100% found this document useful (5 votes)

2K views27 pagesComputerized Embroidery Machine

The document discusses a computerized embroidery machine. It provides details on the types of stitches the machine can perform like straight, satin, and fill stitches. It describes the physical components of the machine like the embroidery arm, needles, threads, and hoop. The advantages are also summarized as less labor, time and cost compared to manual embroidery. Finally, it outlines the basic process of using the machine from designing the artwork digitally to hooping the fabric and running the machine.

Uploaded by

vibhavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (5 votes)

2K views27 pagesComputerized Embroidery Machine

The document discusses a computerized embroidery machine. It provides details on the types of stitches the machine can perform like straight, satin, and fill stitches. It describes the physical components of the machine like the embroidery arm, needles, threads, and hoop. The advantages are also summarized as less labor, time and cost compared to manual embroidery. Finally, it outlines the basic process of using the machine from designing the artwork digitally to hooping the fabric and running the machine.

Uploaded by

vibhavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Computerized Embroidery Machine: Introduction to the project on computerized embroidery machines, submitted by specific students to their professor.

- Introduction: Describes computerized embroidery, its operations, and types of stitches utilized.

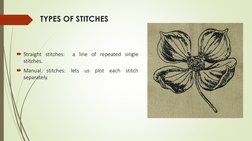

- Types of Stitches: Explains different types of stitches used in embroidery, including straight and manual stitches.

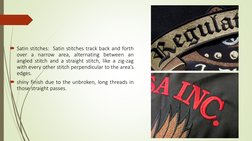

- Satin Stitches: Details satin stitches, their function, and visual effect in embroidery.

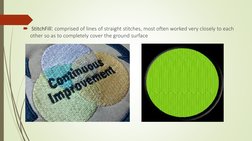

- Stitch Fill: Discusses the technique of stitch filling in embroidery and how it covers ground surfaces.

- Advantages: Highlights the advantages of computerized embroidery including cost-effectiveness and time-saving aspects.

- Physical Components: Examines the physical components of the embroidery machine including the arm, head, and needle bar.

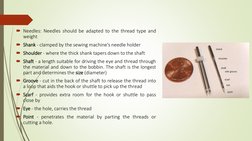

- Needle Details: Provides specifics on needle usage for embroidery, covering part functions and structures.

- Thread and Frame Information: Gives information on thread types used and details of the frame for embroidery work.

- Electronic Controls: Details electronic controls of the embroidery machine including LCD displays and memory function.

- Melco Amaya Bravo: Introduces the Melco Amaya Bravo embroidery machine and highlights its key features.

- Specifications: Details the specifications of the Melco Amaya Bravo machine including dimensions and technical capacities.

- Feed Type: Explains the feed types used in the embroidery process and how they adjust thread flow.

- Lubrication: Describes the lubrication process required to maintain the embroidery machine's performance.

- Embroidery Setup Procedures: Outlines the steps for setting up embroidery designs, converting files, and preparing settings.

- Operational Steps: Details operational steps like fabric hooping and machine set-up during the embroidery process.