Professional Documents

Culture Documents

Painting Report Batch 4

Painting Report Batch 4

Uploaded by

Galang Pratama PutraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Painting Report Batch 4

Painting Report Batch 4

Uploaded by

Galang Pratama PutraCopyright:

Available Formats

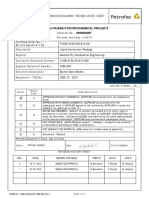

DOC. NO. QA - WHU - 005 REV.

10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 27 June 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 6/26/2023 6/26/2023

TIME 10.00 15.00

AIR TEMPERATURE oC 28.7 28,3

WET BULB TEMP oC

RELATIVE HUMIDITY % 51.10% 71,2

DEW POINT TEMP C 17.6 22,6

STEEL TEMP oC 28.6 26,7

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 26/06/2023 START TIME : 10.00 FINSH TIME : 15.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 81 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 22 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal / Accepted

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

COAT NO.

THINNER / THINNER /

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 INTERZINC 52 INTERNATIONAL PAINT EPOXY ZINC RICH 3263124026 3263103053 May-23 GRAY RAL 7045 GTA 220 3263123035 9:1 AIRSPAY

2

_______/_______

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

COAT NO.

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END AIR TEMP. (°C) START TIME FINISH TIME TIME

APPLICATION PRODUCT TEMP

POT LIFE DURING STRIPE COAT

METHOD (°C) BEFORE

FOR FOR

APPLICATION COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTED

COATS

1 15.30 15.35 _____/_____ 4 hr 30 C AIR SPRAY 15.45 16.15 150 mic 150 mic 75 mic 70 - 85 mic ACCEPTED

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY

REMARKS

71726-20010 4 Paint system P11

71726-20013 2 Paint system P11

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HERY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 27/06/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 27 June 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 6/26/2023 6/26/2023

TIME 10.00 15.00

AIR TEMPERATURE oC 28.7 28,3

WET BULB TEMP oC

RELATIVE HUMIDITY % 51.10% 71,2

DEW POINT TEMP C 17.6 22,6

STEEL TEMP oC 28.6 26,7

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 26/06/2023 START TIME : 10.00 FINSH TIME : 15.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 81 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 22 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal / Accepted

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. THINNER / THINNER / MIXING / AGITATING

COAT NO. PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 INTERZINC 52 INTERNATIONAL PAINT EPOXY ZINC RICH 3263124026 3263103053 May-23 GRAY RAL 7045 GTA 220 3263123035 9:1 AIRSPAY

2 _______/_______

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END AIR TEMP. (°C) START TIME FINISH TIME TIME

APPLICATION PRODUCT TEMP

COAT NO. POT LIFE DURING STRIPE COAT

METHOD (°C) BEFORE

FOR FOR

APPLICATION COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 15.30 15.35 _____/_____ 4 hr 30 C AIR SPRAY 15.45 16.15 150 mic 150 mic 75 mic 70 - 85 mic ACCEPTED

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY REMARKS

71725-20006 47 Paint system P11

71725-20007 6 Paint system P11

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HERY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 27/06/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 27 June 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 6/26/2023 6/26/2023

TIME 10.00 15.00

AIR TEMPERATURE oC 28.7 28,3

WET BULB TEMP oC

RELATIVE HUMIDITY % 51.10% 71,2

DEW POINT TEMP C 17.6 22,6

STEEL TEMP oC 28.6 26,7

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 26/06/2023 START TIME : 10.00 FINISH TIME : 15.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 81 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 22 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal / Accepted

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. THINNER / THINNER / MIXING / AGITATING

COAT NO. PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 INTERZINC 52 INTERNATIONAL PAINT EPOXY ZINC RICH 3263124026 3263103053 May-23 GRAY RAL 7045 GTA 220 3263123035 9:1 AIRSPAY

2 _______/_______

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END AIR TEMP. (°C) START TIME FINISH TIME

TIME

APPLICATION PRODUCT TEMP

COAT NO. POT LIFE DURING STRIPE COAT

METHOD (°C) BEFORE

FOR FOR

Start: End: START /END TIME ELAPSED APPLICATION BETWEEN REQUIRED ACTUAL REQUIRED ACTUAL

APPLICATION COATING COATING

COATS

1 15.30 15.35 _____/_____ 4 hr 30 C AIR SPRAY 15.45 16.15 150 mic 150 mic 75 mic 70 - 85 mic ACCEPTED

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY REMARKS

71729-10001 2 Paint system P11

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HERY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 27/06/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE…………………..

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE

TIME

AIR TEMPERATURE oC

WET BULB TEMP o

C

RELATIVE HUMIDITY %

DEW POINT TEM o C

STEEL TEMP o C

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW______ / PAINTED______/ GALVANIZED______ DATE:________ START TIME:_______ FINSH TIME:_____ JOB SPEC.: NACE/SSPC-SP-/ISO

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_______GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE: SPECIFIED ųm ACHIEVED ųm

DEGREE OF CORROSION: DEGREE OF CONTAMINATION: BLAST HOSE SIZE: NOZZLE SIZE:_____ / PSI:______ MEASUREMENT

WELD: MOISTURE /OIL: TOTAL SOLUBLE SALT TEST: _______mg/m² _______ųg/cm² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION:

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

THINNER / THINNER /

COAT NO.

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 _______/_______

2 _______/_______

3 _______/_______

4 _______/_______

5 _______/_______

MIXING / SWEAT IN (INDUCTION) TIME PAINT ELAPSED

WFT (Microns) DFT (Microns) VISUAL

AGITATING TIME START / END AIR TEMP. PRODUCT START TIME FINISH TIME TIME

COAT NO.

APPLICATION

POT LIFE (°C) DURING STRIPE COAT

METHOD

TEMP (°C) FOR FOR

APPLICATION BEFORE COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION

REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 _____/_____

AIRLESS SPRAY

2 _____/_____

3 _____/_____

4 _____/_____

5 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE_________________________SERIAL NUMBER____________________CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

STEEL STRUCTURE No ITEM QTY MARK NO. QTY

PAINT MANUFACTURER REMARKS

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME:_________________________________ NAME:_________________________________ NAME:_________________________________

SIGNE:_________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE:__________________________________ DATE:__________________________________ DATE:__________________________________

You might also like

- Painting Inspection ReportDocument1 pagePainting Inspection ReportAlfian Imaduddin100% (4)

- BS en Iso 14713-1 2017Document26 pagesBS en Iso 14713-1 2017Nada100% (1)

- Rhourde El Baguel LPG Extraction Plant Feed Planning Rev 0 PDFDocument3 pagesRhourde El Baguel LPG Extraction Plant Feed Planning Rev 0 PDFZakari LOUNISNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray NozzlebecpavanNo ratings yet

- Painting Report TemplateDocument1 pagePainting Report TemplateEdy Alam100% (1)

- Power Hammer Project ReportDocument48 pagesPower Hammer Project Reportjon100% (2)

- Painting Report Batch 2Document5 pagesPainting Report Batch 2Galang Pratama PutraNo ratings yet

- Paint Report Batch 1Document5 pagesPaint Report Batch 1Galang Pratama PutraNo ratings yet

- Painting Inspection FormDocument1 pagePainting Inspection FormMarhendraNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech AnandNo ratings yet

- Leak Test Valve ReportDocument2 pagesLeak Test Valve Reportadnansh1No ratings yet

- (F-QCD-002) NDT Request FormDocument1 page(F-QCD-002) NDT Request Formvinson bayNo ratings yet

- 07blasting and Painting ReportDocument2 pages07blasting and Painting ReportVenkateswaraRaoNo ratings yet

- QC Form 9Document2 pagesQC Form 9rashid ahmadiNo ratings yet

- Vacum BoxDocument2 pagesVacum BoxrudiNo ratings yet

- 380 1 PDFDocument7 pages380 1 PDFJimyTeránAgudeloNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Inspection Report: V'Groove DetailsDocument4 pagesInspection Report: V'Groove DetailsVijay Makwana VishwakarmaNo ratings yet

- QC Form 14Document1 pageQC Form 14rashid ahmadiNo ratings yet

- Rubber InspectionDocument1 pageRubber InspectionShalin mishraNo ratings yet

- Spci Cemex STR 312 Q01 0001Document8 pagesSpci Cemex STR 312 Q01 0001angelito bernalNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةNo ratings yet

- Bolt Torque ReportDocument1 pageBolt Torque Reportranjith_007No ratings yet

- Liquid Penetrant Testing Report: Size Result of Test Accept / RejectDocument1 pageLiquid Penetrant Testing Report: Size Result of Test Accept / RejectAbdul NaveedNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- QC Form 2Document4 pagesQC Form 2rashid ahmadiNo ratings yet

- Promain Paint Project Job Sheet 23 08 2021Document2 pagesPromain Paint Project Job Sheet 23 08 2021ARFAOUI SABERNo ratings yet

- Blasting & Painting Report: Surface PreparationDocument1 pageBlasting & Painting Report: Surface PreparationSandra SandersNo ratings yet

- Daily Welding Report: Qc/Qa FormDocument4 pagesDaily Welding Report: Qc/Qa FormLipika GayenNo ratings yet

- Data Sheet Level Gauge: GeneralDocument5 pagesData Sheet Level Gauge: GeneralJKKNo ratings yet

- PMCM Form-074 Megger TestingDocument1 pagePMCM Form-074 Megger TestingAbnar KumplishaNo ratings yet

- Nicco Engineering Services Limited: Valtest Job SheetDocument1 pageNicco Engineering Services Limited: Valtest Job SheetLALCHAND RAWANINo ratings yet

- QC Form 6Document1 pageQC Form 6rashid ahmadiNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- Pipe, Ma Pri To FR BK Hose, L 51420-67L30Document6 pagesPipe, Ma Pri To FR BK Hose, L 51420-67L30majidNo ratings yet

- Painting ReportDocument1 pagePainting ReportanandNo ratings yet

- SP F22-W2014 W. Push Twist Back TankDocument13 pagesSP F22-W2014 W. Push Twist Back TankKetty TerrelNo ratings yet

- Painting Repair Isnpection Report FormDocument2 pagesPainting Repair Isnpection Report FormDavid Frizt Siregar100% (3)

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Pc-Me-F-0012-000 Pin Hole Detection Report For Coating & WrappingDocument3 pagesPc-Me-F-0012-000 Pin Hole Detection Report For Coating & Wrappingคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Reporte Hdpe 2Document2 pagesReporte Hdpe 2Woodrow Fox100% (1)

- Pipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23Document5 pagesPipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23majidNo ratings yet

- SAMPLE Defect SheetDocument2 pagesSAMPLE Defect SheetshafanyNo ratings yet

- Maru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23Document5 pagesMaru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23majidNo ratings yet

- Test Results of 20GK0022Document12 pagesTest Results of 20GK0022Mae Ann GonzalesNo ratings yet

- Daily Painting & Inspection Report (WI-05-A2) 170&pipe 1Document1 pageDaily Painting & Inspection Report (WI-05-A2) 170&pipe 1pstechnical_433126970% (1)

- Hilux OQC FormatDocument3 pagesHilux OQC FormatAkash DeepNo ratings yet

- Rabigh Phase Ii Petrochemical Project: Michael HaddadDocument22 pagesRabigh Phase Ii Petrochemical Project: Michael HaddadsonalisabirNo ratings yet

- Form JIDocument4 pagesForm JIBryan RimbingNo ratings yet

- 100 PSV 001 AZ Safety Pressure Valve (Design)Document2 pages100 PSV 001 AZ Safety Pressure Valve (Design)magdy salehNo ratings yet

- Pipe, Ma Sec To FR BK Hose, R 51410-67L40Document4 pagesPipe, Ma Sec To FR BK Hose, R 51410-67L40majidNo ratings yet

- Compressor Cb01Document3 pagesCompressor Cb01Adnan FrrNo ratings yet

- AGITATORDATA HWPDocument1 pageAGITATORDATA HWPbrat.jose2023No ratings yet

- 7.2 TW09166 CMTR-FlangeDocument3 pages7.2 TW09166 CMTR-FlangeYair Sánchez blancoNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- QC Form 4Document2 pagesQC Form 4rashid ahmadiNo ratings yet

- PT Report Form FA17 - SimplifiedDocument2 pagesPT Report Form FA17 - SimplifieddonciriusNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- Proceedings of the 41st International Conference on Advanced Ceramics and CompositesFrom EverandProceedings of the 41st International Conference on Advanced Ceramics and CompositesWaltraud M. KrivenNo ratings yet

- 17. Daily Repot 22 SeptemberDocument3 pages17. Daily Repot 22 SeptemberGalang Pratama PutraNo ratings yet

- 19. Daily Repot 25 SeptemberDocument3 pages19. Daily Repot 25 SeptemberGalang Pratama PutraNo ratings yet

- 21. Daily Repot 27 SeptemberDocument3 pages21. Daily Repot 27 SeptemberGalang Pratama PutraNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Rumus Kebutuhan CatDocument2 pagesRumus Kebutuhan CatGalang Pratama PutraNo ratings yet

- In Creating These Paper Craft Models We Use 110kg Kent Paper StockDocument3 pagesIn Creating These Paper Craft Models We Use 110kg Kent Paper Stockpingon4xNo ratings yet

- 1212 Shed PlansDocument11 pages1212 Shed PlanskenNo ratings yet

- 429 U Tung AluMillDocument12 pages429 U Tung AluMillDANIEL MANRIQUEZ FAVILANo ratings yet

- Coke Drum Repair Welch Aquilex WSI DCU Calgary 2009Document37 pagesCoke Drum Repair Welch Aquilex WSI DCU Calgary 2009Oscar DorantesNo ratings yet

- OAW, Brazing ClusterDocument8 pagesOAW, Brazing ClusterAdriano MendezNo ratings yet

- Ebore Twin Cutter EnglishDocument7 pagesEbore Twin Cutter EnglishLeandro LechechenNo ratings yet

- Per Carlsson, Henrik Wiinikka, Magnus Marklund, Carola Grönberg, Esbjörn Pettersson, Marcus Lidman, Rikard GebartDocument10 pagesPer Carlsson, Henrik Wiinikka, Magnus Marklund, Carola Grönberg, Esbjörn Pettersson, Marcus Lidman, Rikard GebartRoasted ScizorNo ratings yet

- Joining MethodsDocument15 pagesJoining MethodsAliyu Ibrahim SalihuNo ratings yet

- The World of Brick ProductionDocument8 pagesThe World of Brick ProductionBorly GonzagaNo ratings yet

- Elliott Tube CleanersDocument28 pagesElliott Tube CleanersIslam Hosny MohamedNo ratings yet

- Datasheet For Steel Grades Structure Steel Q235Document2 pagesDatasheet For Steel Grades Structure Steel Q235bruarNo ratings yet

- SOPs LABDocument8 pagesSOPs LABVijayNo ratings yet

- EN DX51D - 1.0226 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocument2 pagesEN DX51D - 1.0226 - SteelNumber - Chemical Composition, Equivalent, PropertiesliusfNo ratings yet

- Control of CorrosionDocument12 pagesControl of CorrosionSyed ShahbazNo ratings yet

- Selection and RevampDocument13 pagesSelection and RevampChristianGuerreroNo ratings yet

- Ratchet Type Tap - GT PDFDocument1 pageRatchet Type Tap - GT PDFPutri LestariNo ratings yet

- Water PurificationDocument12 pagesWater PurificationRoseNavyaNo ratings yet

- g133 ManualDocument12 pagesg133 ManualValmac ServicesNo ratings yet

- 2191 Teile0160-Probojci PDFDocument60 pages2191 Teile0160-Probojci PDFalex94kgNo ratings yet

- Katalog Techno VeneerDocument24 pagesKatalog Techno VeneerMarina JocicNo ratings yet

- Welcome To The World Of: ADD AdditivesDocument18 pagesWelcome To The World Of: ADD AdditivesSandra RojasNo ratings yet

- V2500 Capability ListDocument11 pagesV2500 Capability ListVuppala RavitejaNo ratings yet

- Document Information For:: Type Name Revision StateDocument36 pagesDocument Information For:: Type Name Revision StatePNo ratings yet

- 7 Common Practical Uses For PlywoodDocument17 pages7 Common Practical Uses For PlywoodRobert Kier Tanquerido TomaroNo ratings yet

- Pa538 TDSDocument1 pagePa538 TDSJhoan RodríguezNo ratings yet

- Vaal University of Technology: Faculty of Engineering and Technology Department of Metallurgical EngineeringDocument18 pagesVaal University of Technology: Faculty of Engineering and Technology Department of Metallurgical EngineeringjamesNo ratings yet

- S51 - S62Document12 pagesS51 - S62Flaviu-Andrei AstalisNo ratings yet