Professional Documents

Culture Documents

Mechanical Test

Uploaded by

GooftilaaAniJiraachuunkooYesusiin0 ratings0% found this document useful (0 votes)

44 views50 pagesOriginal Title

mechanical test.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views50 pagesMechanical Test

Uploaded by

GooftilaaAniJiraachuunkooYesusiinCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 50

Tension test

Specimen can be round, flat or tubular

ASTM specifications

Stress-Strain Curve

Elastic region

Plastic region

Necking

Mechanical Behavior,

Testing and Manufacturing

Properties of Materials

Strength

Hardness

Toughness

Stiffness

Strength/Density

Tension test formulas

•

Hooke’s law

•

FIGURE 2.1 (a) A standard tensile-test specimen before and after pulling, showing original

and final gage lengths. (b) Stages in specimen behavior in a tension test.

FIGURE 2.2 A typical stress–strain curve obtained from a tension test, showing

various features.

Plastic deformation

Proportional limit – the stress that the specimen undergoes nonlinear

elastic deformation

Permanent(plastic) deformation – occurs when the yield stress of the

material is reached

Y(yield stress) is often determined using the offset method (.2%

elongation) figure 2.2

FIGURE 2.3 Schematic illustration of the loading and the unloading of a tensile-test specimen. Note

that, during unloading, the curve follows a path parallel to the original elastic slope.

Ultimate tensile strength

The maximum engineering stress is called the tensile strength or

ultimate tensile strength and is the maximum stress found from the

σ-ε diagram

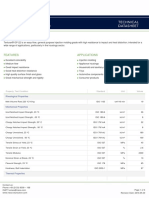

TABLE 2.2 Mechanical Properties of Various Materials at Room Temperature

ductility

•

FIGURE 2.5 (a) Load–elongation curve in tension testing of a stainless steel specimen. (b) Engineering stress–

engineering strain curve, drawn from the data in Fig. 2.5a. (c) True stress–true strain curve, drawn from the data in Fig.

2.5b. Note that this curve has a positive slope, indicating that the material is becoming stronger as it is strained. (d) True

stress–true strain curve plotted on log–log paper and based on the corrected curve in Fig. 2.5c. The correction is due to the

triaxial state of stress that exists in the necked region of the specimen.

True stress & true strain

•

TABLE 2.3 Typical Values for K and n for Metals at Room Temperature

Strain at necking in a

tension test

The true strain at the onset of necking is numerically equal to the

strain-hardening exponent, n, of the material. Thus, the higher the

value of n, the higher the strain that a piece of material can

experience before it begins to neck.

Note: from table 2.3 these have high n values and can be stretched

uniformly to a greater extent than can the other metals listed.

Annealed copper

Brass

Stainless steel

FIGURE 2.6 True stress–true strain curves in tension at room temperature for various metals. The curves start at a finite level of

stress: The elastic regions have too steep a slope to be shown in this figure; thus, each curve starts at the yield stress, Y, of the

material.

Temperature effects

Increasing the temperature…

Ductility increases

Toughness increases

Yield stress decreases

Modulus of elasticity decreases

n decreases (strain-hardening

exponent)

FIGURE 2.7 Effect of temperature on mechanical properties of a carbon steel. Most materials display similar temperature

sensitivity for elastic modulus, yield strength, ultimate strength, and ductility.

Deformation rate

Deformation rate is defined as the speed at which a tension test is

being carried out (ft/min, m/sec…)

Strain rate is a function of the specimen’s length. A short specimen

elongates proportionally more during the same period than does a

long specimen.

Superplasticity refers to the capacity of some materials to undergo

large uniform elongation prior to necking and fracture in tension

(examples: bubble gum, glass, thermoplastics at room temperature)

Compression test

Solid cylindrical specimen between two well lubricated flat dies

(platens)

Because of friction between the specimen and the platens, the

specimen’s cylindrical surfaces bulge (barreling)

Slender specimens buckle

For ductile materials, the true stress-true strain curves coincide

Brittle materials are generally stronger and more ductile in

compression

Disk test is also used to test compressive stress

FIGURE 2.9 Disk test on a brittle material, showing the direction of loading and the fracture path.

torsion

•

FIGURE 2.10 A typical torsion-test specimen; it is mounted between the two heads of a testing machine and twisted. Note the

shear deformation of an element in the reduced section of the specimen.

Bending (flexure)

• Used for brittle materials

• Three point or four point

• Rectangular cross section specimens

• Modulus of rupture is the stress at fracture

FIGURE 2.11 Two bend-test methods for brittle materials: (a) three-point bending; (b) four-point bending. The areas on the

beams represent the bending moment diagrams, described in texts on the mechanics of solids. Note the region of constant

maximum bending moment in (b); by contrast, the maximum bending moment occurs only at the center of the specimen in (a).

hardness

• Defined as the resistance to permanent indentation

• Hardness tests use different indenter materials and shapes

• Brinell

• Rockwell

• Vickers

• Knoop

FIGURE 2.12 Selected hardness testers. (a) A Micro Vickers hardness tester; (b) Rockwell hardness tester; (c) Durometer; (d)

Leeb tester. Source: (a) through (c) Courtesy of Newage Testing Instruments, Inc.; (d) Courtesy of Wilson ® Instruments.

FIGURE 2.13 General characteristics of hardness-testing methods and formulas for calculating hardness.

Hardness and strength

• UTS=3.5(HB) SI units (UTS in MPa)

• UTS=500(HB) English units (UTS in psi)

• HB is Brinell hardness

• Since hardness is the resistance to permanent indentation it

can be likened to performing a compression test on a small

volume on the surface of a material

Fatigue

• Rapid fluctuating cyclic or periodic loads

• Parts fail at a stress level below that at which failure would occur

under static loading

• Failure is found to be associated with cracks that grow with every

stress cycle and propagate through the material

• FATIGUE FAILURE-responsible for the majority of failures in

mechanical components

• Rotating machine elements under constant bending stresses as with

shafts

Fatigue test

• Testing specimens under various states of stress, usually in a

combination of tension and bending

• Stress amplitudes S

• Number of cycles N

• S-N Curves

• Endurance limit (fatigue limit): the maximum stress the material can

be subjected without fatigue failure, regardless of N

FIGURE 2.16 (a) Typical S–N curves for two metals. Note that, unlike steel, aluminum does not have

an endurance limit. (b) S–N curves for common polymers.

creep

• CREEP is the permanent elongation of a component under a

static load maintained for a period of time.

• Metals, thermoplastics, rubbers

• Occurs at any temperature

• Recall: creep at elevated temperatures is attributed to grain-

boundary sliding

Creep test

• The test generally consists of subjecting a specimen to a constant

tensile load at elevated temperature and measuring the changes in

length at various time increments

• Primary stage/Secondary stage/Tertiary stage

• STRESS RELAXATION-the stresses resulting from loading of a structural

component decrease in magnitude over a period of time, even

though the dimensions of the component remain constant (example:

piano wire)

FIGURE 2.17 Ratio of endurance limit to tensile strength for various metals, as a function of tensile

strength. Because aluminum does not have an endurance limit, the correlations for aluminum are

based on a specific number of cycles, as is seen in Fig. 2.16.

FIGURE 2.18 Schematic illustration of a typical creep curve. The linear segment of the curve

(secondary) is used in designing components for a specific creep life.

impact

• A typical impact test consists of placing a notched specimen in an

impact tester and breaking the specimen with a swinging pendulum

• CHARPY

• IZOD

• Impact Toughness-the energy dissipated by breaking the specimen

• Materials with high impact resistance generally have high strength,

ductility, toughness

FIGURE 2.19 Impact test specimens. (a) Izod; (b) Charpy .

Failure and fracture

• Fracture- through either internal or external cracking

• Ductile-plastic deformation which proceeds to failure

• Brittle–little or no gross plastic deformation

• Buckling – a long slender column under compressive loads

FIGURE 2.20 Schematic illustration of types of failures in materials: (a) necking and fracture of ductile materials;

(b) buckling of ductile materials under a compressive load; (c) fracture of brittle materials in compression; (d)

cracking on the barreled surface of ductile materials in compression.

FIGURE 2.21 Schematic illustration of the types of fracture in tension: (a) brittle fracture in

polycrystalline metals; (b) shear fracture in ductile single crystals—see also Fig. 1.5a; (c)

ductile cup-and-cone fracture in polycrystalline metals; (d) complete ductile fracture in

polycrystalline metals, with 100%reduction of area.

FIGURE 2.23 Sequence of events in the necking and fracture of a tensile-test specimen: (a)

early stage of necking; (b) small voids begin to form within the necked region; (c) voids

coalesce, producing an internal crack; (d) the rest of the cross section begins to fail at the

periphery, by shearing; (e) the final fracture, known as a cup- (top fracture surface) and-

cone-(bottom surface) fracture, surfaces.

FIGURE 2.24 Schematic illustration of the deformation of soft and hard inclusions and of

their effect on void formation in plastic deformation. Note that, because they do not conform to

the overall deformation of the ductile matrix, hard inclusions can cause internal voids.

Transition temperature

• Many metals undergo a sharp change in ductility and

toughness across a narrow temperature range

• Occurs mainly in bcc and hcp metals

FIGURE 2.25 Schematic illustration of transition temperature in metals .

Brittle fracture

• Occurs with little or no gross plastic deformation

• In tension fracture takes place along the crystallographic plane

(cleavage plane) on which the normal tensile stress is a maximum

• In general low temperature & high deformation rate promote brittle

fracture

• DEFECTS explain why brittle materials are weak in tension compared

to compression

• CATASTROPHIC FAILURE-under tensile stresses cracks propagate

rapidly

FIGURE 2.26 Fracture surface of steel that has failed in a brittle manner. The fracture path is

transgranular (through the grains). Magnification: 200. Source: Courtesy of B.J. Schulze and S.L.

Meiley and Packer Engineering Associates, Inc.

FIGURE 2.27 Intergranular fracture, at two different magnifications. Grains and grain boundaries are clearly

visible in this micrograph. The fracture path is along the grain boundaries. Magnification: left, 100 ; right, 500.

Source: Courtesy of B.J. Schulze and S.L. Meiley and Packer Engineering Associates, Inc.

Residual stress

• Residual stresses are those that remain in a workpiece after it has

been plastically deformed and then has had all external forces

removed

• Eliminated by stress-relief annealing, further plastic deformation, or

relaxation over time

You might also like

- ME491-Ch 2Document36 pagesME491-Ch 2Yazan MannaNo ratings yet

- Material Testing On Mechanical Properties Top 5Document37 pagesMaterial Testing On Mechanical Properties Top 5Hezron gibronNo ratings yet

- Lecture 12Document8 pagesLecture 12Mechanical ZombieNo ratings yet

- Https Attachment - Fbsbx.com File (Pdownload PDFDocument46 pagesHttps Attachment - Fbsbx.com File (Pdownload PDFAshish JainNo ratings yet

- Lecture 11Document6 pagesLecture 11Mechanical ZombieNo ratings yet

- Proses Manufaktur-5 - MhsDocument47 pagesProses Manufaktur-5 - MhsBintang NurimanNo ratings yet

- Ultimate Tensile StrengthDocument12 pagesUltimate Tensile StrengthR BNo ratings yet

- UNIT-II Mechanical Property MeasurementDocument127 pagesUNIT-II Mechanical Property Measurementlol WANo ratings yet

- Materials For Mechanical PartsDocument20 pagesMaterials For Mechanical PartsasmaNo ratings yet

- 06 Comp+hardnessDocument8 pages06 Comp+hardnessamokhtaNo ratings yet

- Mechanical Properties: Echanical RopertiesDocument14 pagesMechanical Properties: Echanical Ropertieskoiuy12No ratings yet

- Uniaxial TestDocument6 pagesUniaxial Testanil chejaraNo ratings yet

- Bending Test.Document24 pagesBending Test.Suzzo Sherwood0% (1)

- Chapter 3: Tensile TestingDocument10 pagesChapter 3: Tensile TestingKhairul MuzafarNo ratings yet

- Impact Test Ravi Agarwal 09003017 Group GDocument8 pagesImpact Test Ravi Agarwal 09003017 Group GRavi Agarwal100% (1)

- MM207E | Materials Science | Lab2_Tensile Test | Mechanic LabDocument4 pagesMM207E | Materials Science | Lab2_Tensile Test | Mechanic LabKerem Taha TekinNo ratings yet

- Structural Integrity Analysis 3. Mechanical PropertiesDocument23 pagesStructural Integrity Analysis 3. Mechanical PropertiesbountymaniNo ratings yet

- Civil Lect 2 - Material Properties 2015Document29 pagesCivil Lect 2 - Material Properties 2015Abdelhay Mohamed HassanNo ratings yet

- C Yyyy Yy Yy Yy Yy Y Y: Yyy YyyyyyyyyyyyyyDocument5 pagesC Yyyy Yy Yy Yy Yy Y Y: Yyy YyyyyyyyyyyyyyMadan MaharanaNo ratings yet

- MATERIAL SCIENCE LECTURE ON MECHANICAL PROPERTIESDocument33 pagesMATERIAL SCIENCE LECTURE ON MECHANICAL PROPERTIES翁绍棠No ratings yet

- Lap Beres Smoga Dapat BDocument17 pagesLap Beres Smoga Dapat BPria Akbar SejatiNo ratings yet

- SIA 3 Mechanical PropertiesDocument22 pagesSIA 3 Mechanical PropertiesSrinivas RallabandiNo ratings yet

- Bisalloy Technical Manual SectionsDocument65 pagesBisalloy Technical Manual Sectionsramaus100% (1)

- VIBRATORY STRESS RELIEF: A FUNDAMENTAL STUDY OF ITS EFFECTIVENESSDawson MoffatDocument9 pagesVIBRATORY STRESS RELIEF: A FUNDAMENTAL STUDY OF ITS EFFECTIVENESSDawson MoffatgreatsteelNo ratings yet

- Lab. 2 - Strengthing Materials by Cold WorkingDocument4 pagesLab. 2 - Strengthing Materials by Cold WorkingDonNo ratings yet

- Polymer Testing: Dr. Mohammad Dalour Hossen Beg Fkksa, UmpDocument29 pagesPolymer Testing: Dr. Mohammad Dalour Hossen Beg Fkksa, UmpmirazieyNo ratings yet

- Testing of FastenersDocument4 pagesTesting of Fastenersmp87_ingNo ratings yet

- Mechanical Properties and Stress-Strain Diagram of Tensile Tested SteelDocument13 pagesMechanical Properties and Stress-Strain Diagram of Tensile Tested Steelالشهاب ناروتوNo ratings yet

- Properties of Construction Materials and Their Stress/strain BehaviourDocument15 pagesProperties of Construction Materials and Their Stress/strain BehaviourOmokhiboria JoshuaNo ratings yet

- Fracture Mechanics Lecture SlidesDocument37 pagesFracture Mechanics Lecture SlidesCrystal WoodsNo ratings yet

- Diversi'ed Testing Labs: ISO/IEC 17043 AccreditationDocument1 pageDiversi'ed Testing Labs: ISO/IEC 17043 AccreditationKirat Jot SinghNo ratings yet

- Ultimate Tensile StrengthDocument8 pagesUltimate Tensile StrengthstevenspillkumarNo ratings yet

- ISE316 Chapter 3 - Mechanics of MaterialsDocument37 pagesISE316 Chapter 3 - Mechanics of MaterialsAnonymous 7ZYHilDNo ratings yet

- Ultimate Tensile StrengthDocument8 pagesUltimate Tensile Strengthphutd09No ratings yet

- Identifying Unknown SamplesDocument12 pagesIdentifying Unknown SamplesJason Paul RoqueNo ratings yet

- Stress-Strain Curve - Wikipedia, The Free EncyclopediaDocument4 pagesStress-Strain Curve - Wikipedia, The Free EncyclopediaKarthik PallavaliNo ratings yet

- Faculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetDocument18 pagesFaculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetPanadol PanadolNo ratings yet

- Stress-Strain Curve - WikipediaDocument3 pagesStress-Strain Curve - WikipediaTomy GeorgeNo ratings yet

- Module 7: Testing The Tensile Strength of Steel BarsDocument5 pagesModule 7: Testing The Tensile Strength of Steel BarsPrincess Tamani ManzanoNo ratings yet

- AER507 Lab ManualDocument39 pagesAER507 Lab Manualarmon_domingoNo ratings yet

- TranskripDocument5 pagesTranskripDendi AriyonoNo ratings yet

- Bending Test.Document21 pagesBending Test.julio padronNo ratings yet

- ENCI 317 - LAB 1 - Lab MaterialDocument15 pagesENCI 317 - LAB 1 - Lab MaterialSherry YousafNo ratings yet

- Chapter 4 Year 3Document27 pagesChapter 4 Year 3Mohd SoufianNo ratings yet

- DT SampDocument18 pagesDT SampvijaylearNo ratings yet

- Fig. Torsional Shear StressDocument51 pagesFig. Torsional Shear StresskrishNo ratings yet

- Theory of Tensile Test Engineering Essay PDFDocument8 pagesTheory of Tensile Test Engineering Essay PDFgraNo ratings yet

- Stresss, Strain, ModulusDocument18 pagesStresss, Strain, ModulusSaif IslamNo ratings yet

- Mechanical Behavior, Testing, and Manufacturing Properties of MaterialsDocument35 pagesMechanical Behavior, Testing, and Manufacturing Properties of MaterialsFennyFebrinaNurlitaSariNo ratings yet

- Strength of Materials Lab-Ahmed Alshara (4)Document24 pagesStrength of Materials Lab-Ahmed Alshara (4)MṜ ΛßßΛSNo ratings yet

- Flexural or Bending Test Lab ReportDocument9 pagesFlexural or Bending Test Lab ReportAman NigamNo ratings yet

- 09 Torsion Moment & Torsion Angle of ShaftDocument7 pages09 Torsion Moment & Torsion Angle of ShaftElaine PuiNo ratings yet

- Mos-I Lab Manual PDFDocument31 pagesMos-I Lab Manual PDFFArzand E GulNo ratings yet

- Chapter 03 Mechanical PropertiesDocument8 pagesChapter 03 Mechanical PropertiesSumaya MahmoodNo ratings yet

- Strength of Material - Young Modulus ExperimentDocument31 pagesStrength of Material - Young Modulus Experimentfangyingtee25100% (1)

- Materials Engg Hardness TestDocument8 pagesMaterials Engg Hardness TestSourav KayalNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Methodology: The Combined Torque and Emission Control Will Be Validated On A 2.3L TurDocument2 pagesMethodology: The Combined Torque and Emission Control Will Be Validated On A 2.3L TurGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Creep-Fatigue Crack Initiation Assessment ProceduresDocument12 pagesCreep-Fatigue Crack Initiation Assessment ProceduresGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Best, Life Prediction Model For Creep-Fatigue Interaction of P92 Advanced Grade Martensitic SteelDocument51 pagesBest, Life Prediction Model For Creep-Fatigue Interaction of P92 Advanced Grade Martensitic SteelGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Engineering Models For SofteningDocument13 pagesEngineering Models For SofteningGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Creep-Fatigue Behavior of Aluminum Alloy-Based Metal MatrixDocument22 pagesCreep-Fatigue Behavior of Aluminum Alloy-Based Metal MatrixGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Writing A Research Grant Proposal PDFDocument19 pagesWriting A Research Grant Proposal PDFsimranNo ratings yet

- Dasar Dasar Terapi Cairan Dan ElektrolitDocument15 pagesDasar Dasar Terapi Cairan Dan ElektrolitMaulydia PelluNo ratings yet

- Understanding Stress & StrainDocument36 pagesUnderstanding Stress & StrainGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Sample Grant 2Document4 pagesSample Grant 2GooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Creep DescriptionDocument11 pagesCreep DescriptionGerry AnandaNo ratings yet

- Writing Competitive ProposalsDocument48 pagesWriting Competitive ProposalsGauravNo ratings yet

- 01 Res 37 4 509Document12 pages01 Res 37 4 509GooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Fatigue Failure Analysis of Crankshafts-A ReviewDocument14 pagesFatigue Failure Analysis of Crankshafts-A ReviewGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Materials TestingDocument32 pagesMaterials TestingArun Babu KNo ratings yet

- Materials TestingDocument32 pagesMaterials TestingArun Babu KNo ratings yet

- Materials TestingDocument32 pagesMaterials TestingArun Babu KNo ratings yet

- Mechannica TestsDocument78 pagesMechannica TestsGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- DMS Chap5 Part3 FTransformDocument54 pagesDMS Chap5 Part3 FTransformGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Polymers Deformation PDFDocument68 pagesPolymers Deformation PDFGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Product Design ProcessDocument14 pagesProduct Design ProcessGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Bench MarkingDocument39 pagesBench Markingjanagyrama1No ratings yet

- Machine Design II Clutches DesignDocument14 pagesMachine Design II Clutches DesignGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- BenchmarkingDocument31 pagesBenchmarkingHaseeb BokhariNo ratings yet

- Product Design ProcessDocument14 pagesProduct Design ProcessGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Modeling Input-Output SystemsDocument57 pagesModeling Input-Output SystemsGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Product Concept Selection 11Document14 pagesProduct Concept Selection 11GooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Input-Output Modeling of SystemsDocument108 pagesInput-Output Modeling of SystemsGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Generalized Approach To ModelingDocument51 pagesGeneralized Approach To ModelingGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Rigid Body Motion: Angular Momentum and TorqueDocument31 pagesRigid Body Motion: Angular Momentum and TorqueGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Astm B23Document4 pagesAstm B23Angel GarciaNo ratings yet

- SCIA1203Document392 pagesSCIA1203Issac JasminNo ratings yet

- Rotary EndodonticsDocument61 pagesRotary EndodonticsVijayendra kamathNo ratings yet

- Mechanics of SolidsDocument164 pagesMechanics of Solidsmdaashu007No ratings yet

- Ampco 18: Technical Data SheetDocument2 pagesAmpco 18: Technical Data SheetAchilles AldaveNo ratings yet

- MDSP Problem Coaching Part 2Document403 pagesMDSP Problem Coaching Part 2Sadam August DulomNo ratings yet

- SFRC Load Bearing Study ReportDocument14 pagesSFRC Load Bearing Study ReportRainakNo ratings yet

- Analysis of Wear Using LS - DYNADocument10 pagesAnalysis of Wear Using LS - DYNAwondwosenAyeleNo ratings yet

- Orkot BearingsDocument20 pagesOrkot BearingsTrelleborgSealsNo ratings yet

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy Detailcharles_boyle_3No ratings yet

- Problemas de Concentracion de EsfuerzosDocument7 pagesProblemas de Concentracion de EsfuerzosJonathan MendozaNo ratings yet

- MEE 212 Pre - CH 2Document53 pagesMEE 212 Pre - CH 2alhassan Abdul MaleeqNo ratings yet

- Navid Moslemi - A Novel Systematic Numerical Approach On Determination of Heat Source Parameters in Welding Process PDFDocument18 pagesNavid Moslemi - A Novel Systematic Numerical Approach On Determination of Heat Source Parameters in Welding Process PDFaceroman21No ratings yet

- W. H. Mosley, J. H. Bungey, R. Hulse (Auth.) - Reinforced Concrete Design-Macmillan Education UK (1999)Document397 pagesW. H. Mosley, J. H. Bungey, R. Hulse (Auth.) - Reinforced Concrete Design-Macmillan Education UK (1999)divakar100% (3)

- Review of Fatigue Strength Assessment ofDocument18 pagesReview of Fatigue Strength Assessment ofNrl SyafiniNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Aci SP-17Document260 pagesAci SP-17Sarkis Masis100% (2)

- Anchor Channel - 202 Seismic Design of Facade AttachmentsDocument37 pagesAnchor Channel - 202 Seismic Design of Facade AttachmentsPerry PintoNo ratings yet

- Shear Transfer in Concrete Having Reinforcement at An Angle To Shear PlaneDocument26 pagesShear Transfer in Concrete Having Reinforcement at An Angle To Shear PlanePremasiri Karunarathna100% (1)

- AmmcDocument55 pagesAmmcSrikanth Reddy100% (2)

- Plate Buckling eDocument51 pagesPlate Buckling eViet Duc DangNo ratings yet

- Minimum Steel Concrete Beam DesignDocument9 pagesMinimum Steel Concrete Beam DesignalshaijiNo ratings yet

- Esab Chrome Moly Electrode BrochureDocument21 pagesEsab Chrome Moly Electrode BrochureShankar Gurusamy100% (1)

- API 5CT Scope For Pup JointsDocument3 pagesAPI 5CT Scope For Pup JointsKapil HarchekarNo ratings yet

- Development Length On Concrete With Bundle BarsDocument5 pagesDevelopment Length On Concrete With Bundle BarsVetriselvan ArumugamNo ratings yet

- PHD ThesisDocument256 pagesPHD ThesisTadeu Felix0% (1)

- Cold Rolling and Tensile Testing Effects on MetalsDocument14 pagesCold Rolling and Tensile Testing Effects on MetalsSean BiseNo ratings yet

- Alloy Steels - Grades - Compositions - PropertiesDocument7 pagesAlloy Steels - Grades - Compositions - PropertiesAnirudhreddy SafalNo ratings yet

- Area 01: Arpp: Instructions: Encircle The Best Answer. NO ERASURESDocument13 pagesArea 01: Arpp: Instructions: Encircle The Best Answer. NO ERASURESLəonardo SasingNo ratings yet

- Lecture 12Document15 pagesLecture 12Farhan KhanNo ratings yet