Professional Documents

Culture Documents

Daily Report - of June 2012

Uploaded by

masudalamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Report - of June 2012

Uploaded by

masudalamCopyright:

Available Formats

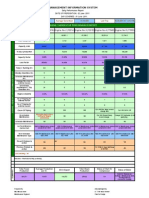

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 02 June- 2012 DAY COVERED: 01 June - 2012 Average Demand MW Average Generation 14.22 MW Last Plant Trip

21/05/2012 01:39 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,037.1 3,565 86,400 66,165 76.58% 77.98% 23.8 0 0 0 52,477.1 3,579 86,400 54,925 63.57% 74.14% 20.7 0 2 0 55,881.7 3,250 86,400 66,463 76.92% 85.21% 24 0 0 0 33,072.1 7,698 201,360 153,881 76.42% 83.64% 23.9 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

0.2 99.17% 1 0 Cyl 8/A dev Pcc ball valve change and spark plug gap adjust Nil

1.3 94.58% 0 0 Nil Lub oil filter change 1000 RH maintanance

0 100.00% 0 0 Nil Nil Nil

0.1 99.58% 1 0 Normal stop for Ht temp high Nil Nil

24 0.00% 0 0 Nil Nil Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 318.4 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 979.3 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 228.3 RHs 589 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed : Fresh-1,2=25 min.Mtc-1,2,3=20 min.

SUMMARY Total Power Production

341,434

Average Production per Hr.

14,226

33 kV Export

0

Total Steam Production

218.22

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md.Amir Hamza Sr. Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 03 June- 2012 DAY COVERED: 02 June - 2012 Average Demand MW Average Generation 15.80 MW Last Plant Trip

21/05/2012 01:39 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,061.1 3,375 86,400 72,788 84.25% 89.86% 24 0 0 0 52,501.1 3,367 86,400 70,516 81.62% 87.26% 24 0 2 0 55,905.7 3,320 86,400 70,618 81.73% 88.63% 24 0 0 0 33,095.7 8,020 201,360 165,469 82.18% 87.42% 23.6 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

0 100.00% 0 0 Nil Nil Nil

0 100.00% 0 0 Nil Nil Nil

0 100.00% 0 0 Nil Nil Nil

0.4 98.33% 1 0 control air press low Nil Nil

24 0.00% 0 0 Nil Nil Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 294.4 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 955.3 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 204.3 RHs 565.4 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :L-1= 9 min due to Earth fault.L-2=5 min due to E4 trip load management active.L-5=3 min due to Everest E-1 trip.Fresh-1=43

min,Fresh-2=53 min due to Fresh -4 ball mill running time. SUMMARY Total Power Production

379,391

Average Production per Hr.

15,808

33 kV Export

0

Total Steam Production

204.80

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md.Amir Hamza Sr. Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 04 June- 2012 DAY COVERED: 03 June - 2012 Average Demand MW Average Generation 15.80 MW Last Plant Trip

03/06/2012 05:09 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,084.7 3,370 86,400 74,918 86.71% 94.20% 23.6 0 0 0 52,524.7 3,365 86,400 71,372 82.61% 89.87% 23.6 0 2 0 55,929.4 3,270 86,400 71,222 82.43% 91.90% 23.7 0 0 0 33,117.9 7,685 201,360 161,034 79.97% 94.39% 22.2 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

0.4 98.33% 1 0

0.4 98.33% 2 0 Plant trip, Exht. Temp. high cyl.6/A

0.3 98.75% 2 0

1.8 92.50% 2 0

24 0.00% 0 0

Plant trip.

Plant trip ,cyl dev 4/B

Plant trip, cyl.dev 2/A. Replace clean pcc ball valve cyl. 2/A, 10/B, Replace old spark plug cyl. 2/A, 3/B, 7/B, Ex Nil

Nil

Nil

Nil

Replace clean pcc ball valve cyl 4/B Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 270.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 931.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 180.6 RHs 543.2 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant trip at 5:09pm due to Everest Power Plant trip (Earth fault) yesterday. Down time- 0:28 min. Loadshed :L-1=29 min due to plant trip. L-2=29 min due to plant trip. L-3=28 min due to plant trip, L-5=29 min due to plant trip .Fresh1=3:36 min, due to (EPGCL E-3 trip, EPGCL E-1 trip, After plant trip), Fresh-2=3.41 min due to (EPGCL E-3 trip, EPGCL E-1 trip, After plant trip), Fresh-3=-3.42 min due to (EPGCL E-3 tripe, EPGCL E-1 trip, After plant trip). SUMMARY Total Power Production

378,546

Average Production per Hr.

15,773

33 kV Export

0

Total Steam Production

205.10

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Sk Mainuddin Asst. Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 05 June- 2012 DAY COVERED: 04 June - 2012 Average Demand MW Average Generation 16.100 MW Last Plant Trip

03/06/2012 05:09 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,108.6 3,600 86,400 72,289 83.67% 84.02% 23.9 0 0 0 52,548.7 3,456 86,400 70,917 82.08% 85.50% 24 0 0 0 55,953.4 3,474 86,400 71,397 82.64% 85.63% 24 0 0 0 33,141.9 7,772 201,360 171,805 85.32% 92.11% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

0.1 99.58% 1 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Exht. Temp. cyl. Dev. 7/A. Replace clean pcc ball valve cyl. 7/A & spark plug gap adjust cyl. 5/A, 7/A, 8/A. Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 246.9 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 907.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 156.6 RHs 519.2 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :L-1=4:15hr due to earth fault Fresh cement control room side HT cabal Insolator Problem , L-5=25 min due to Engine1 trip .Fresh-2=0:49 min. due to EPGCL E-1 trip, Fresh-3=4:54hr. due to Fresh cement control room side HT cabal insolator problem. MTC1,2,3&4=0:35min. due to Engine -1 trip. SUMMARY Total Power Production

386,408

Average Production per Hr.

16,100

33 kV Export

0

Total Steam Production

250.69

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 06 June- 2012 DAY COVERED: 05 June - 2012 Average Demand MW Average Generation 16.318 MW Last Plant Trip

05/06/2012 08:28 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,131.9 3,676 86,400 71,475 82.73% 83.45% 23.3 0 0 0 52,572.3 3,497 86,400 74,365 86.07% 90.11% 23.6 0 0 0 55,977.2 3,434 86,400 71,675 82.96% 87.70% 23.8 0 0 0 33,165.4 7,819 201,360 174,119 86.47% 94.76% 23.5 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

0.7 97.08% 2 1 Exht. Temp. cyl. Dev. 4/A.& 6/A, Plant trip. Replace clean pcc ball valve cyl. 4/A, 6/A & Replace old spark plug cyl. 6/A, Nil

0.4 98.33% 1 1 Plant trip, Exht. Temp. cyl. High 6/A.

0.2 99.17% 0 1

0.5 97.92% 0 1

24 0.00% 0 0

Plant trip

Plant trip.

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 223.6 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 884.1 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 132.8 RHs 495.7 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant trip at 8:28pm due to Everest Power buscupler trip for over current yesterday. Down time= 0:13min. Loadshed :L-1=0:24min. due to plant trip, L-2=0:24min. Due to plant trip, L-3=0:21min. Due to plant trip, L-5=35 min due to Engine-1 trip &

plant trip, Fresh-1=3:00hr. due to EPGCL E-1maint. & plant trip, Fresh-2=3:00hr. due toEPGCL E-1 maint. & plant trip, Fresh-3=0:20min. due to plant trip., MTC-1=1:03hr. due to E-1 trip &plant trip, MTC-2=2:57hr.due to Plant trip & E-1 trip, MTC-3=4:29hr. due to E-1 trip, plant trip & EPGCL E-1 maint., MTC-4= 5:45hr. due to E-1 trip, plant trip & EPGCL E-1 maint. SUMMARY Total Power Production

391,634

Average Production per Hr.

16,318

33 kV Export

0

Total Steam Production

243.06

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 07 June- 2012 DAY COVERED: 06 June - 2012 Average Demand MW Average Generation 16.318 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,155.3 3,549 86,400 73,705 85.31% 88.75% 23.4 0 0 0 52,596.0 3,388 86,400 70,589 81.70% 87.91% 23.7 0 0 0 56,001.1 3,399 86,400 72,181 83.54% 88.85% 23.9 0 0 0 33,187.1 7,809 201,360 157,133 78.04% 92.73% 21.7 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0.6 97.50% 2 1 Exht. Temp. cyl. Dev. 9/A, Plant trip. Replace clean pcc ball valve cyl. 9/A & Replace old spark plug cyl. 9/A, Nil

0.3 98.75% 0 1

0.1 99.58% 0 1

2.3 90.42% 2 1 Plant trip.& exh. Temp. deb. Cyl- 3/A, 4/A. Replace clean pcc ball valve cyl - 3/A, 4/A, 9/B, 10/B & HT lead interchange cyl - 4/A to 3/A & 3/A to 5/A. Nil

24 0.00% 0 0

Plant trip,

Plant trip

Nil

Un-schedule Maintenance

Nil

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 200.2 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 860.4 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 108.9 RHs 474.0 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant trip at 12:52 PM due to all engine over voltage & MTC OHL rod fall yesterday. Down time= 0:14min.

Loadshed :L-1 = 15 min. due to plant trip, L-2 = 23 min. Due to plant trip, L-3 = 36 min. Due to plant trip, L-5 = 27 min due to Engine-4 trip &

plant trip, Fresh - 3 = 30 min due to EPGCL E-2 trip, Fresh-4= 1:06hr. due plant trip. MTC - 1 = 1:02 Hr; MTC - 2 = 1:04 Hr, MTC - 4 = 1:11 Hr. SUMMARY

Total Power Production

373,608

Average Production per Hr.

15,567

33 kV Export

0

Total Steam Production

197.59

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Promod Sutradhar Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 08 June- 2012 DAY COVERED: 07 June - 2012 Average Demand MW Average Generation 16.061 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,179.3 3,691 86,400 72,800 84.26% 82.18% 24 0 0 0 0 100.00% 0 0 52,619.1 3,499 86,400 70,061 81.09% 86.68% 23.1 0 0 0 0.9 96.25% 1 0 56,025.1 3,560 86,400 73,189 84.71% 85.66% 24 0 0 0 0 100.00% 0 0 33,210.6 7,884 201,360 169,416 84.14% 91.44% 23.5 0 0 0 0.5 97.92% 1 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0 24 0.00% 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Today's Running Hrs Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Woodward 723 Major Alarm

Nil

Exht. temp. cyl. dev. 4/A. Replace old spark plug cyl 4/A, & Orifish clean. Nil

Nil

Nil Nil

Nil Nil

Nil Nil

Nil Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 176.2 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 837.3 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 84.9 RHs 450.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed : L-5 = 0:04 min. due to Engine-4 trip, Fresh-3 =0:55 min due to E-4 & EPGCL E-2 trip, MTC-1=0:20min.due to E-4 trip, MTC2=1:06hr.due to E-4 & EPGCL E-2 trip, MTC-3=0:20min. Due to E-4 trip, MTC-4=1:10hr. Due to E-4 & EPGCL E-2 trip. SUMMARY Total Power Production

385,466

Average Production per Hr.

16,061

33 kV Export

0

Total Steam Production

219.97

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 09 June- 2012 DAY COVERED: 08 June - 2012 Average Demand MW Average Generation 16.061 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,203.3 3,559 86,400 72,468 83.88% 84.84% 24 0 0 0 0 100.00% 0 0 52,643.1 3,437 86,400 70,738 81.87% 85.76% 24 0 0 0 0 100.00% 0 0 56,049.1 3,382 86,400 71,882 83.20% 88.56% 24 0 0 0 0 100.00% 0 0 33,234.6 7,631 201,360 173,765 86.30% 94.88% 24 0 0 0 0 100.00% 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0 24 0.00% 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Today's Running Hrs Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil Nil

Nil Nil

Nil Nil

Nil Nil

Nil Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 152.2 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 813.3 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 60.9 RHs 426.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshe : Fresh - 3 = 31 min. due to Everest E - 2 trip.

SUMMARY Total Power Production

388,853

Average Production per Hr.

16,202

33 kV Export

0

Total Steam Production

221.66

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Promod Sutradhar Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 10 June- 2012 DAY COVERED: 09 June - 2012 Average Demand MW Average Generation 16.061 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,227.3 3,498 86,400 75,172 87.00% 89.54% 24 0 0 0 0 100.00% 0 0 52,667.1 3,111 86,400 68,624 79.43% 91.91% 24 0 0 0 0 100.00% 0 0 56,073.1 3,295 86,400 73,006 84.50% 92.32% 24 0 0 0 0 100.00% 0 0 33,258.6 7,612 201,360 180,444 89.61% 98.77% 24 0 0 0 0 100.00% 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0 24 0.00% 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Today's Running Hrs Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil Centrifugal filter clean complete

Nil Centrifugal filter clean complete

Nil Centrifugal filter clean complete

Nil Centrifugal filter clean complete

Nil Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 128.2 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 789.3 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 36.9 RHs 402.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshe : Nil

SUMMARY Total Power Production

397,246

Average Production per Hr.

16,552

33 kV Export

0

Total Steam Production

222.59

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Promod Sutradhar Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 11 June- 2012 DAY COVERED: 10 June - 2012 Average Demand MW Average Generation 16.061 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,250.9 3,468 86,400 75,368 87.23% 92.09% 23.6 0 0 0 0.4 98.33% 1 0 52,691.1 3,454 86,400 72,588 84.01% 87.57% 24 0 0 0 0 100.00% 0 0 56,096.7 3,419 86,400 72,455 83.86% 89.80% 23.6 0 0 0 0.4 98.33% 1 0 33,282.6 7,767 201,360 182,382 90.58% 97.84% 24 0 0 0 0 100.00% 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0 24 0.00% 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Today's Running Hrs Standby Downtime Hrs. Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Exh. Temp. dev. Cyl - 6/A

Nil

Exh. Temp. dev. Cyl - 2/B Replace PCC ball valve of cyl - 2/B & spark plug gap adjust of cyl - 3/A, 2/b, 4/B. Oil bath filter mut collection complete

Nil

Nil

Replace PCC ball valve of cyl - 6/A & spark plug gap Nil adjust of cyl - 6/A, 9/A. Oil bath filter mud collection Oil bath filter mut collection complete complete

Nil Oil bath filter mut collection complete

Nil Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 104.6 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 765.3 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 13.3 RHs 378.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshe : MTC - 1 = 40 min due to E - 1 trip, MTC - 2 = 33 min due to E - 1 trip, MTC - 3 = 35 min due to E - 1 trip, MTC - 4 = 40 min due to E - 1 trip.

SUMMARY Total Power Production

402,793

Average Production per Hr.

16,783

33 kV Export

0

Total Steam Production

220.71

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Promod Sutradhar Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 12 June- 2012 DAY COVERED: 11 June - 2012 Average Demand MW Average Generation 16.061 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,274.9 3,543 86,400 76,809 88.90% 90.33% 24 0 0 0 0 100.00% 0 0 52,714.7 3,397 86,400 70,821 81.97% 88.34% 23.6 0 0 0 0.4 98.33% 1 0 56,120.4 3,345 86,400 70,979 82.15% 89.53% 23.7 0 0 0 0.3 98.75% 2 0 Exh. Temp. dev. Cyl - 8/A, 6/B. 33,306.6 7,877 201,360 180,707 89.74% 95.59% 24 0 0 0 0 100.00% 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0 24 0.00% 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

Nil

Exh. Temp. dev. Cyl - 4/A.

Nil

Nil

Un-schedule Maintenance

Nil

Replace PCC ball valve of cyl - 4/A & spark plug replace old cyl. - 4/A, 6/A.. ( R.H - 52711 ) Nil

Replace PCC ball valve of cyl - 8/A, 6/B.

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 55110.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 80.6 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 741.7 RHS 1000 RH maintenance over 2000 RH maintenance After 1000RH maintenance after 10.4 RHs 354.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshe : L - 5 = 4:03 Hr. due to MTC belt conveyer maintenance.

SUMMARY Total Power Production

399,316

Average Production per Hr.

16,638

33 kV Export

0

Total Steam Production

231.14

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Promod Sutradhar Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 13 June- 2012 DAY COVERED: 12 June - 2012 Average Demand 15.76 MW Average Generation 15.76 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,298.9 3,520 86,400 72,674 84.11% 86.03% 24 0 0 0 52,738.7 3,271 86,400 70,794 81.94% 90.18% 24 0 0 0 56,142.3 3,225 86,400 63,467 73.46% 89.86% 21.9 0 2.1 0 33,330.6 7,764 201,360 171,258 85.05% 91.91% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Nil

Nil

Nil

Un-schedule Maintenance

Nil

Nil

Nil

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

1000hr maint. Done.

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 56.6 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 717.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 979.7 RHs 330.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshe : Nil

SUMMARY Total Power Production

378,193

Average Production per Hr.

15,758

33 kV Export

0

Total Steam Production

236.53

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By M.A Motaleb Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 14 June- 2012 DAY COVERED: 13 June - 2012 Average Demand 15.30 MW Average Generation 15.30 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,322.9 3,320 86,400 70,064 81.09% 87.93% 24 0 0 0 52,762.7 3,380 86,400 68,770 79.59% 84.78% 24 0 0 0 56,165.7 3,250 86,400 64,666 74.84% 84.31% 23.6 0 0 0 33,354.6 7,822 201,360 171,258 85.05% 91.23% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0.4 98.33% 4 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Cyl 9/B,1/A,9/B dev

Nil

Nil

Un-schedule Maintenance

Nil

Nil

Pcc ball valve change

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 49355.5ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 32.6 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 693.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 956.1 RHs 306.5 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :L-1,5=4 min,L-2=1.40 min due to L-4 OHL cable connection.

SUMMARY Total Power Production

374,758

Average Production per Hr.

15,615

33 kV Export

0

Total Steam Production

233.97

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md.Amir Hamza Sr.Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 15 June- 2012 DAY COVERED: 14 June - 2012 Average Demand 15.17 MW Average Generation 15.17 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,345.6 3,380 86,400 69,737 80.71% 90.89% 22.7 0 0 0 52,786.7 3,375 86,400 71,566 82.83% 88.35% 24 0 0 0 56,189.7 3,214 86,400 73,442 85.00% 95.21% 24 0 0 0 33,375.2 7,764 201,360 149,219 74.11% 93.30% 20.6 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

1.3 94.58% 1 0

0 100.00% 0 0

0 100.00% 0 0

3.4 85.83% 1 0

24 0.00% 0 0

Cyi dev 1B

Nil

Nil

Cyi dev 9A New S/P replace to cyl 8A,9A,1B,2B. 9A pcc valve change. 4A,6B tappet chacked. HT flexible pipe chaned (from E5) Nil

Nil

Un-schedule Maintenance

Nil

Nil

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

1000hr maint done, All pcc clean & S/P regap.

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 978.4 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 669.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 932.1 RHs 285.9 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :L-5=4 min due to E4 trip, MTC-all mills 3:30min due to E4 maint.

SUMMARY Total Power Production

363,964

Average Production per Hr.

15,165

33 kV Export

0

Total Steam Production

217.04

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By M.A Motaleb Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 16 June- 2012 DAY COVERED: 15 June - 2012 Average Demand 16.6 MW Average Generation 16.6 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,369.2 3,325 86,400 74,263 85.95% 94.64% 23.6 0 0 0 52,810.7 3,315 86,400 74,704 86.46% 93.90% 24 0 0 0 56,213.7 3,270 86,400 73,538 85.11% 93.70% 24 0 0 0 33,399.2 7,866 201,360 176,068 87.44% 93.26% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0.4 98.33% 1 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Cyl dev 7A

Nil

Nil

Nil

Nil

Un-schedule Maintenance

Cyl 7A pcc change & s/p regap.

Nil

Nil

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 954.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 645.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 908.1 RHs 261.9 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :L-5 17min due to E1 trip & engine over load. Fresh-04 starting delay 1hr20min for everest E2 maint. Two ball mills of MTC- 8hr15min due to Engine ove load.

SUMMARY Total Power Production

398,573

Average Production per Hr.

16,607

33 kV Export

0

Total Steam Production

242.76

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By M.A Motaleb Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 17 June- 2012 DAY COVERED: 16 June - 2012 Average Demand 16.93 MW Average Generation 16.93 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,393.2 3,320 86,400 77,015 89.14% 96.66% 24 0 0 0 52,834.7 3,325 86,400 77,673 89.90% 97.33% 24 0 0 0 56,237.4 3,265 86,400 71,570 82.84% 92.49% 23.7 0 0 0 33,423.2 7,727 201,360 180,247 89.51% 97.20% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0.3 98.75% 2 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Cyl 6/A,4/B dev

Nil

Nil

Un-schedule Maintenance

Nil

Nil

Pcc ball valve change and Ht lead chaange.(old)

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 930.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 621.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 884.4 RHs 237.9 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High.

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :Nil

SUMMARY Total Power Production

406,505

Average Production per Hr.

16,938

33 kV Export

0

Total Steam Production

247.15

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md.Amir Hamza Sr.Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 18 June- 2012 DAY COVERED: 17 June - 2012 Average Demand 16.96 MW Average Generation 16.96 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,417.2 3,317 86,400 76,460 88.50% 96.05% 24 0 0 0 52,858.7 3,312 86,400 75,513 87.40% 95.00% 24 0 0 0 56,261.4 3,215 86,400 74,230 85.91% 96.20% 24 0 0 0 33,447.2 7,738 201,360 180,871 89.82% 97.39% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Nil

Nil

Nil

Un-schedule Maintenance

Nil

Nil

Nil

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 906.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 597.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 860.4 RHs 213.9 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :Fresh 4=3.20 min due to Everest Island mode.

SUMMARY Total Power Production

407,074

Average Production per Hr.

16,961

33 kV Export

0

Total Steam Production

243.04

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Amir Hamza Sr.Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 19 June- 2012 DAY COVERED: 18 June - 2012 Average Demand 16.90 MW Average Generation 16.90 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,441.2 3,315 86,400 77,037 89.16% 96.83% 24 0 0 0 52,882.7 3,319 86,400 75,509 87.39% 94.79% 24 0 0 0 56,285.2 3,220 86,400 72,294 83.67% 94.33% 23.8 0 0 0 33,471.2 7,731 201,360 180,808 89.79% 97.45% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0.2 99.17% 1 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Cyl 6/A dev

Nil

Nil

Un-schedule Maintenance

Nil

Nil

Pcc ball valve change and spark plug gap adjust

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 882.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 573.7 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 836.6 RHs 189.9 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :Fresh 3=1.18 min due to Everest E-3 trip. L-5=12 min due to uppl E-3 trip.

SUMMARY Total Power Production

405,648

Average Production per Hr.

16,902

33 kV Export

0

Total Steam Production

240.39

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Amir Hamza Sr.Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 20 June- 2012 DAY COVERED: 19 June - 2012 Average Demand 16.21 MW Average Generation 16.21 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,465.2 3,331 86,400 74,209 85.89% 92.83% 24 0 0 0 52,905.9 3,321 86,400 66,580 77.06% 86.41% 23.2 0 0 0 56,309.2 3,225 86,400 72,282 83.66% 93.39% 24 0 0 0 33,495.2 7,773 201,360 176,038 87.42% 94.36% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0.8 96.67% 2 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Cyl 8/A,3/B dev

Nil

Nil

Nil

Un-schedule Maintenance

Nil

Pcc ball valve change 3/B cyl. and spark plug change(old) cyl.3/B,6/B.

Nil

Nil

Nil

Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 858.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 550.5 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 812.6 RHs 165.9 RHs 882.1 RH T.C RPM A/B -Bank shown wrong in SCADA., Ht outlet Alternator 3-phase shorted. flexible pipe water leakage. T.C RPM A/B -Bank shown wrong in SCADA. Nil

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed :L-2=30 min due to lighting arrestor connected.

SUMMARY Total Power Production

389,109

Average Production per Hr.

16,213

33 kV Export

0

Total Steam Production

230.31

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Amir Hamza Sr. Shift Engineer

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 21 June- 2012 DAY COVERED: 20 June - 2012 Average Demand 16.792 MW Average Generation 16.792 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,489.2 3,442 86,400 77,214 89.37% 93.47% 24 0 0 0 52,929.2 3,425 86,400 71,079 82.27% 89.07% 23.3 0 0 0 56,333.2 3,435 86,400 73,864 85.49% 89.60% 24 0 0 0 33,519.2 7,791 201,360 180,841 89.81% 96.71% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0.7 97.08% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Nil

Nil

Nil

Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 834.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 527.2 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 788.6 RHs 141.9 RHs 882.1 RH T.C RPM A/B -Bank shown Alternator 3-phase shorted. wrong in SCADA.. T.C RPM A/B -Bank shown wrong in SCADA.

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed : No loadshed yesterday.

SUMMARY Total Power Production

402,998

Average Production per Hr.

16,792

33 kV Export

0

Total Steam Production

227.32

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 22 June- 2012 DAY COVERED: 21 June - 2012 Average Demand MW Average Generation 17.005 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,513.2 3,510 86,400 77,845 90.10% 92.41% 24 0 0 0 52,953.2 3,450 86,400 74,885 86.67% 90.44% 24 0 0 0 56,357.2 3,350 86,400 74,065 85.72% 92.12% 24 0 0 0 33,543.2 8,202 201,360 181,324 90.05% 92.11% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Nil

Nil

Nil

Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 810.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 503.2 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 764.6 RHs 117.9 RHs 882.1 RH T.C RPM A/B -Bank shown Alternator 3-phase shorted. wrong in SCADA.. T.C RPM A/B -Bank shown wrong in SCADA.

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed : Fresh-3=4:19hr. , MTC-1=4:43hr., MTC-2=4:46hr., MTC-3=4:40hr., MTC-4=4:48hr. Due to EPGCL Engin- 1 & 2 trip yesterday.

SUMMARY Total Power Production

408,119

Average Production per Hr.

17,005

33 kV Export

0

Total Steam Production

236.35

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 23 June- 2012 DAY COVERED: 22 June - 2012 Average Demand 17.057 MW Average Generation 17.057 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,537.2 3,478 86,400 77,800 90.05% 93.20% 24 0 0 0 52,977.2 3,473 86,400 76,915 89.02% 92.28% 24 0 0 0 56,381.2 3,331 86,400 73,905 85.54% 92.45% 24 0 0 0 33,567.2 7,895 201,360 180,738 89.76% 95.39% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Nil

Nil

Nil

Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 786.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 479.2 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 740.6 RHs 93.9 RHs 882.1 RH T.C RPM A/B -Bank shown Alternator 3-phase shorted. wrong in SCADA.. T.C RPM A/B -Bank shown wrong in SCADA.

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed : No loadshed yesterday.

SUMMARY Total Power Production

409,358

Average Production per Hr.

17,057

33 kV Export

0

Total Steam Production

235.36

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 24 June- 2012 DAY COVERED: 23 June - 2012 Average Demand MW Average Generation 17.097 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,561.2 3,517 86,400 77,960 90.23% 92.36% 24 0 0 0 53,001.2 3,457 86,400 77,065 89.20% 92.89% 24 0 0 0 56,405.2 3,324 86,400 74,065 85.72% 92.84% 24 0 0 0 33,591.2 7,855 201,360 181,230 90.00% 96.13% 24 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

0 100.00% 0 0

24 0.00% 0 0

Nil

Nil

Nil

Nil

Nil

Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 762.8 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 455.2 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 716.6 RHs 69.9 RHs 882.1 RH T.C RPM A/B -Bank shown Alternator 3-phase shorted. wrong in SCADA.. T.C RPM A/B -Bank shown wrong in SCADA.

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Nil

Remarks : Plant didn't trip yesterday. Loadshed : Fresh-3= 2:56hr.due to EPGCL Engine-3 problem yesterday.

SUMMARY Total Power Production

410,320

Average Production per Hr.

17,097

33 kV Export

0

Total Steam Production

243.74

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Md. Mohiuddin Sohag Sr. Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

MANAGEMENT INFORMATION SYSTEM

Daily Performance Report

DATE OF PREPERATION: 25 June- 2012 DAY COVERED: 24 June - 2012 Average Demand MW Average Generation 17.097 MW Last Plant Trip

06/06/2012 12:52 pm

Particulars

Total Running Hrs Peak Load(KW) Capacity, kWh To days production Capacity Factor Load Factor Today's Running Hrs Standby Downtime Hrs.

ENGINE / GENERATOR PERFORMANCE REPORT Engine No-1 Engine No-2 Engine No-3 Engine No-4 (10316) (10314) (10315) (17045)

50,583.9 3,426 86,400 63,005 72.92% 81.01% 22.7 0 0 0 53,024.5 3,423 86,400 63,458 73.45% 79.57% 23.3 0 0 0 56,427.7 3,261 86,400 58,749 68.00% 80.07% 22.5 0 0 0 33,613.8 7,924 201,360 144,102 71.56% 80.47% 22.6 0 0 0

Engine No-5 (17052)

27,972.7 0 201,360 0 0.00% #DIV/0! 0 0 0 0

ENGINE / GENERATOR PERFORMANCE REPORT

Schedule Maintenance Hrs. Stopage time due to external reason Unschedule maintenance + Trip Downtime Hrs. Engine Avilability No of Tripping for internal reason No of Tripping for external reason Cause Of Triping

1.3 94.58% 0 3

0.7 97.08% 1 3

1.5 93.75% 5 3

1.4 94.17% 0 3

24 0.00% 0 0

Plant trip

Cyl. Dev. - 8/A ( low load ) & Cyl. Dev. - 1/B, 9/B & plant plant trip trip Replace PCC ball valve, old S/P replace & orific clean of cyl. - 9/B. Plant trip. Nil

Plant trip.

Nil

Un-schedule Maintenance Schedule Maintenance Last maintenance Carried Out Next Schedule Maintenance Type Present Problem & Action Previous Problem & Action

Nil

Nil

Nil

Nil

Nil

Nil

Nil

Nil

1000 RH Maintenance 1000 RH Maintenance 1000 Hr Maintenance 1000 Hr Maintenance 2000 Hr Maintenance carried out at 50324.0 ERH carried out at 52458.0 ERH carried out at 56122.0ERH carried out at 32658.2 ERH carried out at 27854.8 ERH 1000 RH Maintenance after 740.1 RHs Winding temp high & Lt water temp high 1000 RH Maintnance after 431.9 RHS 1000 RH maintenance after 2000 RH maintenance After 1000RH maintenance after 694.1 RHs 47.3 RHs 882.1 RH T.C RPM A/B -Bank shown Alternator 3-phase shorted. wrong in SCADA.. T.C RPM A/B -Bank shown wrong in SCADA.

Lube oil temp. High

Lt water temp high

Nil

Nil

Nil

Nil

Remarks : Plant trip at - 8:04 AM due to Everest plant trip that time plant trip ( D.T - 16 min ). Plant trip at - 8:01 PM due to Everest plant trip that time plant trip ( D.T - 14 min ). Plant trip at - 1:32 AM due to Everest plant trip that time plant trip ( D.T 12 min ). Loadshed : Feeder - 1 = 51 min. ( P.S.D ), Feeder -2 = 52 min.( P.S.D ), Feeder - 3 = 1:29 Hr. ( P.S.D ) & OHL ( L - 4 mint. ), Feeder - 5 = 1:24 Hr. ( P.S.D ) & E - 3 trip, Fresh - 3 = 4:39 Hr.( P.S.D), Fresh - 4 = 9:09 Hr ( P.S.D ) & Everest E - 3 trip, MTC - 1 = 4:39 Hr ( P.S.D ); MTC - 2 = 4:00 Hr ( P.S.D ), MTC - 3 = 1:46 Hr. ( P.S.D ), MTC - 4 = 3:43 Hr. ( P.S.D ).

SUMMARY Total Power Production

329,314

Average Production per Hr.

13,721

33 kV Export

0

Total Steam Production

183.34

Status of Start Air Compressor

OK

Status of Boiler

OK

Prepared By Promod Sutradhar Shift Leader

Acknowledged by Md. Masud Alam Sr. Shift Leader

UPPL-1

UPPL-1

You might also like

- Particulars Engine No-1 (10316) Engine No-2 (10314) Engine No-3 (10315) Engine No-4 (17045) Engine No-5 (17052)Document40 pagesParticulars Engine No-1 (10316) Engine No-2 (10314) Engine No-3 (10315) Engine No-4 (17045) Engine No-5 (17052)masudalamNo ratings yet

- Manual BookDocument154 pagesManual BookAnonymous nHT1rzjmcNo ratings yet

- Trane AnalisisDocument13 pagesTrane AnalisisHendri PoerbaNo ratings yet

- PSRPT 2021-08-19 11.06.03Document9 pagesPSRPT 2021-08-19 11.06.03Ahmed Mohammed KhalafNo ratings yet

- Cat C280-12 Spec SheetsDocument16 pagesCat C280-12 Spec SheetsThan Htet100% (1)

- RP 1007 01Document23 pagesRP 1007 01Anil PanjaniNo ratings yet

- SC MCI40 WC StarCool ServicemanualDocument275 pagesSC MCI40 WC StarCool ServicemanualciupcicNo ratings yet

- MTU20V4000DS2800 2500kW DCCP PDFDocument4 pagesMTU20V4000DS2800 2500kW DCCP PDFNestor AlbarranNo ratings yet

- G3412 - 450 KW Performance DataDocument3 pagesG3412 - 450 KW Performance DataJacob De CasillasNo ratings yet

- Tad730ge 111797s01Document8 pagesTad730ge 111797s01roozbehxoxNo ratings yet

- Hybrid Servo-Driven IMMsDocument32 pagesHybrid Servo-Driven IMMsFalecyaRedinaNo ratings yet

- 3516-2fw00264-Shelf Drilling Ad1 Gen 1-Engine Overhaul Report@65047hrs ...Document30 pages3516-2fw00264-Shelf Drilling Ad1 Gen 1-Engine Overhaul Report@65047hrs ...Ken ANo ratings yet

- Auxillary Power ConsumptionDocument47 pagesAuxillary Power ConsumptionMohit KumarNo ratings yet

- Model: T1900 Diesel GensetDocument5 pagesModel: T1900 Diesel Gensetengnajeeb75No ratings yet

- Model: J300K Diesel GensetDocument5 pagesModel: J300K Diesel GensetJorge CarrascoNo ratings yet

- 1265 - 1010KVA DG Set SpecificationDocument35 pages1265 - 1010KVA DG Set SpecificationTien Nguyen100% (1)

- 70 KvaDocument4 pages70 KvaLeonardusHSijabatNo ratings yet

- Cat Electronic Technician 2020A v1.0 Product Status ReportDocument25 pagesCat Electronic Technician 2020A v1.0 Product Status ReportDamian BrzozowskiNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- GT Operation (Nanjin)Document146 pagesGT Operation (Nanjin)Ady FardyNo ratings yet

- Generator SetDocument4 pagesGenerator Setbiz2721No ratings yet

- M20CDocument79 pagesM20CMuhammad AsifNo ratings yet

- CC Pump Manual Full OriginalDocument109 pagesCC Pump Manual Full OriginalKanphong.smNo ratings yet

- File - 20220609 - 210203 - Ce Handing Over NotesDocument5 pagesFile - 20220609 - 210203 - Ce Handing Over NotesPhuc ChuNo ratings yet

- Grafica de Medidas para Recesion de Valvulas G3400Document3 pagesGrafica de Medidas para Recesion de Valvulas G3400carlos angelNo ratings yet

- Dri Equipment Breakdown Analysis Report: Date: - 19/05/2015Document8 pagesDri Equipment Breakdown Analysis Report: Date: - 19/05/2015abhinay02meNo ratings yet

- 1500 KvaDocument4 pages1500 KvaYeye AngelNo ratings yet

- Deutz 616Document6 pagesDeutz 616sdiamanNo ratings yet

- Td520ge PDFDocument11 pagesTd520ge PDFThanapong Usupan100% (1)

- Diesel Generator Set: Prime Model:LP90P Standby Model:LP100SDocument4 pagesDiesel Generator Set: Prime Model:LP90P Standby Model:LP100SLeonardusHSijabatNo ratings yet

- Model: T1400 Diesel GensetDocument5 pagesModel: T1400 Diesel Gensetengnajeeb75No ratings yet

- HvacDocument28 pagesHvacvarshneyrk@rediffmail.comNo ratings yet

- Highflux, Highpower Leds: Reliability DataDocument0 pagesHighflux, Highpower Leds: Reliability DataBudi SulaimanNo ratings yet

- Desiccant Dehumidifier ML1100Document2 pagesDesiccant Dehumidifier ML1100blackfzoneNo ratings yet

- CEP SamalkotDocument96 pagesCEP SamalkotkukugargNo ratings yet

- Cat C280-8Document16 pagesCat C280-8riz506100% (2)

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezNo ratings yet

- 2000kw Diesel Generator Datasheet X2000uc2 (English)Document4 pages2000kw Diesel Generator Datasheet X2000uc2 (English)HugoRinconNo ratings yet

- Caterpillar 3606 2425kVA GensetDocument6 pagesCaterpillar 3606 2425kVA GensetMuhammad Irfan KhanNo ratings yet

- Energy-Saving and Easy Maintenance: Printed in Japan (H)Document6 pagesEnergy-Saving and Easy Maintenance: Printed in Japan (H)Bánh Cuốn Tôm ThịtNo ratings yet

- 3612Document6 pages3612Chandrashekar PatigeNo ratings yet

- DV 10 Techical Leaflet PDFDocument12 pagesDV 10 Techical Leaflet PDFbalu9999No ratings yet

- High Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)Document26 pagesHigh Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)SAKDA MAPRADITKULNo ratings yet

- Abb Crane Duty Motor CatalogDocument10 pagesAbb Crane Duty Motor Catalogyaduvanshi1No ratings yet

- Marine Propulsion Engine: Fast VesselDocument4 pagesMarine Propulsion Engine: Fast VesselaldandanalNo ratings yet

- MTU Series 2000 M94Document272 pagesMTU Series 2000 M94latranca100% (1)

- g3520c Natural Gas For 1950Document6 pagesg3520c Natural Gas For 1950Shahzad AliNo ratings yet

- Cummins 250KVA 1Document4 pagesCummins 250KVA 1Pio Roni100% (2)

- VGF24GL GLD 8068 0710Document2 pagesVGF24GL GLD 8068 0710npsNo ratings yet

- Failures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Document5 pagesFailures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Ahmed Nahrawy100% (1)

- Taylor Power SystemsDocument4 pagesTaylor Power SystemsTeresa CarterNo ratings yet

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pages2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (2)

- 195 - DR 858 CP 858 7.5 - 10.0 HP Regenerative Blower (1) AMETEKDocument2 pages195 - DR 858 CP 858 7.5 - 10.0 HP Regenerative Blower (1) AMETEKFrancisco RenteriaNo ratings yet

- SCA Technical Spec GE Frame 9E S Rev1 9e SpecificationDocument144 pagesSCA Technical Spec GE Frame 9E S Rev1 9e Specificationzhangj5100% (2)

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Dz2000 Series Step Type Digital Indicating ControllerDocument8 pagesDz2000 Series Step Type Digital Indicating ControllermasudalamNo ratings yet

- 100/-Uvkv G J GVB Evsjv 'K Cövbre Ûi 75Zg Ôw Õ Gi DJVDJDocument1 page100/-Uvkv G J GVB Evsjv 'K Cövbre Ûi 75Zg Ôw Õ Gi DJVDJmasudalamNo ratings yet

- Kv‡Ri Wnmve: Μwgk Bs Zvwil Evi Weeib Rb Gyryix/Uvkv ‡Gvu Uvkv Gšíe¨Document3 pagesKv‡Ri Wnmve: Μwgk Bs Zvwil Evi Weeib Rb Gyryix/Uvkv ‡Gvu Uvkv Gšíe¨masudalamNo ratings yet

- 723PLUS Digital Speed Control For Reciprocating Engines-Process ControlDocument176 pages723PLUS Digital Speed Control For Reciprocating Engines-Process ControlmasudalamNo ratings yet

- 723PLUS Digital Speed Control For Reciprocating Engines - Performance Control 424'Document192 pages723PLUS Digital Speed Control For Reciprocating Engines - Performance Control 424'masudalamNo ratings yet

- Unique Power Plan T LTD - 1: Mechanical Job Summary Month of March'Document1 pageUnique Power Plan T LTD - 1: Mechanical Job Summary Month of March'masudalamNo ratings yet

- Start Air Compressor No 5 Maintenance HistoryDocument3 pagesStart Air Compressor No 5 Maintenance HistorymasudalamNo ratings yet

- 723PLUS Digital Control: ApplicationsDocument4 pages723PLUS Digital Control: ApplicationsmasudalamNo ratings yet

- UPPL-Generator Water Test Report-2013Document1 pageUPPL-Generator Water Test Report-2013masudalamNo ratings yet

- 723PLUS Digital Speed Control For Reciprocating Engines-DSLC™ CompatibleDocument166 pages723PLUS Digital Speed Control For Reciprocating Engines-DSLC™ CompatiblemasudalamNo ratings yet

- 723 Digital Control: Product SpecificationDocument4 pages723 Digital Control: Product SpecificationmasudalamNo ratings yet

- Product Manual 02881 (Revision D) : 723PLUS Digital Marine ControlDocument108 pagesProduct Manual 02881 (Revision D) : 723PLUS Digital Marine ControlmasudalamNo ratings yet

- 723PLUS Digital Speed Control For Reciprocating Engines: Product Manual 02882 (Revision A)Document154 pages723PLUS Digital Speed Control For Reciprocating Engines: Product Manual 02882 (Revision A)masudalamNo ratings yet

- 723PLUS Digital DSLC/MSLC Gateway: Product Manual 02831 (Revision C)Document112 pages723PLUS Digital DSLC/MSLC Gateway: Product Manual 02831 (Revision C)masudalamNo ratings yet

- Tipos de ExcitacionDocument15 pagesTipos de ExcitacionmasudalamNo ratings yet

- Unique Power Plant Limited: Lub Oil Filter Change HistoryDocument1 pageUnique Power Plant Limited: Lub Oil Filter Change HistorymasudalamNo ratings yet

- This Thesis Is Submitted in Partial Fulfillment For The Requirement of The Degree of Bachelor of Science in Electrical & Electronic EngineeringDocument9 pagesThis Thesis Is Submitted in Partial Fulfillment For The Requirement of The Degree of Bachelor of Science in Electrical & Electronic EngineeringmasudalamNo ratings yet

- Misir Ali Unsolved by Humayun AhmedDocument93 pagesMisir Ali Unsolved by Humayun AhmedShopnochura NahinNo ratings yet

- Local Item ListDocument57 pagesLocal Item Listmasudalam100% (1)

- Plant Shutdown Summary March, 13Document1 pagePlant Shutdown Summary March, 13masudalamNo ratings yet

- Regarding Control Air ReciverDocument1 pageRegarding Control Air RecivermasudalamNo ratings yet

- Unique Power Plant LTD.: Monthly Generator Performane CalculationDocument4 pagesUnique Power Plant LTD.: Monthly Generator Performane CalculationmasudalamNo ratings yet

- Cylinderwise Maintenance HistoryDocument11 pagesCylinderwise Maintenance HistorymasudalamNo ratings yet

- AlternatorDocument24 pagesAlternatorRashmi Singh100% (3)

- Trouble Report For UPPLDocument1 pageTrouble Report For UPPLmasudalamNo ratings yet

- Trouble Report For EPGCLDocument1 pageTrouble Report For EPGCLmasudalamNo ratings yet

- Scanner and Xcal Comperative Analysis v2Document22 pagesScanner and Xcal Comperative Analysis v2Ziya2009No ratings yet

- Shree New Price List 2016-17Document13 pagesShree New Price List 2016-17ontimeNo ratings yet

- Case Studies of Transportation Public-Private Partnerships Around The WorldDocument158 pagesCase Studies of Transportation Public-Private Partnerships Around The WorldzhenhuaruiNo ratings yet

- Port Name: Port of BaltimoreDocument17 pagesPort Name: Port of Baltimoremohd1khairul1anuarNo ratings yet

- Better - Homes.and - Gardens.usa - TruePDF December.2018Document136 pagesBetter - Homes.and - Gardens.usa - TruePDF December.2018MadaMadutsaNo ratings yet

- Assignment Booklet July 2021Document22 pagesAssignment Booklet July 2021Saksham TiwariNo ratings yet

- Surface TensionDocument13 pagesSurface TensionElizebeth GNo ratings yet

- Inferring The Speaker's Tone, ModeDocument31 pagesInferring The Speaker's Tone, Modeblessilda.delaramaNo ratings yet

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 pagesColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanNo ratings yet