Professional Documents

Culture Documents

Maru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23

Uploaded by

majidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23

Uploaded by

majidCopyright:

Available Formats

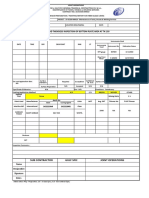

MARU-A PARTS MONTHLY DATA Date: 03.07.

23

Part Name: PIPE,RR BK HOSE TO RR W/C,L Supplier Name: M/s ALBA

Part Number: 51520-55S00 Date of issue:

June For the month of June,23

MARU-A item Method Frequency 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Appearance Visual check 100% / / / / / / / / / / / / / / / / O / / / / / / / / / / / / /

Vernier

Flaring Size Caliper/P.Projecto n=5/Lot / / / / / / / / / / / / / / / / O / / / / / / / / / / / / /

r

Air Pressure Air Gun 100% / / / / / / / / / / / / / / / / O / / / / / / / / / / / / / ok

Pressure Resistance Sanoh Report Sanoh Report Attached ok

ok

OK: NG:✕ No production:/

Prepared By Checked By Verified By

ALBA ENGINEERING

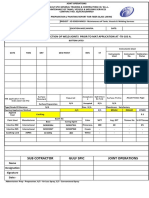

Appearance & Flaring Check sheet

PART NAME: PIPE,RR BK HOSE TO RR W/C,L MARU A SPOT QTY.: DATE: 03.07.23

PART NUMBER: 51520-55S00 STD. REFERENCE: PART STAGE: Regular

MODEL: Y4J MONTH: June June,23

Sample Date

Sr.#. Description Standard Qty Method Result Remarks

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

APPEARANCE

Outer PVDF coating

crack, Flaws, Rust

1

&sticking of foreign

100% / / / / / / / / / / / / / / / / O / / / / / / / / / / / / / Visual ok

bodies not allowed

Flaring Vernier Caliper/

2

Size As per Drawing n=5/Lot / / / / / / / / / / / / / / / / O / / / / / / / / / / / / /

P.Projector

ok

3

Air Cleaning of pipe at 80 100% / / / / / / / / / / / / / / / / O / / / / / / / / / / / / / Air Gun ok

Pressure psi

Prepared By Checked By Verified By

ALBA ENGINEERING COMPANY

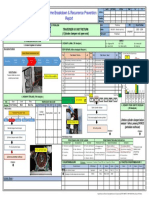

Purpose:

1- Inspection & MARU "A" Check sheet.

Tube Dia: Ø4.76mm

Part Name: _____PIPE RR BK HOSE TO RR W/C,L

Part N0. 51520-55S00

Model: ______Y4J

Date :

Inspection Sample Units mm

Sr.No. Standard Tool Frequency

Items 1 2 3 4 5 Remarks

Appearance Section

No Burr, No Crack, No

i Scratch,Surface OK

1 Appearance Finishing Visual

flaw or adhesion of

ii foreign particles OK

2 Hardware Quantity Nut (M10x1.0) 100% OK

Heat shrinkable

3 polyethylene tube

Should Be Persent Visual OK

Should be apply to

4 Preton Oil Application OK

both ends

Dimension Section

5 Tube Dia 4.68~4.84 VC 4.73 4.77 4.73 4.76 4.72 OK

6 A 6.6~7.1 VC 5 Psc Per Lot 6.80 6.84 6.89 6.93 6.97 OK

First 2 pcs,

7 B 3.0~3.7 VC Middle 1 pc, 3.37 3.39 3.42 3.40 3.41 OK

8 C 1.2~1.6 VC Last 2 pcs 1.39 1.42 1.44 1.41 1.38 OK

9 Thickness T 0.7±0.08 VC 0.77 0.75 0.76 0.72 0.76 OK

10 Degree 90±30' 90.18 - - - - OK

1 Piece

Per Lot

11 Degree 45±2 P. Projector 45.09 - - - - OK

12 Radius 0.7~1.3 0.7 - - - - OK

13 Leakage Test 1.96 MPa Sanoh Report Attached OK

Air Pressure Cleaning

14 80 psi Air Gun 100% OK

15 Bending Should Qualify on CF CF 5 Psc Per Lot OK

Approved By: Inspected By:

ALBA ENGINEERING COMPANY

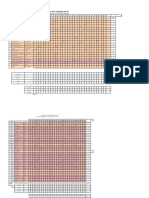

GAP ANALYSIS REPORT

PART NAME: PIPE , FR BK HOSE TO RR W/C,L PART No: 51520-55S00

MODEL: Y4J CUSTOMER: PAK SUZUKI

DATE: ITEM CODE: 640481

E F

D

G

b a

C

B

LOCAL LOCAL LOCAL LOCAL LOCAL LOCAL LOCAL

SAMPLE 1 SAMPLE 2 SAMPLE 3 SAMPLE 4 SAMPLE 5 SAMPLE 6 SAMPLE 7

Sr. No. CHECKING ITEM INSTRUMENT STD

ACTUAL ACTUAL ACTUAL ACTUAL ACTUAL ACTUAL ACTUAL JUD

1 BLOCK A CLAMP 0±0 0.0 0.0 0.0 OK

BLOCK B

a 3.2 2.5 3.4 OK

Taper Gauge 3±3

2 b 2.8 3.5 2.6 OK

c 2.2 3.0 2.2 OK

PP 1 ON CF 5±5 0.0 0.0 0.0 Ok

BLOCK C

a 2.5 3.2 2.0 OK

3 Taper Gauge 3±3

b 3.5 2.8 4.0 OK

c 3.0 2.4 3.1 OK

4 BLOCK D CLAMP 0±0 0.0 0.0 0.0 OK

BLOCK E

a 2.4 3.0 2.5 OK

5 Taper Gauge 3±3

b 3.6 3.0 3.5 OK

c 2.0 3.0 3.4 OK

BLOCK F

a 3.5 2.2 3.1 OK

Taper Gauge 3±3

6 b 2.5 3.8 2.9 OK

c 2.0 2.4 3.3 OK

PP 2 ON CF 5±5 0.0 0.0 0.0 OK

BLOCK G CLAMP 0±0 0.0 0.0 0.0 OK

8

Length block (G) ON CF 3±3 0.0 0.0 0.0 OK

INSPECTED BY :

You might also like

- Pipe, P Valve To RR BK Hose, LDocument8 pagesPipe, P Valve To RR BK Hose, LmajidNo ratings yet

- Pipe, P Valve To RR BK Hose, RDocument9 pagesPipe, P Valve To RR BK Hose, RmajidNo ratings yet

- Pipe, RR BK Hose To RR W/C, RDocument5 pagesPipe, RR BK Hose To RR W/C, RmajidNo ratings yet

- Pipe, Ma Pri To FR BK Hose, L 51420-67L30Document6 pagesPipe, Ma Pri To FR BK Hose, L 51420-67L30majidNo ratings yet

- Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23Document6 pagesMaru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23majidNo ratings yet

- Pipe, Ma Sec To FR BK Hose, R 51410-67L40Document4 pagesPipe, Ma Sec To FR BK Hose, R 51410-67L40majidNo ratings yet

- Pipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23Document5 pagesPipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23majidNo ratings yet

- Tk-103-Fgl-36 Final Inspection - After Gel Coat.01Document1 pageTk-103-Fgl-36 Final Inspection - After Gel Coat.01joseNo ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- Cargo Measurement Devices Test & Calibration Log: Zenith Gemi İşletmeciliği A.ŞDocument3 pagesCargo Measurement Devices Test & Calibration Log: Zenith Gemi İşletmeciliği A.ŞCelal BozdoganNo ratings yet

- Cilar Checklist: Maintenance Job DeskDocument1 pageCilar Checklist: Maintenance Job DeskedlistiantoNo ratings yet

- 05) MSM QF-MR-05 Equipment MasterDocument4 pages05) MSM QF-MR-05 Equipment Mastervijay padaleNo ratings yet

- TK-103-FGL-32 Tissue Visual and Thickness InspectionDocument1 pageTK-103-FGL-32 Tissue Visual and Thickness InspectionjoseNo ratings yet

- Concrete CubesDocument7 pagesConcrete CubesMohammed AbbasNo ratings yet

- TK-103-FGL-16-caulking InspectionDocument1 pageTK-103-FGL-16-caulking InspectionjoseNo ratings yet

- Samples Measurements Recording/Rezultati Merenja Uzoraka: 1621-1YY0103 3a 06/08/14 Kinwong OKDocument1 pageSamples Measurements Recording/Rezultati Merenja Uzoraka: 1621-1YY0103 3a 06/08/14 Kinwong OKDjurdjina PetkovicNo ratings yet

- Form Pengukuran GroundingDocument2 pagesForm Pengukuran GroundingghooestiepNo ratings yet

- Lab Dip Submittal FormDocument1 pageLab Dip Submittal FormHaseeb AnwarNo ratings yet

- SACEP - RTCC - Delivery #0971542-11Document16 pagesSACEP - RTCC - Delivery #0971542-11Ryan condeNo ratings yet

- Phase 2 Expansion (Stage 2B - Separation & Processing Unit)Document1 pagePhase 2 Expansion (Stage 2B - Separation & Processing Unit)saravananNo ratings yet

- 5why Clamper KO MesinDocument1 page5why Clamper KO MesinOfficial AulianrNo ratings yet

- CERT 165 - Ingles 5086010203149Document1 pageCERT 165 - Ingles 5086010203149naldinhoowNo ratings yet

- Daily Report Replating DivisionDocument3 pagesDaily Report Replating DivisionYarham SuaibNo ratings yet

- Inspection Report: Wesco LLCDocument8 pagesInspection Report: Wesco LLCEduardNo ratings yet

- MPPDocument5 pagesMPPalokbdasNo ratings yet

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- Preventive KompresorDocument13 pagesPreventive KompresorSatria PradanaNo ratings yet

- Abd Tatagari Invoice Attendance For The August 2021 CorrectionDocument2 pagesAbd Tatagari Invoice Attendance For The August 2021 CorrectionSheikh AshfaqueNo ratings yet

- Master Format SummaryDocument5 pagesMaster Format Summaryunto gunungNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- SACEP - RTCC - Delivery #0971558-12Document16 pagesSACEP - RTCC - Delivery #0971558-12Ryan condeNo ratings yet

- 00904B-B00104 Isir RepDocument7 pages00904B-B00104 Isir RepMechtek LabNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- CES-107 U Assembly Test 21000 SeriesDocument15 pagesCES-107 U Assembly Test 21000 SeriesAlfredo SantanaNo ratings yet

- 1 - Example of PPM ScheduleDocument1 page1 - Example of PPM ScheduleDavidNo ratings yet

- TK-103-FGL-26-matt Inspection Prior To Tissue ApplicationDocument1 pageTK-103-FGL-26-matt Inspection Prior To Tissue ApplicationjoseNo ratings yet

- 7.2 TW09166 CMTR-FlangeDocument3 pages7.2 TW09166 CMTR-FlangeYair Sánchez blancoNo ratings yet

- Final Inspection Report TurbineDocument20 pagesFinal Inspection Report TurbineMuhammad ZakiNo ratings yet

- Env-F021 Weekly Toilet InspectionDocument1 pageEnv-F021 Weekly Toilet InspectionnagaaNo ratings yet

- 006 Dozer Track LoaderDocument3 pages006 Dozer Track LoaderFuad Ahmad NafisNo ratings yet

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- Toxic & Flammable Atmosphere Check Log: Zenith Gemi İşletmeciliği A.ŞDocument2 pagesToxic & Flammable Atmosphere Check Log: Zenith Gemi İşletmeciliği A.ŞCelal BozdoganNo ratings yet

- Specification For WHCP GPF Osf 9500 Spe Cs 5003 2 0001Document27 pagesSpecification For WHCP GPF Osf 9500 Spe Cs 5003 2 0001Vraja KisoriNo ratings yet

- Lightning Arrester 1Document1 pageLightning Arrester 1Noel SantosNo ratings yet

- Formats of SoilsDocument23 pagesFormats of SoilsShesha ShayanNo ratings yet

- DHL30291 C 0Document1 pageDHL30291 C 0Joel MinafiNo ratings yet

- Certified Test, Adjust and Balance Report: Balancing DevicesDocument1 pageCertified Test, Adjust and Balance Report: Balancing Devicesahmed younisNo ratings yet

- 8 Material Inspection ReportDocument1 page8 Material Inspection Reportvinson bayNo ratings yet

- Frame Process PlannerDocument5 pagesFrame Process Plannerapi-538048965No ratings yet

- Zppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Ahmed ThaerNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- RT-Blower Dismantling & InspectionDocument9 pagesRT-Blower Dismantling & Inspectionانجینیئر قاسم بلالNo ratings yet

- Form Commtest TADocument9 pagesForm Commtest TAAdi SusenoNo ratings yet

- NDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)Document2 pagesNDT Ultrasonic Phased Array Examination (NDT Examen de Ultrasonido Arreglo de Fases)reyserNo ratings yet

- NDT Report - Tower Drilling& Towing BarDocument10 pagesNDT Report - Tower Drilling& Towing Barbonski3155No ratings yet

- Fire Extinguisher Inspection ReportDocument4 pagesFire Extinguisher Inspection Reportjeffry.mitraparamagemilangNo ratings yet

- Adhession Pull Off Test ReportDocument14 pagesAdhession Pull Off Test ReportFerdie WakeUp FromAdversity100% (1)

- Daily Welding Chamber Skirt AssemblyDocument1 pageDaily Welding Chamber Skirt AssemblyMa'ruf firmansyahNo ratings yet

- Pipe W Comp Brake (City) 13-Jan-22Document2 pagesPipe W Comp Brake (City) 13-Jan-22majidNo ratings yet

- Clip Record AlbaDocument5 pagesClip Record AlbamajidNo ratings yet

- B Me 297 PresentationDocument51 pagesB Me 297 PresentationmajidNo ratings yet

- RecheckingDocument2 pagesRecheckingmajidNo ratings yet

- Pipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23Document5 pagesPipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23majidNo ratings yet

- Pipe, Ma Sec To FR BK Hose, R 51410-67L40Document4 pagesPipe, Ma Sec To FR BK Hose, R 51410-67L40majidNo ratings yet

- 4m Change ClassificationDocument3 pages4m Change ClassificationmajidNo ratings yet

- 226-Article Text-601-1-10-20210702Document12 pages226-Article Text-601-1-10-20210702Leni NopriyantiNo ratings yet

- Legislation Statutory Inspection ChecklistDocument2 pagesLegislation Statutory Inspection ChecklistAry PutraNo ratings yet

- Pro Tester ManualDocument49 pagesPro Tester ManualRobson AlencarNo ratings yet

- 747Document12 pages747GurdevBaines100% (3)

- New Techniques of Predictions # 1Document5 pagesNew Techniques of Predictions # 1bhagathi nageswara raoNo ratings yet

- Huawei FusionServer RH2288 V3 Data Sheet PDFDocument2 pagesHuawei FusionServer RH2288 V3 Data Sheet PDFMartenMattisenNo ratings yet

- Stelma & Cameron PDFDocument35 pagesStelma & Cameron PDFCatarinaNo ratings yet

- h2s Naoh Equilibrium CurveDocument22 pagesh2s Naoh Equilibrium Curvesmartleo_waloNo ratings yet

- The Child and Adolescent Learners and Learning PrinciplesDocument8 pagesThe Child and Adolescent Learners and Learning PrinciplesAragon KhailNo ratings yet

- CES Wrong Answer SummaryDocument2 pagesCES Wrong Answer SummaryВладислав КомаровNo ratings yet

- International Journal of Agricultural ExtensionDocument6 pagesInternational Journal of Agricultural Extensionacasushi ginzagaNo ratings yet

- Directional: 12 1/4in Sdi519 PDCDocument1 pageDirectional: 12 1/4in Sdi519 PDCKhairatul Nada BurhanuddinNo ratings yet

- Term Paper On Strategic ManagementDocument8 pagesTerm Paper On Strategic Managementea7j5ys3100% (1)

- BS9266 2013 Adaptable HousingDocument46 pagesBS9266 2013 Adaptable HousingGrant MastersonNo ratings yet

- 3393 - Supervision of Concrete Construction Volume 2Document271 pages3393 - Supervision of Concrete Construction Volume 2Oum ChhayNoy100% (11)

- METR3210 Clausius ClapeyronDocument28 pagesMETR3210 Clausius Clapeyronshubhang2392No ratings yet

- PCI Express Test Spec Platform 3.0 06182013 TSDocument383 pagesPCI Express Test Spec Platform 3.0 06182013 TSDeng XinNo ratings yet

- MYP Unit Planner - MathDocument5 pagesMYP Unit Planner - MathMarija CvetkovicNo ratings yet

- Synchronous Motor AC DrivesDocument40 pagesSynchronous Motor AC DrivesHarshal Thakur100% (1)

- Cibse TM65 (2020)Document67 pagesCibse TM65 (2020)Reli Hano100% (1)

- Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationDocument8 pagesHydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationINOPETRO DO BRASILNo ratings yet

- Physics 16 - Thermal ProcessesDocument19 pagesPhysics 16 - Thermal ProcessesSuhaan HussainNo ratings yet

- 1 Ha Cabbages - May 2018 PDFDocument1 page1 Ha Cabbages - May 2018 PDFMwai EstherNo ratings yet

- DAC AnalysisDocument19 pagesDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుNo ratings yet

- CC Course IntroDocument11 pagesCC Course IntroSaid TahatNo ratings yet

- Daftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceDocument2 pagesDaftar Isian 3 Number Plate, Danger Plate, Anti Climbing DeviceMochammad Fauzian RafsyanzaniNo ratings yet

- Behaviour Modification Testbank PDFDocument118 pagesBehaviour Modification Testbank PDFjade tagabNo ratings yet

- 3PM - Project Management Method - Sales MessagingDocument5 pages3PM - Project Management Method - Sales Messagingberuang kutubNo ratings yet

- SOM-based Generating of Association RulesDocument5 pagesSOM-based Generating of Association RulesKishor PeddiNo ratings yet

- Cellular Respiration MDL361Document46 pagesCellular Respiration MDL361Krystal CraigNo ratings yet