Professional Documents

Culture Documents

Clutches (Contd

Uploaded by

ravi0 ratings0% found this document useful (0 votes)

9 views13 pagesClutches (Contd

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentClutches (Contd

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views13 pagesClutches (Contd

Uploaded by

raviClutches (Contd

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 13

Cone Clutch

A cone clutch serves the same purpose as a disk or

plate clutch. However, instead of mating two spinning

disks, the cone clutch uses two conical surfaces to

transmit torque by friction.

The cone clutch transfers a higher torque than plate or

disk clutches of the same size due to the wedging

action and increased surface area. Cone clutches are

generally now only used in low peripheral speed

applications although they were once common in

automobiles and other combustion engine

transmissions.

1. female cone and male cone

2. Shaft: male cone is sliding on splines

3. Friction material: usually on female cone, here on

male cone

4. Spring: brings the male cone back after using the

clutch control

5. Clutch control: separating both cones by pressing

6. Rotating direction: both direction of the axis are

possible

They are usually now confined to very specialist

transmissions in racing, rallying, or in extreme off-

road vehicles, although they are common in power

boats. This is because the clutch does not have to be

pushed in all the way and the gears will be changed

quicker. Small cone clutches are used in synchronizer

mechanisms in manual transmissions.

working

The engine shaft consists of a female cone and the

male cone is mounted on the splined clutch shaft. It

has friction surfaces on the conical portion of the

clutch. The male cone can slide on the clutch shaft and

When the clutch is engaged the friction surfaces of the

male cone are in contact with that of the female cone

due to the force of spring. When the clutch pedal is

pressed, the male cone slides against the spring force

and the clutch is disengaged

Advantages

The normal force acting on the friction (contact) surfaces

is greater than the axial force as compared to single plate

clutch in which the normal force acting on the friction

surfaces is equal.

It is used in race cars and power boats and extreme off

road vehicles.

Disadvantages

If the angle of cone is made smaller than 20 degree, the

male cone tends to bind in the female cone and it becomes

difficult to disengage the clutch after its removed.

a small amount of wear on the cone surfaces results in a

considerable amount of the axial movement of the male

cone for which it will be difficult to allow.

Centrifugal Clutch

The input of the clutch is connected to the

engine crankshaft while the output may drive a shaft,

chain, or belt. As engine revolutions per minute

increase, weighted arms in the clutch swing outward

and force the clutch to engage. The most common

types have friction pads or shoes radially mounted that

engage the inside of the rim of a housing.

On the centre shaft there are an assorted number of

extension springs, which connect to a clutch shoe.

When the central shaft spins fast enough, the springs

extend causing the clutch shoes to engage the friction

face.

It can be compared to a drum brake in reverse. This

type can be found on most home built karts, lawn and

garden equipment, fuel-powered model cars and low

power chainsaws. Another type used in racing karts

has friction and clutch disks stacked together like a

motorcycle clutch. The weighted arms force these

disks together and engage the clutch.

When the engine reaches a certain speed, the clutch

activates, working somewhat like a continuously

variable transmission.

Centrifugal clutches are often used

In mopeds, underbones, lawnmowers, go-

karts, chainsaws, mini bikes, and some paramotors to

keep the internal combustion engine from stalling when

the output shaft is slowed or stopped abruptly

disengage loads when starting and idling.

You might also like

- Manual Transmissions (Gearbox)Document29 pagesManual Transmissions (Gearbox)raviNo ratings yet

- Clutch MaterialsDocument6 pagesClutch MaterialsraviNo ratings yet

- TransmissionDocument13 pagesTransmissionraviNo ratings yet

- Diaphragm ClutchDocument13 pagesDiaphragm Clutchravi0% (1)

- Clutches Part 3Document11 pagesClutches Part 3raviNo ratings yet

- ClutchesDocument22 pagesClutchesravi100% (1)

- Safety RegulationsDocument12 pagesSafety RegulationsraviNo ratings yet

- Type of Drive Trains ContdDocument18 pagesType of Drive Trains ContdraviNo ratings yet

- Types of Drive TrainsDocument25 pagesTypes of Drive TrainsraviNo ratings yet

- Layout of An AutomobileDocument18 pagesLayout of An AutomobileraviNo ratings yet

- Automobile History and DevelopmentDocument26 pagesAutomobile History and DevelopmentraviNo ratings yet

- Automobile History and DevelopmentDocument26 pagesAutomobile History and DevelopmentraviNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SP 1212 Check SheetDocument5 pagesSP 1212 Check SheetDaniel MartinezNo ratings yet

- Transport Phenomena - MSC - Lecture 11Document17 pagesTransport Phenomena - MSC - Lecture 11showravNo ratings yet

- Rothenberger R600 ManualDocument10 pagesRothenberger R600 Manualdorin stoicuNo ratings yet

- 05 FS GduDocument18 pages05 FS GduAnonymous O0lyGOShYGNo ratings yet

- DBR ChecklistDocument9 pagesDBR ChecklistJai ThakkarNo ratings yet

- Operation, Installation & Maintenance Manual For Diesel Engine Fire Pump Controller Automatic Controller Model GPDDocument74 pagesOperation, Installation & Maintenance Manual For Diesel Engine Fire Pump Controller Automatic Controller Model GPDAnoirNo ratings yet

- She55p PDFDocument42 pagesShe55p PDFStephan SchaaNo ratings yet

- AE 2012 Fuid Mechanics SyllabusDocument4 pagesAE 2012 Fuid Mechanics SyllabusamaniNo ratings yet

- Lecture 1 Foundation Engineering IntroductionDocument52 pagesLecture 1 Foundation Engineering IntroductionRamesh Adhikari100% (1)

- Vogel Ipr Calculation MethodDocument7 pagesVogel Ipr Calculation MethodShaho Abdulqader MohamedaliNo ratings yet

- Liebherr A309 Litronic Wheel Excavator Service Repair Manual SN20221 and Up PDFDocument170 pagesLiebherr A309 Litronic Wheel Excavator Service Repair Manual SN20221 and Up PDFjfjksekdmeikNo ratings yet

- Company ProfileDocument11 pagesCompany ProfileUthayan SPNo ratings yet

- Sheet #6Document2 pagesSheet #6AHMED BAKRNo ratings yet

- Lo 5-2410-241-13Document12 pagesLo 5-2410-241-13"Rufus"No ratings yet

- Grade XI - Phys. T2 Ans KeyDocument7 pagesGrade XI - Phys. T2 Ans Keyrohan fernandesNo ratings yet

- Career PathDocument24 pagesCareer PathMandrata LimdrawanNo ratings yet

- Pump & Motor Catalog: Aluminum Bushing SeriesDocument116 pagesPump & Motor Catalog: Aluminum Bushing SeriesMario SouzaNo ratings yet

- Free Body Diagram Work Book StudentDocument15 pagesFree Body Diagram Work Book StudentwshhytNo ratings yet

- 72 Olympique (Owners Manual)Document40 pages72 Olympique (Owners Manual)JacobnMarie LaaksoNo ratings yet

- RK-2001E2 English TraductionDocument2 pagesRK-2001E2 English TraductionwxcvbnnbvcxwNo ratings yet

- Vibration Control Techniques During Turn PDFDocument22 pagesVibration Control Techniques During Turn PDFAhmed EzzNo ratings yet

- Total Pressure Governor (TPG) OEM Quick Manual: Installation Wiring HarnessDocument2 pagesTotal Pressure Governor (TPG) OEM Quick Manual: Installation Wiring HarnessErick Portela cruzNo ratings yet

- DEE APPLIED PHYSICS - Remedial TestDocument2 pagesDEE APPLIED PHYSICS - Remedial TestMilan SasmolNo ratings yet

- Homemade Paintball GunDocument8 pagesHomemade Paintball GunAinis Štelemėkas0% (1)

- Bolted ConnectionDocument36 pagesBolted ConnectionMeenuNo ratings yet

- Volkswagen Touareg - Adaptive Cruise Control (ACC) With Front AssistDocument23 pagesVolkswagen Touareg - Adaptive Cruise Control (ACC) With Front AssistMarius Ioan BaleaNo ratings yet

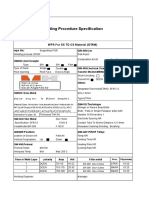

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Catia v5 Course ContentsDocument2 pagesCatia v5 Course ContentsVishwajit ShirudeNo ratings yet

- BerlinerLuft. Brochure HygCond 2017-2021 Eng. WebDocument24 pagesBerlinerLuft. Brochure HygCond 2017-2021 Eng. WebFabian FelsNo ratings yet

- Spong, Block - The PendubotDocument2 pagesSpong, Block - The Pendubotaleong1No ratings yet