Professional Documents

Culture Documents

Tool Compensation (CNC Cells) - Peter

Uploaded by

PeterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tool Compensation (CNC Cells) - Peter

Uploaded by

PeterCopyright:

Available Formats

CNC Cells

Created by Peter Bates

What is a CNC Cell

A CNC cell is a grouping of

multiple CNC machines, working

together.

Often aided by conveyers or

robots to move materials

around.

CNC Cell’s use less resources.

Because of this they have lower

operating costs.

Because of the automation, CNC

Cells often have better

repeatability the manual

operations.

Tool

Compensation

What is Tool Compensation

Tool compensation refers to

the allowances made by the

CNC machine the size of

the tool.

CNC’s always work from the

center of the tool, so

offsets are required.

The cutting tools will run

along the programmed line

unless offsets are added.

- No Offset - Offset

Cutter is on the Cutter is moved off Without offsets work may

centre of the the programmed line be cut smaller than

programmed line intended.

Cutter Radius Compensation

Many CNC’s use radius compensation

to account for tool size.

G41 - executes cutter radius G40 G41 G42

compensation to the left. (when

climb milling)

G42 - executes cutter radius

No Cutter Offset

compensation to the right. (When Applied (Cut inside Cutter Offset

conventional milling) of intended Applied (G41)

profile)

G40 - cancels cutter radius

compensation.

It is important to use the correct g

code to avoid cutting a part to the

wrong profile.

Tool Length Compensation

• Tool z,0 position may not be at the

Tool Length Register Z Offset end of the tool.

H1 -12.628 • To avoid incorrect depth cuts offsets

are used to position the length of

H2 -6.358 the tool correctly from the

H3 2.785 workpiece.

H4 6.894 • Tool length compensation is a single

variable, that can be saved to the

H5 -1.567 machine.

H6 7.125 • G43 to manually allocated length

H7 0.667 offset.

• G49 to use no offset

Tool Nose Radius Compensation

Tools intended path.

Cut Line.

All tool assumed to have 0

radius, resulting in inaccuracy's, As the work piece is to

if not compensated for. the Right of the tool G

As with Cutter radius code G41 would be used

compensation, G codes G40, G41 to offset the tool left.

and G42 are used.

Tool radiuses are stored in the Tools intended path.

machines offset table and when

G41 or G42 are called they Cut Line.

calculate the correct amount of

tool compensation. As the work piece is to

the left of the tool G

code G41 would be used

to offset the tool left.

You might also like

- Indiegogo Crowdfunding Calendars Checklists ALL PDFDocument8 pagesIndiegogo Crowdfunding Calendars Checklists ALL PDFshiriishNo ratings yet

- CNC Part ProgrammingDocument40 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- Close Out ReportDocument16 pagesClose Out ReportAriff MuhamadNo ratings yet

- CNC Part ProgrammingDocument53 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- Jm201 - CNC MillingDocument24 pagesJm201 - CNC MillingMuhd Zulhusni Ag Jaludin100% (1)

- Calculation of Short Circuit Current As Per IEC60909Document16 pagesCalculation of Short Circuit Current As Per IEC60909MuhammadHaekal100% (1)

- Polar coordinate interpolation function G12.1 programming guideDocument10 pagesPolar coordinate interpolation function G12.1 programming guideElias Mora BecerraNo ratings yet

- Jenbacher Type-6 EngineDocument24 pagesJenbacher Type-6 EngineAb Hannan chowdhury100% (1)

- Deckel FPXNC Dialog 4 Dialog 11 Programming RkloppDocument260 pagesDeckel FPXNC Dialog 4 Dialog 11 Programming RkloppStelian Crisan100% (1)

- 8200T CNC Lathe Programming Manual V2.2Document330 pages8200T CNC Lathe Programming Manual V2.2ahmed kamalNo ratings yet

- Leak Detection EquipmentDocument2 pagesLeak Detection EquipmentH2oNetNo ratings yet

- Configure a router with Netmiko PythonDocument5 pagesConfigure a router with Netmiko PythonAye KyawNo ratings yet

- 1.0 Introduction of CNC Turning MachineDocument9 pages1.0 Introduction of CNC Turning Machineeizhar50% (4)

- Internet Linguistics David CrystalDocument25 pagesInternet Linguistics David CrystalTamara Petković67% (3)

- Lab Manual CNC LatheDocument10 pagesLab Manual CNC LatheSai Naga Sri Harsha100% (1)

- G and M Coding Lab 03Document24 pagesG and M Coding Lab 03Mohsin Qazi100% (1)

- CNC Cutter Diameter Compensation GuideDocument12 pagesCNC Cutter Diameter Compensation GuideSankaralingam ShankarNo ratings yet

- Cutter Radius CompensationDocument2 pagesCutter Radius CompensationSivateja NallamothuNo ratings yet

- Manufacturing Processes UTA026Document40 pagesManufacturing Processes UTA026CrocodileNo ratings yet

- Experiment No 1: CNC TURNING: MEP310 - Manufacturing Process Automation Lab ManualDocument10 pagesExperiment No 1: CNC TURNING: MEP310 - Manufacturing Process Automation Lab ManualBandam Nitish kumarNo ratings yet

- CNC - Chapter 11 - Offsets & Polar Coordinate SystemDocument10 pagesCNC - Chapter 11 - Offsets & Polar Coordinate Systembarbu ioanNo ratings yet

- Typical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingDocument82 pagesTypical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingAbdul RehmanNo ratings yet

- CNC Tool Nose Radius CompensationDocument11 pagesCNC Tool Nose Radius CompensationManjunatha Gr100% (1)

- Code Description Milling (M) Turning (T) Corollary InfoDocument5 pagesCode Description Milling (M) Turning (T) Corollary InfoivtrubeljaNo ratings yet

- Cutter CompDocument3 pagesCutter CompJordan TranNo ratings yet

- Sect 9 CRCDocument22 pagesSect 9 CRCjuan carlos mejia riveraNo ratings yet

- CNC Codes and LettersDocument48 pagesCNC Codes and LettersIvo DimitrovNo ratings yet

- CNC CodingDocument26 pagesCNC CodingNEF RIDERSNo ratings yet

- Cutter Radius Compensation Relates To Machining Centers Tool Nose Radius Compensation Relates To Turning CentersDocument137 pagesCutter Radius Compensation Relates To Machining Centers Tool Nose Radius Compensation Relates To Turning CentersSuresh RajagopalNo ratings yet

- Ankit Kumar CNC/IPC/15 Summary ReportDocument54 pagesAnkit Kumar CNC/IPC/15 Summary Reportshivam modanwalNo ratings yet

- Solution of Cim AsignmentDocument49 pagesSolution of Cim AsignmentP20MF010MANGESH SHARMANo ratings yet

- Cnccodes Msnc500 enDocument14 pagesCnccodes Msnc500 enigorNo ratings yet

- Offsetting On CNC Milling MachineDocument2 pagesOffsetting On CNC Milling Machinekhayam khanNo ratings yet

- Dept. of Mech & Mfg. EnggDocument14 pagesDept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- CNC PresentationDocument13 pagesCNC PresentationMaryam AlbalooshiNo ratings yet

- Me 473 - Unit 4 - 1Document70 pagesMe 473 - Unit 4 - 1Ama Serwaa YeboahNo ratings yet

- Cam Lab ManualDocument14 pagesCam Lab Manualelangandhi0% (1)

- AI Nano CNC For High-Speed, High-Accuracy MachiningDocument24 pagesAI Nano CNC For High-Speed, High-Accuracy MachiningarashNo ratings yet

- Cutter Compensation ExampleDocument8 pagesCutter Compensation ExampletarasasankaNo ratings yet

- Series8000LatheOperation PDFDocument324 pagesSeries8000LatheOperation PDFSnaldo EstradaNo ratings yet

- G-Code - Wikipedia, The Free EncyclopediaDocument6 pagesG-Code - Wikipedia, The Free EncyclopediajoydeepNo ratings yet

- The Basics of CNC Machining Programming (For Lathe) : Computerized Numerical Controller (CNC)Document38 pagesThe Basics of CNC Machining Programming (For Lathe) : Computerized Numerical Controller (CNC)Thanh Kieu Nguyen ThiNo ratings yet

- TCPO Lsn14 - Reading MaterialDocument13 pagesTCPO Lsn14 - Reading Materialaravind madavanNo ratings yet

- NC - CNC - DNCDocument99 pagesNC - CNC - DNCsanjeevani rawatNo ratings yet

- CADCAM Intro1Document10 pagesCADCAM Intro1Yousef AshryNo ratings yet

- 12lesson Twelve PresentationDocument77 pages12lesson Twelve PresentationSuresh RajagopalNo ratings yet

- CNC Lathe2Document41 pagesCNC Lathe2Ruby SmithNo ratings yet

- Yashwant InternshipDocument17 pagesYashwant InternshipGoku RocksNo ratings yet

- My CNCDocument5 pagesMy CNCzoranteicNo ratings yet

- Practical CNC Lathe and Milling ReportDocument26 pagesPractical CNC Lathe and Milling ReportAndi MandiNo ratings yet

- CNC Programming Guide: Coordinate Systems, Plane Selection, and Interpolation FunctionsDocument90 pagesCNC Programming Guide: Coordinate Systems, Plane Selection, and Interpolation FunctionsDerik NelsonNo ratings yet

- CNC Milling Process GuideDocument16 pagesCNC Milling Process GuidezarepNo ratings yet

- CNC Codes and LettersDocument48 pagesCNC Codes and LettersJag DeshNo ratings yet

- Reference Basic G and M Codes PDFDocument5 pagesReference Basic G and M Codes PDFnwohaNo ratings yet

- Lesson Ten TextDocument9 pagesLesson Ten TextVignesh WaranNo ratings yet

- EML 342/2 Lab Report on CNC MachiningDocument9 pagesEML 342/2 Lab Report on CNC MachiningMark SelvanNo ratings yet

- WheelTool 1Document18 pagesWheelTool 1M Mostafa MasalmaNo ratings yet

- Dept. of Mech & Mfg. EnggDocument16 pagesDept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- Manufacturing Processes UTA026Document39 pagesManufacturing Processes UTA026SIDDHANT JAINNo ratings yet

- Study of CNC MachinesDocument53 pagesStudy of CNC MachinesPreethi VadivelNo ratings yet

- Declaration - by Signing and Submitting This FormDocument1 pageDeclaration - by Signing and Submitting This FormatllNo ratings yet

- Infineon-CE217633 BLE Blood Pressure Sensor With PSoC 6 MCU With BLE Connectivity-Code Example-V01 00-EnDocument17 pagesInfineon-CE217633 BLE Blood Pressure Sensor With PSoC 6 MCU With BLE Connectivity-Code Example-V01 00-EnJose PereiraNo ratings yet

- Spectra Enhanced 7 Series IR Look-Up PTZ: High-Speed PTZ, Surevision, and Including Pelco Advanced AnalyticsDocument15 pagesSpectra Enhanced 7 Series IR Look-Up PTZ: High-Speed PTZ, Surevision, and Including Pelco Advanced AnalyticsMithilesh GuruNo ratings yet

- SNR - Engineering - 19 - Unit3 - Ia1 - Ass - Inst - Project PDFDocument9 pagesSNR - Engineering - 19 - Unit3 - Ia1 - Ass - Inst - Project PDFPaul TatelNo ratings yet

- CV MonirDocument3 pagesCV MonirMIslamMonirNo ratings yet

- Camara DCS 2100+Document137 pagesCamara DCS 2100+alfredoxxxxNo ratings yet

- Logcat 1702664817732Document13 pagesLogcat 1702664817732fabiandejesuscentenoNo ratings yet

- VTU B.E CSE Sem 8 Software Testing NotesDocument26 pagesVTU B.E CSE Sem 8 Software Testing NotesAravind RossiNo ratings yet

- Strobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maDocument2 pagesStrobostomp HD™ Owner'S Instruction Manual V1.1 En: 9V DC Regulated 85maShane FairchildNo ratings yet

- Medical RoboticsDocument5 pagesMedical Roboticsapi-355890357No ratings yet

- G Ym 6 F 8 HEtoev 4 GEbDocument6 pagesG Ym 6 F 8 HEtoev 4 GEbPrakhar AgarwalNo ratings yet

- CRMDocument5 pagesCRMLieanne EspinosaNo ratings yet

- EE - 453 Power Quality and Harmonics: Harmonic MitigationDocument88 pagesEE - 453 Power Quality and Harmonics: Harmonic MitigationDevangi ChoudharyNo ratings yet

- Guidelines Poster PresentationDocument3 pagesGuidelines Poster PresentationtatianantlNo ratings yet

- Bosch Bulding Technologies Academy - Training Catalog 2024Document55 pagesBosch Bulding Technologies Academy - Training Catalog 2024erc001No ratings yet

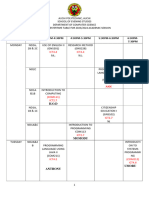

- Timetable First Semester 2023-2024Document12 pagesTimetable First Semester 2023-2024promiseikosimi43No ratings yet

- Student Result Managmenat SystemDocument11 pagesStudent Result Managmenat SystemPratim KhodareNo ratings yet

- TCLDocument13 pagesTCLYc ChenNo ratings yet

- Catalogo Typhoon Piaggio 125 4T 2V 2010-2011Document62 pagesCatalogo Typhoon Piaggio 125 4T 2V 2010-2011elysbrNo ratings yet

- SW DK TM4C123G Ug 2.1.0.12573Document22 pagesSW DK TM4C123G Ug 2.1.0.12573trungkiena6No ratings yet

- Positive Customer For VoipDocument47 pagesPositive Customer For VoipAnoyNo ratings yet

- MGT 513 Technology Forecasting and Assessment Fall 2014Document14 pagesMGT 513 Technology Forecasting and Assessment Fall 2014Arun VenkatesanNo ratings yet

- Car Technology and Safety - 52612Document2 pagesCar Technology and Safety - 52612CAROLINA CASTILLONo ratings yet