being balanced

through the PTC thermistor are turned on. After a second

and the auxiliary cell is greater than 1V. With a 13.2V

internally set delay of 35ms, the termination sense com- difference, the clamp draws 475µA of current. In the worst

parator starts monitoring the voltages across the auxiliary case scenario, a 16V difference may appear between the

cell and the battery. The battery stays connected to the auxiliary cell and a battery. The internal clamp draws 600µA

auxiliary cell until the voltage difference decreases to of current in this scenario.

VTERMINATE or a tBAT timeout occurs (tBAT is the maximum

time that a battery remains connected to the auxiliary cell In the state when both the top and bottom side switches

and is programmed by a capacitor on the CTBAT pin). This are turned on, the PTCFLT pin will be pulled low if the

timer is reset each time the auxiliary cell is connected to voltage difference between the battery being balanced and

a different battery. the auxiliary cell is greater than 1V. If during the balancing

operation the voltage difference becomes less than 1V, the

At this point, all switches are turned off and the next bat-

PTCFLT pin returns to its high impedance state.

tery in the stack is connected to the auxiliary cell. After

the switches have been turned off, an internal 40ms delay The BATX and BATY pins indicate which battery in the

provides a break-before-make time after which the nega- stack is currently connected to the auxiliary cell as shown

tive terminal of the next battery in the stack is connected in Table 3. In shutdown, the BATX and BATY pins are in

to the negative terminal of the auxiliary cell via its bottom a High Z state and the BAL pin is also in a High Z state.

switches. Table 2 shows the top and bottom switches Table 3. State of BATX and BATY Pins

used to connect each battery for different battery stack STATE OF OPERATION BATX BATY

configurations. When only the bottom switches are on, Battery 1 Connected High Z High Z

there is a conduction path between the auxiliary cell and Battery 2 Connected High Z 0

the battery through the body diodes of the top switches. Battery 3 Connected 0 0

Current will flow through this conduction path if the aux- Battery 4 Connected 0 High Z

iliary cell and the battery are more than two diode drops

apart. The current is limited by the PTC resistor.

Once all batteries in the stack are balanced the DONE pin

Table 2. Top and Bottom Switch Arrangement is pulled low, the BAL pin is in its high impedance state

BATTERY BEING TOP BOTTOM and the part is put in a low power OFF state.

EN1, EN2 BALANCED SWITCHES SWITCHES

1,1 Battery 1 N2, N7 N1, N9 A four-battery stack is deemed balanced when the ter-

(4 Bat App) Battery 2 N3, N6 N2, N8 mination sense comparator detects VTERMINATE on five

Battery 3 N4, N7 N3, N9 consecutive cycles that connect each of the batteries to

Battery 4 N5, N6 N4, N8 the auxiliary cell using the bottom switches only.

1,0 Battery 1 N2, N7 N1, N8

(3 Bat App) Battery 2 N4, N6 N2, N9

Battery 3 N5, N7 N4, N8

0,1 Battery 1 N7 N9

(2 Bat App) Battery 2 N5 N8

3305fb

12 For more information www.linear.com/LTC3305

LTC3305

OPERATION

In timer mode, a capacitor at the CTON pin programs the voltages could differ by up to twice the programmed

maximum time, tON, that the balancing operation can run VTERMINATE when balanced.

for. The balancing operation is terminated either when the

batteries in the stack are deemed to be balanced or a tON Charge Pump Operation

time out occurs. After the balancing operation has been The LTC3305 uses external NMOS devices as switches to

terminated, the LTC3305 is put in a low power OFF state connect a battery to the auxiliary cell. The LTC3305 has a

for a fixed time, tOFF. The tOFF time is programmed by a charge pump that generates the higher voltage required

capacitor at the CTOFF pin. In the OFF state, the BAL pin to turn on some of the external NMOS switches.

is put in its high impedance state. Once tOFF times out,

the LTC3305 is put back in its ON state and the balancing Two external capacitors CFLY and CBOOST, two diodes D1

operation begins again. The tON timer may be defeated by and D2, and resistors R1 and R2 are required for charge

tying the CTON pin to GND. In this scenario, the LTC3305 pump operation as shown in Figure 2. When the LTC3305

will enter the OFF state only when all the batteries in the is enabled, the charge pump is turned on. CFLY initially

stack are deemed to be balanced. charges with a current ICHG through external diode D1,

resistor R1, and the internal NMOS switch N1 to GND. When

Continuous Mode (MODE = 1) CFLY is charged to 10.5V, an internal comparator switches

the internal NMOS switch off and turns on switch P1. CFLY

In the continuous mode of operation the part functions in connects to CBOOST through diode D2, resistor R2 and the

much the same way as in timer mode with the following internal PMOS switch P1. Charge is transferred from CFLY

differences. to CBOOST with a current IDISCHG. When CFLY is discharged

1. There is no ON or OFF state. The CTON and CTOFF pins to 9.5V, it is disconnected from CBOOST, recharged back up

must be tied to GND in continuous mode. The balanc- to 10.5V, and then reconnected to CBOOST. In this fashion

ing operation continues even if the stack is in balance. the voltage across CBOOST is built up.

The balancing operation is terminated only if the part

ICHG

is put in shutdown. The BAL pin is always pulled low

in continuous mode. D1

2. In timer mode, if the termination comparator senses R1 IDISCHG

that a battery is balanced to the auxiliary cell with only

the bottom plates connected, the balancing operation CFLY

on that battery is terminated. This is not the case in CM CP D2

continuous mode. In continuous mode the top switches P1 R2

BOOST

are turned on and the balancing operation on a battery N1

is terminated only by a tBAT time out. Since the auxiliary CBOOST

cell remains connected to the battery until a tBAT time V4

out occurs, its voltage can change before it connects

to the next battery in the stack. As a result, when the LTC3305

stack is balanced and the DONE pin is pulled low, the

voltages across the individual batteries in the stack

may differ by more than the programmed VTERMINATE.

In the worst case when the capacity of the auxiliary cell 3305 F02

is much smaller than the battery, the individual battery Figure 2. Charge Pump Operation

3305fb

For more information www.linear.com/LTC3305 13

LTC3305

OPERATION

Once the CBOOST capacitor has 6.95V across it, balancing is drawn from the regulator, the VREG voltage will drop

begins. When CBOOST is charged to 8.45V, the charge below its undervoltage threshold, disabling the LTC3305

pump operation is disabled and CFLY remains connected and terminating the balancing operation. The balancing

to CBOOST. Charge pump operation resumes when CBOOST operation restarts when the regulator recovers from its

discharges to 8.25V. undervoltage state. In short circuit, the VREG current is

limited to 15mA. The VREG pin should be decoupled with

Undervoltage and Overvoltage Fault Detection at least a 1µF capacitor to GND.

The undervoltage and overvoltage thresholds can be

Thermal Shutdown

programmed using the resistor at the ISET pin in con-

junction with resistors at the VL and VH pins. The voltage The LTC3305 has an overtemperature detect circuit that

present at the VL or VH pin programs the corresponding shuts down the balancing operation when the internal

fault threshold to 10× that voltage for each battery in the silicon junction temperature exceeds 155°C. The LTC3305

stack. An internal amplifier accurately gains up the voltage resumes balancing when the temperature drops to 145°C.

at the VL and VH pins and shifts the threshold voltage to In thermal shutdown, the low voltage regulator remains

the appropriate battery common mode level. The VL and powered.

VH pins have a programming range from 0.4V to 1.6V.

The internal undervoltage and overvoltage comparators Balancing Battery Stacks with Two or Three Batteries

may not trip correctly for a program voltage outside this The LTC3305 can also be configured to balance battery

range. An internal clamp prevents the thresholds from stacks of two or three batteries. The state of the enable pins

being programmed to greater than 20V. tells the LTC3305 to select the correct switch sequencing.

When an undervoltage or overvoltage fault condition is For a two battery stack, the LTC3305 must be enabled

detected, the corresponding UVFLT or OVFLT pin is pulled with EN1 = 0 and EN2 = 1. For a three battery stack, the

to GND. The balancing operation is not interrupted during LTC3305 must be enabled with EN1 = 1 and EN2 = 0. The

this time. If an undervoltage or overvoltage fault condition external NMOS switch arrangements for a two-battery

goes away during the balancing operation, the correspond- and three-battery application are shown in Figures 3 and

ing fault pin returns to its high impedance state. 4 respectively. If pin NGATE6 is unused, it must be con-

nected to the BOOST pin. All other unused NGATE pins

If the undervoltage and overvoltage fault detection is not

must be connected to V4 as shown in Figures 3 and 4.

needed, the VL and VH pins must be tied to GND. The UVFLT

and OVFLT pins may either be tied to GND or left floating. A two battery stack is deemed balanced if the termination

sense comparator senses the voltage difference between

Low Voltage Regulator the auxiliary cell and the battery is less than VTERMINATE

on three successive cycles when the auxiliary cell and a

The LTC3305 has an always on regulator that provides

battery are connected using only the bottom switches.

2.5V at the VREG pin. The VREG pin may be driven externally

up to 5.5V. The VREG pin cannot sink current and will not In the case of a three battery stack, four successive cycles

pull down an externally applied voltage. The regulator can are required to deem the stack balanced.

source up to 3mA of current. If more than 3mA of current

3305fb

14 For more information www.linear.com/LTC3305

LTC3305

OPERATION

10µF

25V

ALL NMOS DEVICES = SiR882DP

D2 D1, D2 = CMMSH1-100

249Ω 1.33k

CM CP

VREG BOOST

1µF D1

EN1

6V NGATE6

EN2

MODE

22µF

25V

TERM1

TERM2

UVFLT V4

4

OVFLT NGATE1-4 NGATE5

DONE 6.04k

V3

100k EACH BAL

PTCFLT LTC3305

BATX V2

10µF +

BATY BAT2

CTON 25V

10nF V1

10µF

+

25V BAT1

CTOFF

100nF

4 NGATE7

CTBAT NGATE5, 7, 8, 9 6.04k

22nF

VL PTC

27.4k AUXP

+

10µF

AUX

25V

VH

42.2k AUXN 6.04k

NGATE8

ISET GND

12.1k 3305 F03

6.04k

NGATE9

Figure 3. Two-Battery Application Showing External Switch Arrangement

3305fb

For more information www.linear.com/LTC3305 15

LTC3305

OPERATION

10µF

25V

ALL NMOS SWITCHES = SiR882DP

D2 D1, D2 = CMMSH1-100

249Ω 1.33k

CM CP

VREG BOOST

1µF D1

EN1

6V EN2 10µF

25V

MODE V4

NGATE5

6.04k

TERM1

TERM2 NGATE3

UVFLT V3

OVFLT

NGATE4 +

DONE 10µF 6.04k BAT3

100k EACH BAL 25V

PTCFLT LTC3305

BATX V2

BATY NGATE2

10µF +

CTON 6.04k BAT2

10nF 25V

V1

CTOFF

10µF NGATE6

100nF NGATE1

25V +

6.04k 6.04k BAT1

CTBAT

22nF

8 NGATE7

VL NGATE1, 2, 4-9

27.4k 6.04k

PTC

VH AUXP +

42.2k 10µF AUX

25V

ISET AUXN

GND 6.04k

12.1k 3305 F04

NGATE8

6.04k

NGATE9

Figure 4. Three-Battery Application Showing External Switch Arrangement

3305fb

16 For more information www.linear.com/LTC3305

LTC3305

APPLICATIONS INFORMATION

Selecting the PTC Thermistor PTC Current Voltage Characteristics

A PTC thermistor is a type of resistor with a Positive Tem-

perature Coefficient that serves as a protection device by CURIE POINT

limiting its current above a certain threshold. The PTC device

limits the peak current that transfers charge between the

CURRENT →

auxiliary cell and the battery. When the voltage across the

PTC is small, the power dissipated in the PTC is small and

the PTC resistance remains constant. As the voltage across

the PTC increases, power dissipation in the PTC increases

which causes the PTC temperature to rise. When the tem-

perature reaches the Curie Temperature, further increases

VOLTAGE →

in voltage will cause the PTC resistance to increase rapidly, 3305 F05a

which limits the current through the device and thus limits (a)

the power dissipation in the PTC. This behavior is shown

in the PTC Current Voltage Characteristics in Figure 5a. In

Increasing Current at Large Voltage

this fashion the PTC serves to protect the external NMOS

switches from operating outside of their SOA region.

As seen in the PTC Current Voltage Characteristics in Figure PTC RESISTOR IN PARALLEL

5a, when the PTC has a small voltage or a high voltage WITH A RESISTOR

across it, the current flowing through it is small. For small

CURRENT →

SINGLE PTC RESISTOR

voltages, this is OK since the battery and the auxiliary cell RESISTOR ONLY

are close to balance. For high voltages, this slows down

balancing. To increase balance currents at high voltages

a power resistor can be placed in parallel with the PTC

device, as shown in Figure 5b. Additionally, multiple PTC

resistors may be connected in parallel to increase current VOLTAGE →

3305 F05b

flow at all voltages.

(b)

PTC devices are manufactured in two styles: ceramic and

poly fuse. Only a ceramic style PTC device should be used Figure 5. PTC Behavior

in this application. Poly fuse devices have a very limited

number of lifetime trip cycles and are not suitable in a Table 4. Recommended Ceramic PTC Thermistors

balancing application. RESISTANCE

PART NUMBER MANUFACTURER VOLTAGE (Ω)

The PTC must be selected such that power dissipation PTGL7SARR47M1B51B0 Murata 16V 0.47

through the external NMOS switches never exceeds their

PTGLASARR27M1B51B0 Murata 16V 0.27

rated SOA power dissipation value. Refer to Table 4 for a

PTGLESARR15M1B51B0 Murata 16V 0.15

list of recommended PTC thermistors.

PTGL12AR1R2H2B51B0 Murata 30V 1.2

2381 663 51121 Vishay 30V 0.7

2381 663 51321 Vishay 30V 0.5

2381 664 52021 Vishay 30V 0.3

3305fb

For more information www.linear.com/LTC3305 17

LTC3305

APPLICATIONS INFORMATION

Selecting the Auxiliary Cell the capacity of the battery stack. Using a large capacity

The auxiliary cell must be capable of sourcing and sink- auxiliary cell supplements stack capacity. Smaller capac-

ing current and withstand the maximum voltage of any ity batteries may be used in the stack which helps reduce

individual battery in the stack. The ESR of the auxiliary system costs.

cell must be small compared to the PTC thermistor. Any

Precharging the Auxiliary Cell

voltage dropped across the auxiliary cell ESR appears as

an offset voltage at the input of the termination comparator. When using stacked supercapacitors or a single high volt-

age capacitor as the auxiliary cell, the auxiliary cell may

The auxiliary cell used may be a lead-acid battery, a stacked

be initially discharged with a voltage of 0V. At startup, a

supercapacitor, or a low leakage, high voltage capacitor.

large voltage exists across the PTC resistor, which will

When using a supercapacitor stack, the voltage across

cause the PTC resistance to increase. This limits the cur-

each individual supercapacitor must not exceed its rated

rent and hence the charge transfer between the auxiliary

operating voltage.

cell and the battery it is connected to. The auxiliary cell

Figure 6a shows a battery stack made of 4 batteries, will be charged very slowly with an indeterminate time,

each with a nominal capacity of 50Ah, but with a 10% as it sequentially connects to each battery in the stack.

capacity mismatch. With no balancing, the stack capacity Once the auxiliary cell has been charged to a point where

is determined by the weakest battery in the stack and is the PTC device operates as a low resistance device, the

limited to 45Ah. balancing process is sped up.

In Figure 6b, a small capacity auxiliary cell, such as a A more time efficient solution is to precharge the auxiliary

supercapacitor stack, is used to balance the battery stack. cell to the average voltage of the batteries in the stack. Figure

When balanced the stack capacity can be made to approach 7a shows a circuit using a high voltage buck regulator to

the nominal capacity of 50Ah despite the 10% mismatch. precharge the auxiliary cell to V4/4 volts. NMOS devices

In Figure 6c, the auxiliary cell has the same capacity as N2A and N2B eliminate a parasitic charging path from

the batteries in the stack. Each of the batteries in Figure 6c BATTERY1 to the auxiliary cell when AUXN is connected

has a nominal capacity of only 40Ah but the stack capac- to GND through N10. Figures 7b and 7c are scope photos

ity approaches 50Ah since the auxiliary cell supplements showing a complete precharging and balancing operation.

55Ah 55Ah 44Ah

(+10%) (+10%) (+10%)

50Ah 50Ah 40Ah

PTC PTC

50Ah 50Ah 40Ah

4Ah 40Ah

45Ah 45Ah (AUX) 36Ah (AUX)

(–10%) (–10%) (–10%)

STACK CAPACITY STACK CAPACITY STACK CAPACITY

=45Ah ≈50Ah ≈50Ah

(a) (b) (c)

Figure 6. Increasing Stack Capacity with an Auxiliary Cell

3305fb

18 For more information www.linear.com/LTC3305

LTC3305

APPLICATIONS INFORMATION

D1, D2 = CMMSH1-100 N1A, N1B, N2, N3A, N3B, N4, N5, N6, N7, N8, N9, N10 - SiR882DP

D3 = CMMSH2-80

10µF D2

1.33k

25V

249Ω

CM CP NGATE5

VREG BOOST

1µF 10µF D1 6.04k

TERM1

6V 25V

TERM2

N5

MODE V4

NGATE4

+

10µF 6.04k BAT4

EN1

25V

EN2 N4

UVFLT V3

3.01k 2.2µF

OVFLT NGATE3

DONE + 100V

10µF BAT3

BAL 25V

PTCFLT N3A N3B VIN

SS RUN

BATX V2

6.04k FBO ISET

BATY LTC3305 NGATE2 SW

CTON 10µF + 174k

BAT2 LTC3630A

10nF 25V

VPROG1

N2A N2B

V1 FB VPROG2

GND

CTOFF 10µF 6.04k

100nF NGATE6 NGATE1

25V +

6.04k BAT1

CTBAT

10nF 9 N6 N1

NGATE1-9 6.04k

NGATE7

VL

27.4k N7

PTC D3 100µH

VH AUXP

42.2k N8

10µF + 5.11M

25V AUX 6.04k D4, D5, D6 = 1N914 V+

ISET IN– OUT

AUXN NGATE8 D4 REF

12.1k GND N9 365k

2.21M LTC1440 40.2k

D5

6.04k IN+ HYST

D6

NGATE9

2.21M 365k 2.43M

N12 V– GND

N10

S N11

D Q 681k

CLK

START

Q N11, N12 = FDV301N

R

3305 F07

(a)

BAT1, BAT2, BAT3, BAT4, AUXP-AUXN = 2V/DIV AUXP-AUXN = 2V/DIV

AUXN = 10V/DIV; START, EN_3305 = 5V/DIV AUXN = 10V/DIV; START, EN_3305 = 5V/DIV

TIME = 20s/DIV TIME = 5s/DIV

(b) (c)

Figure 7. Precharging the Auxiliary Cell Using the LTC3630A and LTC1440

3305fb

For more information www.linear.com/LTC3305 19

LTC3305

APPLICATIONS INFORMATION

Selection of External NMOS Switches the NMOS device. Programming a higher current reduces

the NMOS device turn on time. Programming a large gate

The external NMOS switches must be capable of with-

source voltage reduces the on resistance of the NMOS

standing a reverse voltage equal to the battery stack volt-

device. During turn off, the gate capacitor discharges

age. They should also be capable of carrying DC current

through the gate source resistor.

up to the PTC thermistor trip point. The maximum power

dissipated in the NMOS should not cause it to operate Programming Undervoltage and Overvoltage

outside of its Safe Operating Area. Refer to Table 5 for a Thresholds

list of recommended NMOS switches.

Referring to the Block Diagram, the voltage at the ISET pin

Table 5. Recommended NMOS Switches is servoed to 1.2V. An external resistor, RISET, from this

PART NUMBER MANUFACTURER IDS(MAX) VDC(MAX) pin to GND programs a current which is divided down and

SiR882DP Vishay 60A 100V mirrored to the VL and VH pins. The ISET pin current has

SiS892DN Vishay 25A 100V a programmed range from 50µA to 150µA.

IPD70N10S3-12 Infineon 70A 100V

The ISET pin current is given by:

IPB35N10S3L-26 Infineon 35A 100V

RJK1051DPB Renesas 60A 100V 1.2V

I ISET =

RJK1054DPB Renesas 92A 100V RISET

The current out of the VL and VH pins is given by:

Programming NMOS Turn On I ISET

IVL = IVH =

The NMOS switches are turned on by developing a voltage 3

across an external resistor from the gate to the source. External resistors RVL from the VL pin to GND and RVH

The current through the resistor is delivered from the from the VH pin to GND program the undervoltage and

NGATE pins and is programmed by the current at the overvoltage thresholds for each battery. The undervolt-

ISET pin. The internal current sources that provide the age threshold for a battery is given by:

NGATE pin currents operate from the V4 and BOOST R

supplies as shown in the Block Diagram. The BOOST VBAT,UV = 4V • VL

RISET

pin voltage is regulated at 8.45V greater than V4. It is

recommended that the gate turn on voltage be set to no The overvoltage threshold for a battery is given by:

more than 7.5V. The current flowing through the gate R

VBAT,OV = 4V • VH

turn on resistor connected to the NGATE3 pin is given by: RISET

26.4V Programming the tBAT Parameter

I NGATE3 =

RISET The tBAT parameter is programmed using a capacitor

The current flowing through the other NGATE pins is from the CTBAT pin to GND. tBAT is given by:

given by: C

13.2V tBAT = 5sec• TBAT

I NGATE = 10nF

RISET A C0G type capacitor is recommended due to its superior

The NGATE3 current has a programmed range from 1mA temperature characteristics.

to 3mA. All other NGATE currents have a programmed Programming the tON and tOFF Parameters

range from 500µA to 1.5mA.

The tON parameter is programmed by a capacitor from

The NGATE current initially charges the gate capacitor of the CTON pin to GND. tON is given by:

the NMOS device to turn it on. The external gate source CTON

resistor maintains a constant gate to source voltage on tON = 0.48hrs•

10nF

3305fb

20 For more information www.linear.com/LTC3305

LTC3305

APPLICATIONS INFORMATION

The tOFF parameter is programmed by a capacitor from dissipation in the internal switch connected from V4 to

the CTOFF pin to GND. tOFF is given by: VREG, which causes die temperature to increase. In Figure 8,

C an external switching regulator generates a 3.3V rail that

tOFF = 0.48hrs• TOFF back drives the VREG pin and provides power to the external

10nF

microprocessor and other low voltage circuits. There is

C0G type capacitors are recommended due to their superior no on-chip loading on the VREG pin and thus no on chip

temperature characteristics. power dissipation in the low voltage regulator.

In the continuous operation mode (MODE = 1), the CTON In Figure 8, external resistors R1, R2, R3, R4, and R5 are in

and CTOFF pins are unused and should be connected to series with the on-chip current sources that provide NGATE

GND. pin current. These resistors reduce the voltage across the

on-chip current sources and thus reduce on-chip power

Selecting Charge Pump Components dissipation. As an example, the current source at NGATE1

delivers current from the V4 pin. When this current source

Referring to Figure 2, recommended values for R1, R2

is turned on, the voltage across it is V4-VNGATE1. For a

and CFLY are 249Ω, 1.33k & 10µF respectively for all ap- typical application with V4 = 52.8V, programmed INGATE =

plications. For applications in which V4 is no lower than 506µA and VNGATE1 = 6.12V, the on-chip power dissipated

32V a 10µF capacitor is recommended for CBOOST. For in the current source is 23mW. In Figure 8, resistor R1

applications which may have lower voltages at V4, the

operates with approximately 30.5V across it. The on-chip

recommended value for CBOOST is 22µF. Schottky diodes

power dissipated in the current source is reduced to ap-

with a breakdown voltage larger than the maximum V4

proximately 8mW. In similar fashion resistors R2, R3,

voltage are recommended for diodes D1 and D2.

R4, and R5 reduce the on-chip power dissipation on the

Selecting Decoupling Capacitors respective current sources. When choosing these resistors

it is recommended to have the internal current sources

Decoupling capacitors of at least 10µF must be placed biased with at least 6V across them under all operating

across each battery, from the BOOST pin to V4 and from conditions. Power dissipation through the on-chip current

the AUXP pin to the AUXN pin. These capacitors must be sources may be further reduced by programming a lower

placed as close as possible to the LTC3305. The capacitors gate current through the NGATE pins.

must be capable of withstanding the maximum voltage

across each battery. Capacitors with an X5R or X7R type Balancing Battery Stacks with more than Four Batteries

dielectric should be used.

To balance battery stacks that have more than four batter-

Thermal Considerations and Limiting On-Chip Power ies, multiple LTC3305 devices may be stacked together. In

Dissipation this scenario, it is recommended that each LTC3305 be

run in continuous mode and at least one battery in each

Excessive on-chip power dissipation will cause the sub-stack of four is common to two LTC3305s. Each

LTC3305 to enter thermal shutdown. It is important to LTC3305 needs an auxiliary cell for the balancing opera-

understand the source of the power dissipation and how tion. Figure 9 shows an eight battery stack being balanced

power dissipation can be reduced. The two contributions using three LTC3305 devices connected together. Figure

of on-chip power dissipation on the LTC3305 that may be 10 shows a stack of six batteries being balanced using

controlled by the user are the loading on the low voltage two LTC3305 devices. To balance a battery stack with

regulator and the power dissipated through the current n batteries, the minimum number of LTC3305 devices

sources that provide the NGATE pin currents. required is [(n-1)/3] rounded up to the nearest integer.

The low voltage linear regulator provides a 2.5V output. In this calculation, each LTC3305 is assumed to be used

Any current provided by the regulator will cause power in a four-battery configuration and at least one battery

interleaves two LTC3305 devices.

3305fb

For more information www.linear.com/LTC3305 21

LTC3305

APPLICATIONS INFORMATION

When multiple LTC3305 devices are stacked, the logic out- The no-connect pin on the LTC3305 must be soldered to

put pins may need to be level shifted and ground referred. a pad on the PCB and must be electrically isolated from

In Figure 9, optical isolators are used for level shifting. any other circuit node.

Figure 11 shows an application in which an eight battery The trace that connects the AUXP pin to the positive

stack is balanced using two LTC3305 devices and two terminal of the auxiliary source must be as close to the

auxiliary cells. BAT1, BAT2, BAT3, and BAT4 are balanced auxiliary source positive terminal as possible. Otherwise

to each other using the lower LTC3305 whereas BAT5, the trace impedance adds to the ESR of the auxiliary cell

BAT6, BAT7, and BAT8 are balanced to each other by the which manifests itself as an offset at the internal termina-

upper LTC3305. tion comparator.

PCB Considerations The V1, V2, V3 and V4 traces must be Kelvin connected

directly to the battery terminal and must not share a com-

In operation the LTC3305 can dissipate large amounts mon trace through which high balance current will flow.

of power which can increase die temperature and cause Any voltage drop in these traces also manifests itself as

the part to enter thermal shutdown. The exposed pad of an offset voltage at the termination comparator input.

LTC3305 must be well soldered to the PCB to provide

adequate heat sinking. The exposed pad also provides an

electrical GND to the LTC3305.

10µF

25V ALL NMOS SWITCHES = SiR882DP

D1, D2 = CMMSH1-100

D2

249Ω

LTC3630A 3.3V CM CP 1.33k NGATE5

VREG BOOST

BUCK REGULATOR 10µF 12.1k

EN1

EN2 25V

D1

MODE V4

100k EACH TERM1 NGATE4

+

TERM2 10µF 12.1k BAT4

25V

UVFLT V3

OVFLT 6.04k 10k

DONE NGATE3

R3 +

MICROPROCESSOR BAL 10µF BAT3

PTCFLT 25V

BATX

V2

BATY 12.1k 37.4k

LTC3305 NGATE2

10µF R2 +

CTON 25V BAT2

10nF

V1

CTOFF 10µF 12.1k 60.4k

12.1k

100nF 25V NGATE6 NGATE1

R1 +

9 BAT1

CTBAT NGATE1-9

10nF 12.1k 12.1k

NGATE7

VL R4

59k

PTC = PTGL13AROR8H2B71B0

VH AUXP +

93.1k 10µF AUX 12.1k

25V

AUXN NGATE8

ISET

GND

23.7k

12.1k 20k

NGATE9 3305 F08

R5

Figure 8. 4-Battery Application with External Resistors to Limit Power Dissipation

3305fb

22 For more information www.linear.com/LTC3305

LTC3305

APPLICATIONS INFORMATION

100k 100k 100k 100k 100k 100k 100k

10µF ALL NMOS DEVICES = SiR882DP

TO 25V D1, D2, D3, D4, D5, D6 = CMMSH1-100

µP

D6

2.43k 2.43k 2.43k 2.43k 2.43k 2.43k 2.43k CM CP

VREG 249Ω 1.33k

NGATE5C

EN1 BOOST

EN2 10µF D5 5.49k

1µF

MODE 25V

6V V4

TERM1 +

CPC1301G TERM2 10µF NGATE4C BAT8

25V 5.49k

UVFLT V3

OVFLT

DONE 2.74k +

10µF NGATE3C BAT7

BAL

25V

PTCFLT

BATX

BATY V2

+

LTC3305 NGATE2C BAT6

10µF

CTON 5.49k

25V

V1

CTOFF

10µF NGATE6C NGATE1C

10nF

25V 5.49k 5.49k

CTBAT 9 NGATE1C-9C

NGATE1-9

20k NGATE7C

VL 5.49k

PTC

32.4k AUXP

VH +

10µF AUX3

25V +

5.49k BAT5

8.06k AUXN NGATE8C

ISET

GND 5.49k

100k 100k 100k 100k 100k 100k 100k

NGATE9C

10µF

TO 25V

µP

D4

2.43k 2.43k 2.43k 2.43k 2.43k 2.43k 2.43k CM CP

VREG 249Ω 1.33k

NGATE5B

EN1 BOOST

1µF EN2 10µF 5.49k

D3

6V MODE 25V

TERM1 V4

CPC1301G TERM2 NGATE4B

10µF 5.49k

25V

UVFLT

OVFLT V3

DONE 2.74k

BAL 10µF NGATE3B

PTCFLT 25V

BATX

BATY V2

LTC3305 NGATE2B

10µF

CTON 25V 5.49k

V1

CTOFF

10µF NGATE6B NGATE1B

10nF 25V

5.49k 5.49k +

CTBAT 9 NGATE1B-9B BAT4

NGATE1-9

20k NGATE7B

VL 5.49k

PTC

32.4k AUXP

VH 10µF +

AUX2

25V 5.49k

8.06k AUXN NGATE8B

ISET

+

GND 5.49k BAT3

NGATE9B

10µF

25V

D2

CM CP

3.3V VREG 249Ω 1.33k

NGATE5A

100k 100k 100k 100k 100k 100k 100k EN1 BOOST

1µF EN2 10µF D1 5.49k

6V MODE 25V

V4

TERM1

TO TERM2 NGATE4A

µP 10µF 5.49k

UVFLT 25V

OVFLT V3

DONE 2.74k

BAL NGATE3A

PTCFLT 10µF

25V

BATX V2

BATY

+

CTON LTC3305 NGATE2A BAT2

10µF

5.49k

25V

CTOFF V1

10µF +

25V NGATE6A NGATE1A BAT1

CTBAT 5.49k 5.49k

10nF 9 NGATE1A-9A

NGATE1-9

NGATE7A

VL 5.49k

20k PTC

AUXP

VH

10µF +

32.4k 25V AUX1 5.49k

NGATE8A

AUXN

ISET

8.06k GND 5.49k

NGATE9A

3305 F07

Figure 9. Three LTC3305 Devices Connected to Balance Eight Lead-Acid Batteries

3305fb

For more information www.linear.com/LTC3305 23

LTC3305

APPLICATIONS INFORMATION

10µF

25V ALL NMOS DEVICES = SiR882DP

D1, D2, D3, D4 = CMMSH1-100

D4

CM CP 1.33k NGATE5B

VREG 249Ω

1µF EN1 BOOST 6.04k

6V 10µF D3

EN2

MODE 25V

V4

TERM1 NGATE4B +

475Ω 475k BAT6

TERM2 10µF 6.04k

25V

UVFLT

OVFLT V3

DONE 3.01k

BAL NGATE3B

PTCFLT 10µF

BATX 25V

BATY V2

LTC3305 +

CTON NGATE2B BAT5

10µF

25V 6.04k

CTOFF

V1

6.04k

10µF NGATE6B

CTBAT 25V

10nF 9

NGATE1-9

VL NGATE1B-9B 6.04k

NGATE7B

27.4k

VH PTC +

42.2k AUXP BAT4

10µF +

ISET 25V AUX2 6.04k NGATE1B

12.1k AUXN NGATE8B 6.04k

GND

6.04k

NGATE9B

10µF

25V

D2

CM CP 1.33k NGATE5A

VREG 249Ω +

1µF EN1 6.04k BAT3

BOOST

6V EN2 10µF

D1

MODE 25V

V4

TERM1 NGATE4A

475k

TERM2 10µF 6.04k

25V

UVFLT

OVFLT V3

DONE 3.01k

BAL NGATE3A

PTCFLT 10µF

BATX 25V

BATY V2

LTC3305 +

CTON NGATE2A BAT2

10µF

25V 6.04k

CTOFF

V1

6.04k

10µF NGATE6A

CTBAT 25V

10nF 9

NGATE1-9 +

VL NGATE1A-9A 6.04k BAT1

NGATE7A

27.4k

VH PTC

42.2k AUXP

10µF +

ISET 25V AUX1 6.04k NGATE1A

12.1k AUXN NGATE8A 6.04k

GND

6.04k

NGATE9A

3305 F08

Figure 10. Two LTC3305 Devices Connected to Balance Six Lead-Acid Batteries with AND’d DONE Indicator

3305fb

24 For more information www.linear.com/LTC3305

LTC3305

APPLICATIONS INFORMATION

ALL NMOS

DEVICES = SiR892DP

10µF D4 D1, D2, D3, D4 = CMMSH1-100

25V

CM CP 249Ω

VREG 1.33k

BOOST NGATE5B

1µF EN1

6V 10µF 6.04k

EN2 D3

100k 25V

MODE

V4 +

TERM1 6.04k

NGATE4B BAT8

TERM2 10µF

UVFLT 25V

OVFLT

DONE V3 +

3.01k BAT7

BAL NGATE3B

PTCFLT 10µF

BATX 25V

BATY

V2 +

LTC3305 NGATE2B BAT6

10µF

CTON 25V 6.04k

V1 +

CTOFF 6.04k BAT5

NGATE6B NGATE1B

10µF 6.04k

10nF 9 25V

CTBAT NGATE1-9 6.04k

NGATE1B-9B NGATE7B

VL PTC

AUXP

10µF +

VH AUX2

25V 6.04k

AUXN NGATE8B

12.1k I

SET

GND 6.04k

NGATE9B

10µF D2

25V

CM CP 249Ω

VREG 1.33k

BOOST NGATE5A

1µF EN1

6V 10µF 6.04k

EN2 D1

100k 25V

MODE

V4

TERM1 6.04k

NGATE4A +

TERM2 10µF BAT4

UVFLT 25V

OVFLT

DONE V3

3.01k

BAL NGATE3A +

PTCFLT 10µF BAT3

BATX 25V

BATY

V2

LTC3305 10µF NGATE2A +

CTON 25V BAT2

6.04k

V1

CTOFF 6.04k

NGATE6A NGATE1A +

10µF BAT1

6.04k

10nF 9 25V

CTBAT NGATE1-9 6.04k

NGATE1A-9A NGATE7A

VL PTC

AUXP +

AUX1

VH 10µF

25V 6.04k

AUXN NGATE8A

12.1k I

SET

GND 6.04k

3305 F11 NGATE9A

Figure 11. Eight Battery Balancer Using Two LTC3305 Devices

3305fb

For more information www.linear.com/LTC3305 25

LTC3305

PACKAGE DESCRIPTION

Please refer to http://www.linear.com/product/LTC3305#packaging for the most recent package drawings.

FE Package

38-Lead Plastic TSSOP (4.4mm)

(Reference LTC DWG # 05-08-1772 Rev C)

Exposed Pad Variation AA

4.75 REF 9.60 – 9.80*

(.378 – .386)

4.75 REF

(.187)

38 20

6.60 ±0.10

2.74 REF

4.50 REF

SEE NOTE 4 6.40

2.74

0.315 ±0.05 REF (.252)

(.108)

BSC

1.05 ±0.10

0.50 BSC

RECOMMENDED SOLDER PAD LAYOUT

1 19

1.20

4.30 – 4.50* (.047)

(.169 – .177) 0.25 MAX

REF

0° – 8°

0.50

0.09 – 0.20 0.50 – 0.75 (.0196) 0.05 – 0.15

(.0035 – .0079) (.020 – .030) BSC (.002 – .006)

0.17 – 0.27

FE38 (AA) TSSOP REV C 0910

(.0067 – .0106)

TYP

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS 4. RECOMMENDED MINIMUM PCB METAL SIZE

2. DIMENSIONS ARE IN MILLIMETERS FOR EXPOSED PAD ATTACHMENT

(INCHES) *DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

3. DRAWING NOT TO SCALE SHALL NOT EXCEED 0.150mm (.006") PER SIDE

3305fb

26 For more information www.linear.com/LTC3305

LTC3305

REVISION HISTORY

REV DATE DESCRIPTION PAGE NUMBER

A 09/15 Added timer mode section. 13

Modified Figure 6 schematic. 16

Modified Figure 8 schematic. 22

Modified Figure 9 schematic. 23

B 03/16 Updated Feature bulleted items and description 1

Updated Application schematic 1

Enhanced Operation section 11

3305fb

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

For more

tion that the interconnection information

of its circuits www.linear.com/LTC3305

as described herein will not infringe on existing patent rights. 27

LTC3305

TYPICAL APPLICATION

A Minimum Component Application in Which an LED is Used to Display Status

10µF

25V

D1, D2 = CMMSH1-100

D1

CM CP 1.33k NGATE5

VREG 249Ω

1µF EN1 BOOST 6.04k

10µF

6V EN2 D2

25V

MODE V4

TERM1 NGATE4 +

100Ω BAT4

TERM2 10µF 6.04k

25V

UVFLT

OVFLT V3

DONE 3.01k

BAL NGATE3

+

PTCFLT 10µF BAT3

BATX 25V

BATY V2

LTC3305 NGATE2

10µF +

CTON 6.04k BAT2

25V

V1

CTOFF 10µF

6.04k

25V NGATE6 NGATE1 +

6.04k BAT1

9

CTBAT NGATE1-9

10nF

6.04k ALL NMOS

NGATE7

DEVICES = SiR882DP

VL

PTC

AUXP

VH 10µF +

25V AUX 6.04k

ISET AUXN NGATE8

12.1k GND

6.04k

NGATE9 3305 TA02

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC3300-1 High Efficiency Bidirectional Multicell Battery Balancer Balances Up to 6 Li-Ion Batteries Per IC. Stackable to Balance Large

LTC3300-2 Battery Stacks

LT8584 2.5A Monolithic Active Cell Balancer with Telemetry Integrated 6A, 50V Switch. Stackable to Balance Large Battery Stacks

Interface

LTC4015 Multichemistry Buck Battery Charger Controller with Monitors System Parameters, Pre-programmed Maximum Power Point

Digital Telemetry System Tracking Algorithm

LTC4020 55V Buck-Boost Multi-Chemistry Battery Charger Capable of Charging 4 Lead-Acid Batteries up to 55V

LTC4000 High Voltage High Current Controller for Battery Charging Complete High Performance Battery Charger When Paired with a DC/DC

and Power Management Converter

LTC3630A High Efficiency, 65V 500mA Synchronous Step Down Efficiently Generates a Low Voltage Rail. Synchronous Operation for high

Converter Efficiency

LTC2946 Wide Range I2C Power, Charge and Energy Monitor Measures Current, Voltage, Power, Charge and Energy in a Battery Stack

up to 100V

3305fb

28 Linear Technology Corporation

LT 0316 REV B • PRINTED IN USA

1630 McCarthy Blvd., Milpitas, CA 95035-7417

For more information www.linear.com/LTC3305

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com/LTC3305 LINEAR TECHNOLOGY CORPORATION 2015

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Analog Devices Inc.:

LTC3305EFE#TRPBF LTC3305IFE#PBF LTC3305EFE#PBF LTC3305IFE#TRPBF DC2043B

You might also like

- Wbs and Division of Work Excel Spread Sheet1Document12 pagesWbs and Division of Work Excel Spread Sheet1Adrian Christian Lee100% (1)

- 50kW MEGATRON - Battery Energy Storage Systems Datasheet - 2022 - Symtec...Document13 pages50kW MEGATRON - Battery Energy Storage Systems Datasheet - 2022 - Symtec...Sanjayan MaratNo ratings yet

- Automatyczna Ładowarka Akumulatorów Ołowiowych: Kity AVTDocument8 pagesAutomatyczna Ładowarka Akumulatorów Ołowiowych: Kity AVTadyhansoloNo ratings yet

- C16 - Diploma in Chemical Engineering (Plastic & Polymers)Document217 pagesC16 - Diploma in Chemical Engineering (Plastic & Polymers)Nandan KumarNo ratings yet

- Features Description: LTC3558 Linear USB Battery Charger With Buck and Buck-Boost RegulatorsDocument32 pagesFeatures Description: LTC3558 Linear USB Battery Charger With Buck and Buck-Boost RegulatorsdefsyNo ratings yet

- Description Features: LTC1235 Microprocessor Supervisory CircuitDocument17 pagesDescription Features: LTC1235 Microprocessor Supervisory Circuitkhawar mukhtarNo ratings yet

- Engine Electrical SystemDocument11 pagesEngine Electrical SystemRaka Putra HanafiNo ratings yet

- Description Features: LTC4101 Smart Battery Charger ControllerDocument30 pagesDescription Features: LTC4101 Smart Battery Charger ControllerVasile GurezNo ratings yet

- 1154 FCDocument18 pages1154 FCZekeZer0xNo ratings yet

- Features Description: Ltc4011 High Efficiency Standalone Nickel Battery ChargerDocument26 pagesFeatures Description: Ltc4011 High Efficiency Standalone Nickel Battery ChargerAbdul KurniadiNo ratings yet

- 2AZ-FE Charging CH1-17Document17 pages2AZ-FE Charging CH1-17AlelukinNo ratings yet

- Features Description: LTC4110 Battery Backup System ManagerDocument52 pagesFeatures Description: LTC4110 Battery Backup System ManagertumblNo ratings yet

- Sensorless BLDC Controller A4960: Description Features and BenefitsDocument34 pagesSensorless BLDC Controller A4960: Description Features and BenefitsadilNo ratings yet

- DTC Circuitos BateriaDocument23 pagesDTC Circuitos BateriaRoberto Garcia GodoyNo ratings yet

- Application Tip: Using 2 Paralleling OptionDocument3 pagesApplication Tip: Using 2 Paralleling OptionMohamed MeeranNo ratings yet

- Features Descriptio: ObsoleteDocument12 pagesFeatures Descriptio: ObsoleteNavvishal DhimanNo ratings yet

- Features Descriptio: LTC4052-4.2 Lithium-Ion Battery Pulse Charger With Overcurrent ProtectionDocument12 pagesFeatures Descriptio: LTC4052-4.2 Lithium-Ion Battery Pulse Charger With Overcurrent Protectionmuhamadjayadi9No ratings yet

- A4960 A Automotive DatasheetDocument34 pagesA4960 A Automotive DatasheetCanerNo ratings yet

- 614 CodeDocument20 pages614 CodeAdamNo ratings yet

- Cummins Efc Valve PDFDocument5 pagesCummins Efc Valve PDFDavid Arbildo100% (1)

- LTC4162 LDocument52 pagesLTC4162 Lmar_barudjNo ratings yet

- Features Description: D D D D D D D D D D D D D DDocument31 pagesFeatures Description: D D D D D D D D D D D D D Dismail turkNo ratings yet

- Features Description: D D D D D D D D D D D D D DDocument34 pagesFeatures Description: D D D D D D D D D D D D D DMahmoud El-abdNo ratings yet

- LTC 4252Document37 pagesLTC 4252curzNo ratings yet

- Features Description: LTC3851 Synchronous Step-Down Switching Regulator ControllerDocument28 pagesFeatures Description: LTC3851 Synchronous Step-Down Switching Regulator ControllerDjems DjemsNo ratings yet

- Features Description: Ltc4354 Negative Voltage Diode-Or Controller and MonitorDocument14 pagesFeatures Description: Ltc4354 Negative Voltage Diode-Or Controller and Monitorm3y54mNo ratings yet

- Downloaded 14 11Document1 pageDownloaded 14 11wilsonNo ratings yet

- 4415fa PDFDocument20 pages4415fa PDFNguyen HuanNo ratings yet

- System Diagram: ECM Battery Current SensorDocument4 pagesSystem Diagram: ECM Battery Current Sensorblack coreNo ratings yet

- Lead Acid Batteries Installation GuideDocument2 pagesLead Acid Batteries Installation GuideBernardo Mikjhael Mamani IñiguezNo ratings yet

- An5649 How To Evaluate and Improve Triacs Immunity To Eft Bursts StmicroelectronicsDocument19 pagesAn5649 How To Evaluate and Improve Triacs Immunity To Eft Bursts StmicroelectronicsSérgio SilvaneresNo ratings yet

- LTC4000-High Voltage High Current CTRL For Battery Charging and Power ManagementDocument40 pagesLTC4000-High Voltage High Current CTRL For Battery Charging and Power ManagementVio ChiNo ratings yet

- 25781-Designing Battery Management Systems PDFDocument5 pages25781-Designing Battery Management Systems PDFAnonymous ZRyj23t36b100% (2)

- 2-Series, 3-Series, and 4-Series Cell Lithium-Ion or Lithium-Polymer Battery Protection AfeDocument33 pages2-Series, 3-Series, and 4-Series Cell Lithium-Ion or Lithium-Polymer Battery Protection AfeGabi Si Florin JalencuNo ratings yet

- 2-Series, 3-Series, and 4-Series Cell Lithium-Ion or Lithium-Polymer Battery Protection AfeDocument32 pages2-Series, 3-Series, and 4-Series Cell Lithium-Ion or Lithium-Polymer Battery Protection AfeGiridharan SanthakumarNo ratings yet

- Description Features: Ltc4100 Smart Battery Charger ControllerDocument30 pagesDescription Features: Ltc4100 Smart Battery Charger ControllerAlexander VargasNo ratings yet

- LTC6803 2 PDFDocument40 pagesLTC6803 2 PDFGuilleNo ratings yet

- MCTDocument9 pagesMCTChristine GomezNo ratings yet

- TP4056 Lithium Ion Battery Charger - Circuit, 18650 Battery ChargingDocument13 pagesTP4056 Lithium Ion Battery Charger - Circuit, 18650 Battery ChargingPedro LopesNo ratings yet

- bq2031 PDFDocument21 pagesbq2031 PDFBruno PilzNo ratings yet

- Lead-Acid Fast-Charge IC: FeaturesDocument17 pagesLead-Acid Fast-Charge IC: FeaturesmoannaNo ratings yet

- BQ 2031Document21 pagesBQ 2031makerlog200No ratings yet

- A4935 DatasheetDocument25 pagesA4935 DatasheetVinod KaruvatNo ratings yet

- Datasheet LTC3728L & LTC3728LX PDFDocument32 pagesDatasheet LTC3728L & LTC3728LX PDFSelmar CavalcantiNo ratings yet

- LTC4412 FDocument13 pagesLTC4412 FbocarocaNo ratings yet

- Model 1 EMSDocument3 pagesModel 1 EMSminoothwinNo ratings yet