Professional Documents

Culture Documents

Jacket Sewing Section

Uploaded by

YASHIKA0 ratings0% found this document useful (0 votes)

22 views7 pagesThe document provides details on the jacket sewing section of a factory. It includes:

- The number of operations for front/back, lining, and sleeves sections, totaling 96 operations across the factory.

- The machinery used, including over 30 sewing machines, 15 ironing tables, and various specialized machines.

- Automated processes like welting, pressing, and triple bed pressing are used.

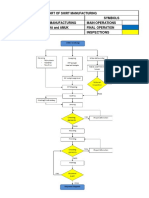

- A flow chart shows the organization of preparatory, lining, front, assembly, and finishing lines.

- Problems mentioned are absenteeism, low work-in-progress, high defect rates, and issues with steam disposal and machine documentation.

Original Description:

SOP OF SEWING

Original Title

Jacket

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides details on the jacket sewing section of a factory. It includes:

- The number of operations for front/back, lining, and sleeves sections, totaling 96 operations across the factory.

- The machinery used, including over 30 sewing machines, 15 ironing tables, and various specialized machines.

- Automated processes like welting, pressing, and triple bed pressing are used.

- A flow chart shows the organization of preparatory, lining, front, assembly, and finishing lines.

- Problems mentioned are absenteeism, low work-in-progress, high defect rates, and issues with steam disposal and machine documentation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views7 pagesJacket Sewing Section

Uploaded by

YASHIKAThe document provides details on the jacket sewing section of a factory. It includes:

- The number of operations for front/back, lining, and sleeves sections, totaling 96 operations across the factory.

- The machinery used, including over 30 sewing machines, 15 ironing tables, and various specialized machines.

- Automated processes like welting, pressing, and triple bed pressing are used.

- A flow chart shows the organization of preparatory, lining, front, assembly, and finishing lines.

- Problems mentioned are absenteeism, low work-in-progress, high defect rates, and issues with steam disposal and machine documentation.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 7

JACKET SEWING SECTION

SOP FOR JACKET SEWING

JACKET SEWING SECTION

NO. OF OPERATIONS

1. Front and Back = 32 ops

2. Lining section = 26 ops

3. Sleeve section = 15 ops

4. Assembly = 23 ops

Total = 96 ops

Total SAM = 75.74 min(approx.)

Note: There is 4 WIP between operators, if more than 10 Pieces are there that means it is a bottleneck

operation.

-For pressing parts of jacket different pressing machine is used.

MACHINES USED(LINE 1)

Machine Name Number of Machine Machine Name Number of Machine

SNLS 34 SNLS with cylindrical bed 4

SNLS with Feeder 1 SNLS with folder 1

Zig-Zag 5 Bartack 2

Blind hem 2 Iron table 15

SNEC 2 Key buttonhole 2

Saddle Machine 1 Button attachment 1

AUTOMATION USED :-

• WELTING MACHINE

• BUCK PRESSING - block pressing

shoulder split press shape

shoulder pad press

inseam split pressing shape

lapel split press shape

lapel edge pressing

• TRIBLE BED PRESSING - side seam split press

• BOTTOM PRESSING - bottom folding

JACKET SEWING LINES

Preparatory line

LINING L Front CP

Lining FRONT

L

CP

ASSEMBLY LINE 2 ASSEMBLY LINE 1

END LINE INSP FINISHING AREA

PROBLEMS

• Absenteeism

• Less WIP in lines

• Defects rates are high

• No proper system for disposal of steam.

• No proper chart for every machine.

You might also like

- Tahira and HafsaDocument13 pagesTahira and Hafsalaraibtahir07No ratings yet

- 1294 Bernina 117 InsDocument52 pages1294 Bernina 117 InsJoyce DavisNo ratings yet

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!From EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Rating: 3 out of 5 stars3/5 (2)

- Instruction Manual FOR Sewing Machine: WhiteDocument33 pagesInstruction Manual FOR Sewing Machine: WhiteBhupinder GillNo ratings yet

- White 1750 Sewing Machine Instruction ManualDocument31 pagesWhite 1750 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Basic Garment Construction-ReportDocument28 pagesBasic Garment Construction-Reportsporti1412No ratings yet

- Mitsubishi MAZ4 Sewing Machine Instruction ManualDocument42 pagesMitsubishi MAZ4 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff 9Document44 pagesPfaff 9Cosmin PuniNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home Workshop PDFDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home Workshop PDFmac100% (1)

- White ET6/10 Sewing Machine Instruction ManualDocument42 pagesWhite ET6/10 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1744 Sewing Machine Instruction ManualDocument32 pagesWhite 1744 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Huskystar 207/215 Sewing Machine Instruction ManualDocument40 pagesHuskystar 207/215 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Service Manual: Printed in SwitzerlandDocument16 pagesService Manual: Printed in Switzerlandathalim1463No ratings yet

- Juki LK-980 Instruction ManualDocument32 pagesJuki LK-980 Instruction ManualAdiputra IskandarNo ratings yet

- Bernette DINA5-Brosch B30-Serie ENDocument12 pagesBernette DINA5-Brosch B30-Serie ENTina Wan QenobiNo ratings yet

- Questioned Documents Examination: Prepared By: Geraldine B. Tuliao, RcrimDocument53 pagesQuestioned Documents Examination: Prepared By: Geraldine B. Tuliao, RcrimChristian QuebecNo ratings yet

- SEIKO Industrial Sewing Machine Catalog 2016Document84 pagesSEIKO Industrial Sewing Machine Catalog 2016Peter DavidsonNo ratings yet

- Domestic 1665 Sewing Machine Instruction ManualDocument55 pagesDomestic 1665 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- TMS PDFDocument8 pagesTMS PDFIrish RomNo ratings yet

- White 1010 Sewing Machine Instruction ManualDocument46 pagesWhite 1010 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

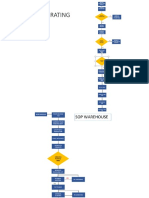

- Process Flow Chart of Shirt ManufacturingDocument8 pagesProcess Flow Chart of Shirt ManufacturingAASTHA KUMARINo ratings yet

- Spec Sheet & BOMDocument6 pagesSpec Sheet & BOMSatadeep DattaNo ratings yet

- In-Die Tapping: by Chandan Kumar H.KDocument58 pagesIn-Die Tapping: by Chandan Kumar H.KJM PraveenNo ratings yet

- PVH Current and Proposed Pressing MethodDocument12 pagesPVH Current and Proposed Pressing MethodRanathunga ThennakoonNo ratings yet

- Baby Lock Amelia BL100A Sewing Machine Instruction ManualDocument42 pagesBaby Lock Amelia BL100A Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Seiko LSC Instruction ManualDocument19 pagesSeiko LSC Instruction ManualIskriceNo ratings yet

- White 645 Sewing Machine Instruction ManualDocument50 pagesWhite 645 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Auto ConeDocument38 pagesAuto ConeAbdul Rafay100% (2)

- White 656/565 Sewing Machine Instruction ManualDocument28 pagesWhite 656/565 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- DAY SUN MON Cardio Class Step RUN Weight ARM ChestDocument5 pagesDAY SUN MON Cardio Class Step RUN Weight ARM ChestSarayoot YoisaengNo ratings yet

- White 1766 Sewing Machine Instruction ManualDocument33 pagesWhite 1766 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- PressDocument15 pagesPressRekha HNo ratings yet

- Kenmore 158.1232 Sewing Machine Instruction ManualDocument44 pagesKenmore 158.1232 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- White 1515/1525 Sewing Machine Instruction ManualDocument36 pagesWhite 1515/1525 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Singer 9802 9812 9814 9816 9818 9824 9828 9829 9832 9836Document67 pagesSinger 9802 9812 9814 9816 9818 9824 9828 9829 9832 9836Francisco Gaviria100% (2)

- Frister + Rossman Euro 21 Sewing Machine Instruction ManualDocument38 pagesFrister + Rossman Euro 21 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Pfaff SZA-645F Sewing Machine Instruction ManualDocument45 pagesPfaff SZA-645F Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Eam Maliban Textiles Jordan (PVT) LTD: Mechanic RequirementDocument3 pagesEam Maliban Textiles Jordan (PVT) LTD: Mechanic RequirementNadeera AbesekaraNo ratings yet

- Pfaff 9 Sewing Machine Instruction ManualDocument44 pagesPfaff 9 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Cut Spread Iron 27-2-12Document13 pagesCut Spread Iron 27-2-12manjeet6151_55394803No ratings yet

- Husqvarna/Viking Iris Sewing Machine Instruction ManualDocument52 pagesHusqvarna/Viking Iris Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Typecast (We R) - Instruction SheetDocument14 pagesTypecast (We R) - Instruction Sheetangelica leivaNo ratings yet

- The Millroom ProgramDocument48 pagesThe Millroom ProgramNguyễn Văn ĐiệpNo ratings yet

- Alfa 233 236 333 336 Sewing Machine Instruction ManualDocument40 pagesAlfa 233 236 333 336 Sewing Machine Instruction ManualJohan KristerssonNo ratings yet

- Husqvarna/Viking Scandinavia 200 Sewing Machine Instruction ManualDocument44 pagesHusqvarna/Viking Scandinavia 200 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Note 1Document19 pagesNote 1shivam ojhaNo ratings yet

- Cutting Time StudyDocument19 pagesCutting Time StudyNeha ChauhanNo ratings yet

- Spme & DBMSDocument23 pagesSpme & DBMSGairika SahaNo ratings yet

- Emerald 183 203 Manual en H-1Document48 pagesEmerald 183 203 Manual en H-1Eunice TimbrookNo ratings yet

- Cutting Time StudyDocument19 pagesCutting Time StudyNeha Chauhan100% (1)

- Chino Pant Layout PlanDocument2 pagesChino Pant Layout PlanNaveed HussainNo ratings yet

- Blind StitchdDocument22 pagesBlind StitchdDev GuptaNo ratings yet

- Ovja 1.1 TTRB: Full 3-Way Jacquard - With Full Electronic Control On Both Fabric Faces. With Stripes, Transfer and WeltDocument2 pagesOvja 1.1 TTRB: Full 3-Way Jacquard - With Full Electronic Control On Both Fabric Faces. With Stripes, Transfer and WeltJavier A.R.No ratings yet

- 1409 Instruction ManualDocument28 pages1409 Instruction ManualAjay Singh Patial100% (1)

- Screw BookDocument182 pagesScrew BookNeoNo ratings yet

- SpecificationsDocument64 pagesSpecificationsakuma ioriNo ratings yet

- White 1500/1505 Sewing Machine Instruction ManualDocument47 pagesWhite 1500/1505 Sewing Machine Instruction Manualiliiexpugnans100% (1)

- 02 - Vertical Milling in The Home WorkshopDocument93 pages02 - Vertical Milling in The Home Workshopj43951048No ratings yet

- Carbon FootprintDocument2 pagesCarbon FootprintYASHIKANo ratings yet

- Pad Assignment 2Document12 pagesPad Assignment 2YASHIKANo ratings yet

- Research ProjectDocument17 pagesResearch ProjectYASHIKANo ratings yet

- Standard Operating ProcedureDocument2 pagesStandard Operating ProcedureYASHIKANo ratings yet

- Top 10 Leading Textile Industries of India: 1. Wardhman TextilesDocument4 pagesTop 10 Leading Textile Industries of India: 1. Wardhman TextilesYASHIKANo ratings yet

- Kullu ShawlsDocument21 pagesKullu ShawlsYASHIKA100% (1)

- Aqm Document by Venya and YashikaDocument17 pagesAqm Document by Venya and YashikaYASHIKANo ratings yet