0% found this document useful (0 votes)

72 views28 pagesComprehensive Guide to Plain Cement Concrete

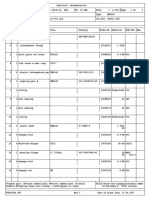

The document outlines the establishment and role of the Central Public Works Department (CPWD) in India, detailing its mission to provide quality construction and maintenance services across the nation. It includes a project overview for the Eklavya Model Residential Schools, emphasizing the importance of quality education for tribal communities, and describes various construction techniques such as Plain Cement Concrete, Compressive Strength Testing, Sieve Analysis, and Slump Testing. The document serves as a comprehensive guide for understanding the processes and standards involved in civil engineering and construction management.

Uploaded by

giponiw119Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

72 views28 pagesComprehensive Guide to Plain Cement Concrete

The document outlines the establishment and role of the Central Public Works Department (CPWD) in India, detailing its mission to provide quality construction and maintenance services across the nation. It includes a project overview for the Eklavya Model Residential Schools, emphasizing the importance of quality education for tribal communities, and describes various construction techniques such as Plain Cement Concrete, Compressive Strength Testing, Sieve Analysis, and Slump Testing. The document serves as a comprehensive guide for understanding the processes and standards involved in civil engineering and construction management.

Uploaded by

giponiw119Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd