Professional Documents

Culture Documents

Presented By:-: Rohit Sharma EEE 1711580

Uploaded by

Naveen KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presented By:-: Rohit Sharma EEE 1711580

Uploaded by

Naveen KumarCopyright:

Available Formats

Presented by:-

ROHIT SHARMA

EEE

1711580

These are the energy resources, which we are using to

generate power for the past 200 years.

Ex : Thermal, Hydel, Nuclear.

NON CONVENTIONAL ENERGY SOURCES :

These are the energy resources, which are rarely used to

generate power.

Ex : Wind, solar, Tidal, Geo-Thermal, Ocean.

A power plant is a facility to generate

electric power with continuous energy

conversion

Heat Energy

Mechanical Energy

Electrical Energy

A thermal power station is a power plant in

which the prime mover is steam driven.

Water is heated, turns into steam and spins

a steam turbine which either drives an

electrical generator or does some other work,

like ship propulsion.

Working Principle :

Coal is burnt in the furnace which releases the heat energy.

This heat energy is used to convert the water into high pressure

steam in the boiler.

This high pressure & high temperature steam is passed through the

turbine, Which rotates the turbine shaft. (where the heat energy is

converted into mechanical energy)

The turbine is coupled with the generator to produce the electrical

energy.

The steam coming out of the turbine passes through the condenser,

where the steam is condensed into water and then circulated to the

boiler.

OPERATIONS OF A THERMAL POWER

STATION:

Below is a Diagram of the Basic Operation of a Thermal

Power Station.

Superheater

Fossil fuel power plants can have a superheater and/or

reheater section in the steam generating furnace

In a fossil fuel plant, after the steam is conditioned by

the drying equipment inside the steam drum, it is

piped from the upper drum area into tubes inside an

area of the furnace known as the superheter.

Reheater:-

Power plant furnaces may have a reheater section

containing tubes heated by hot flue gases

outside the tubes. Exhaust steam from the high

pressure turbine is rerouted to go inside the

reheater tubes to pickup more energy to go drive

intermediate or lower pressure turbines. This is called

thermal power plant.

Steam turbine-driven electric generator:

The steam turbine generator being rotating equipment

generally has a heavy, large diameter shaft.

The shaft therefore requires not only supports but also

has to be kept in position while running. To minimise

the frictional resistance to the rotation, the shaft has a

number of bearings

Feedwater heater: Preheating the feedwater reduces

the irreversibilities involved in steam generation and

therefore improves the thermodynamic efficiency of

the system. This reduces plant operating costs and also

helps to avoid thermalshock to the boiler metal when

the feed-water is introduced back into the steam cycle.

Deaerator:

Generally, power stations use a deaerator to provide

for the removal of air and other dissolved gases from

the boiler feed water.

A deaerator typically includes a vertical, domed

deaeration section mounted on top of a horizontal

cylindrical vessel which serves as the deaerated boiler

feed water storage tank.

There are many different designs for a deaerator and

the designs will vary from one manufacturer to another

Initial cost is low compared to hydel

plant.

Generation of power is continuous.

Less space is required.

It can respond to rapidly changing load.

It can be located near the load centre,

hence transmission cost & losses are

reduced.

Transportation & handling of fuel is major

difficulty.

Long time required for erection.

Maintenance & operation cost are high.

Efficiency of the plant is less.

Power generation cost is high compared to hydel

power plants.

Coal resources are depleting continuously.

Life of the power plant is comparatively less.

You might also like

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Thermal Power PlantsDocument24 pagesThermal Power Plantslakshmigsr6610100% (1)

- Me Lab 3Document27 pagesMe Lab 3Jerome Vega AndesNo ratings yet

- Industrial SayariDocument14 pagesIndustrial SayariSayari RoychoudhuryNo ratings yet

- PoweplantDocument33 pagesPoweplantAgateNo ratings yet

- Layout of Thermal Power PlantDocument21 pagesLayout of Thermal Power PlantRaj_Jai03100% (1)

- Report On Thermal Power PlantDocument22 pagesReport On Thermal Power PlantNitinNo ratings yet

- Thermal Power PlantDocument27 pagesThermal Power Plantvenki249100% (1)

- Project Report by Manish YadavDocument53 pagesProject Report by Manish Yadavmanish yaduvanshiNo ratings yet

- Water HarvestingDocument44 pagesWater HarvestingTanmay KhuranaNo ratings yet

- Power Plant Engineering OutlineDocument27 pagesPower Plant Engineering OutlineDexter Baret0% (1)

- Thermal Power - WikipediaDocument24 pagesThermal Power - WikipediaEusebia MaedzwaNo ratings yet

- Cfakepathlayoutofthermalpowerplant 091031114144 Phpapp01Document21 pagesCfakepathlayoutofthermalpowerplant 091031114144 Phpapp01Shruti GuptaNo ratings yet

- Steam Power Plant PresentationDocument37 pagesSteam Power Plant PresentationsharenslaNo ratings yet

- Thermal Power Plant: Gaini Zail Singh Punjab Technical University Campus (Bathinda)Document30 pagesThermal Power Plant: Gaini Zail Singh Punjab Technical University Campus (Bathinda)Sriram ramsNo ratings yet

- Electric Power Generating Stations: A Presentation OnDocument29 pagesElectric Power Generating Stations: A Presentation OnSaravanan T YNo ratings yet

- Basic Civil and Mechanical Engineering Unit III Classification of Power PlantsDocument21 pagesBasic Civil and Mechanical Engineering Unit III Classification of Power PlantsSiman NapstervkkNo ratings yet

- Power PlantDocument4 pagesPower PlantNumair AshrafNo ratings yet

- Thermal Power Plant Project ReportDocument63 pagesThermal Power Plant Project Reportasutoshjena28171% (24)

- Abhishek Kumar Asif Ahmad Niket Rakeshan Zeeshan AliDocument21 pagesAbhishek Kumar Asif Ahmad Niket Rakeshan Zeeshan AliSuphi YükselNo ratings yet

- Thermal Power Plant Diagram All You Need To Know About ItDocument7 pagesThermal Power Plant Diagram All You Need To Know About Itngoc hoangNo ratings yet

- DVC Mejia ReportDocument37 pagesDVC Mejia ReportRahul RoyNo ratings yet

- Gajendra KumarDocument23 pagesGajendra KumarGAJENDRA KUMARNo ratings yet

- Thermal Power PlantDocument42 pagesThermal Power PlantAravind C.KNo ratings yet

- Thermal Power StationDocument17 pagesThermal Power StationJayAr EsquilloNo ratings yet

- EET 411 Chapter 1Document24 pagesEET 411 Chapter 18gfdtyyrgnNo ratings yet

- REPORT On Power Plants and Electric Transmission196035Document11 pagesREPORT On Power Plants and Electric Transmission196035Rohit SaxenaNo ratings yet

- A Report On Industrial VisitDocument15 pagesA Report On Industrial VisitChandni Bhagchandani100% (1)

- Training ReportDocument61 pagesTraining ReportAnkur PanchalNo ratings yet

- Thermal Power PlantDocument11 pagesThermal Power PlantAnand Kalani100% (1)

- Report On Jenco Thermal Power PlantDocument18 pagesReport On Jenco Thermal Power PlantMuhammadAbbasJafriNo ratings yet

- Industrial Training AT: Submitted By: Rishikesh (11-1-6-002) NIT, SilcharDocument26 pagesIndustrial Training AT: Submitted By: Rishikesh (11-1-6-002) NIT, SilcharRakesh Roshan KeshriNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power PlantmudarNo ratings yet

- Thermal Power Plant BasicsDocument79 pagesThermal Power Plant BasicsMukundan SwamynathanNo ratings yet

- Thermal Power Plant: Name: Ayesha Khadri USN: 1WS18AT001Document8 pagesThermal Power Plant: Name: Ayesha Khadri USN: 1WS18AT001Ash khadriNo ratings yet

- Steam Power Plant: Boiler CondenserDocument4 pagesSteam Power Plant: Boiler Condenserwajahat aliNo ratings yet

- Tharmal 2Document48 pagesTharmal 2Prittam Kumar JenaNo ratings yet

- Thermal EngineeringDocument10 pagesThermal Engineeringlokeshdhangar842No ratings yet

- Different Types of Power Plants in India and Abroad.: Siddhant Yadav RA1911026010043 Waste To Wealth To Wheels AssignmentDocument5 pagesDifferent Types of Power Plants in India and Abroad.: Siddhant Yadav RA1911026010043 Waste To Wealth To Wheels AssignmentSiddhant YadavNo ratings yet

- EEE Notes Unit 3 Conventional Energy Resources PDFDocument8 pagesEEE Notes Unit 3 Conventional Energy Resources PDFAyush NandurkarNo ratings yet

- DVC Mejia Thermal Power StationReportDocument35 pagesDVC Mejia Thermal Power StationReportRahul RoyNo ratings yet

- Thermal Power PlantDocument35 pagesThermal Power PlantAngelaa DassNo ratings yet

- Thermal Power Generation Full Seminar Report 74537Document23 pagesThermal Power Generation Full Seminar Report 74537Umang Vyas88% (8)

- Introduction and Thermal Power PlantDocument27 pagesIntroduction and Thermal Power PlantKshitij AggarwalNo ratings yet

- Power System by PawanDocument20 pagesPower System by PawanPäwän Kümär MäüryäNo ratings yet

- Copy of A Report On Industrial VisitDocument15 pagesCopy of A Report On Industrial Visitrafik1995No ratings yet

- Report On "Generation of Thermal Power" AT NTPC DadriDocument17 pagesReport On "Generation of Thermal Power" AT NTPC DadriVaibhav RaoNo ratings yet

- Geothermal Power PlantDocument6 pagesGeothermal Power PlantDonabell B. MonteclarosNo ratings yet

- Power Plant EngineeringDocument25 pagesPower Plant EngineeringlitonNo ratings yet

- Types of Power Plant and Their Working PrinciplesDocument11 pagesTypes of Power Plant and Their Working PrinciplesRamzi JamalNo ratings yet

- Mani Report 1Document53 pagesMani Report 1Mani MukatiNo ratings yet

- Honorable Chief Engineer (Thermal) Genco, FaisalabadDocument50 pagesHonorable Chief Engineer (Thermal) Genco, FaisalabadraowaleedahmadNo ratings yet

- 17.THERMAL POWER PLANT PPT 1Document25 pages17.THERMAL POWER PLANT PPT 1Amit kumar Gupta100% (6)

- Thermal Power PlantDocument5 pagesThermal Power PlantAnudeep ChittluriNo ratings yet

- تقرير محطات الطاقهDocument45 pagesتقرير محطات الطاقهعبد الرحمن إبراهيمNo ratings yet

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)

- PLT Lecture NotesDocument5 pagesPLT Lecture NotesRamzi AbdochNo ratings yet

- PVAI VPO - Membership FormDocument8 pagesPVAI VPO - Membership FormRajeevSangamNo ratings yet

- Rating SheetDocument3 pagesRating SheetShirwin OliverioNo ratings yet

- Basic of An Electrical Control PanelDocument16 pagesBasic of An Electrical Control PanelJim Erol Bancoro100% (2)

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDocument9 pagesForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaNo ratings yet

- Data Sheet WD Blue PC Hard DrivesDocument2 pagesData Sheet WD Blue PC Hard DrivesRodrigo TorresNo ratings yet

- Tradingview ShortcutsDocument2 pagesTradingview Shortcutsrprasannaa2002No ratings yet

- Zelio Control RM35UA13MWDocument3 pagesZelio Control RM35UA13MWSerban NicolaeNo ratings yet

- Hager Pricelist May 2014Document64 pagesHager Pricelist May 2014rajinipre-1No ratings yet

- Avalon LF GB CTP MachineDocument2 pagesAvalon LF GB CTP Machinekojo0% (1)

- Audit On ERP Implementation UN PWCDocument28 pagesAudit On ERP Implementation UN PWCSamina InkandellaNo ratings yet

- Micron Interview Questions Summary # Question 1 Parsing The HTML WebpagesDocument2 pagesMicron Interview Questions Summary # Question 1 Parsing The HTML WebpagesKartik SharmaNo ratings yet

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Document3 pagesAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNo ratings yet

- Weekly Learning PlanDocument2 pagesWeekly Learning PlanJunrick DalaguitNo ratings yet

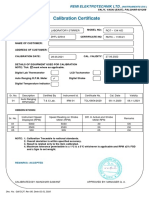

- Calibration CertificateDocument1 pageCalibration CertificateSales GoldClassNo ratings yet

- PFI High Flow Series Single Cartridge Filter Housing For CleaningDocument2 pagesPFI High Flow Series Single Cartridge Filter Housing For Cleaningbennypartono407No ratings yet

- BASUG School Fees For Indigene1Document3 pagesBASUG School Fees For Indigene1Ibrahim Aliyu GumelNo ratings yet

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajNo ratings yet

- Gender Ratio of TeachersDocument80 pagesGender Ratio of TeachersT SiddharthNo ratings yet

- (X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Document9 pages(X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Bharath KumarNo ratings yet

- Cam Action: Series: Inch StandardDocument6 pagesCam Action: Series: Inch StandardVishwa NNo ratings yet

- What Is Retrofit in Solution Manager 7.2Document17 pagesWhat Is Retrofit in Solution Manager 7.2PILLINAGARAJUNo ratings yet

- Module 5 Data Collection Presentation and AnalysisDocument63 pagesModule 5 Data Collection Presentation and AnalysisAngel Vera CastardoNo ratings yet

- Hotel Reservation SystemDocument36 pagesHotel Reservation SystemSowmi DaaluNo ratings yet

- Rebar Coupler: Barlock S/CA-Series CouplersDocument1 pageRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefNo ratings yet

- XgxyDocument22 pagesXgxyLïkïth RäjNo ratings yet

- 23 Things You Should Know About Excel Pivot Tables - Exceljet PDFDocument21 pages23 Things You Should Know About Excel Pivot Tables - Exceljet PDFRishavKrishna0% (1)

- Personal Best B1+ Unit 1 Reading TestDocument2 pagesPersonal Best B1+ Unit 1 Reading TestFy FyNo ratings yet

- Check Fraud Running Rampant in 2023 Insights ArticleDocument4 pagesCheck Fraud Running Rampant in 2023 Insights ArticleJames Brown bitchNo ratings yet

- BSCSE at UIUDocument110 pagesBSCSE at UIUshamir mahmudNo ratings yet