Professional Documents

Culture Documents

2006-Chocolate Production

Uploaded by

Aman Singh0 ratings0% found this document useful (0 votes)

1 views11 pagesOriginal Title

2006-Chocolate production.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views11 pages2006-Chocolate Production

Uploaded by

Aman SinghCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 11

Chocolate production

Anniina Teittinen - 2006

The production

Harvesting the cocoa beans

Fermenting

Roasting

Blending

Conching

Tempering

Moulding

Storing

Harvesting

Harvesting the cacao pods

Separating the beans

Fermenting

Pouring into baskets

Fermentation

- biochemical changes

- determines the smell, taste and quality

Drying the beans

Bagging for transport

Roasting

cleaning, inspecting and sorting the beans

at the factory

Roasted in special equipment

at a temperature of 130150

the shells are removed and the cocoa

beans are crushed into cocoa nibs

cocoa-nibs are ground (75 microns)

cocoa liquor

Blending

Cocoa liquor, sugar, cocoa butter

= plain dark chocolate

+ milk or milk powder and vanilla

= milk chocolate

- cocoa liquor

= white chocolate

Conching

intensive mixing at high temperature

A conche (container filled with metal

beads) acts as grinder, also heavy rollers

can be used

more homogeneous consistency

the length of the process determines the final

smoothness and quality of the chocolate

Tempering

long and complex process

chocolate mass must be cooled

specific heat treatment

the problem: cocoa-butter is a polymorphic fat

crystallizes and congeals

takes different consistencies

the purpose:

to assure that only the best form is present

the uniform sheen and crisp bite

best appearance and mouth feel

most stable crystals so the texture and appearance will not

degrade over time

Moulding

pouring into heated moulds

adding extras, if wanted (like nuts)

the chocolate solidifies

packed

Storing

ideal temperature between 15 and 19

relative humidity of less than 50 %

stored away from other foods

can absorbs different aromas

Repetition

You might also like

- Bakery Manufacturing ProcessesDocument26 pagesBakery Manufacturing ProcessesKhundrakpam Satyabarta50% (2)

- Chapter 12 - ConfectioneryDocument30 pagesChapter 12 - Confectioneryninacool26100% (1)

- Cocoa ProcessingDocument4 pagesCocoa ProcessingcjachemNo ratings yet

- Chapter 3 - Cake Decor 2021Document35 pagesChapter 3 - Cake Decor 2021Ain Natasya ZulfikreeNo ratings yet

- Agenda: - Moulding StarchDocument60 pagesAgenda: - Moulding StarchISRAEL ATONAL SALAZAR100% (2)

- Beryl's ChocolateDocument25 pagesBeryl's ChocolateKhairul Anuar Mohd Isa60% (5)

- ChocolateDocument4 pagesChocolatemeet143bmNo ratings yet

- Guidelines For Final Project: Bachelor of Journalism and Mass Communication BJMC Vi-SemesterDocument14 pagesGuidelines For Final Project: Bachelor of Journalism and Mass Communication BJMC Vi-SemesterAman SinghNo ratings yet

- Chocolate Production: Anniina Teittinen - 2006Document11 pagesChocolate Production: Anniina Teittinen - 2006Aman SinghNo ratings yet

- Cocoa & ChocolateDocument28 pagesCocoa & ChocolateAdarsh ShrivastavaNo ratings yet

- Presentation Realised by Pădurean AlexandruDocument29 pagesPresentation Realised by Pădurean AlexandruAS DenisNo ratings yet

- Wa0009.Document11 pagesWa0009.jadhavpayal493No ratings yet

- Physical and Sensory Consideration For Better Formulation of Chocolate Products (Susanto Purwo)Document38 pagesPhysical and Sensory Consideration For Better Formulation of Chocolate Products (Susanto Purwo)Purnama HadiNo ratings yet

- How To Make ChocolateDocument14 pagesHow To Make ChocolateHaris Hafiy HafizNo ratings yet

- ChocolateDocument24 pagesChocolateKHOZA SBUSISIWENo ratings yet

- Lecture 5. Chocolate Manufacturing-1Document34 pagesLecture 5. Chocolate Manufacturing-1Store22june7100% (1)

- ChocolateDocument2 pagesChocolateapi-259636807No ratings yet

- Chapter 11 - Cookie MakingDocument31 pagesChapter 11 - Cookie MakingamalinaNo ratings yet

- Cocoa ProcessingDocument3 pagesCocoa ProcessingCNJSWAMI100% (1)

- BreadsDocument17 pagesBreadsMarissa AlcantaraNo ratings yet

- ch04 Tempering ChocolateDocument20 pagesch04 Tempering ChocolateYarina MoralesNo ratings yet

- Chocolate in EnglishDocument1 pageChocolate in EnglishmikaarsinghNo ratings yet

- Chocolate Process: Elier Michael Oropeza Esparza 6202Document9 pagesChocolate Process: Elier Michael Oropeza Esparza 6202Ruben Eduardo Sanchez LopezNo ratings yet

- Malts and Malting: Andy HejlDocument27 pagesMalts and Malting: Andy HejlJ Elver SilvaNo ratings yet

- Production Process of ChocolateDocument12 pagesProduction Process of ChocolateAtul MahaleNo ratings yet

- Chapter 3 - Cake DecorDocument35 pagesChapter 3 - Cake Decorninacool26No ratings yet

- Cocoa ProcessingDocument15 pagesCocoa ProcessingVijay Kumar KothaNo ratings yet

- ChocolatesDocument15 pagesChocolatesvinay4u_92No ratings yet

- Chocolate From Cocoa - PPT 5.15Document21 pagesChocolate From Cocoa - PPT 5.15Sandhya ArulNo ratings yet

- ChocDocument6 pagesChocrahulnavetNo ratings yet

- B B: T C S: EAN TO AR HE Hocolate ToryDocument3 pagesB B: T C S: EAN TO AR HE Hocolate ToryRUDHRA DHANASEKARNo ratings yet

- 19 Cocoa Fermentation General AspectsDocument43 pages19 Cocoa Fermentation General AspectsLuis Miguel CorreaNo ratings yet

- ChocolateDocument16 pagesChocolateعليمحمدصالحعقلانNo ratings yet

- Chocolate PresentationDocument19 pagesChocolate Presentationcalinu19940% (1)

- 2.chapter 2 Introduction To ChocolateDocument14 pages2.chapter 2 Introduction To ChocolateTaylor's University Symphony OrchestraNo ratings yet

- ChocolateDocument6 pagesChocolateKunal NairNo ratings yet

- From Cacao Beans To ChocolateDocument33 pagesFrom Cacao Beans To Chocolateazulkipl1No ratings yet

- Other Foods - BreadDocument29 pagesOther Foods - BreadCastro KapolyoNo ratings yet

- Dt2102-Traditional Dairy ProductsDocument25 pagesDt2102-Traditional Dairy Productsjameelabasheer2000No ratings yet

- Cane SugarDocument55 pagesCane Sugartiara amandaNo ratings yet

- Unit 260 Prepare and Cook Basic Pastry DishesDocument17 pagesUnit 260 Prepare and Cook Basic Pastry Dishesapi-3846732100% (1)

- ChocolateDocument5 pagesChocolatePrashant RohillaNo ratings yet

- CheeseDocument34 pagesCheeseThefoodieswayNo ratings yet

- Sugar Industry (Autosaved)Document39 pagesSugar Industry (Autosaved)Divyansh NagarNo ratings yet

- Confectionary ProductsDocument20 pagesConfectionary Productsrupesh ghadge100% (1)

- Nota Kitchen ChocolateDocument7 pagesNota Kitchen ChocolateNadia FarhanaNo ratings yet

- Chocolate TrufflesDocument1 pageChocolate TrufflessascrusaderNo ratings yet

- ChocolateDocument7 pagesChocolateगौ रव कृष्णNo ratings yet

- Chocolate: KBPA100 Foundations of BakingDocument10 pagesChocolate: KBPA100 Foundations of Bakingjduan2012No ratings yet

- Lecture FourDocument32 pagesLecture Fourሸዋረጋ ሀብታሙ ሀይሌNo ratings yet

- Bakery UNIT 2Document27 pagesBakery UNIT 2vanishivshettyNo ratings yet

- Food Facts & Fallacies YSCN0006Document28 pagesFood Facts & Fallacies YSCN0006GAURI AGROTECHNo ratings yet

- Ice CreamDocument20 pagesIce Creamhtc587uyNo ratings yet

- Chocolate Making NotesDocument6 pagesChocolate Making Notesapi-240759474No ratings yet

- PPTDocument60 pagesPPTShamla Abdul Latheef0% (1)

- Course/ Qualification: Bread and Pastry Production NC IIDocument10 pagesCourse/ Qualification: Bread and Pastry Production NC IIEuropez AlaskhaNo ratings yet

- Candy ProcessingDocument14 pagesCandy ProcessingMercedes GaleonNo ratings yet

- Final Year Project (Repaired)Document30 pagesFinal Year Project (Repaired)PoojaNo ratings yet

- Sweet Chocolate: Homemade Chocolate Praline and Cookies RecipesFrom EverandSweet Chocolate: Homemade Chocolate Praline and Cookies RecipesNo ratings yet

- Composition of NPAsDocument4 pagesComposition of NPAsAkshay LodayaNo ratings yet

- Linux Act1Document3 pagesLinux Act1Aman SinghNo ratings yet

- FrontpageDocument7 pagesFrontpageAman SinghNo ratings yet

- FrontpageDocument7 pagesFrontpageAman SinghNo ratings yet

- Consolidated 6979 PDFDocument9 pagesConsolidated 6979 PDFSHUBHAM SINGHNo ratings yet

- Daa LabDocument4 pagesDaa LabAman SinghNo ratings yet

- Microsoft Word - Front PageDocument1 pageMicrosoft Word - Front PageAman SinghNo ratings yet

- Advt - No .9-RC (NT) 2019Document4 pagesAdvt - No .9-RC (NT) 2019Aman SinghNo ratings yet

- Examination To Be Held in November, 2019: Date & Day Subject, Paper & Code NoDocument4 pagesExamination To Be Held in November, 2019: Date & Day Subject, Paper & Code NoAman SinghNo ratings yet

- Kurt LewinDocument2 pagesKurt LewinManuel Garcia GrandyNo ratings yet

- Auckland International Campus: Graduate Diploma in Applied ManagementDocument8 pagesAuckland International Campus: Graduate Diploma in Applied ManagementAman SinghNo ratings yet

- Production CoverLetterDocument1 pageProduction CoverLettervractivaNo ratings yet

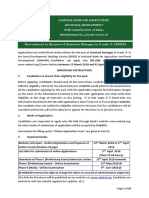

- Notification BECIL Skill Manpower Consultant OtherDocument4 pagesNotification BECIL Skill Manpower Consultant OtherSaikiranNo ratings yet

- Introduction: Executive Summary of The Project Executive SummaryDocument41 pagesIntroduction: Executive Summary of The Project Executive SummaryAman SinghNo ratings yet

- Shweta MaviDocument81 pagesShweta MaviAman SinghNo ratings yet

- Art-The Language of Emotion: Excerpt From The EssayDocument6 pagesArt-The Language of Emotion: Excerpt From The EssayAman SinghNo ratings yet

- 1ybxv24lpd3xa3ufoxcvrgad 1.Document2 pages1ybxv24lpd3xa3ufoxcvrgad 1.Aman SinghNo ratings yet

- DssDocument13 pagesDssKrishna Vijay Kumar GangisettyNo ratings yet

- OTA ChannaiDocument36 pagesOTA ChannaiAman SinghNo ratings yet

- Front PageDocument1 pageFront PageAman SinghNo ratings yet

- ds1018 PDFDocument3 pagesds1018 PDFAman SinghNo ratings yet

- Notification NABARD Asst Manager PostsDocument28 pagesNotification NABARD Asst Manager Postsrakesh_200003No ratings yet

- HarpreetDocument9 pagesHarpreetAman SinghNo ratings yet

- Project Report On Consumer Behavior Towards Bingo ChipsDocument7 pagesProject Report On Consumer Behavior Towards Bingo ChipsAnkit AhujaNo ratings yet

- UbaidDocument1 pageUbaidAman SinghNo ratings yet

- 12 Business Studies CH 01 Nature and Significance of ManagementDocument7 pages12 Business Studies CH 01 Nature and Significance of ManagementAman SinghNo ratings yet

- Guru Gobind Singh Indraprastha University New DelhiDocument53 pagesGuru Gobind Singh Indraprastha University New DelhiAman SinghNo ratings yet

- Curriculum Vitae Harsimranjeet SinghDocument2 pagesCurriculum Vitae Harsimranjeet SinghAman SinghNo ratings yet

- Resume: Name: Akshay Kamra Address: B-1/212 Mayur Apt., Sec 9 Rohini, Delhi-85 Mobile: 9711925747Document3 pagesResume: Name: Akshay Kamra Address: B-1/212 Mayur Apt., Sec 9 Rohini, Delhi-85 Mobile: 9711925747Aman SinghNo ratings yet