Professional Documents

Culture Documents

Process Control Final Assignment

Uploaded by

Lad GoldenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Control Final Assignment

Uploaded by

Lad GoldenCopyright:

Available Formats

Page |1

CHAPTER ONE INTRODUCTION Process control is a statistics and engineering discipline that deals with architectures, mechanisms, and algorithms for controlling the output of a specific process. For example, heating up the temperature in a room is a process that has the specific, desired outcome to reach and maintain a defined temperature (e.g. 20C), kept constant over time. Here, the temperature is the controlled variable. At the same time, it is the input variable since it is measured by a thermometer and used to decide whether to heat or not to heat. The desired temperature (20C) is the setpoint. The state of the heater (e.g. the setting of the valve allowing hot water to flow through it) is called the manipulated variable since it is subject to control actions. A commonly used control device called a programmable logic controller, or a PLC, is used to read a set of digital and analog inputs, apply a set of logic statements, and generate a set of analog and digital outputs. Using the example in the previous paragraph, the room temperature would be an input to the PLC. The logical statements would compare the setpoint to the input temperature and determine whether more or less heating was necessary to keep the temperature constant. A PLC output would then either open or close the hot water valve, an incremental amount, depending on whether more or less hot water was needed. Larger more complex systems can be controlled by a Distributed Control System (DCS) or SCADA system.

Page |2

In practice, process control systems can be characterized as one or more of the following forms:

Discrete Found in many manufacturing, motion and packaging applications. Robotic assembly, such as that found in automotive production, can be characterized as discrete process control. Most discrete manufacturing involves the production of discrete pieces of product, such as metal stamping.

Batch Some applications require that specific quantities of raw materials be combined in specific ways for particular durations to produce an intermediate or end result. One example is the production of adhesives and glues, which normally require the mixing of raw materials in a heated vessel for a period of time to form a quantity of end product. Other important examples are the production of food, beverages and medicine. Batch processes are generally used to produce a relatively low to intermediate quantity of product per year (a few pounds to millions of pounds).

Continuous Often, a physical system is represented through variables that are smooth and uninterrupted in time. The control of the water temperature in a heating jacket, for example, is an example of continuous process control. Some important continuous processes are the production of fuels, chemicals and plastics. Continuous processes in manufacturing are used to produce very large quantities of product per year (millions to billions of pounds).

Applications having elements of discrete, batch and continuous process control are often called hybrid applications.

Page |3

Statistical Process Control Statistical Process Control (SPC) is an effective method of monitoring a process through the use of control charts. Much of its power lies in the ability to monitor both process center and its variation about that center. By collecting data from samples at various points within the process, variations in the process that may affect the quality of the end product or service can be detected and corrected, thus reducing waste as well as the likelihood that problems will be passed on to the customer. It has an emphasis on early detection and prevention of problems. Multivariable Process Control A type of Statistical Process Control where a matrix of variables ( MV and CV ) are created and their variations captured by doing a step test. The Dynamics captured in the model curves are used to control the plant Examples A thermostat is a simple example for a closed control loop: It constantly measures the current temperature and controls the heater's valve setting to increase or decrease the room temperature according to the user-defined setting. A simple method switches the heater either completely on, or completely off, and an overshoot and undershoot of the controlled temperature must be expected. A more expensive method varies the amount of heat provided by the heater depending on the difference between the required temperature (the "setpoint") and the actual temperature. This minimizes over/undershoots; an anti-lock braking system (ABS) is a more complex example, consisting of multiple inputs, conditions and outputs.

Page |4

CHAPTER TWO ROLE OF PROCESS CONTROL IN MEDICINE The streams of innovation in engineering and biology in the twentieth century have set the stage for a very exciting twenty-first, the products of which will revolutionize the prevention and treatment of disease as well as the promotion of health. Right now, this all resides in our visions and desires to make the potential real. Making the reality will emanate from intellectual creativity and innovation using the acquired knowledge in genomics, molecular and cellular biology, and the various disciplines of engineering, There will be a marriage of the disciplines of design, information sciences, engineering and biology that will require interdisciplinary efforts, the creation of new disciplinary areas, new resources, and change. This term paper tells us that we have already begun process. Two of the areas of innovation in engineering that have profoundly affected medicine are computational technology and the ability to "make machines small." The following two examples illustrate this point:

The digital data from whole body CT scans or MRIs, can now be integrated into threedimensional images that can be viewed in 360 degrees. This capacity has enabled facial reconstruction in children with inborn errors in development, positioning of instruments in organs in order to sample tissue or deliver therapy, enhanced diagnostic accuracy and planning of surgical interventions, and has provided an effective supplement to the teaching and understanding of anatomy for medical students and practitioners.

Page |5

The assessment of gas tensions, such as oxygen and carbon dioxide, in the blood of intensive care unit patients, is a critical measurement. The measurement used to be very complex and take a lot of time (the van Slyck method). Now, we use in-line sensors with continuous measurement in patients. Countless lives have been saved with this capability.

Biologists have known about chromosomes for a long time, and interest in genetics has been around since the time of Mendel. In the twentieth century, Watson and Crick began a movement that would change biology forever: the description of deoxyribonucleic acid -- DNA. This is the "stuff of life." The characterization of the human genome will be completed in a few short years. The major advances that have facilitated the rapid progress of the past 15-20 years have stemmed from developments in the technology of molecular biology and the science of molecular and cellular biology and genetics. These areas have come to understand how cells talk internally and externally, how the protein factories in the cell are regulated, and how the genetic material itself is organized and works. These disciplines cut across the classic fields of biochemistry, microbiology, anatomy, physiology, and pharmacology. These new fields have reorganized the way biology is practiced and have promoted both interdisciplinary and interscholastic research. New fields have emerged, such as genomics and proteinomics. New support systems that will become new disciplines, such as computational biology, biomathematics and bioinformatics, and bioengineering have already developed or are developing now. These latter areas house the structural and compositional data of genes and proteins. The end result of all this is primarily descriptive; this is what the twenty-first century is all about.

Page |6

The following four examples illustrate some of the bridging and co-mingling of biology and engineering that we have begun to see over the past ten years:

The insertion of a new gene into a cell remains one of the problems hindering progress with gene therapies for genetic diseases. A favorite way to accomplish this is with viral vectors. This approach is difficult, somewhat complicated, and modestly successful. A novel technology was recently developed: a gun that shoots the new gene into the target cell on a particle of gold.

Cell culture systems have developed to the extent that embryonic stem cells can be cultured. These cells have the capacity to differentiate into almost any kind of cell, depending on the biologic factors or messengers that they come into contact with. Achieving this milestone has made the vision of growing new organs in culture a reality.

New skin is now used to cover burned skin. Epithelial cells are cultured and the sheets of cells fixed to an artificially made matrix. The combination constitutes skin that is then placed on the burn area. The artificial matrix is then naturally replaced with endogenous matrix and new skin appears.

Liver cells are now placed into collagen matrix and placed inside the lumens of capillary tubes. This is the same capillary technology that is used for hemodialysis. These cells function and can be modulated with other biologic agents to focus the desired biologic functions. This describes the bio-artificial liver, an extra corporeal device that is currently in clinical testing as a treatment for liver failure.

Page |7

Areas where process control play a vital role in medicine: Blood Glucose Controller Blood Glucose Controller is also called Artificial Pancreas which automatically monitors blood glucose level continuously and injects insulin/glucose to control blood glucose level. The bedside-type STG-22 is a closed-loop glycemic control system which achieves continuous blood glucose monitoring through the glucose sensor electrode by withdrawing blood from the peripheral venous vein and automatically feed-back insulin or glucose infusion to maintain the appropriate blood glucose level.

The Accuracy of a Continuous Blood Glucose Monitor During Surgery Protocols for tight control of blood glucose can be difficult to achieve in the surgical setting, especially when relying upon intermittent blood glucose testing. A continuous blood glucose monitoring system can facilitate blood glucose management. This was compared blood glucose

Page |8

measured continuously (STG-22), during surgery with coincident measurements obtained intermittently using a conventional laboratory glucometer. Tight control of glucose has been reported to reduce mortality in critically ill patients. However, despite frequent blood glucose testing, it has been shown that blood glucose may exceeded 180 mg/dL in about 45% of intensive care unit patients. The insulin infusion protocol itself is usually complex, requiring education and continuing staff monitoring for correct adherence. A report showed that the percentage of patients with severe hypoglycemia, defined as glucose values under 59 mg/dL was about 1% and that hypoglycemic events could not be avoided during intensive insulin therapy with intermittent blood glucose sampling. Therefore, a continuous blood glucose monitor would be beneficial to maintain target blood glucose levels. Here the role of process control is to determine the reliability and accuracy of the continuous method during surgery. Adaptive controller for automatic ventilators An automatic controller utilizes a pulse oximeter signal to regulate the oxygen mixture output, peak expiratory end pressure, and inspiratory ventilation time from a positive pressure respiratory assist ventilator. The pulse oximeter senses a patient's hemoglobin saturation and pulse rate by an optical sensor to develop a signal which is used by calculator to determine the patient's corresponding partial pressure of arterial blood. The calculated partial pressure of arterial blood is then used by the calculator in determining the level of inspired oxygen, peak expiratory end pressure, and inspiratory ventilation time provided to the patient. The calculator generates a signal to control the level of inspired oxygen, expiratory end pressure, and inspiratory ventilation time output from a positive pressure respiratory assist ventilator. The level of inspired oxygen, peak expiratory end pressure, and inspiratory ventilation time provided from

Page |9

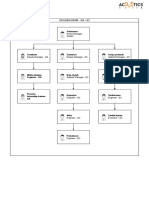

the ventilator to the patient is varied to maintain a desired predetermined partial pressure of arterial oxygen. Drug Infusion Blood pressure (MAP) and cardiac output (CO) from an intensive care "patient" were simulated using Simulink. These patient outputs were measured in response to certain drugs (Nitroprusside, and Dopamine), and mathematical models were calculated to represent the responses. Using these models, a controller can be designed to read the patient outputs and adjust them according to a pre-determined steady-state setpoint using the two drugs, Nitroprusside and Dopamine. With the controller in place on the "patient," a heart attack was simulated as a test of the controller's ability to keep the patient outputs at the steady-state levels. It was found that the controller worked well using the two drugs, but only in the case of the patient outputs being depressed. A third drug, at least, as well as another controller function will be needed to control step changes in the positive direction. The purpose of this model is to show the response of a "patient" to several different infused drugs. Process control uses the modeled information to design a control device to read several patient outputs, and to adjust the dosage of several drugs accordingly.

Fig. 2

P a g e | 10 The model shows a detailed system of closed loop drug delivery (CLDD) which is developed for use with coronary artery disease. The CLDD is designed to be safe and efficient. A feedback control algorithm is used to dose the patient. The patient's response is then monitored and the drug infusion is adjusted for the large physiological variety in people. Then, the drug infusion system simplifies the physician's job. The system also adds safety, by constantly monitoring the response, and when the patient's response is not within the "safety limits" or becomes hazardous, the system can notify the operator, or stop the drug delivery altogether. The system is also more uniform and more flexible than injection infusions. Preliminarily, a PD model was constructed. There existed a time delay which was due in part to physiological factors. "From a control design perspective, the important issues from the PD model are the large variability in the observed responses, typical of biological systems, and the significant delay between the HR response and the infusion administration.

Model Development for Controller Design of the Above Diagram with Transfer Function

First order transfer function

Parametric control in anesthesia

P a g e | 11

This presents a compartmental model for delivery of three drugs (isoflurane, dopamine and sodium nitroprusside) for regulation of anesthesia. The key feature of this model is that mean arterial pressure, cardiac output and unconsciousness of the patient can be simultaneously regulated. This model is validated by carrying out a number of dynamic state simulations and then used for designing model based parametric controllers.

Self-learning fuzzy logic control in medicine Self-learning fuzzy logic control has the important property of accommodating uncertain, nonlinear and time-varying process characteristics. This intelligent control scheme starts with no fuzzy control rules and learns how to control each process presented to it in real-time without the need for detailed process modelling. Medicine abounds with suitable applications for this technique. An outline of the methodology is used to demonstrate its clinical effectiveness for application in anaesthesia. Thus the investigation of its application to atracurium-induced neuromuscular block during surgery, showed an improved control over complex numerical techniques. This self-learning fuzzy control technique shows much promise for other medical applications such as post-operative blood pressure management, intra-operative control of anaesthetic depth, and multivariable circulatory management of intensive care patients. Process control of breathing in mammals: coupling neural dynamics to peripheral gas exchange and transport A model for aspects of the control of respiration in mammals has been developed. The model integrates a reduced representation of the brainstem respiratory neural controller together with peripheral gas exchange and transport mechanisms. The neural controller consists of two

P a g e | 12

components. One component represents the inspiratory oscillator in the pre-Btzinger complex (pre-BtC) incorporating bio-physical mechanisms for rhythm generation. The other component represents the ventral respiratory group (VRG), which is driven by the pre-BtC for generation of inspiratory (pre)motor output. The neural model was coupled to simplified models of the lungs incorporating oxygen and carbon dioxide transport. The simplified representation of the brainstem neural circuitry has regulation of both frequency and amplitude of respiration and is done in response to partial pressures of oxygen and carbon dioxide in the blood using proportional (P) and proportional plus integral (PI) controllers. We have studied the coupled system under open and closed loop control. We show that two breathing regimes can exist in the model. In one regime an increase in the inspiratory frequency is accompanied by an increase in amplitude. In the second regime an increase in frequency is accompanied by a decrease in amplitude. The dynamic response of the model to changes in the concentration of inspired O2 or inspired CO2 was compared qualitatively with experimental data reported in the physiological literature. We show that the dynamic response with a PI-controller fits the experimental data better but suggests that when high levels of CO2 are inspired the respiratory system cannot reach steady state. Our model also predicts that there could be two possible mechanisms for apnea appearance when 100% O2 is inspired following a period of 5% inspired O2. This paper represents a novel attempt to link neural control and gas transport mechanisms, highlights important issues in amplitude and frequency control and sets the stage for more complete neurophysiological control models. Reduced neural control model

P a g e | 13

Our neural model incorporates separate mechanisms for oscillatory activity generation and generation of inspiratory activity pattern in a configuration that allows for independent control of inspiratory frequency and the amplitude of inspiratory neural drive to the lung diaphragm.

Fig. 3 Reduced neural control model. The model consists of two interacting components: an oscillator responsible for rhythm generation and an inspiratory pattern generator that is driven by the oscillator and transforms the drive in a ramp pattern of neural activity. We represent the transformation of the drive from the pre-BtC oscillator into a ramping neural signal as a leaky integration process. This ramping waveform is characteristic of the neural elements in the ventral respiratory group (VRG) of the medulla that drive the diaphragm and lung ventilation. The ramp signal is the control model output and serves as an input signal to the diaphragm. Frequency and amplitude are controlled by the two parameters K and . Next we describe each of the control model components in detail and show how frequency and amplitude can be controlled. Cardiac output controller

P a g e | 14

This apparatus is for modifying cardiac output of the heart of a subject, including one or more sensors which sense signals responsive to cardiac activity, and a stimulation probe including one or more stimulation electrodes which apply non-excitatory stimulation pulses to a cardiac muscle segment. Signal generation circuitry is coupled to the one or more sensors and the stimulation probe, which circuitry receives the signals from the one or more sensors and generates the nonexcitatory stimulation pulses responsive to the signals.

CONCLUSION

Increased automation is a key for desired increased production. In the scope of industrialization, automation is a step beyond mechanization. Whereas mechanization provided human operators with machinery to assist them with the muscular requirements of work, automation greatly reduces the need for human sensory and mental requirements as well. Processes and systems can also be automated. Automation plays an increasingly important role in the global economy and in daily experience. Engineers strive to combine automated devices with mathematical and organizational tools to create

P a g e | 15 complex systems for a rapidly expanding range of applications and human activities. Many roles for humans in industrial processes presently lie beyond the scope of automation. Human-level pattern recognition, language recognition, and language production ability are well beyond the capabilities of modern mechanical and computer systems. In this presentation we are about to have an overview of industrial automation concepts like computer integrated manufacturing, flexible manufacturing systems, industrial robots, artificial intelligence, advanced automatic material handling systems etc With the recent advances in medical imaging and computing power, detailed models of vascular structure and blood flow in the heart have been made possible, through the application of process control engineering in medicine. With the emphasis is on improving outcomes process controls in improves the quality of outcome in medical and bio-medical engineering.

REFRENCES Batzel JJ, Kappel F, Schneditz D, Tran HT. Cardiovascular & Respiratory Systems: Modeling, Analysis & Control. Frontiers in Applied Mathematics. SIAM. 2006 Batzel JJ, Tran HT. Modeling instability in the control system for human respiration: applications to infant non-REM sleep. Appl. Math. Comput. 2000;110:151.

P a g e | 16

Ben-Tal A. Simplified models for gas exchange in the human lungs. Journal of Theoretical Biology. 2006;238:474495. [PubMed] Berssenbrugge A, Dempsey J, Iber C, Skatrud J, Wilson P. Mechanisms of hypoxia-induced periodic breathing during sleep in humans. Journal of physiology. 1983;343:507524. [PMC free article] [PubMed] Butera RJ, Rinzel J, Smith JC. Models of respiratory rhythm generation in the pre-btzinger complex. I. bursting pacemaker neurons. Journal of Neurophysiology. 1999a;81:382397. Butera RJ, Rinzel J, Smith JC. Models of respiratory rhythm generation in the pre-btzinger complex. II. populations of coupled pacemaker neurons. Journal of Neurophysiology. 1999b;81:398415. Carley DW, Shannon DC. A minimal mathematical model of human periodic breathing. J. Appl. Physiol. 1988;65(3):14001409. [PubMed] Comroe JH. Physiology of respiration. 2nd Edition. Year Book Medical Publishers, Inc.; 1977. Computer Aided Chemical Engineering Volume20, 2005, Pages1015-1020

European Symposium on Computer-Aided Process Engineering-15, 38th European Symposium of the Working Party on Computer Aided Process Engineering Dangelo E, Santambrogio G, Agostoni E. Effect of diaphragm activity or paralysis on distribution of pleural pressure. J. Appl. Physiol. 1974;37:311315. [PubMed]

You might also like

- Combined Cooling, Heating and Power: Decision-Making, Design and OptimizationFrom EverandCombined Cooling, Heating and Power: Decision-Making, Design and OptimizationNo ratings yet

- Bioreactor Instrumentation and ControlDocument9 pagesBioreactor Instrumentation and ControlJoel CariazNo ratings yet

- Thermal and Energetic Studies of Cellular Biological SystemsFrom EverandThermal and Energetic Studies of Cellular Biological SystemsA. M. JamesNo ratings yet

- Principles of Measurement and Transduction of Biomedical VariablesFrom EverandPrinciples of Measurement and Transduction of Biomedical VariablesNo ratings yet

- Dimensional Analysis: Practical Guides in Chemical EngineeringFrom EverandDimensional Analysis: Practical Guides in Chemical EngineeringNo ratings yet

- Literature Review On CryotherapyDocument4 pagesLiterature Review On Cryotherapyaflspyogf100% (1)

- Micro Fluidics ApplicationsDocument3 pagesMicro Fluidics ApplicationsAhmedAbubakrNo ratings yet

- Chapter One Biotechnology and Biochemical EngineeringDocument22 pagesChapter One Biotechnology and Biochemical EngineeringYonas MegersaNo ratings yet

- 1 Bioprocess Engineering CH 1Document22 pages1 Bioprocess Engineering CH 1Fasil ManNo ratings yet

- Heat Transfer and Fluid Flow in Biological ProcessesFrom EverandHeat Transfer and Fluid Flow in Biological ProcessesSid M. BeckerNo ratings yet

- Che 511 Lecture Note 2023Document5 pagesChe 511 Lecture Note 2023Bright ChimezieNo ratings yet

- Scaling Chemical Processes: Practical Guides in Chemical EngineeringFrom EverandScaling Chemical Processes: Practical Guides in Chemical EngineeringNo ratings yet

- Fermentation Technology, Bioprocessing and Scaleup - ChistiDocument39 pagesFermentation Technology, Bioprocessing and Scaleup - Chistirobertoagonzalezc0% (1)

- Review. Advantages and Disadvantages of Control Theories Applied in Greenhouse Climate Control SystemsDocument13 pagesReview. Advantages and Disadvantages of Control Theories Applied in Greenhouse Climate Control Systemskevin hoxhaNo ratings yet

- Practical Design, Construction and Operation of Food FacilitiesFrom EverandPractical Design, Construction and Operation of Food FacilitiesRating: 5 out of 5 stars5/5 (2)

- Energy Autonomy of Batteryless and Wireless Embedded Systems: Aeronautical ApplicationsFrom EverandEnergy Autonomy of Batteryless and Wireless Embedded Systems: Aeronautical ApplicationsNo ratings yet

- Thermodynamics of Phase Equilibria in Food EngineeringFrom EverandThermodynamics of Phase Equilibria in Food EngineeringCamila Gambini PereiraNo ratings yet

- Baris Yuce ThesisDocument7 pagesBaris Yuce Thesisquaobiikd100% (2)

- Recent Developments in The Monitoring, Modeling and Control of Biological Production SystemsDocument5 pagesRecent Developments in The Monitoring, Modeling and Control of Biological Production SystemsGabriel PatrascuNo ratings yet

- Physical-Chemical Properties of Foods: New Tools for PredictionFrom EverandPhysical-Chemical Properties of Foods: New Tools for PredictionNo ratings yet

- Nonlinear Control for Blood Glucose Regulation of Diabetic Patients: An LMI ApproachFrom EverandNonlinear Control for Blood Glucose Regulation of Diabetic Patients: An LMI ApproachNo ratings yet

- Journal of Microscopy SubmissionDocument16 pagesJournal of Microscopy SubmissionNorhan MadinaNo ratings yet

- Interdisciplinary Approach To BioprocessingDocument9 pagesInterdisciplinary Approach To BioprocessingTamoor TariqNo ratings yet

- Fermentation Monitoring and Control: A Perspective: Biotechnology and Genetic Engineering ReviewsDocument43 pagesFermentation Monitoring and Control: A Perspective: Biotechnology and Genetic Engineering ReviewsChevery DidierNo ratings yet

- Heat Transfer Enhancement Using Nanofluid Flow in Microchannels: Simulation of Heat and Mass TransferFrom EverandHeat Transfer Enhancement Using Nanofluid Flow in Microchannels: Simulation of Heat and Mass TransferNo ratings yet

- Biosensor RegenerationDocument10 pagesBiosensor RegenerationJuanka G. JulioNo ratings yet

- Systems Metabolic Engineering The Creation of MIcrobial Cell Factories by Rational Metabolic Design and EvolutionDocument23 pagesSystems Metabolic Engineering The Creation of MIcrobial Cell Factories by Rational Metabolic Design and EvolutionIan Rey Israel GubatNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Design of A Portable Urine Glucose Monitoring System For Health CareDocument12 pagesDesign of A Portable Urine Glucose Monitoring System For Health CareaksssudhakarNo ratings yet

- Chapter 1: General Information of Engineering and Its ApplicationDocument3 pagesChapter 1: General Information of Engineering and Its ApplicationSOm KAntaNo ratings yet

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- Optimal On-Line Decision Making For Food Thermal ProcessesDocument6 pagesOptimal On-Line Decision Making For Food Thermal Processesrocanrol2No ratings yet

- LabonchipDocument27 pagesLabonchipManoj MurthyNo ratings yet

- Characterization of Cooling Equipment in The Food Industry - 2021 - EnvironmentDocument14 pagesCharacterization of Cooling Equipment in The Food Industry - 2021 - EnvironmentAlexander VassilevNo ratings yet

- Instruments and Measurement SystemDocument14 pagesInstruments and Measurement SystemMonty KushwahaNo ratings yet

- Prior Solutions: (Research Paper)Document4 pagesPrior Solutions: (Research Paper)Adam AbdalaleemNo ratings yet

- Noaa 40089 DS1Document12 pagesNoaa 40089 DS1ryhseduyadNo ratings yet

- Unitops CH 1Document13 pagesUnitops CH 1Arturo TorresNo ratings yet

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningFrom EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningRating: 5 out of 5 stars5/5 (4)

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Crude Oil Fouling: Deposit Characterization, Measurements, and ModelingFrom EverandCrude Oil Fouling: Deposit Characterization, Measurements, and ModelingFrancesco ColettiNo ratings yet

- Systems Biomedicine: Concepts and PerspectivesFrom EverandSystems Biomedicine: Concepts and PerspectivesEdison T. LiuNo ratings yet

- Thermochimica Acta: Graham BucktonDocument13 pagesThermochimica Acta: Graham BucktonJerusalen BetancourtNo ratings yet

- Assignment No: 03 Applications of Chemical SensorsDocument14 pagesAssignment No: 03 Applications of Chemical SensorsJannat fatima100% (1)

- Basic Concepts of Measurement and InstrumentationDocument16 pagesBasic Concepts of Measurement and Instrumentationዘረአዳም ዘመንቆረርNo ratings yet

- Measurement and Control Basics, 4th EditionFrom EverandMeasurement and Control Basics, 4th EditionRating: 4 out of 5 stars4/5 (11)

- Thesis ZcuDocument7 pagesThesis ZcuWritingServicesForCollegePapersCanada100% (2)

- Applied Sciences: Water Jacket Systems For Temperature Control of Petri Dish Cell Culture ChambersDocument18 pagesApplied Sciences: Water Jacket Systems For Temperature Control of Petri Dish Cell Culture ChambersMouna MorchidNo ratings yet

- From Pinch Methodology to Pinch-Exergy Integration of Flexible SystemsFrom EverandFrom Pinch Methodology to Pinch-Exergy Integration of Flexible SystemsNo ratings yet

- Bioprocesses Parameters ControlDocument5 pagesBioprocesses Parameters ControlShaikh Muhammad Usama100% (1)

- Thermodynamics of Microbial Growth and MetabolismDocument17 pagesThermodynamics of Microbial Growth and MetabolismJeimy MaciasNo ratings yet

- About NanomaterislDocument25 pagesAbout NanomaterislpriyaNo ratings yet

- Food Engineering Thesis PDFDocument6 pagesFood Engineering Thesis PDFsamanthajonessavannah100% (2)

- Unit 8 Packet KeyDocument21 pagesUnit 8 Packet KeyHiddenNo ratings yet

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDocument53 pagesGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADNo ratings yet

- Organogram - Qa / QC: Srinivasan SrinivasanDocument4 pagesOrganogram - Qa / QC: Srinivasan SrinivasanGowtham VenkatNo ratings yet

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70No ratings yet

- METHOD STATEMENT FOR INSTALLATION OF Light FixturesDocument5 pagesMETHOD STATEMENT FOR INSTALLATION OF Light FixturesNaveenNo ratings yet

- Riber 6-s1 SP s17-097 336-344Document9 pagesRiber 6-s1 SP s17-097 336-344ᎷᏒ'ᏴᎬᎪᏚᎢ ᎷᏒ'ᏴᎬᎪᏚᎢNo ratings yet

- High Speed DoorsDocument64 pagesHigh Speed DoorsVadimMedooffNo ratings yet

- REV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Document2 pagesREV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Bacano CapoeiraNo ratings yet

- Answers To Your Questions About Circumcision and HIV/AIDSDocument2 pagesAnswers To Your Questions About Circumcision and HIV/AIDSAlex BrownNo ratings yet

- Neopuff PDFDocument4 pagesNeopuff PDFoechimNo ratings yet

- Service Bulletins For Engine Model I0360kb.3Document6 pagesService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezNo ratings yet

- United States v. Victor Vallin-Jauregui, 4th Cir. (2013)Document4 pagesUnited States v. Victor Vallin-Jauregui, 4th Cir. (2013)Scribd Government DocsNo ratings yet

- Castle 1-3K E ManualDocument26 pagesCastle 1-3K E ManualShami MudunkotuwaNo ratings yet

- CXC - Past - Paper - 2022 Solutions PDFDocument17 pagesCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadNo ratings yet

- AMS 48 - 2000-n - D0114354 - 055 - 00Document116 pagesAMS 48 - 2000-n - D0114354 - 055 - 00wanhall100% (1)

- Art of Facing InterviewsDocument15 pagesArt of Facing Interviewskrish_cvr2937100% (2)

- Long Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesDocument4 pagesLong Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesAngélica Valenzuela AndrighiNo ratings yet

- Benzil PDFDocument5 pagesBenzil PDFAijaz NawazNo ratings yet

- Senior Project RiceberryDocument76 pagesSenior Project RiceberryIttisak PrommaNo ratings yet

- Conference Version of SB 1Document486 pagesConference Version of SB 1Paul MastersNo ratings yet

- Guinea Pig: Domestication: Basic Species InformationDocument4 pagesGuinea Pig: Domestication: Basic Species InformationBondNo ratings yet

- Business Plan Example - Little LearnerDocument26 pagesBusiness Plan Example - Little LearnerCourtney mcintosh100% (1)

- Report in Per Dev CorrectedDocument34 pagesReport in Per Dev CorrectedJosh lyan RiveraNo ratings yet

- Lichens - Naturally Scottish (Gilbert 2004) PDFDocument46 pagesLichens - Naturally Scottish (Gilbert 2004) PDF18Delta100% (1)

- Comparison and Contrast Essay FormatDocument5 pagesComparison and Contrast Essay Formattxmvblaeg100% (2)

- Laboratory Cold ChainDocument22 pagesLaboratory Cold ChainEmiNo ratings yet

- Basic Electrical Engineering NotesDocument25 pagesBasic Electrical Engineering NotesAnas AnsariNo ratings yet

- Medical Records in Family PracticeDocument22 pagesMedical Records in Family PracticenurfadillahNo ratings yet

- Employment Offer: 1. Employer InformationDocument2 pagesEmployment Offer: 1. Employer InformationnavidNo ratings yet