Professional Documents

Culture Documents

Painting Report Batch 3

Painting Report Batch 3

Uploaded by

Galang Pratama PutraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Painting Report Batch 3

Painting Report Batch 3

Uploaded by

Galang Pratama PutraCopyright:

Available Formats

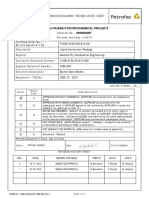

DOC. NO. QA - WHU - 005 REV.

10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 31 May 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 6/16/2023

TIME 13.00

AIR TEMPERATURE oC 30.2

WET BULB TEMP oC

RELATIVE HUMIDITY % 68.8%

DEW POINT TEMP C 21.8

STEEL TEMP C o

27

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 16/06/2023 START TIME : 12.30 FINSH TIME : 16.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 88 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 22 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal /Accepted

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

COAT NO.

THINNER / THINNER /

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

2

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END

COAT NO.

AIR TEMP. PRODUCT START TIME FINISH TIME TIME

APPLICATION

POT LIFE (°C) DURING STRIPE COAT

METHOD

TEMP (°C) FOR FOR

APPLICATION BEFORE COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION

REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 _____/_____

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY REMARKS

71727 - 10001 10 SBO / Shot Blast Only

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HARY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 17/06/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 31 May 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 6/16/2023

TIME 13.00

AIR TEMPERATURE oC 30.2

WET BULB TEMP oC

RELATIVE HUMIDITY % 68.8%

DEW POINT TEMP C 21.8

STEEL TEMP C o

27

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 16/06/2023 START TIME : 12.30 FINSH TIME : 16.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 88 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 22 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal /Accepted

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

COAT NO.

THINNER / THINNER /

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

2

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END

COAT NO.

AIR TEMP. PRODUCT START TIME FINISH TIME TIME

APPLICATION

POT LIFE (°C) DURING STRIPE COAT

METHOD

TEMP (°C) FOR FOR

APPLICATION BEFORE COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION

REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 _____/_____

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY REMARKS

71723 - 40001 6 SBO / Shot Blast Only

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HARY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 17/06/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 31 May 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

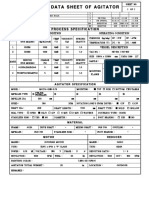

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 6/16/2023 6/16/2023

TIME 13.00 16.40

AIR TEMPERATURE oC 30.2 28.3

WET BULB TEMP C o

RELATIVE HUMIDITY % 68.8% 71,2

DEW POINT TEMP C 21.8 22.6

STEEL TEMP oC 27 26.7

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 26/06/2023 START TIME : 12.30 FINSH TIME : 16.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 88 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 22 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal /Accepted

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

COAT NO.

THINNER / THINNER /

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 INTERZINC 52 INTERNATIONAL PAINT EPOXY ZINC RICH 3263124026 3263103053 May-23 GTA 220 3263123035 9:1 AIRSPAY

GREY RAL

7045

2 _______/_______

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END

COAT NO.

AIR TEMP. PRODUCT START TIME FINISH TIME TIME

APPLICATION

POT LIFE (°C) DURING STRIPE COAT

METHOD

TEMP (°C) FOR FOR

APPLICATION BEFORE COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION

REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 16.15 16.20 _____/_____ 4 hr 30 C AIR SPRAY 16.30 17.30 150 mic 150 mic 75 mic 70 - 85 mic ACCEPTED

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY

REMARKS

71726 - 20002 10 PAINT SYSTEM P11

71726 - '20004 18 PAINT SYSTEM P11

71726 - '20005 7 PAINT SYSTEM P11

71726 - '20006 10 PAINT SYSTEM P11

71726 - '20007 33 PAINT SYSTEM P11

71726 - 20009 4 PAINT SYSTEM P11

71726 - 20011 2 PAINT SYSTEM P11

71726 - 20012 4 PAINT SYSTEM P11

71726 - 20014 2 PAINT SYSTEM P11

71726 - 20016 2 PAINT SYSTEM P11

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HARY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 16/06/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE : 31 May 2023

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE 29/5/2023 29/5/2023

TIME 12.30 16.30

AIR TEMPERATURE oC 30,9 30,9

WET BULB TEMP oC

RELATIVE HUMIDITY % 50,4% 71,2

DEW POINT TEMP C 18,8 25,0

STEEL TEMP C o

32 31,3,0

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW STEEL STRUCTURE DATE : 29/05/2023 START TIME : 12.30 FINSH TIME : 17.00 JOB SPEC.: SSPC-SP-10 / ISO 8501-1 SA 2,5

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_ V _____GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE : STEEL GRIT G-40 SPECIFIED 50 ųm ACHIEVED 98 ųm

DEGREE OF CORROSION : GRADE A DEGREE OF CONTAMINATION : NO BLAST HOSE SIZE: NOZZLE SIZE : 7 mm / Pressure : 6-7 bar MEASUREMENT

WELD : SOME MOISTURE /OIL : NO TOTAL SOLUBLE SALT TEST : 16,8 mg/m² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION : Normal

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

COAT NO.

THINNER / THINNER /

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 INTERZINC 52 INTERNATIONAL PAINT EPOXY ZINC RICH 3263103053 3263124026 May-23 GTA 220 3263123035 9:1 AIRSPAY

GREY RAL

7045

2 _______/_______

MIXING / AGITATING SWEAT IN (INDUCTION) TIME ELAPSED

PAINT WFT (Microns) DFT (Microns) VISUAL

TIME START / END

COAT NO.

AIR TEMP. PRODUCT START TIME FINISH TIME TIME

APPLICATION

POT LIFE (°C) DURING STRIPE COAT

METHOD

TEMP (°C) FOR FOR

APPLICATION BEFORE COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION

REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 16.15 16.20 _____/_____ 4 hr 30 C AIR SPRAY 16.30 17.30 150 mic 150 mic 75 mic 70 - 85 mic ACC

2 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE POSITECTOR 6000____SERIAL NUMBER _______CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

PAINT MANUFACTURER STEEL STRUCTURE No ITEM QTY MARK NO. QTY

REMARKS

71726 - 20001 1 PAINT SYSTEM P11

71726 - '20003 1 PAINT SYSTEM P11

71726 - '20004 1 PAINT SYSTEM P11

71726 - '20005 7 PAINT SYSTEM P11

71726 - '20006 4 PAINT SYSTEM P11

71726 - 20007 27 PAINT SYSTEM P11

71726 - 20008 1 PAINT SYSTEM P11

71726 - 20015 1 PAINT SYSTEM P11

71726 - 20017 1 PAINT SYSTEM P11

71726 - 20018 1 PAINT SYSTEM P11

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME : HARY SUBIYAKTO_____________________________ NAME:_________________________________ NAME:_________________________________

SIGNE : _________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE : 31/05/2023____________________________ DATE:__________________________________ DATE:__________________________________

DOC. NO. QA - WHU - 005 REV.10

WILLIAM HARE U.A.E L.L.C. REPORT NO…………………………..

SHEET NO…………….OF……………

SHIFT …………………DATE…………………..

PAINTING INSPECTION REPORT

CLIENT: PROJECT:

CLIMATE CONDITIONS BLASTING FIRST COAT SECOND COAT THIRD COAT FOURTH COAT FIFTH COAT

DATE

TIME

AIR TEMPERATURE oC

WET BULB TEMP o

C

RELATIVE HUMIDITY %

DEW POINT TEM o C

STEEL TEMP o C

SURFACE CONDITION SURFACE PREPARATION SURFACE CLEANLINESS & PROFILE MEASUREMENNTS

MATERIAL NEW______ / PAINTED______/ GALVANIZED______ DATE:________ START TIME:_______ FINSH TIME:_____ JOB SPEC.: NACE/SSPC-SP-/ISO

NEW MATERIAL EVIDENT VISIBLE DEFECTS: SOLVENT CLEAN:_____ / HAND TOOL CLEAN:_____ / POWER TOOL CLEAN:_____ NACE/SSPC/ISO SPEC/VISUAL STD.

PAINTED MATERIAL EVIDENT VISIBLE DEFECTS: HIGH PRESSURE WATER WASH: ______PSI PROFILE CHECK: DISC_______ TAPE_______GAUGE_______

GALVANIZED MATERIAL EVIDENT VISIBLE DEFECTS: ABRASIVE BLAST: ABRASIVE TYPE: SPECIFIED ųm ACHIEVED ųm

DEGREE OF CORROSION: DEGREE OF CONTAMINATION: BLAST HOSE SIZE: NOZZLE SIZE:_____ / PSI:______ MEASUREMENT

WELD: MOISTURE /OIL: TOTAL SOLUBLE SALT TEST: _______mg/m² _______ųg/cm² AIR SUPPLY CLEANLINESS (BLOTTER TEST):

SCALE___/ PITTING___/ HOLES CREVICES___/ SHARP EDGES____ EQUIPMENT CONDITION:

PAINT MATERIAL'S VISUAL DEFECTS BEFORE APPLICATION :

PAINTING SYSTEM AND APPLICATION

COATING EQUIPMENT TYPE:____________________________COATING SPRAY GUN TYPE:______________________________NOZZLE TIP :_______________________________APPLICATION PRESSURE:______________________________

BATCH NO. MIXING / AGITATING

THINNER / THINNER /

COAT NO.

PRODUCT NAME PAINT MANUFACTURER NAME TYPE OF PAINT EXPIRY DATE COLOUR REDUCER REDUCER

A B TYPE / QTY BATCH Ratio Method VERIFICATION

1 _______/_______

2 _______/_______

3 _______/_______

4 _______/_______

5 _______/_______

MIXING / SWEAT IN (INDUCTION) TIME PAINT ELAPSED

WFT (Microns) DFT (Microns) VISUAL

AGITATING TIME START / END AIR TEMP. PRODUCT START TIME FINISH TIME TIME

COAT NO.

APPLICATION

POT LIFE (°C) DURING STRIPE COAT

METHOD

TEMP (°C) FOR FOR

APPLICATION BEFORE COATING COATING BETWEEN

Start: End: START /END TIME ELAPSED APPLICATION

REQUIRED ACTUAL REQUIRED ACTUAL ACCEPTANCE

COATS

1 _____/_____

AIRLESS SPRAY

2 _____/_____

3 _____/_____

4 _____/_____

5 _____/_____

DRY FILM THICKNESS (DFT) COATING GAUGE : TYPE_________________________SERIAL NUMBER____________________CALIBRATION DUE __________________ ACCURACY CHECK_______________ CURE TEST: SOLVENT RUB TEST ___________MEK TEST (IF APPLICABLE)______________

STEEL STRUCTURE No ITEM QTY MARK NO. QTY

PAINT MANUFACTURER REMARKS

NAME:_________________________________

SIGNE: ________________________________ REFFER ATTACHMENT

DATE:__________________________________

WE HEREBY CERTIFY THAT MATERIALS ARE COATED IN ACCORDANCE TO THE PROJECT SPECIFICATIONS

COATING WORK SHOP ENGINEER / SUPERVISOR / FOREMAN QC INSPECTOR CLIENT REPRESENTATIVE

NAME:_________________________________ NAME:_________________________________ NAME:_________________________________

SIGNE:_________________________________ SIGNE:_________________________________ SIGNE:_________________________________

DATE:__________________________________ DATE:__________________________________ DATE:__________________________________

You might also like

- Painting Inspection ReportDocument1 pagePainting Inspection ReportAlfian Imaduddin100% (4)

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray NozzlebecpavanNo ratings yet

- Painting Report TemplateDocument1 pagePainting Report TemplateEdy Alam100% (1)

- Astm A240 PDFDocument11 pagesAstm A240 PDFTam Huynh Thanh88% (17)

- Painting Report Batch 2Document5 pagesPainting Report Batch 2Galang Pratama PutraNo ratings yet

- Paint Report Batch 1Document5 pagesPaint Report Batch 1Galang Pratama PutraNo ratings yet

- Painting Inspection FormDocument1 pagePainting Inspection FormMarhendraNo ratings yet

- Report TemplateDocument3 pagesReport TemplatePretech AnandNo ratings yet

- Leak Test Valve ReportDocument2 pagesLeak Test Valve Reportadnansh1No ratings yet

- (F-QCD-002) NDT Request FormDocument1 page(F-QCD-002) NDT Request Formvinson bayNo ratings yet

- 07blasting and Painting ReportDocument2 pages07blasting and Painting ReportVenkateswaraRaoNo ratings yet

- QC Form 9Document2 pagesQC Form 9rashid ahmadiNo ratings yet

- Vacum BoxDocument2 pagesVacum BoxrudiNo ratings yet

- 380 1 PDFDocument7 pages380 1 PDFJimyTeránAgudeloNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Inspection Report: V'Groove DetailsDocument4 pagesInspection Report: V'Groove DetailsVijay Makwana VishwakarmaNo ratings yet

- QC Form 14Document1 pageQC Form 14rashid ahmadiNo ratings yet

- Rubber InspectionDocument1 pageRubber InspectionShalin mishraNo ratings yet

- Spci Cemex STR 312 Q01 0001Document8 pagesSpci Cemex STR 312 Q01 0001angelito bernalNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةNo ratings yet

- Bolt Torque ReportDocument1 pageBolt Torque Reportranjith_007No ratings yet

- Liquid Penetrant Testing Report: Size Result of Test Accept / RejectDocument1 pageLiquid Penetrant Testing Report: Size Result of Test Accept / RejectAbdul NaveedNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- QC Form 2Document4 pagesQC Form 2rashid ahmadiNo ratings yet

- Promain Paint Project Job Sheet 23 08 2021Document2 pagesPromain Paint Project Job Sheet 23 08 2021ARFAOUI SABERNo ratings yet

- Blasting & Painting Report: Surface PreparationDocument1 pageBlasting & Painting Report: Surface PreparationSandra SandersNo ratings yet

- Daily Welding Report: Qc/Qa FormDocument4 pagesDaily Welding Report: Qc/Qa FormLipika GayenNo ratings yet

- Data Sheet Level Gauge: GeneralDocument5 pagesData Sheet Level Gauge: GeneralJKKNo ratings yet

- PMCM Form-074 Megger TestingDocument1 pagePMCM Form-074 Megger TestingAbnar KumplishaNo ratings yet

- Nicco Engineering Services Limited: Valtest Job SheetDocument1 pageNicco Engineering Services Limited: Valtest Job SheetLALCHAND RAWANINo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- QC Form 6Document1 pageQC Form 6rashid ahmadiNo ratings yet

- Pipe, Ma Pri To FR BK Hose, L 51420-67L30Document6 pagesPipe, Ma Pri To FR BK Hose, L 51420-67L30majidNo ratings yet

- Painting ReportDocument1 pagePainting ReportanandNo ratings yet

- SP F22-W2014 W. Push Twist Back TankDocument13 pagesSP F22-W2014 W. Push Twist Back TankKetty TerrelNo ratings yet

- Painting Repair Isnpection Report FormDocument2 pagesPainting Repair Isnpection Report FormDavid Frizt Siregar100% (3)

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Pc-Me-F-0012-000 Pin Hole Detection Report For Coating & WrappingDocument3 pagesPc-Me-F-0012-000 Pin Hole Detection Report For Coating & Wrappingคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Reporte Hdpe 2Document2 pagesReporte Hdpe 2Woodrow Fox100% (1)

- Pipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23Document5 pagesPipe, Fuel: Maru-A Parts Monthly Data Date: Part Name: Supplier Name: M/s ALBA Part Number: Date of Issue: Oct, 23majidNo ratings yet

- Maru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23Document5 pagesMaru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23majidNo ratings yet

- SAMPLE Defect SheetDocument2 pagesSAMPLE Defect SheetshafanyNo ratings yet

- Test Results of 20GK0022Document12 pagesTest Results of 20GK0022Mae Ann GonzalesNo ratings yet

- Daily Painting & Inspection Report (WI-05-A2) 170&pipe 1Document1 pageDaily Painting & Inspection Report (WI-05-A2) 170&pipe 1pstechnical_433126970% (1)

- Hilux OQC FormatDocument3 pagesHilux OQC FormatAkash DeepNo ratings yet

- Rabigh Phase Ii Petrochemical Project: Michael HaddadDocument22 pagesRabigh Phase Ii Petrochemical Project: Michael HaddadsonalisabirNo ratings yet

- Form JIDocument4 pagesForm JIBryan RimbingNo ratings yet

- 100 PSV 001 AZ Safety Pressure Valve (Design)Document2 pages100 PSV 001 AZ Safety Pressure Valve (Design)magdy salehNo ratings yet

- Pipe, Ma Sec To FR BK Hose, R 51410-67L40Document4 pagesPipe, Ma Sec To FR BK Hose, R 51410-67L40majidNo ratings yet

- Compressor Cb01Document3 pagesCompressor Cb01Adnan FrrNo ratings yet

- AGITATORDATA HWPDocument1 pageAGITATORDATA HWPbrat.jose2023No ratings yet

- 7.2 TW09166 CMTR-FlangeDocument3 pages7.2 TW09166 CMTR-FlangeYair Sánchez blancoNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- QC Form 4Document2 pagesQC Form 4rashid ahmadiNo ratings yet

- PT Report Form FA17 - SimplifiedDocument2 pagesPT Report Form FA17 - SimplifieddonciriusNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- Proceedings of the 41st International Conference on Advanced Ceramics and CompositesFrom EverandProceedings of the 41st International Conference on Advanced Ceramics and CompositesWaltraud M. KrivenNo ratings yet

- 17. Daily Repot 22 SeptemberDocument3 pages17. Daily Repot 22 SeptemberGalang Pratama PutraNo ratings yet

- 19. Daily Repot 25 SeptemberDocument3 pages19. Daily Repot 25 SeptemberGalang Pratama PutraNo ratings yet

- 21. Daily Repot 27 SeptemberDocument3 pages21. Daily Repot 27 SeptemberGalang Pratama PutraNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Rumus Kebutuhan CatDocument2 pagesRumus Kebutuhan CatGalang Pratama PutraNo ratings yet

- Abschreckmedien EDocument24 pagesAbschreckmedien EhsemargNo ratings yet

- Training Handbook en LQDocument95 pagesTraining Handbook en LQprakashp111No ratings yet

- Principal Application Fields Case Hardening Steel:: Technical Card 16Mncr5Document1 pagePrincipal Application Fields Case Hardening Steel:: Technical Card 16Mncr5Bhuvnesh VermaNo ratings yet

- Is 1367 Part 1Document3 pagesIs 1367 Part 1Otavio123100% (1)

- 000 MW SP 0001 Painting SpecificationsDocument74 pages000 MW SP 0001 Painting Specificationsjcarbajal2013No ratings yet

- Filler Wires PDFDocument7 pagesFiller Wires PDFJayaram MVNo ratings yet

- Maintenance of Water Cooling System in Finishing Mill of WRMDocument52 pagesMaintenance of Water Cooling System in Finishing Mill of WRMRoshan Joe MathewNo ratings yet

- Flexible Hoses 2015 - AlchiliDocument5 pagesFlexible Hoses 2015 - Alchilipec21102002No ratings yet

- Welding Journal 1960 12Document151 pagesWelding Journal 1960 12AlexeyNo ratings yet

- Beam Design ReportDocument22 pagesBeam Design Reportkwoshaba pidsonNo ratings yet

- Unit 4 Aircraft StructuresDocument12 pagesUnit 4 Aircraft Structurespiravi66No ratings yet

- Term Paper - 1 Flame HardeningDocument11 pagesTerm Paper - 1 Flame HardeningSiva PrasadNo ratings yet

- Kiefner - Low Frequency ERW and Lap Welded Longitudinal Seam EvaluationDocument99 pagesKiefner - Low Frequency ERW and Lap Welded Longitudinal Seam EvaluationJames PhillipsNo ratings yet

- Bms Assignment 1Document28 pagesBms Assignment 1Aakarshit JainNo ratings yet

- General Mock 6 Master KeyDocument16 pagesGeneral Mock 6 Master KeyM SadahNo ratings yet

- Form QC ReportDocument6 pagesForm QC ReportDezi KurniawanNo ratings yet

- Rapid Determination Steel-Making: of CarbonDocument4 pagesRapid Determination Steel-Making: of CarbontabibkarimNo ratings yet

- Plasterers Bead and Mesh. PVC - OriginalDocument11 pagesPlasterers Bead and Mesh. PVC - OriginalSowmiya Rajagopal100% (1)

- Curriculum Vitae: Career ObjectiveDocument4 pagesCurriculum Vitae: Career Objectivesaga_nifft2k3No ratings yet

- Electric Furnace SteelDocument7 pagesElectric Furnace SteelGilson JuniorNo ratings yet

- A - General Bray InternationalDocument16 pagesA - General Bray InternationalNestor QuevedoNo ratings yet

- Internship ReportDocument41 pagesInternship ReportPankaj KumarNo ratings yet

- Steel Doors and WindowsDocument15 pagesSteel Doors and WindowsVidya HittiNo ratings yet

- WM - TK Hi Integrity Trunnion Mounted Ball ValvesDocument28 pagesWM - TK Hi Integrity Trunnion Mounted Ball ValvesLuis Eduardo PerillaNo ratings yet

- BS en 10025-3Document28 pagesBS en 10025-3yasser awadallhNo ratings yet

- F 1789 - 04Document11 pagesF 1789 - 04LuisNo ratings yet

- 42CrMo DatasheetDocument2 pages42CrMo DatasheetAhmad AlshahrourNo ratings yet

- The Piping GuideDocument214 pagesThe Piping GuideMohamed RjebNo ratings yet

- United Flexible Willcox Hose CatalogDocument44 pagesUnited Flexible Willcox Hose Catalogpo truongNo ratings yet