Professional Documents

Culture Documents

Mpi Report With Uv Trdi1 Spacer Can New1

Mpi Report With Uv Trdi1 Spacer Can New1

Uploaded by

Khalil ChabbouhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mpi Report With Uv Trdi1 Spacer Can New1

Mpi Report With Uv Trdi1 Spacer Can New1

Uploaded by

Khalil ChabbouhCopyright:

Available Formats

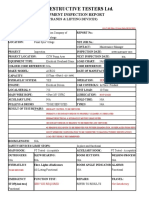

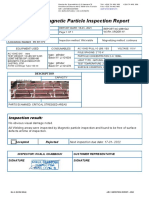

Customer : MAGNETIC PARTICLE INSPECTION REPORT Inspection Report n° : WF-TRS-4681-1880

Location : BASE TRS Inspection Date : 12/05/2015

Rig /Well Name&No : N/A

Material Description : FILLUP TOOL Expired Date : 11/11/2015

Customer PO n° : N/A SN :TRDI03 WO :72198132

TYPE : Manufacturer : Rated Capacity :

Testing Equpt Black light :ULT02 Calibrated : 04/8/2014 UV Meter : 8254

Mag UNIT :0005 Light Intensity at 15 inch from the light source : 1259 µW/cm2

NDT Chemicals : Product code : Pfinder 150 Magnetic powder suspension fluorescent L1002877

Inspection Standard API RP 8B VISUAL Costomer Spec API RP 7K API RP 7L Procedure Ref Tuboser MPI I nspection Procedure 01 January 2013 Revision 0/Weatherford proc

Field indicators :M1160 Test with Castrol strip OK/NO OK

Inspection Methods WMPI FL WMPI V DMPI Visual Insp UT

NDE/VISUAL INSPECTION RESULT: All critical areas and connection of This

Inspection Category Category I Category 2 Category 3 Category4 Category 5

Item were MPI inspected and were found to be free of surface defects at time

Mandrel, INTR of inspection.

Inspection Frequency 6 Months 1 year 2 year 5 year Others

Sleeve Slider

Status: ACCEPTED REJECTED

Areas Inspected Weld area Full body Lifting pad eye

Spring,Fillup Indicated

200 Series Stress area

Sub, Ported Bottom

Housing,MSV,200 Series

Signature : Inspected by : Imed Hammouda

Full body MPI inspected And Qualification : ASNT Level II MT PT UT

accepted Lev I

You might also like

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- LT 2021-6847 (Equipment Inspection Report - Crane & Lifting Devices)Document4 pagesLT 2021-6847 (Equipment Inspection Report - Crane & Lifting Devices)michaelNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- NDT Report - Old.Turbine BearingsDocument3 pagesNDT Report - Old.Turbine BearingsOm Ar TanNo ratings yet

- Ir - L1904-32 17apr19-Mt (Sfjt-E)Document5 pagesIr - L1904-32 17apr19-Mt (Sfjt-E)Alleyson Akin100% (1)

- D.P. Test ReportDocument1 pageD.P. Test Reportvirendra katkeNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- 109.8181.MPI - Pre.Unit.730395.Cover RadiatorDocument2 pages109.8181.MPI - Pre.Unit.730395.Cover RadiatorHerr Ddiman100% (1)

- A. 169.7 MpaDocument46 pagesA. 169.7 MpaBrilliantJohnMalandacRubiaNo ratings yet

- Liquid Penetrant Examination Report: PO No.&Document2 pagesLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- BC - Unit IV - Slope Intercept InvestigationDocument5 pagesBC - Unit IV - Slope Intercept InvestigationMichael ParsonsNo ratings yet

- Valve Inspection and Test ReportDocument1 pageValve Inspection and Test ReportAmal AmranNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Lecture Casting InSteelCon 2007Document8 pagesLecture Casting InSteelCon 2007radynasrNo ratings yet

- Installation of Padeyes Ad Load Test: Front CoverDocument40 pagesInstallation of Padeyes Ad Load Test: Front CoverAhmedA.HassanNo ratings yet

- Mpi Report With Ac Yoke Lifting Eyes and Sje AdapterDocument2 pagesMpi Report With Ac Yoke Lifting Eyes and Sje AdapterKhalil ChabbouhNo ratings yet

- Control Panel FMS SN CP0001 MpiDocument1 pageControl Panel FMS SN CP0001 MpiKhalil ChabbouhNo ratings yet

- New Report 13 3-8 Inch Slips Sa 1402Document1 pageNew Report 13 3-8 Inch Slips Sa 1402Khalil ChabbouhNo ratings yet

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 pagesNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniNo ratings yet

- Mpi CB, LBDocument7 pagesMpi CB, LBSuhari AriNo ratings yet

- Tmu-1105 Job Card Ta-2019Document20 pagesTmu-1105 Job Card Ta-2019Anonymous YRyGcKPNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- MPI Report SWL 5 Ton BoxDocument2 pagesMPI Report SWL 5 Ton BoxYusuf bagewadiNo ratings yet

- Hmmu331021 9Document5 pagesHmmu331021 9ANGEL ANTONIO GUTIERREZ CONTRERASNo ratings yet

- CAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Document3 pagesCAT-ECI-19-035 Pad Eyes On M 310B Fan Room (AFT) Rigging Locker #7Komang Triwahyudi100% (1)

- MT PipaDocument70 pagesMT PipaDani Madrid12No ratings yet

- 02-Singl Joint 1Document8 pages02-Singl Joint 1Abdou BoucheritNo ratings yet

- WO1831 - Arabtec 09.02.2020.Document1 pageWO1831 - Arabtec 09.02.2020.Pradeep ManivannanNo ratings yet

- Doosan Power Systems India PVT Limited: Magnetic Particle Examination ReportDocument1 pageDoosan Power Systems India PVT Limited: Magnetic Particle Examination ReportBalkishan DyavanapellyNo ratings yet

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- 07 Mpi Report - 1Document12 pages07 Mpi Report - 1Abdou BoucheritNo ratings yet

- IRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestDocument40 pagesIRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestAfzaalUmairNo ratings yet

- 107.8182.MPI - Pre.Unit.730395.Fuel TankDocument2 pages107.8182.MPI - Pre.Unit.730395.Fuel TankHerr DdimanNo ratings yet

- Client:: Olectra Greentech LTDDocument1 pageClient:: Olectra Greentech LTDnareshNo ratings yet

- Interloop Satellite Stitching Unit: RecommendationDocument13 pagesInterloop Satellite Stitching Unit: RecommendationFraz AhmadNo ratings yet

- MPI Report - M250 - 127mm DiaDocument1 pageMPI Report - M250 - 127mm DiaGyanendraNo ratings yet

- M.T Confident-1 (Docking 2023) MPI Test ReportDocument1 pageM.T Confident-1 (Docking 2023) MPI Test Reportsushanto.mtbdNo ratings yet

- 4-Lembar Pengesahan PengujiDocument163 pages4-Lembar Pengesahan PengujiNico Achmad ZulviansyahNo ratings yet

- Magnetic Examination Report: International Inspection Services L.L.CDocument1 pageMagnetic Examination Report: International Inspection Services L.L.CAzhar AhmadNo ratings yet

- SARENS HEAVY CalibarationDocument2 pagesSARENS HEAVY CalibarationSusil Kumar SahooNo ratings yet

- 2178Document1 page2178qc_531040655No ratings yet

- Certificados Almejas GuvenDocument8 pagesCertificados Almejas GuvenDavid NahNo ratings yet

- A0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Document15 pagesA0146908 Matrix Ve Ut Insp Yellow Dehydrator 16oct2012Madhan KannanNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- 2.WGU-1289-AM Pivot Shaft D375 RHS, SN 9040123338Document1 page2.WGU-1289-AM Pivot Shaft D375 RHS, SN 9040123338wahyuNo ratings yet

- International LTD: Report of Thorough ExaminationDocument1 pageInternational LTD: Report of Thorough ExaminationChisom IkengwuNo ratings yet

- Int Aim 231787 PT 14 1302&03Document1 pageInt Aim 231787 PT 14 1302&03Joshua ClaytonNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraNo ratings yet

- 09 Life RaftDocument2 pages09 Life RaftMaan MrabetNo ratings yet

- 106.8180.MPI - Pre.Unit.730395.Hydraulic TankDocument3 pages106.8180.MPI - Pre.Unit.730395.Hydraulic TankHerr DdimanNo ratings yet

- RINA Cert 4x12cbm GUVEN Radio Remote Control Grab QUO-0000073955-N2K - IR8..Document8 pagesRINA Cert 4x12cbm GUVEN Radio Remote Control Grab QUO-0000073955-N2K - IR8..Matheus BarrosNo ratings yet

- LG (67) - G3-1009-Fan (Turbo) G v.2Document9 pagesLG (67) - G3-1009-Fan (Turbo) G v.2Anonymous Lta32Ta9No ratings yet

- 1 - Reference Section: TsiteDocument3 pages1 - Reference Section: TsiteKuldeep KumarNo ratings yet

- Boot Basket 17485Document1 pageBoot Basket 17485khalilNo ratings yet

- Model Visual and Mpi ReportDocument3 pagesModel Visual and Mpi ReportBLY YEDEKPA NOEL BENITONo ratings yet

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- 2370 Cross OverDocument1 page2370 Cross OverKhalil ChabbouhNo ratings yet

- 0026 Lifting PlugDocument1 page0026 Lifting PlugKhalil ChabbouhNo ratings yet

- 0011 Lifting PlugDocument1 page0011 Lifting PlugKhalil ChabbouhNo ratings yet

- Mpi 44444286 ..Document1 pageMpi 44444286 ..Khalil ChabbouhNo ratings yet

- TB 5003,, (New4Document1 pageTB 5003,, (New4Khalil ChabbouhNo ratings yet

- Fishing Jar 285204 .Document1 pageFishing Jar 285204 .Khalil ChabbouhNo ratings yet

- TB0084Document1 pageTB0084Khalil ChabbouhNo ratings yet

- X Over 8Document1 pageX Over 8Khalil ChabbouhNo ratings yet

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 pagesMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNo ratings yet

- Bushing Drive Sub 31766Document1 pageBushing Drive Sub 31766Khalil ChabbouhNo ratings yet

- 02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfDocument2 pages02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfKhalil ChabbouhNo ratings yet

- 04 Spiral Drill Collar Slip Groove 4 3-4Document2 pages04 Spiral Drill Collar Slip Groove 4 3-4Khalil ChabbouhNo ratings yet

- 4 Legs Sling INA 182-1.Document1 page4 Legs Sling INA 182-1.Khalil ChabbouhNo ratings yet

- Hp013 Lifting SubDocument1 pageHp013 Lifting SubKhalil ChabbouhNo ratings yet

- 03 HWDP Spiral 3 1-2 New ReportDocument2 pages03 HWDP Spiral 3 1-2 New ReportKhalil ChabbouhNo ratings yet

- Cad 1 Project FinalDocument19 pagesCad 1 Project FinalBill 007No ratings yet

- Worksheet 5 Differential Calculus PDFDocument9 pagesWorksheet 5 Differential Calculus PDFShin QuinnNo ratings yet

- Belden Zm6acff01 FRCDocument1 pageBelden Zm6acff01 FRCAirinzVSWhibhowhoNo ratings yet

- Fisher-Tippett-Gnedenko TheoremDocument5 pagesFisher-Tippett-Gnedenko TheoremSri Muslihah BakhtiarNo ratings yet

- Aisi A6Document1 pageAisi A6123vigenNo ratings yet

- Soil Exploration PDFDocument36 pagesSoil Exploration PDFp.v.n. lakshmanNo ratings yet

- Physical Second Quarter ExaminationDocument2 pagesPhysical Second Quarter ExaminationRey Julius RanocoNo ratings yet

- Fixed Base Plate Design-ECPLUS DesignDocument3 pagesFixed Base Plate Design-ECPLUS DesignNivarNo ratings yet

- Boats - Streams NewDocument21 pagesBoats - Streams NewJimNo ratings yet

- Tower Modeling For Lightning Surge Analysis Using Electro-Magnetic Transients ProgramDocument3 pagesTower Modeling For Lightning Surge Analysis Using Electro-Magnetic Transients ProgramAlcides NetoNo ratings yet

- Qualis NovosDocument914 pagesQualis NovoshgdfdNo ratings yet

- A Review On Data-Drive Fault Severity in Rollings or BearingsDocument29 pagesA Review On Data-Drive Fault Severity in Rollings or BearingsLeonardo Herman Osorio MantillaNo ratings yet

- 8MA0 - 02 Statistics and Mechanics MS4et5yhrethrteyhuDocument21 pages8MA0 - 02 Statistics and Mechanics MS4et5yhrethrteyhuTahu BladNo ratings yet

- Regulation UNECE R118: Proposition of Changes For Annex 6 (Horizontal Burning Rate) and Annex 8 (Vertical Burning Rate)Document6 pagesRegulation UNECE R118: Proposition of Changes For Annex 6 (Horizontal Burning Rate) and Annex 8 (Vertical Burning Rate)Shubham KaklijNo ratings yet

- Notes Chapter 2Document122 pagesNotes Chapter 2GAURAV RATHORENo ratings yet

- Talentex SyllabusDocument1 pageTalentex SyllabusJaySharanNo ratings yet

- Upgrading Techniques For Quay Walls: Mohamed DOUAIRI Jarit de GijtDocument8 pagesUpgrading Techniques For Quay Walls: Mohamed DOUAIRI Jarit de GijtMahdi FekiNo ratings yet

- Space Engineering: Thermal Design Handbook - Part 12: LouversDocument106 pagesSpace Engineering: Thermal Design Handbook - Part 12: LouversAsistencia Técnica JLFNo ratings yet

- RC Circuit LabDocument3 pagesRC Circuit LabSail338No ratings yet

- Math CardsDocument5 pagesMath CardsLalaine Villamar DizonNo ratings yet

- Quantum Chemistry in The Age of Machine Learning: AccessDocument12 pagesQuantum Chemistry in The Age of Machine Learning: AccessPeterNo ratings yet

- TLD FormDocument3 pagesTLD Formavirajput1230987No ratings yet

- What Is The Difference Between Rotational and Irrotational Flow - QuoraDocument3 pagesWhat Is The Difference Between Rotational and Irrotational Flow - Quoraabbas6063No ratings yet

- Chem 312 Lab 01 ReportDocument6 pagesChem 312 Lab 01 ReportSalman MiraNo ratings yet

- Density, SG and °API in Crude Oil: According To ASTM D5002 and ISO 12185Document3 pagesDensity, SG and °API in Crude Oil: According To ASTM D5002 and ISO 12185Md MansoorNo ratings yet

- Rankine Cycle ExampleDocument8 pagesRankine Cycle ExampleMahmut KILIÇNo ratings yet

- السلامة من الحرائقDocument72 pagesالسلامة من الحرائقmekhtarNo ratings yet