0% found this document useful (0 votes)

85 views3 pagesCompany Performance Metrics Overview

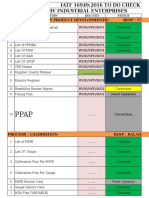

The document outlines company-level data related to various departments and their responsibilities, including targets for audit compliance, customer satisfaction, production performance, and human resources. Each parameter is defined with specific targets, such as adherence percentages, number of incidents, and financial metrics. The focus is on maintaining high standards across internal and external audits, production efficiency, and employee training and safety.

Uploaded by

machineshopqajadhavindustriesCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

85 views3 pagesCompany Performance Metrics Overview

The document outlines company-level data related to various departments and their responsibilities, including targets for audit compliance, customer satisfaction, production performance, and human resources. Each parameter is defined with specific targets, such as adherence percentages, number of incidents, and financial metrics. The focus is on maintaining high standards across internal and external audits, production efficiency, and employee training and safety.

Uploaded by

machineshopqajadhavindustriesCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd