Professional Documents

Culture Documents

Dulux PC Datasheet Luxafloor PTX July 2023

Dulux PC Datasheet Luxafloor PTX July 2023

Uploaded by

snider06primersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dulux PC Datasheet Luxafloor PTX July 2023

Dulux PC Datasheet Luxafloor PTX July 2023

Uploaded by

snider06primersCopyright:

Available Formats

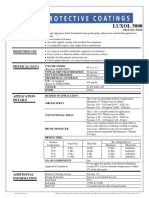

LUXAFLOOR® PTX

Polyurethane Floor Topcoat PC 701

FEATURES • EXCELLENT HIGH BUILD BRUSH & ROLLER APPLICATION

• SUPERIOR GLOSS & COLOUR RETENTION

• GOOD CHEMICAL & ABRASION RESISTANCE

• AVAILABLE IN A WIDE RANGE OF COLOURS FROM THE LUXAFLOOR® COLOUR CHART

USES LUXAFLOOR® PTX is a high performance, high build recoatable polyurethane floor coating designed for ease of

use and exceptional flow out. LUXAFLOOR® PTX exhibits excellent gloss and colour retention under extreme UV

exposure. LUXAFLOOR® PTX can be used over LUXAFLOOR® LGE as a smooth floor coating, and with

LUXAFLOOR® AGGREGATES for slip resistant finishes.

LUXAFLOOR® PTX is available in a wide range colours from the LUXAFLOOR® Colour Chart and can be matched

to most colours in the Dulux® World of Colour range through the COLORFAST™ Tint System.

SPECIFICATIONS AS 4586:2013 Refer to Luxafloor Aggregates Technical Data Sheet for the full list of systems and ratings.

RESISTANCE GUIDE

WEATHERABILITY Excellent gloss and colour retention on SOLVENTS Resists splash and spillage of most

exterior exposure hydrocarbon solvents, refined petroleum

products and most common alcohols

HEAT RESISTANCE Up to 120°C dry heat WATER Excellent resistance to fresh and salt water

but not suitable for immersion

SALTS Unaffected by splash and spillage of neutral ALKALIS Good resistance to splash and spillage of

and alkaline salt solutions most common alkalis

ACIDS Excellent resistance to splash and spillage of ABRASION Excellent when fully cured

most acids

TYPICAL PROPERTIES AND APPLICATION DATA

CLASSIFICATION Acrylic polyurethane coating APPLICATION CONDITIONS

FINISH Gloss Min Max

COLOUR Wide range of tinted colours and N35 Light Air Temp. 10°C 45°C

Grey

Substrate Temp. 10°C 45°C

Relative Humidity 85%

Concrete Moisture <6%

COMPONENTS Two

VOLUME SOLIDS 70% (White) COATING THICKNESS (MICRONS)

VOC LEVEL <280 g/L (White) Min Max Recommended

FLASH POINT 42°C Wet film per coat 110 180 145

(μm)

POT LIFE 2 Hours (4 Litre kit, 25°C) Dry film per coat 75 125 100

(μm)

MIXING RATIO V/V Part A : 4 Part B : 1

THINNER 965-42166 Duthin® 040 SUITABLE Suitably primed diamond ground or track

SUBSTRATES blasted concrete

PRODUCT CODE 771-63001 White/Light Base PRIMERS Luxafloor® Primer, Luxafloor® LGE, and

771-63002 Deep Base Luxafloor® HSG

771-63003 Clear Base

771-38678 N35 Light Grey TOPCOATS Not applicable

976-H0160 Standard Hardener

APPLICATION Brush, roller, conventional, airless spray or

METHODS air assisted spray

DRYING CHARACTERISTICS AT 100 μm DRY FILM THICKNESS*

OVERCOAT

Floor Temperature Humidity Touch Light Traffic Full Cure Min Max

15° C 50% 10 Hours 36 Hours 7 Days 24 Hours Extended

25° C 50% 3 Hours 24 Hours 7 Days 10 Hours Extended

These figures are a guide only, as ventilation, film thickness, humidity, thinning and other factors will influence the rate of drying.

SPREADING RATE 7.0 square metres per litre equals 100 μm dry film thickness

assuming no losses NOTE: Practical spreading rates will vary depending on such factors as application method, ambient

conditions, surface porosity and roughness.

PC 701 July 2023 Page 1 of 3

LUXAFLOOR® PTX

TYPICAL SYSTEMS

This is a guide only and not to be used as a specification. Your specific project needs must be discussed with a Dulux Protective Coatings Consultant.

SURFACE ENVIRONMENT PREPARATION GUIDE SYSTEM DFT (μm)

1st Coat Luxafloor® LGE 125 μm

Remove curing agents and other

Exterior/ OR

CONCRETE surface contaminants. Diamond 100 μm

Interior 1st Coat Luxafloor® Primer

grind or track blast to provide a key nd 100 μm

2 Coat Luxafloor® PTX

Remove curing agents and other 1st Coat Luxafloor® LGE Thin by 10 - 15% 125 μm

Exterior/

CONCRETE surface contaminants. Diamond 2nd Coat Luxafloor® LGE 125 μm

Interior

grind or track blast to provide a key 3rd Coat Luxafloor® PTX Mix in Stir-In Aggregate Coarse @ 30g/L 100 μm

1st Coat Luxafloor® LGE Thin by 10 - 15% 125 μm

2

Sprinkle Broadcast Aggregate No. 36 at 50g/m while still wet

Remove curing agents and other

Exterior/ OR

CONCRETE surface contaminants. Diamond 100 μm

Interior 1st Coat Luxafloor® Primer

grind or track blast to provide a key Sprinkle Broadcast Aggregate No. 36 at 50g/m2 while still wet

2nd Coat Luxafloor® PTX 100 μm

NOTE: If application is by brush or roller, additional coats will be necessary to achieve the minimum DFT and full opacity

SURFACE Specifiers should follow the surface preparation guidelines from the data sheet of the primer used. The first coat

PREPARATION must be clean, sound and free from moisture, grease and other contaminants. If application of the second coat has

exceeded the recoat window of the first coat (refer to data sheet) then the entire surface MUST be abraded.

APPLICATION Mix each can thoroughly using a power mixer until the contents are uniform. Ensure bases have been tinted to the

correct colour before use. DULUX® ASSUMES NO RESPONSIBILITY FOR THE APPLICATION OF INCORRECT

COLOUR. Mix the contents of both packs together thoroughly with a power mixer and let stand for 10 minutes. Box

all containers before use to ensure colour consistency. Remix thoroughly before application.

BRUSH/ROLLER Apply even coats of the mixed material to the prepared surface. Thin, if necessary, with up to 50 ml/litre with Duthin®

040 (965-42166) to aid application. When brushing and rolling additional coats may be required to attain the

specified thickness. Note - If a highly decorative appearance is required it may be necessary to adjust thinning

levels (up to 100 – 150ml/litre), roller type and application technique.

CONVENTIONAL Thin up to 100 ml/litre with DUTHIN® 040 (965-42166) to aid atomisation.

SPRAY Typical Set-up Graco AirPro: 1.8mm (239543)

Pressure at Triton 308: 65-100 kPa (10-15 p.s.i.)

Pressure at Gun: 385-420 kPa (55-60 p.s.i.)

AIRLESS SPRAY Standard airless spray equipment such as a Graco Xtreme 45:1 with a fluid tip of 15-19 thou (0.38-0.48mm) and

an air supply capable of delivering 550-690 kPa (80-100 p.s.i.) at the pump. Thinning is not normally required but

up to 50 ml/litre of Duthin® 040 (965-42166) may be added to aid application.

PRECAUTIONS This is an industrial product designed for use by experienced Protective Coating applicators. Where conditions

may require variation from the recommendations on this Product Data Sheet contact your nearest Dulux ®

Consultant for advice prior to painting. Do not apply in conditions outside the parameters stated in this document

without the written consent of Dulux® Australia. Freshly mixed material must not be added to material that has been

mixed for some time. The rate of cure is dependent upon temperature. Do not apply at temperatures below 10°C.

Do not apply at relative humidity above 85% or when the surface is less than 3°C above the dewpoint. Ensure that

you read and understand the safety precautions on the Material Safety Data Sheets for the two components before

using. The recommended thinner MUST be used as some solvents react with the isocyanate hardener seriously

degrading the life of the coating. Under no circumstances should water or non-specified thinner be allowed to

contaminate the product. . Note – Rubber-tyred vehicles, particularly those using new high-performance car tyres,

may cause yellowing or staining on floor coatings. The rubber can contain materials that will migrate into the surface

coating and cause this effect. This is dependent on the composition and age of the tyre and may affect all coatings

to a greater or lesser extent. Refer to our tech note (https://www.duluxprotectivecoatings.com.au/media/1542/139-

concrete-floors-tyre-staining.pdf) to find out more about tyre staining and how it can be managed. Dulux Protective

Coatings.

CLEAN UP Clean all equipment with Duthin® 040 (965-42166) immediately after use

OVERCOATING Degrease with Gamlen CA 1 according to the manufacturer’s written instructions and all safety warnings. Test

adhesion of existing coating by standard cross hatch adhesion test. If the coating fails, remove it. Use a suitable

epoxy filling mortar to fill any cracks or defects in the concrete. Spot prime bare areas with Luxafloor® LGE.

Mechanically grind the existing coating to remove any gloss and create a good key for the new coating. Vacuum

clean to remove all dust.

SAFETY Read Data Sheet, SAFETY DATA SHEET and any precautions on container labels. SAFETY DATA SHEET

PRECAUTIONS is available from Customer Service (13 23 77) or www.duluxprotectivecoatings.com.au

STORAGE Store as required for a flammable liquid Class 3 in a bunded area under cover. Store in well-ventilated area away

from sources of heat or ignition. Keep containers closed at all times.

HANDLING As with any chemical, ingestion, inhalation and prolonged or repeated skin contact should be avoided by good

occupational work practice. Eye protection approved to AS1337 should be worn where there is a risk of splashes

entering the eyes. Always wash hands before smoking, eating, drinking or using the toilet.

USING Use with good ventilation and avoid inhalation of spray mists and fumes. If risk of inhalation of spray mists exists,

wear combined organic vapour/particulate respirator. When spraying, users must comply with their respective State

Spray Painting Regulations.

FLAMMABILITY This product is flammable. All sources of ignition must be eliminated in, or near the working area. DO NOT SMOKE.

Fight fire with foam, CO2 or dry chemical powder. On burning will emit toxic fumes.

WELDING Avoid inhalation of fumes if welding surfaces coated with this paint. Grind off coating before welding.

PC 701 July 2023 Page 2 of 3

COMPANY INFORMATION PACKAGING, TRANSPORT AND STORAGE

Dulux Protective Coatings a division of PACKAGING Available in 10 litre packs

DuluxGroup (Australia) Pty Ltd DuluxGroup (New Zealand) Pty Ltd TRANSPORTATION WEIGHT 1.43 kg/litre (Average of components)

1956 Dandenong Road, Clayton 3168 150 Hutt Park Road, Lower Hutt, NZ Part A: Class 3 UN 1263

DANGEROUS GOODS

A.B.N. 67 000 049 427 A.B.N. 55 133 404 118 Part B: Class 3 UN 1263

Dulux, and Luxafloor are registered trade marks of DuluxGroup (Australia) Pty Ltd.

Any advice, recommendation, information, assistance or service provided by Dulux Australia in relation to goods manufactured by it or their use and application is given

in good faith and is believed by Dulux to be appropriate and reliable. However, any advice, recommendation, information, assistance or service provided by Dulux is

provided without liability or responsibility PROVIDED THAT the foregoing shall not exclude, limit, restrict or modify the right entitlements and remedies conferred upon

any person or the liabilities imposed upon Dulux by any condition or warranty implied by Commonwealth, State or Territory Act or ordinance void or prohibiting such

exclusion limitation or modification. Products can be expected to perform as indicated in this sheet so long as applications and application procedures are as

recommended. Specific advice should be sought from Dulux for application in highly corrosive areas and for large projects to ensure proper performance.

PC 701 July 2023 Page 3 of 3

You might also like

- Luxepoxy STL: Solventless Epoxy Tank Lining PC 246Document2 pagesLuxepoxy STL: Solventless Epoxy Tank Lining PC 246livefreakNo ratings yet

- Dulux PC Datasheet Luxafloor HSG July-2023Document4 pagesDulux PC Datasheet Luxafloor HSG July-2023snider06primersNo ratings yet

- Luxepoxy T: Tintable Two Pack Epoxy FinishDocument2 pagesLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakNo ratings yet

- Luxafloor Rollcoat: High Build High Solids Epoxy Floor CoatingDocument3 pagesLuxafloor Rollcoat: High Build High Solids Epoxy Floor CoatinglivefreakNo ratings yet

- Duremax Gpe ZP Aug 2018Document3 pagesDuremax Gpe ZP Aug 2018Biju_PottayilNo ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Duremax GPE: General Purpose Epoxy CoatingDocument4 pagesDuremax GPE: General Purpose Epoxy CoatinglivefreakNo ratings yet

- Luxepoxy UHB: Ultra High Build EpoxyDocument2 pagesLuxepoxy UHB: Ultra High Build EpoxylivefreakNo ratings yet

- Zincanode 304: Solvent Borne Inorganic Zinc SilicateDocument3 pagesZincanode 304: Solvent Borne Inorganic Zinc SilicatelivefreakNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Aquagalv: Water Borne Inorganic Zinc SilicateDocument3 pagesAquagalv: Water Borne Inorganic Zinc SilicatelivefreakNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Durebild HSE: High Build Two Pack Epoxy CoatingDocument3 pagesDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNo ratings yet

- SUPER COVER ACRYLIC Technical Data SheetDocument3 pagesSUPER COVER ACRYLIC Technical Data SheetPaul HillierNo ratings yet

- Metalshield Premium Aug 2018Document2 pagesMetalshield Premium Aug 2018Biju_PottayilNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Hi Temp Uniprime May 2020Document2 pagesHi Temp Uniprime May 2020Muhamad Reza HabibiNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Zinc Rich 1p pc102Document2 pagesZinc Rich 1p pc102livefreakNo ratings yet

- Apexior-No 1 Aug 2018Document2 pagesApexior-No 1 Aug 2018emadsafy20002239No ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Revchem HRC 870Document3 pagesRevchem HRC 870marciobispoalmeidaNo ratings yet

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Durocoat 90A: Polyaspartic ChemistryDocument3 pagesDurocoat 90A: Polyaspartic ChemistryVaittianathan MahavapillaiNo ratings yet

- Luxatherm 6200Document2 pagesLuxatherm 6200PraveenNo ratings yet

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocument3 pagesDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarNo ratings yet

- Hi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFDocument5 pagesHi Pon 90 08 Epoxy Ultra HB Ver 2.0 PDFPushpendraNo ratings yet

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- 3500-00 Simathane Gloss (Finish Coat)Document3 pages3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNo ratings yet

- 3500-00 Simathane GlossDocument3 pages3500-00 Simathane GlossSAEFUDDIN SAEFUDDINNo ratings yet

- Pds Luxathane 5000 VocDocument2 pagesPds Luxathane 5000 Vocmuthukumar100% (1)

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- KAN-TAURUS High Build Epoxy Finish: CharacteristicsDocument2 pagesKAN-TAURUS High Build Epoxy Finish: Characteristicsazam RazzaqNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Product Data Sheet: Simathane GlossDocument3 pagesProduct Data Sheet: Simathane GlossAdnan FrrNo ratings yet

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- Epilux 218: Product DescriptionDocument2 pagesEpilux 218: Product DescriptionMoin AltafNo ratings yet

- Hi Temp 400: Silicone Based High Temperature Coating PC 929Document2 pagesHi Temp 400: Silicone Based High Temperature Coating PC 929JeromeNo ratings yet

- KCC DataSheet LT313ENGDocument2 pagesKCC DataSheet LT313ENGNasir AnsariNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- RobbiathaneDocument2 pagesRobbiathaneAnson FranklinNo ratings yet

- TDS-PDF-Interchar 1290 Eng A4 20170228Document4 pagesTDS-PDF-Interchar 1290 Eng A4 20170228shameelNo ratings yet

- Pds Luxol 1000 VocDocument2 pagesPds Luxol 1000 VocmuthukumarNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- Epilux 5: Product DescriptionDocument2 pagesEpilux 5: Product DescriptionShyam ShrishNo ratings yet

- Durebild Ste Glass Flake pc239Document3 pagesDurebild Ste Glass Flake pc239livefreakNo ratings yet

- Epoxy Primer - Epilux610 - 4079Document2 pagesEpoxy Primer - Epilux610 - 4079GautamNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- Pds Luxol 5000 VocDocument2 pagesPds Luxol 5000 VocmuthukumarNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- g9) Berger Apcofine 905 - 8096Document2 pagesg9) Berger Apcofine 905 - 8096Wasek SarkerNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Peimar EN SF420MDocument2 pagesPeimar EN SF420MDaniel I. PopNo ratings yet

- Elimelech - Som Refrence 1Document9 pagesElimelech - Som Refrence 1Aya HossamNo ratings yet

- Msds Chemguard 3% Afff C-301msDocument4 pagesMsds Chemguard 3% Afff C-301msMatías YaegerNo ratings yet

- O Chemistry-1 PDFDocument334 pagesO Chemistry-1 PDFDolbert Asasira100% (1)

- Data 07 00140DVADSWADSSDDocument9 pagesData 07 00140DVADSWADSSD16061977No ratings yet

- Ss1 Chemistry First TermDocument52 pagesSs1 Chemistry First TermOseni MuibaNo ratings yet

- Module 2Document15 pagesModule 2Xang Yi100% (1)

- Monopol Cromatic System Industry: PortugalDocument16 pagesMonopol Cromatic System Industry: PortugalPatrick QuadrosNo ratings yet

- Experiment 2: Elemental Analysis by Sodium FusionDocument11 pagesExperiment 2: Elemental Analysis by Sodium FusionSandra Nicole RiveraNo ratings yet

- Nucleas Kota Inorganic Chemistry Question BankDocument37 pagesNucleas Kota Inorganic Chemistry Question Bankarorayash603No ratings yet

- FIA 010 - Method For Ammonia Determination v2.1Document7 pagesFIA 010 - Method For Ammonia Determination v2.1Wahid ArdaniNo ratings yet

- Safety Data Sheet: V-Sorb Ultraviolet Absorber 326Document8 pagesSafety Data Sheet: V-Sorb Ultraviolet Absorber 326TSM MediaNo ratings yet

- Interpretive Essay FormatDocument5 pagesInterpretive Essay Formatafhbfqccp100% (2)

- 4612 - ALBA Liquid Vapor Equilibrium in An Azeotropic MixtureDocument6 pages4612 - ALBA Liquid Vapor Equilibrium in An Azeotropic MixtureDoge WoweNo ratings yet

- Chemical Usage SOP1Document3 pagesChemical Usage SOP1Hadi AmirNo ratings yet

- Fosroc Nitomortar FC (B) : Constructive SolutionsDocument2 pagesFosroc Nitomortar FC (B) : Constructive SolutionsVincent JavateNo ratings yet

- Created By: Heri Reksa S.Pd. Chemistry Teacher SMAN 1 BogorDocument45 pagesCreated By: Heri Reksa S.Pd. Chemistry Teacher SMAN 1 BogorHeri ReksaNo ratings yet

- Abstract of ASTM F901 2001Document5 pagesAbstract of ASTM F901 2001Jesse ChenNo ratings yet

- Nanoparticle Characterization What To MeasureDocument26 pagesNanoparticle Characterization What To MeasureMarwaya EmamNo ratings yet

- Karl Gerard Siagan - General Chemistry Learning Kit 1Document3 pagesKarl Gerard Siagan - General Chemistry Learning Kit 1Karl SiaganNo ratings yet

- Reusing Textile Waste As Reinforcements in CompositesDocument16 pagesReusing Textile Waste As Reinforcements in CompositesYouness BouhajNo ratings yet

- Using Diaminomethanal As An Entrainer For The Separation of Isopropanol + Water MixtureDocument12 pagesUsing Diaminomethanal As An Entrainer For The Separation of Isopropanol + Water MixturenehaNo ratings yet

- NTSE Delhi Question Papers 2019 20Document22 pagesNTSE Delhi Question Papers 2019 20Technical AyushNo ratings yet

- Aflatoxins and Mycotoxins - ChromatographyDocument16 pagesAflatoxins and Mycotoxins - ChromatographyMinaMilić100% (1)

- Actividad 3 - Compressed PDFDocument7 pagesActividad 3 - Compressed PDFLUIS LIBROSNo ratings yet

- POGIL Ox Phos S PDFDocument5 pagesPOGIL Ox Phos S PDFDoug GilmourNo ratings yet

- Environmental Science 14th Edition Cunningham Test BankDocument22 pagesEnvironmental Science 14th Edition Cunningham Test Bankmarykirbyifsartwckp100% (12)

- Palm and Palm Kernel Supply Chain - Fractions Derivatives and Product Uses WEBDocument7 pagesPalm and Palm Kernel Supply Chain - Fractions Derivatives and Product Uses WEBAnonymous DJrec2100% (1)

- Science 10 Jan 2023 Study PlanDocument1 pageScience 10 Jan 2023 Study PlanmalikmuhieddineNo ratings yet

- QQ A 200e - GenDocument15 pagesQQ A 200e - GenGerman FuentesNo ratings yet