100% found this document useful (1 vote)

676 views15 pagesPneumatic Brakes for Heavy Vehicles

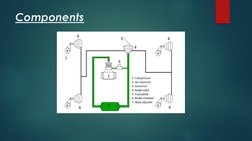

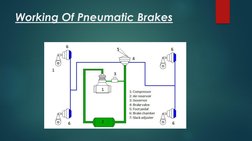

Pneumatic brakes use compressed air to apply pressure to brake pads to stop vehicles. Air is compressed by an engine-driven compressor and stored in a reservoir. When the brake pedal is pressed, air flows through valves and lines to brake chambers, where pistons push out pads into brake drums attached to wheels. This creates friction to slow the vehicle. Pneumatic brakes are commonly used in heavy vehicles like trucks and buses due to their simple design and ability to use an unlimited air supply.

Uploaded by

BilalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

676 views15 pagesPneumatic Brakes for Heavy Vehicles

Pneumatic brakes use compressed air to apply pressure to brake pads to stop vehicles. Air is compressed by an engine-driven compressor and stored in a reservoir. When the brake pedal is pressed, air flows through valves and lines to brake chambers, where pistons push out pads into brake drums attached to wheels. This creates friction to slow the vehicle. Pneumatic brakes are commonly used in heavy vehicles like trucks and buses due to their simple design and ability to use an unlimited air supply.

Uploaded by

BilalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd