Professional Documents

Culture Documents

Vertical Alignment

Uploaded by

Hassan TahirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vertical Alignment

Uploaded by

Hassan TahirCopyright:

Available Formats

Highway Engineering

The vertical alignment of a transportation facility consists of tangent grades (straight line in the vertical plane) vertical curves. Vertical alignment is documented by the profile.

Tangent grades are designated according to their slopes or grades. Maximum grades vary depending on the type of facility, and usually do not constitute an absolute standard. The effect of a steep grade is to slow down the heavier vehicles (which typically have the lowest power/weight ratios) and increase operating costs.

Passenger cars: all passenger cars can negotiate the grade up to 4 to 5% without much reduction in speed Trucks: effect of grade on speed is more important in trucks than on passenger cars. Max. Speed of truck depends on steepness of grade length of grade weight to power ratio of truck

Max. grade Itself is not a complete design critical length is also important Definition: max. Length of a designated upgrade on which a loaded truck can operate without unreasonable reduction in speed is critical length

For critical length of grade assumptions required are size and power of truck entry speed minimum truck speed below which interference to the following vehicle is considerd unreasonable.

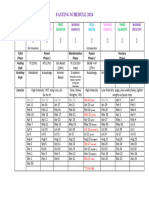

8.1

7.9

7.7

7.5

speed

7.3

1% upgrade

2% upgrade 3% upgrade 4% upgrade

7.1

6.9

6.7

6.5 0 1 2 3 4 5 6 7 8

distance

Vertical tangents with different grades are joined by vertical curves.

Symmetrical Vertical Curve

Vertical curves are normally parabolas centered about the point of intersection (P.I.) of the vertical tangents they join. Vertical curves are thus of the form

where

y = elevation of a point on the curve yo = elevation of the beginning of the vertical curve (BVC) g1 = grade just prior to the curve x = horizontal distance from the BVC to the point on the curve r = rate of change of grade

The rate of change of grade, in turn, is given by

where g2 is the grade just beyond the end of the vertical curve (EVC) and L is the length of the curve. Vertical curves are classified as sags where g2 > g1 and crests otherwise. Not that r (and hence the term rx2 /2) will be positive for sags and negative for crests. If grades are in percent, horizontal distance must be in stations If grades are dimensionless ratios, horizontal distances must be in meters.

The R is the percent per unit length The reciprocal of this is known as K value which is a measure of curvature K value is useful in determining minimum length of vertical curves for various design speeds

Design standards for vertical curves establish their minimum lengths for specific circumstances based on sight distance, on comfort standards involving vertical acceleration, or appearance criteria.

In most cases, sight distance or appearance standards will govern for highways. the equations used to calculate minimum lengths of vertical curves based on sight distance depend on whether the sight distance is greater than or less than the vertical curve length.

There are two types of vertical curves crust vertical curves summit vertical curves

For crest vertical curves, the minimum length depends on the sight distance the height of the drivers eye the height of the object to be seen over the crest of the curve.

When SL

When SL

where S = sight distance (from Table) L = vertical curve length A = absolute value of the algebraic difference in grades, in percent, |g1-g2| h1 = height of eye h2 = height of object

If we use the formulae for the calculation of minimum length then in actual the K line will touch the vertical axis So, for small value of A the vertical curve length will be zero But is no desirable design practice General practise is to provide L min= 0.6v, where V is the design speed in km/hr. L is in metre .

A minimum grade of 0.3% should be reached at a point about 50ft from the top level of curve This corresponds to K=167 per percent change in grade Values below this indicates flatter curves, so special care for drainage is required. K=167 is not a design limit, only drainage should be designed more carefully when k is more than 167

For sag vertical curves, stopping sight distance is based on the distance illuminated by the headlights at night. Design standards are based on an assumed headlight height of 600 mm and an upward divergence of the headlight beam of 1. As in the case of crest vertical curves, the formulas for minimum length of vertical curve depend on whether the length of the curve is greater or less than the sight distance.

For sag vertical curves, the formula is

Finally, vertical curve lengths may be limited by the need to provide clearances over or under objects such as overpasses or drainage structures. For the design of sag vertical curve the driver,s comfort is also taken into account. But for crest vertical curve this factor is not considerd.

ANY QUESTION????????

You might also like

- Scientology Abridged Dictionary 1973Document21 pagesScientology Abridged Dictionary 1973Cristiano Manzzini100% (2)

- ETABS RC Slab Design PDFDocument29 pagesETABS RC Slab Design PDFLim Wee BengNo ratings yet

- Concrete Column Design - Design ChartsDocument6 pagesConcrete Column Design - Design ChartsSajid Mehmood100% (1)

- Vertical Alignment DesignDocument41 pagesVertical Alignment DesignNana Kwame Osei AsareNo ratings yet

- Wind DesignDocument5 pagesWind DesignSedin HodžićNo ratings yet

- Designing Vertical Road AlignmentsDocument28 pagesDesigning Vertical Road Alignmentsbe18102024 Konark AroraNo ratings yet

- Monster Visual Discrimination CardsDocument9 pagesMonster Visual Discrimination CardsLanaNo ratings yet

- AWS D1.1 StandardDocument3 pagesAWS D1.1 StandardVI King Pro0% (1)

- Google Search StringsDocument12 pagesGoogle Search StringsPrashant Sawnani100% (1)

- Continuous Sampling PlanDocument2 pagesContinuous Sampling PlanAnonymous wA6NGuyklDNo ratings yet

- Link and Internal HingeDocument10 pagesLink and Internal Hingesagar kumarNo ratings yet

- Design of Vertical CurvesDocument25 pagesDesign of Vertical CurvesBridger WangNo ratings yet

- Floodway Design GuideDocument52 pagesFloodway Design GuideSana NeNo ratings yet

- Vertical CurveDocument10 pagesVertical CurveLarete PaoloNo ratings yet

- CE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemDocument17 pagesCE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemwinminthetgeoNo ratings yet

- The Unbounded MindDocument190 pagesThe Unbounded MindXtof ErNo ratings yet

- Second Quarterly Examination Math 9Document2 pagesSecond Quarterly Examination Math 9Mark Kiven Martinez94% (16)

- Magazines o o o oDocument14 pagesMagazines o o o oTemesgenAbiyNo ratings yet

- CSD 366 Concrete: Topics: 5 Two Way Slabs On Columns 6 ShearDocument55 pagesCSD 366 Concrete: Topics: 5 Two Way Slabs On Columns 6 ShearChan Nov100% (1)

- Setting Out of Circular CurvesDocument9 pagesSetting Out of Circular CurvesEvarist EdwardNo ratings yet

- Horizontal Curves-Superelevation-And Geometric Design StandardsDocument41 pagesHorizontal Curves-Superelevation-And Geometric Design Standardsmannie edet100% (1)

- Akhmatova, Anna - 45 Poems With Requiem PDFDocument79 pagesAkhmatova, Anna - 45 Poems With Requiem PDFAnonymous 6N5Ew3No ratings yet

- CSD 366 CONCRETE DEFLECTION MODELSDocument9 pagesCSD 366 CONCRETE DEFLECTION MODELSChan Nov100% (1)

- Portal FrameDocument7 pagesPortal FrameAzzren Azzrain100% (2)

- PBS-P100 Facilities Standards GuideDocument327 pagesPBS-P100 Facilities Standards Guidecessna5538cNo ratings yet

- Vertical Curve Design and ComputationsDocument25 pagesVertical Curve Design and ComputationsLokesh Kumar MeenaNo ratings yet

- Transition CurveDocument10 pagesTransition CurveMody JiffryNo ratings yet

- Tirfor: Lifting and Pulling Machines With Unlimited Wire RopeDocument26 pagesTirfor: Lifting and Pulling Machines With Unlimited Wire RopeGreg ArabazNo ratings yet

- QP P1 APR 2023Document16 pagesQP P1 APR 2023Gil legaspiNo ratings yet

- Vertical AlignmentDocument56 pagesVertical AlignmentThomas Ditto ErlanggaNo ratings yet

- Oracle Unified Method (OUM) White Paper - Oracle's Full Lifecycle Method For Deploying Oracle-Based Business Solutions - GeneralDocument17 pagesOracle Unified Method (OUM) White Paper - Oracle's Full Lifecycle Method For Deploying Oracle-Based Business Solutions - GeneralAndreea Mirosnicencu100% (1)

- Initial Width and Depth of BeamDocument3 pagesInitial Width and Depth of BeamsssdadaNo ratings yet

- Casestudy3 Hbo MaDocument2 pagesCasestudy3 Hbo Ma132345usdfghjNo ratings yet

- C-Dot Max-XlDocument39 pagesC-Dot Max-XlGourav Roy100% (3)

- 3A1 Lecture 14Document26 pages3A1 Lecture 14nonongmon100% (1)

- Geometric Design of Highways and Railroads: Vertical AlignmentDocument36 pagesGeometric Design of Highways and Railroads: Vertical AlignmentEstephany BrillantesNo ratings yet

- Vertical Curve Part IDocument36 pagesVertical Curve Part IALINo ratings yet

- 12 Vertical Alignment 2Document48 pages12 Vertical Alignment 2Waqas Muneer KhanNo ratings yet

- Sight Distance and Road AlignmentDocument45 pagesSight Distance and Road AlignmentSyed Ali Raza ShahNo ratings yet

- Chapter # 7 - Design of One Way SlabsDocument62 pagesChapter # 7 - Design of One Way SlabsPharo TotNo ratings yet

- Introduction To Beams: Part ADocument49 pagesIntroduction To Beams: Part AMorad AJNo ratings yet

- EARTHQUAKE LATERAL FORCE ANALYSIS (STATIC VS DYNAMIC) PDFDocument41 pagesEARTHQUAKE LATERAL FORCE ANALYSIS (STATIC VS DYNAMIC) PDFJoshua Magat100% (1)

- Engineeringinterviewquestions Com RCC Structures Design Multiple Choice QuestionDocument87 pagesEngineeringinterviewquestions Com RCC Structures Design Multiple Choice QuestionRajeev BansalNo ratings yet

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pages(LECT-21,22) Prestressed Concrete SlabsSushil MundelNo ratings yet

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Document15 pagesAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Appendix A Example 2 2Document76 pagesAppendix A Example 2 2魏学军No ratings yet

- Lateral Load Example PDFDocument19 pagesLateral Load Example PDFSA023100% (1)

- Preliminary Design ReportDocument16 pagesPreliminary Design Reportapi-443631703No ratings yet

- Pavement DesignDocument17 pagesPavement DesignDhanushka Manjula100% (1)

- Design of Short Axially Loaded ColumnsDocument38 pagesDesign of Short Axially Loaded ColumnsMohamed Nk100% (1)

- Derive bending equation: M/I = σ/y = E/RDocument3 pagesDerive bending equation: M/I = σ/y = E/Ryogesh vNo ratings yet

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 pagesVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanNo ratings yet

- Unit-I Thin Plate Theory, Structural InstabilityDocument78 pagesUnit-I Thin Plate Theory, Structural InstabilityNirav LakhaniNo ratings yet

- CE 402 - Module 2Document62 pagesCE 402 - Module 2lakshmi dileep100% (1)

- Slab Design Sandhi KholaDocument15 pagesSlab Design Sandhi Kholasakar shresthaNo ratings yet

- Castigliano 2nd TheoremDocument64 pagesCastigliano 2nd TheoremMađar Robert ErdešiNo ratings yet

- Drain Design (Proag)Document12 pagesDrain Design (Proag)Jeedaran ArshaadNo ratings yet

- The Moment Distribution Method2Document62 pagesThe Moment Distribution Method2Pravin KenNo ratings yet

- Slab Form DesignDocument9 pagesSlab Form DesignRsjBugtongNo ratings yet

- 1992 Esdep Boxgirders AdvancedmethodsDocument16 pages1992 Esdep Boxgirders Advancedmethodsvishal varshneyNo ratings yet

- Syllabus: MX ROAD Total Duration: 64hrs Theory:2hrs/DayDocument4 pagesSyllabus: MX ROAD Total Duration: 64hrs Theory:2hrs/DayM RoyNo ratings yet

- Ekspan EA-EQF-EKR Series Bearing BrochureDocument12 pagesEkspan EA-EQF-EKR Series Bearing Brochurechithirai10No ratings yet

- Strip method for slab design optimizationDocument22 pagesStrip method for slab design optimizationgirma kebedeNo ratings yet

- Vertical CURVE 3 10102016Document28 pagesVertical CURVE 3 10102016Jf OngNo ratings yet

- BOUSSINESQ FORMULAE for VERTICAL STRESS σ Z under LOADED AREASDocument2 pagesBOUSSINESQ FORMULAE for VERTICAL STRESS σ Z under LOADED AREASmarius1979No ratings yet

- 7-Geometric Design and Vertical CurvesDocument27 pages7-Geometric Design and Vertical Curveshassan100% (1)

- Abutment Design Example To BD 30Document16 pagesAbutment Design Example To BD 30Muzammil Moosafeer100% (1)

- CH 12 Compound - CurveDocument19 pagesCH 12 Compound - CurveAbdirahman Waasuge100% (1)

- Determining Moment-Curvature Relationship of Reinforced Concrete Columns (#364338) - 379911Document7 pagesDetermining Moment-Curvature Relationship of Reinforced Concrete Columns (#364338) - 379911srikantheraNo ratings yet

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Vertical CurveDocument24 pagesVertical CurveweynNo ratings yet

- Lecture 6 The Alignment VerticalDocument18 pagesLecture 6 The Alignment VerticalAbdulaziz AbdiNo ratings yet

- Deformation Analysis Simplified MethodsDocument42 pagesDeformation Analysis Simplified MethodsHassan TahirNo ratings yet

- MemosDocument5 pagesMemosHassan TahirNo ratings yet

- Horizontal Alignment TablesDocument8 pagesHorizontal Alignment TablesHassan TahirNo ratings yet

- Development of Comprehensive Low-Volume Pavement Design ProceduresDocument41 pagesDevelopment of Comprehensive Low-Volume Pavement Design ProceduresHassan TahirNo ratings yet

- CE-432 Introduction to Hydraulics Engineering Lec #1Document25 pagesCE-432 Introduction to Hydraulics Engineering Lec #1Hassan TahirNo ratings yet

- Energy CRISES IN PAKISTANDocument10 pagesEnergy CRISES IN PAKISTANHassan TahirNo ratings yet

- Delhi (The Capital of India) : Ebook by Ssac InstituteDocument27 pagesDelhi (The Capital of India) : Ebook by Ssac InstituteAnanjay ChawlaNo ratings yet

- Decembermagazine 2009Document20 pagesDecembermagazine 2009maria_diyah4312No ratings yet

- History and Development of the Foodservice IndustryDocument23 pagesHistory and Development of the Foodservice IndustryMaria Athenna MallariNo ratings yet

- OPHTHALDocument8 pagesOPHTHALVarun ChandiramaniNo ratings yet

- Internal Resistance and Matching in Voltage SourceDocument8 pagesInternal Resistance and Matching in Voltage SourceAsif Rasheed Rajput100% (1)

- CP Mother's Day Lesson PlanDocument2 pagesCP Mother's Day Lesson PlanAma MiriNo ratings yet

- GastrectomyDocument19 pagesGastrectomyCyrus GarciaNo ratings yet

- Inspection and Acceptance Report: Stock No. Unit Description QuantityDocument6 pagesInspection and Acceptance Report: Stock No. Unit Description QuantityAnj LeeNo ratings yet

- Moon Fast Schedule 2024Document1 pageMoon Fast Schedule 2024mimiemendoza18No ratings yet

- PrintDocument18 pagesPrintHookandcrookNo ratings yet

- Smart EE June 2022 - PackageDocument19 pagesSmart EE June 2022 - PackageMercy FeNo ratings yet

- WEEK 8. - Gen Math-PortfolioDocument12 pagesWEEK 8. - Gen Math-PortfolioOreo ProductionsNo ratings yet

- JTP Brochure - 2Document6 pagesJTP Brochure - 2YAKOVNo ratings yet

- Organizational Behaviour Group Assignment-2Document4 pagesOrganizational Behaviour Group Assignment-2Prateek KurupNo ratings yet

- Inertial Reference Frames: Example 1Document2 pagesInertial Reference Frames: Example 1abhishek murarkaNo ratings yet

- ??????? ?? ??????Document29 pages??????? ?? ??????Aysha ShahabNo ratings yet

- SolarBright MaxBreeze Solar Roof Fan Brochure Web 1022Document4 pagesSolarBright MaxBreeze Solar Roof Fan Brochure Web 1022kewiso7811No ratings yet