Professional Documents

Culture Documents

OEE Method

Uploaded by

Phan Van Sinh0 ratings0% found this document useful (0 votes)

17 views2 pagesOriginal Title

OEE Method (1).pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesOEE Method

Uploaded by

Phan Van SinhCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 2

OEE is an abbreviation for the manufacturing metric Overall Equipment Effectiveness.

OEE takes into account the various

sub components of the manufacturing process – Availability, Performance and Quality. After the various factors are taken

into account the result is expressed as a percentage.

All time

A Planned Production Time Schedule loss

B Run Time Availability Loss

C Run Time

D Net Run Time = (Ideal Cycle Time × Total Count) Performance Loss

E Real production OEE = B/A x D/C x F/E

Availability Performance Quality

F Good production Quality Loss

A P Q

Quality = Good Count / Total Count

(Temporarily apply: Quality = 98% )

Availability = Run Time / Planned Production Time

( Run Time = Planned Production Time − Stop Time)

Performance = Net Run Time/Run Time

= (Ideal Cycle Time × Total Count) / Run Time

Ideal Cycle Time is the theoretical fastest possible time to manufacture one piece. Therefore, when it is multiplied by Total

Count the result is Net Run Time – the theoretical fastest possible time to manufacture the total quantity of pieces.

You might also like

- OEE CalculatorDocument11 pagesOEE CalculatorosbertodiazNo ratings yet

- Understanding OEEDocument5 pagesUnderstanding OEECristian Ramirez AmayaNo ratings yet

- OEE Training PresentationDocument30 pagesOEE Training PresentationSangram KendreNo ratings yet

- OEE ComienzoDocument2 pagesOEE ComienzoSamuel ArellanoNo ratings yet

- Standardized Work: Creating Continuous FlowDocument13 pagesStandardized Work: Creating Continuous FlowHisar SimanjuntakNo ratings yet

- Overall Equipment Effectiveness: Theory and Application: Oee WorkshopDocument30 pagesOverall Equipment Effectiveness: Theory and Application: Oee WorkshopFerozhKhan100% (1)

- Oee (Referencia Rapida) PDFDocument2 pagesOee (Referencia Rapida) PDFVíctor Hugo Carvajal GaticaNo ratings yet

- Calculate OEE - Definitions, Formulas, and ExamplesDocument4 pagesCalculate OEE - Definitions, Formulas, and ExamplescleitonmoyaNo ratings yet

- Oee 3Document2 pagesOee 3AngelikaNo ratings yet

- Oee CalculatedDocument1 pageOee Calculatedmortezasafir62No ratings yet

- Maintenance KPIsDocument12 pagesMaintenance KPIsIbrahem TahaNo ratings yet

- Week 11 - Numerical Analysis For Productivity ImprovementDocument34 pagesWeek 11 - Numerical Analysis For Productivity ImprovementNguyễn Ngọc Minh QuânNo ratings yet

- Overall Equipment EffectivenessDocument43 pagesOverall Equipment EffectivenessKailas Sree Chandran100% (4)

- Oee 3Document2 pagesOee 3Lowell HarperNo ratings yet

- Overall Equipment EffectivenessDocument19 pagesOverall Equipment EffectivenessKopral JonoNo ratings yet

- What Is Oee?: Intro To LeanDocument3 pagesWhat Is Oee?: Intro To LeanNelson VianaNo ratings yet

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding OEE in Lean Production: Toyota Production System ConceptsFrom EverandUnderstanding OEE in Lean Production: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Cumulative Percent Failure : R S (R A) (R B) (R C) R 1 - ( (1-RA) (1-RB) (1-RC) )Document1 pageCumulative Percent Failure : R S (R A) (R B) (R C) R 1 - ( (1-RA) (1-RB) (1-RC) )Eng. Ahmed MuneerNo ratings yet

- Total Productive Maintenance (TPM)Document17 pagesTotal Productive Maintenance (TPM)Fgj JhgNo ratings yet

- 3 - Performance Measurement of Mining Equipments by Utilizing OEEDocument8 pages3 - Performance Measurement of Mining Equipments by Utilizing OEEGonzalo GarciaNo ratings yet

- Performance Measurement of Mining Equipments by UtDocument8 pagesPerformance Measurement of Mining Equipments by UtHugo AmaralNo ratings yet

- Maintenance Management (FRSI 2153) Lecture: 5 - 6 Eliminate Waste & Overall Equipment Efficiency (Oee)Document35 pagesMaintenance Management (FRSI 2153) Lecture: 5 - 6 Eliminate Waste & Overall Equipment Efficiency (Oee)Fgj JhgNo ratings yet

- Overall Equipment Effectiveness (OEE)Document16 pagesOverall Equipment Effectiveness (OEE)Arif Abu FarhanaNo ratings yet

- Implementation of 5S and KOBETSU KAIZEN (TPM Pillar) in A Manufacturing OrganizationDocument5 pagesImplementation of 5S and KOBETSU KAIZEN (TPM Pillar) in A Manufacturing OrganizationAnonymous kw8Yrp0R5rNo ratings yet

- KPIsDocument5 pagesKPIsyousriabdouli10No ratings yet

- Overall Equipment Effectiveness: Balakumar VDocument10 pagesOverall Equipment Effectiveness: Balakumar VBalakumar VNo ratings yet

- OEE What Is OEE?Document4 pagesOEE What Is OEE?Mamun IENo ratings yet

- CII - AVANTHA Centre For CompetitivenessDocument31 pagesCII - AVANTHA Centre For CompetitivenessRohit TripathiNo ratings yet

- Overall Equipment Effectiveness Calculator: Enter Date / Time Period / EquipmentDocument1 pageOverall Equipment Effectiveness Calculator: Enter Date / Time Period / EquipmentDaniel JiménezNo ratings yet

- Overall Equipment Efficiency (OEE) : © Russel Timothy, Assoc - ProfessorDocument9 pagesOverall Equipment Efficiency (OEE) : © Russel Timothy, Assoc - ProfessornlmydvNo ratings yet

- Performance MonitoringDocument11 pagesPerformance MonitoringdcsekharNo ratings yet

- Productivity: Dr. Ziaul Haq AdnanDocument11 pagesProductivity: Dr. Ziaul Haq AdnanJahid Hasan MenonNo ratings yet

- Oee 2Document9 pagesOee 2fernandothekingNo ratings yet

- Productivity: Prof. Dr. Md. Mamun HabibDocument11 pagesProductivity: Prof. Dr. Md. Mamun HabibKhaled Shams AkashNo ratings yet

- Calculate OeeDocument24 pagesCalculate OeeAyman AliNo ratings yet

- Managing OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryDocument26 pagesManaging OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryMohammad QureshiNo ratings yet

- 2.0 Understanding Overall Equipment Effectiveness (OEE) : SMRP Guideline 2.0Document7 pages2.0 Understanding Overall Equipment Effectiveness (OEE) : SMRP Guideline 2.0Quant ExalmarNo ratings yet

- Introduction To OEE (Notes)Document3 pagesIntroduction To OEE (Notes)Simphiwe MokoriNo ratings yet

- OEE Calculation NorozionsDocument8 pagesOEE Calculation NorozionsNewhame DagneNo ratings yet

- Overall Plant Effectiveness: Losses CalculationDocument1 pageOverall Plant Effectiveness: Losses CalculationchuszNo ratings yet

- Metric 2.1.1 OEEDocument7 pagesMetric 2.1.1 OEEAbdelaziz RagabNo ratings yet

- P6 Anprod Total Productivity ModelDocument17 pagesP6 Anprod Total Productivity ModelUud AchmadNo ratings yet

- 20 Produccion MetricsDocument12 pages20 Produccion MetricsCristopher Jimenez JaramilloNo ratings yet

- QC2 Paper 06 David Sungkono 2014Document5 pagesQC2 Paper 06 David Sungkono 2014camp bali demakNo ratings yet

- Calculate OEEDocument6 pagesCalculate OEEstanley chengNo ratings yet

- Cálculo de OEEDocument1 pageCálculo de OEEAurora CruzNo ratings yet

- DowntimeDocument7 pagesDowntimeJigar DesaiNo ratings yet

- Overall Equipment Effectiveness (Oee) : BY Muhamad Abdul Karim RiskayantiDocument10 pagesOverall Equipment Effectiveness (Oee) : BY Muhamad Abdul Karim RiskayantiMuhamad Abdul KarimNo ratings yet

- Metric 2.1.2 TEEPDocument8 pagesMetric 2.1.2 TEEPAbdelaziz RagabNo ratings yet

- Some Important-IeDocument4 pagesSome Important-IeITM Teck Soft.No ratings yet

- Lecture 8 - Lean OPEx - TPM (March 2024)Document67 pagesLecture 8 - Lean OPEx - TPM (March 2024)ccv2202No ratings yet

- Sep'18 SPM SectionDocument143 pagesSep'18 SPM SectionPatrick AndriesNo ratings yet

- Computer: Manufacturing SystemsDocument39 pagesComputer: Manufacturing SystemsJeganNo ratings yet

- Simple Calculation: Three Loss-Related FactorsDocument8 pagesSimple Calculation: Three Loss-Related FactorsTHANH THAO DO THINo ratings yet

- FerryDocument9 pagesFerryFrederico TariganNo ratings yet

- Net Promoter Score : Project Report-HratDocument1 pageNet Promoter Score : Project Report-HratsriNo ratings yet

- Industrial Engineering Basics - Pharma - OEEDocument5 pagesIndustrial Engineering Basics - Pharma - OEEMelvin MarsNo ratings yet

- 02 TDTDocument4 pages02 TDTwilfredoNo ratings yet

- Thuat Ngu So Do Don TuyenDocument1 pageThuat Ngu So Do Don TuyenPhan Van SinhNo ratings yet

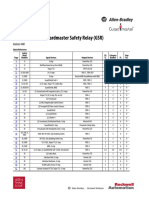

- Next Generation Guardmaster Safety Relay (GSR) : Wiring DiagramDocument124 pagesNext Generation Guardmaster Safety Relay (GSR) : Wiring DiagramPhan Van SinhNo ratings yet

- Single Loop Controller SDC15 User's Manual: "Installation & Configurations"Document208 pagesSingle Loop Controller SDC15 User's Manual: "Installation & Configurations"Phan Van SinhNo ratings yet

- Single Loop Controller SDC15 User's Manual: "Installation & Configurations"Document208 pagesSingle Loop Controller SDC15 User's Manual: "Installation & Configurations"Phan Van SinhNo ratings yet

- G3PJ-515B DC12-24 G3pj-515b-Pu DC12-24 G3PJ-525B DC12-24 G3pj-525b-Pu DC12-24Document14 pagesG3PJ-515B DC12-24 G3pj-515b-Pu DC12-24 G3PJ-525B DC12-24 G3pj-525b-Pu DC12-24Phan Van SinhNo ratings yet

- TF228WNM/U: Communicating Fan Coil ThermostatDocument6 pagesTF228WNM/U: Communicating Fan Coil ThermostatPhan Van SinhNo ratings yet