0% found this document useful (0 votes)

140 views1 pageDaily Air Compressor Pre-Start Inspection Checklist EMF

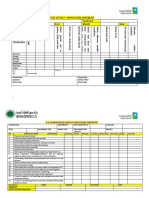

The document is an Air Compressor Daily Inspection Checklist used to ensure the proper functioning and safety of air compressors. It includes a list of items to check, such as oil leakage, coolant levels, and safety valve actuation, along with a section for operator signatures and review by an HSE officer. The checklist aims to identify defects and ensure compliance with safety standards before operation.

Uploaded by

mkhan97082Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

140 views1 pageDaily Air Compressor Pre-Start Inspection Checklist EMF

The document is an Air Compressor Daily Inspection Checklist used to ensure the proper functioning and safety of air compressors. It includes a list of items to check, such as oil leakage, coolant levels, and safety valve actuation, along with a section for operator signatures and review by an HSE officer. The checklist aims to identify defects and ensure compliance with safety standards before operation.

Uploaded by

mkhan97082Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd