Professional Documents

Culture Documents

Nylon

Uploaded by

hakim amir0 ratings0% found this document useful (0 votes)

11 views9 pagesdasdasdasd

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdasdasdasd

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views9 pagesNylon

Uploaded by

hakim amirdasdasdasd

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 9

Nylon

• It refers to a type of polymer

• Nylon is a thermoplastic silky material that can be melt-processed

into fibres, films or shapes.

• Commercially, nylon polymer is made by reacting monomers which

are either lactams, acid/amines or stoichiometric mixtures of

diamines (-NH2) and diacids (-COOH). Mixtures of these can be

polymerized together to make copolymers.

• Can be described as a ubiquitous polymer.

More about Nylon

• Properties

1. Very strong and elastic.

2. Easy to wash.

3. Dries quickly and retains its shape rather well after laundering.

4. Very responsive and resilient as well as relatively resistant to

heat, UV rays and chemicals.

Application of Adipic Acid &

Nylon

Adipic acid

• Used as a monomer product to make nylon through a process called

polycondensation. ( Uses hexamethylene diamine ).

• Also being used to produced polyurethane.

• Its esters are plasticizers which usually refers PVC.

Medicine (adipic cont.)

• Its has been incorporated into controlled-release formulation matrix

tablets to obtain pH-independent release for both weakly basic and

weakly acidic drugs.

• It has also been incorporated into the polymeric coating

of hydrophilic monolithic systems to modulate the integral of pH,

resulting in zero-order release of a hydrophilic drug.

• The intention of obtaining a late-burst release profile.

• Improvement the disintegration at intestinal pH of the enteric

polymer shellac.

Food industry ( adipic cont. )

• Used to adjust the pH (acidity) of foods. It may also be used as a

starch modifying agent, allowing it to withstand heat and freezing.

• Used as a food ingredient as a flavorant and gelling aid.

• Also used as an acidulate in baking powders, it avoids the

undesirable hygroscopic properties of tartaric acid.Adipic acid, rare in

nature, does occur naturally in beets

Nylon ( Nylon 66 )

• Usually used when a high mechanical strength, rigidity, good stability

under heat and/or chemical resistance are required.

• It is commonly used in textiles

• It is used to make airbags, luggage, apparel, and for carpet fibres.

• Also used to make 3D structural objects. ( ball bearing cages, electro-

insulating elements, pipes, profiles, various machine parts, zip ties,

conveyor belts, hoses, polymer framed weapons )

• Phosphorus-based flame retardant systems are used in these fire-safe

polymers and are based on aluminium diethyl phosphinate and

synergists.

Environmental Issue of Adipic Acid & Nylon

• The production of adipic acid is linked to emissions of N2O and it can

cause of stratospheric ozone depletion.

• Nylon is not biodegradable, and will persist in the environment

indefinitely.

• Nylon is also not suited to natural dyes and lowest impact chemical

dyes, meaning that the process of colouring the fiber also creates

significant water pollution.

• With more nylon being produces in countries with weaker

environmental protections in place, this make nylon a significant

contributor to water pollution,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Cooling - Tower - 20200601 (1)Document4 pagesCooling - Tower - 20200601 (1)hakim amirNo ratings yet

- Universiti Teknologi Mara: 1 Confidential 20/ELC151/150/SET 2 Lg/June 20Document12 pagesUniversiti Teknologi Mara: 1 Confidential 20/ELC151/150/SET 2 Lg/June 20hakim amirNo ratings yet

- 2.0 Market Analysis and Market Strategies: 2.1 Introduction To Feasibility Study of Market, Process and TechnologyDocument13 pages2.0 Market Analysis and Market Strategies: 2.1 Introduction To Feasibility Study of Market, Process and Technologyhakim amirNo ratings yet

- CPE520 - Mini Project Management ReportDocument49 pagesCPE520 - Mini Project Management Reporthakim amirNo ratings yet

- Bio Production Sdn. BHD.: Biodiesel Production by TransesterificationDocument47 pagesBio Production Sdn. BHD.: Biodiesel Production by Transesterificationhakim amirNo ratings yet

- UTM CHEMICAL ENGINEERING THERMODYNAMICS GROUP ASSIGNMENTDocument1 pageUTM CHEMICAL ENGINEERING THERMODYNAMICS GROUP ASSIGNMENThakim amirNo ratings yet

- Essay IntroductionDocument5 pagesEssay Introductionhakim amirNo ratings yet

- CHE504 - Lab Report On Gas Absorption L8 PDFDocument23 pagesCHE504 - Lab Report On Gas Absorption L8 PDFRakesh KumarNo ratings yet

- Group Assignment DeclarationDocument1 pageGroup Assignment Declarationhakim amirNo ratings yet

- NylonDocument9 pagesNylonhakim amirNo ratings yet

- Adipic Acid & NylonDocument7 pagesAdipic Acid & Nylonhakim amirNo ratings yet

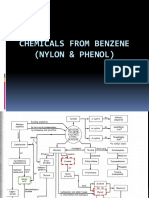

- Chemicals From Benzene (Nylon & Phenol)Document50 pagesChemicals From Benzene (Nylon & Phenol)hakim amirNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Convection and Conduction Heat TransferDocument406 pagesConvection and Conduction Heat Transfertfemilian100% (2)

- Dhuime Et Al. 2012 - ScienceDocument4 pagesDhuime Et Al. 2012 - ScienceLady Johana Buritica CortesNo ratings yet

- Wall Colmonoy Surfacing Alloys Selector ChartDocument3 pagesWall Colmonoy Surfacing Alloys Selector ChartAjimKe'enNo ratings yet

- Thermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDocument20 pagesThermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForAndres Camilo BenitezNo ratings yet

- 1229.1 Steam Sterilization by Direct ContactDocument3 pages1229.1 Steam Sterilization by Direct ContactWasimNo ratings yet

- CHM 1321 Assignment 1 Answers: CN H H H H HDocument10 pagesCHM 1321 Assignment 1 Answers: CN H H H H HSara YuenNo ratings yet

- Determination of Zinc (Experiment)Document3 pagesDetermination of Zinc (Experiment)Hassan Haider100% (4)

- Clay Mineral Cements in SandstonesDocument3 pagesClay Mineral Cements in Sandstonesandrea.cipagautaNo ratings yet

- Fermi DistrbutionDocument17 pagesFermi DistrbutionnazarNo ratings yet

- Spelling Bee WordsDocument3 pagesSpelling Bee WordsDana GomezNo ratings yet

- Lab 6-The Silver GroupDocument6 pagesLab 6-The Silver Groupsteph002100% (1)

- PCA Ion Exchange Membranes - Technical Data SheetDocument2 pagesPCA Ion Exchange Membranes - Technical Data Sheettestuser010% (1)

- How To Make Black PowderDocument7 pagesHow To Make Black Powder8mhno100% (1)

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocument8 pagesProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028No ratings yet

- E 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet SdsDocument9 pagesE 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet Sdsjohnpatt888No ratings yet

- B.pharm. Class NotesDocument817 pagesB.pharm. Class NotesMukesh TiwariNo ratings yet

- Ipsita RoyDocument60 pagesIpsita RoyJohn F ServilleNo ratings yet

- SodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationDocument30 pagesSodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationJacky Lou GermanoNo ratings yet

- Erba URIC ACID DESDocument2 pagesErba URIC ACID DEShexamed bme100% (1)

- Spectro RamanDocument6 pagesSpectro RamanSampada, Astrologer and Vastu Spl. SSBNo ratings yet

- Thermal Analysis Choosing The Right BaselineDocument24 pagesThermal Analysis Choosing The Right BaselineHung NGUYENNo ratings yet

- Documents Resources MacDermid Erifon HD856 Issue 10 A4Document2 pagesDocuments Resources MacDermid Erifon HD856 Issue 10 A4Pedro DutraNo ratings yet

- The Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFDocument452 pagesThe Chemistry of The Morphine Alkaloids Bentley (Oxford 1954) PDFJim Leonard100% (2)

- CO Capture by Absorption With Potassium CarbonateDocument23 pagesCO Capture by Absorption With Potassium CarbonatekumarNo ratings yet

- Lobo and Evans PDFDocument6 pagesLobo and Evans PDFSong HoeNo ratings yet

- Ellc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneDocument9 pagesEllc Rmnbemae Llce Bmmneera Lecl Mebmaren Lcel Nbmemaer: Cell MembraneAlvin PaboresNo ratings yet

- Characteristics - Requirements of Fibre Forming Polymers - Online Textile AcademyDocument1 pageCharacteristics - Requirements of Fibre Forming Polymers - Online Textile AcademyRAFIAHAMMEDNo ratings yet

- Recyclingand Reuseof TextileDocument47 pagesRecyclingand Reuseof TextileRey100% (1)

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNo ratings yet

- ZN ProtocolDocument262 pagesZN ProtocolLavina D'costaNo ratings yet