Professional Documents

Culture Documents

Chapter 13

Uploaded by

SaAhRa0 ratings0% found this document useful (0 votes)

16 views109 pagesThis document discusses various plastic shaping processes including extrusion, molding, casting, and foaming. It provides details on extrusion processes, which is a continuous compression process that forces plastic through a die to produce continuous products like tubes, sheets, and coatings. The key components of an extruder are the barrel, where plastic is melted and compressed, and the screw, which moves the plastic through the barrel. The shape of the extrusion die determines the cross-sectional shape of the extruded plastic product. Extrusion is widely used for making profiles, hollow shapes, wire coatings, sheets, and films on an industrial scale.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses various plastic shaping processes including extrusion, molding, casting, and foaming. It provides details on extrusion processes, which is a continuous compression process that forces plastic through a die to produce continuous products like tubes, sheets, and coatings. The key components of an extruder are the barrel, where plastic is melted and compressed, and the screw, which moves the plastic through the barrel. The shape of the extrusion die determines the cross-sectional shape of the extruded plastic product. Extrusion is widely used for making profiles, hollow shapes, wire coatings, sheets, and films on an industrial scale.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views109 pagesChapter 13

Uploaded by

SaAhRaThis document discusses various plastic shaping processes including extrusion, molding, casting, and foaming. It provides details on extrusion processes, which is a continuous compression process that forces plastic through a die to produce continuous products like tubes, sheets, and coatings. The key components of an extruder are the barrel, where plastic is melted and compressed, and the screw, which moves the plastic through the barrel. The shape of the extrusion die determines the cross-sectional shape of the extruded plastic product. Extrusion is widely used for making profiles, hollow shapes, wire coatings, sheets, and films on an industrial scale.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 109

Chapter 13

SHAPING PROCESSES FOR PLASTICS

• Properties of Polymer Melts

• Extrusion and Related Processes

• Molding Processes

• Casting

• Polymer Foam Processing and Forming

• Product Design Considerations

ISE 316 - Manufacturing Processes

Engineering

Plastic Products

• Plastics can be shaped into a wide variety of

products:

– Molded parts

– Extruded sections

– Films

– Sheets

– Insulation coatings on electrical wires

– Fibers for textiles

ISE 316 - Manufacturing Processes

Engineering

Why Plastic Shaping Processes are Important

• Almost unlimited variety of part geometries

• Plastic molding is a net shape process; further

shaping is not needed

• Less energy is required than for metals because

processing temperatures are much lower

– Handling of product is simplified during production

because of lower temperatures

• Painting or plating is usually not required

ISE 316 - Manufacturing Processes

Engineering

Two Types of Plastics

1. Thermoplastics

– Chemical structure remains unchanged during

heating and shaping

– More important commercially, comprising more than

70% of total plastics tonnage

2. Thermosets

– Undergo a curing process during heating and shaping,

causing a permanent change (called cross‑linking) in

molecular structure

– Once cured, they cannot be remelted

ISE 316 - Manufacturing Processes

Engineering

Classification of Plastics Shaping Processes by

Product Geometry

• Extruded products with constant cross‑section

• Continuous sheets and films

• Continuous filaments (fibers)

• Molded parts which are mostly solid

• Hollow molded parts with relatively thin walls

• Discrete parts made of formed sheets and films

• Castings

• Foamed products

ISE 316 - Manufacturing Processes

Engineering

Polymer Melts

• To shape a thermoplastic polymer it must be

heated so that it softens to the consistency of

a liquid

• In this form, it is called a polymer melt

• Important properties:

– Viscosity

– Viscoelasticity

ISE 316 - Manufacturing Processes

Engineering

Viscosity of Polymer Melts

Fluid property that relates shear stress to shear rate

during flow

• Due to its high molecular weight, a polymer melt is a

thick fluid with high viscosity

• Important because most polymer shaping processes

involve flow through small channels or die openings

• Flow rates are often large, leading to high shear rates

and shear stresses, so significant pressures are

required to accomplish the processes

ISE 316 - Manufacturing Processes

Engineering

Viscosity of a polymer melt decreases with shear rate,

thus the fluid becomes thinner at higher shear rates

Figure 13.1 ‑ Viscosity

relationships for

Newtonian fluid and

typical polymer melt

ISE 316 - Manufacturing Processes

Engineering

Viscosity of a polymer melt decreases with temperature,

thus the fluid becomes thinner at higher temperatures

Figure 13.2 ‑

Viscosity as a

function of

temperature for

selected polymers

at a shear rate of

103 s-1

ISE 316 - Manufacturing Processes

Engineering

Viscoelasticity

Combination of viscosity and elasticity

• Possessed by both polymer solids and polymer

melts

• Example: die swell in extrusion, in which the

hot plastic expands when exiting the die

opening

ISE 316 - Manufacturing Processes

Engineering

Die Swell

Extruded material "remembers" its former shape when

in the larger cross-section of the extruder and

attempts to return to it after leaving the die orifice

Figure 13.3 ‑ Die swell, a manifestation of viscoelasticity in

polymer melts, as depicted here on exiting an extrusion die

ISE 316 - Manufacturing Processes

Engineering

Extrusion

Compression process in which material is forced to flow

through a die orifice to provide long continuous

product whose cross‑sectional shape is determined by

the shape of the orifice

• Widely used for thermoplastics and elastomers to

mass produce items such as tubing, pipes, hose,

structural shapes, sheet and film, continuous

filaments, and coated electrical wire

• Carried out as a continuous process; extrudate is then

cut into desired lengths

ISE 316 - Manufacturing Processes

Engineering

Figure 13.4 ‑ Components and features of a (single‑screw) extruder for

plastics and elastomers

ISE 316 - Manufacturing Processes

Engineering

Two Main Components of an Extruder

1. Barrel

2. Screw

• Die - not an extruder component

– It is a special tool that must be fabricated for

particular profile to be produced

ISE 316 - Manufacturing Processes

Engineering

Extruder Barrel

• Internal diameter typically ranges from 25 to 150

mm (1.0 to 6.0 in.)

• L/D ratios usually between 10 and 30: higher ratios

for thermoplastic, lower ratios for elastomers

• Feedstock fed by gravity onto screw whose

rotation moves material through barrel

• Electric heaters melt feedstock; subsequent mixing

and mechanical working adds heat which

maintains the melt

ISE 316 - Manufacturing Processes

Engineering

Extruder Screw

• Divided into sections to serve several functions:

– Feed section - feedstock is moved from hopper and

preheated

– Compression section - polymer is transformed into

fluid, air mixed with pellets is extracted from melt,

and material is compressed

– Metering section - melt is homogenized and

sufficient pressure developed to pump it through

die opening

ISE 316 - Manufacturing Processes

Engineering

Figure 13.5 ‑ Details of an extruder screw inside the barrel

ISE 316 - Manufacturing Processes

Engineering

Die Configurations and Extruded Products

• The shape of the die orifice determines the

cross‑sectional shape of the extrudate

• Common die profiles and corresponding

extruded shapes:

– Solid profiles

– Hollow profiles, such as tubes

– Wire and cable coating

– Sheet and film

– Filaments

ISE 316 - Manufacturing Processes

Engineering

Extrusion of Solid Profiles

• Regular shapes such as

– Rounds

– Squares

• Irregular cross‑sections such as

– Structural shapes

– Door and window moldings

– Automobile trim

– House siding

ISE 316 - Manufacturing Processes

Engineering

Figure 13.8 ‑ (a) Side view cross‑section of an extrusion die for solid

regular shapes, such as round stock; (b) front view of die, with profile

of extrudate Die swell is evident in both views

(Some die construction details are simplified or omitted for clarity.)

ISE 316 - Manufacturing Processes

Engineering

Hollow Profiles

• Examples: tubes, pipes, hoses, and other

cross‑sections containing holes

• Hollow profiles require mandrel to form the shape

• Mandrel held in place using a spider

– Polymer melt flows around legs supporting the

mandrel to reunite into a monolithic tube wall

• Mandrel often includes an air channel through

which air is blown to maintain hollow form of

extrudate during hardening

ISE 316 - Manufacturing Processes

Engineering

Figure 13.10 ‑ Side view cross‑section of extrusion die for shaping hollow

cross‑sections such as tubes and pipes; Section A‑A is a front view

cross‑section showing how the mandrel is held in place; Section B‑B

shows the tubular cross‑section just prior to exiting the die; die swell

causes an enlargement of the diameter

ISE 316 - Manufacturing Processes

Engineering

Wire and Cable Coating

• Polymer melt is applied to bare wire as it is

pulled at high speed through a die

– A slight vacuum is drawn between wire and

polymer to promote adhesion of coating

• Wire provides rigidity during cooling - usually

aided by passing coated wire through a water

trough

• Product is wound onto large spools at speeds

up to 50 m/s (10,000 ft/min)

ISE 316 - Manufacturing Processes

Engineering

Figure 13.11 ‑ Side view cross‑section of die for coating of electrical wire

by extrusion

ISE 316 - Manufacturing Processes

Engineering

Polymer Sheet and Film

• Sheet

– Thickness from 0.5 mm (0.020 in.) to about 12.5 mm

(0.5 in.)

– Used for products such as flat window glazing and

stock for thermoforming

• Film

– Thickness below 0.5 mm (0.020 in.)

– Used for packaging (product wrapping material,

grocery bags, and garbage bags)

– Thicker film applications include pool covers and

liners for irrigation ditches

ISE 316 - Manufacturing Processes

Engineering

Materials for Polymer Sheet and Film

• All thermoplastic polymers

– Polyethylene, mostly low density PE

– Polypropylene

– Polyvinylchloride

– Cellophane

ISE 316 - Manufacturing Processes

Engineering

Sheet and Film Production Processes

• Most widely used processes are continuous,

high production operations

• Processes include:

– Slit‑Die Extrusion of Sheet and Film

– Blown‑Film Extrusion Process

– Calendering

ISE 316 - Manufacturing Processes

Engineering

Slit‑Die Extrusion of Sheet and Film

Production of sheet and film by conventional

extrusion, using a narrow slit as the die opening

• Slit may be up to 3 m (10 ft) wide and as narrow as

around 0.4 mm (0.015 in)

• A problem in this method is uniformity of thickness

throughout width of stock, due to drastic shape

change of polymer melt during its flow through die

• Edges of film usually must be trimmed because of

thickening at edges

ISE 316 - Manufacturing Processes

Engineering

Figure 13.14 ‑ One of several die configurations for extruding

sheet and film

ISE 316 - Manufacturing Processes

Engineering

Blown‑Film Extrusion Process

Combines extrusion and blowing to produce a

tube of thin film

• Process begins with extrusion of tube that is

drawn upward while still molten and

simultaneously expanded by air inflated into it

through die mandrel

• Air is blown into tube to maintain uniform film

thickness and tube diameter

ISE 316 - Manufacturing Processes

Engineering

Figure 13.16 ‑

Blown‑film process

for high

production of thin

tubular film

ISE 316 - Manufacturing Processes

Engineering

Calendering

Feedstock is passed through a series of rolls to reduce

thickness to desired gage

• Equipment is expensive, but production rate is high

• Process is noted for good surface finish and high

gage accuracy

• Typical materials: rubber or rubbery thermoplastics

such as plasticized PVC

• Products: PVC floor covering, shower curtains, vinyl

table cloths, pool liners, and inflatable boats and toys

ISE 316 - Manufacturing Processes

Engineering

Figure 13.17 ‑ A typical roll configuration in calendering

ISE 316 - Manufacturing Processes

Engineering

Fiber and Filament Products

• Most important application of fibers and

filaments is in textiles

• Their use as reinforcing materials in plastics

(composites) is growing, but still small

compared to textiles

• Definitions:

– Fiber - a long, thin strand whose length is at least

100 times its cross‑section

– Filament - a fiber of continuous length

ISE 316 - Manufacturing Processes

Engineering

Materials for Fibers and Filaments

• Fibers can be natural or synthetic

• Synthetic fibers constitute about 75% of total

fiber market today:

– Polyester is the most important

– Others: nylon, acrylics, and rayon

• Natural fibers are about 25% of total:

– Cotton is by far the most important staple

– Wool production is significantly less than cotton

ISE 316 - Manufacturing Processes

Engineering

Fiber and Filament Production - Spinning

• The term spinning is a holdover from methods used

to draw and twist natural fibers into yarn or thread

For synthetic fibers, spinning = extruding a polymer melt

or solution through a spinneret (a die with multiple

small holes), then drawing and winding the product

onto a bobbin

• Three variations, depending on polymer processed:

1. Melt spinning

2. Dry spinning

3. Wet spinning

ISE 316 - Manufacturing Processes

Engineering

Melt Spinning

Starting polymer is heated to molten state and pumped

through spinneret, similar to conventional extrusion

• Typical spinneret is 6 mm (0.25 in) thick and contains

approximately 50 holes of diameter 0.25 mm (0.010 in)

• Filaments are drawn and air cooled before being

spooled onto bobbin

• Significant extension and thinning of filaments occur

while polymer is still molten, so final diameter wound

onto bobbin may be only 1/10 of extruded size

• Used to produce filaments of polyesters and nylons

ISE 316 - Manufacturing Processes

Engineering

Figure 13.18 ‑ Melt

spinning of

continuous

filaments

ISE 316 - Manufacturing Processes

Engineering

Dry Spinning

Similar to melt spinning, but starting polymer is in

solution and solvent can be separated by

evaporation

• First step is extrusion through spinneret

• Extrudate is pulled through a heated chamber

which removes the solvent, leaving the polymer

• Used to produce filaments of cellulose acetates

and acrylics

ISE 316 - Manufacturing Processes

Engineering

Wet Spinning

• Polymer is also in solution, only solvent is

non‑volatile

• To separate polymer, extrudate is passed

through a liquid chemical that coagulates or

precipitates the polymer into coherent strands

which are then collected onto bobbins

• Used to produce filaments of rayon

(regenerated cellulose)

ISE 316 - Manufacturing Processes

Engineering

Subsequent Processing of Filaments

• Filaments produced by any of the three

processes are usually subjected to further cold

drawing to align crystal structure along

direction of filament axis

– Extensions of 2 to 8 are typical

– Effect is to significantly increase tensile strength

– Drawing is accomplished by pulling filament

between two spools, where winding spool is

driven at a faster speed than unwinding spool

ISE 316 - Manufacturing Processes

Engineering

Injection Molding

Polymer is heated to a highly plastic state and forced

to flow under high pressure into a mold cavity

where it solidifies; molded part is then removed

from cavity

• Produces discrete components almost always to net

shape

• Typical cycle time 10 to 30 sec., but cycles of one

minute or more are not uncommon

• Mold may contain multiple cavities, so multiple

moldings are produced each cycle

ISE 316 - Manufacturing Processes

Engineering

Injection Molded Parts (Moldings)

• Complex and intricate shapes are possible

• Shape limitations:

– Capability to fabricate a mold whose cavity is the

same geometry as part

– Shape must allow for part removal from mold

• Part size from 50 g (2 oz) up to 25 kg (more

than 50 lb), e.g., automobile bumpers

• Injection molding is economical only for large

production quantities due to high cost of mold

ISE 316 - Manufacturing Processes

Engineering

Injection Molding Machine

• Two principal components:

– Injection unit – melts and delivers polymer melt,

operates much like an extruder

– Clamping unit – opens and closes mold each

injection cycle

ISE 316 - Manufacturing Processes

Engineering

Figure 13.20 ‑ A large (3000 ton capacity) injection molding machine (courtesy

Cincinnati Milacron)

ISE 316 - Manufacturing Processes

Engineering

Figure 13.21 ‑ Diagram of an injection molding machine, reciprocating screw

type (some mechanical details are simplified)

ISE 316 - Manufacturing Processes

Engineering

Injection Unit of Molding Machine

• Consists of barrel fed from one end by a

hopper containing supply of plastic pellets

• Inside the barrel is a screw which has two

functions:

1. Rotates for mixing and heating the polymer

2. Acts as a ram to inject molten plastic into mold

• Non‑return valve near tip of screw prevents melt

flowing backward along screw threads

• Later in molding cycle ram retracts to its former

position

ISE 316 - Manufacturing Processes

Engineering

Clamping Unit of Molding Machine

• Functions:

1. Holds two halves of mold in proper alignment

with each other

2. Keeps mold closed during injection by applying a

clamping force sufficient to resist injection force

3. Opens and closes the mold at the appropriate

times in molding cycle

ISE 316 - Manufacturing Processes

Engineering

Figure 13.22 ‑ Typical molding cycle:

(1) mold is closed

ISE 316 - Manufacturing Processes

Engineering

Figure 13.22 ‑ Typical molding cycle:

(2) melt is injected into cavity

ISE 316 - Manufacturing Processes

Engineering

Figure 13.22 ‑ Typical molding cycle:

(3) screw is retracted

ISE 316 - Manufacturing Processes

Engineering

Figure 13.22 ‑ Typical molding cycle:

(4) mold opens and part is ejected

ISE 316 - Manufacturing Processes

Engineering

The Mold

• The special tool in injection molding

• Custom‑designed and fabricated for the part to

be produced

• When production run is finished, the mold is

replaced with a new mold for the next part

• Various types of mold for injection molding:

– Two-plate mold

– Three-plate mold

– Hot-runner mold

ISE 316 - Manufacturing Processes

Engineering

Figure 13.23 ‑ Details of a two‑plate mold for thermoplastic injection

molding: (a) closed. Mold has two cavities to produce two cup‑shaped

parts with each injection shot

ISE 316 - Manufacturing Processes

Engineering

Figure 13.23 ‑ Details of a two‑plate mold for thermoplastic

injection molding: (b) open

ISE 316 - Manufacturing Processes

Engineering

Injection Molding Machines

• Injection molding machines differ in both

injection unit and clamping unit

• The name of the injection molding machine is

generally based on the type of injection unit

used

– Example: Reciprocating-screw machine

• Several clamping designs

– Examples: mechanical (toggle) vs. hydraulic

ISE 316 - Manufacturing Processes

Engineering

Shrinkage

Reduction in linear size during cooling from molding to

room temperature

• Polymers have high thermal expansion coefficients,

so significant shrinkage occurs during cooling in mold

• Typical shrinkage values for selected polymers:

Plastic Shrinkage, mm/mm (in/in)

Nylon‑6,6 0.020

Polyethylene 0.025

Polystyrene0.004

PVC 0.005

ISE 316 - Manufacturing Processes

Engineering

Compensation for Shrinkage

• Dimensions of mold cavity must be larger than

specified part dimensions:

Dc = Dp + DpS + DpS2

where Dc = dimension of cavity; Dp = molded part

dimension, and S = shrinkage value

• Third term on right hand side corrects for

shrinkage in the shrinkage

ISE 316 - Manufacturing Processes

Engineering

Shrinkage Factors

• Fillers in the plastic tend to reduce shrinkage

• Injection pressure – as pressure is increased,

forcing more material into mold cavity, shrinkage

is reduced

• Compaction time - similar effect - forces more

material into cavity during shrinkage

• Molding temperature - higher temperatures lower

polymer melt viscosity, allowing more material to

be packed into mold and reducing shrinkage

ISE 316 - Manufacturing Processes

Engineering

Thermoplastic Foam Injection Molding

Molding of thermoplastic parts that possess dense outer skin

surrounding lightweight foam center

• Part has high stiffness‑to‑weight ratio suited to structural

applications

• Produced either by introducing a gas into molten plastic in

injection unit or by mixing a gas‑producing ingredient with

starting pellets

• During injection, a small amount of melt is forced into

mold cavity, where it expands to fill cavity

• Foam in contact with cold mold surface collapses to form

dense skin, while core retains cellular structure

ISE 316 - Manufacturing Processes

Engineering

Injection Molding of Thermosets

• Equipment and operating procedure must be

modified to avoid premature cross‑linking of TS

polymer

– Reciprocating‑screw injection unit with shorter barrel

length

• Temperatures in barrel are relatively low

• Melt is injected into a heated mold, where

cross‑linking occurs to harden plastic

• Mold is then opened and part is removed

• Curing is the most time‑consuming step in the cycle

ISE 316 - Manufacturing Processes

Engineering

Reaction Injection Molding

Two highly reactive liquid ingredients are mixed and

immediately injected into a mold cavity where

chemical reactions leading to solidification occur

• RIM was developed with polyurethane to produce

large automotive parts such as bumpers and fenders

– RIM polyurethane parts possess a foam internal structure

surrounded by a dense outer skin

• Other materials used in RIM: epoxies, and

urea‑formaldehyde

ISE 316 - Manufacturing Processes

Engineering

Compression Molding

• An old and widely used molding process for

thermosetting plastics

• Applications also include rubber tires and

polymer matrix composite parts

• Molding compound available in several forms:

powders or pellets, liquid, or preform

• Amount of charge must be precisely controlled

to obtain repeatable consistency in the molded

product

ISE 316 - Manufacturing Processes

Engineering

Figure 13.28 ‑ Compression molding for thermosetting plastics:

(1) charge is loaded, (2) and (3) charge is compressed and cured, and (4)

part is ejected and removed (some details omitted)

ISE 316 - Manufacturing Processes

Engineering

Compression Molding Presses

• Oriented vertically

• Contain two platens to which mold halves are

fastened

• Presses have either of two types of actuation:

1. Upstroke of bottom platen

2. Downstroke of top platen

ISE 316 - Manufacturing Processes

Engineering

Molds for Compression Molding

• Simpler than injection molds

• No sprue and runner system in a compression

mold

• Process itself generally limited to simpler part

geometries due to lower flow capabilities of

TS materials

• Mold must be heated, usually by electric

resistance, steam, or hot oil circulation

ISE 316 - Manufacturing Processes

Engineering

Materials and Products in

Compression Molding

• Materials: phenolics, melamine,

urea‑formaldehyde, epoxies, urethanes, and

elastomers

• Typical TS moldings: electric plugs, sockets,

and housings; pot handles, and dinnerware

plates

ISE 316 - Manufacturing Processes

Engineering

Transfer Molding

TS charge is loaded into a chamber immediately

ahead of mold cavity, where it is heated;

pressure is then applied to force soft polymer

to flow into heated mold where it cures

• Two variants:

– Pot transfer molding - charge is injected from a

"pot" through a vertical sprue channel into cavity

– Plunger transfer molding – plunger injects charge

from a heated well through channels into cavity

ISE 316 - Manufacturing Processes

Engineering

Figure 13.29 ‑ (a) Pot transfer molding

(1) charge is loaded into pot,

(2) softened polymer is pressed into mold cavity and cured, and

(3) part is ejected

ISE 316 - Manufacturing Processes

Engineering

Figure 13.29 ‑ (b) plunger transfer molding

(1) charge is loaded into pot,

(2) softened polymer is pressed into mold cavity and cured, and

(3) part is ejected

ISE 316 - Manufacturing Processes

Engineering

Compression and Transfer Molding

Compared

• In both processes, scrap is produced each cycle as

leftover material, called the cull

• The TS scrap cannot be recovered

• Transfer molding is capable of molding more intricate

part shapes than compression molding but not as

intricate as injection molding

• Transfer molding lends itself to molding with inserts,

in which a metal or ceramic insert is placed into cavity

prior to injection, and the plastic bonds to insert

during molding

ISE 316 - Manufacturing Processes

Engineering

Blow Molding

Molding process in which air pressure is used to

inflate soft plastic into a mold cavity

• Important for making one‑piece hollow plastic

parts with thin walls, such as bottles

• Since these items are used for consumer

beverages in mass markets, production is

typically organized for very high quantities

ISE 316 - Manufacturing Processes

Engineering

Blow Molding Process

• Accomplished in two steps:

1. Fabrication of a starting tube, called a parison

2. Inflation of the tube to desired final shape

• Forming the parison is accomplished by

either

– Extrusion or

– Injection molding

ISE 316 - Manufacturing Processes

Engineering

Figure 13.30 ‑ Extrusion blow molding: (1) extrusion of parison; (2)

parison is pinched at the top and sealed at the bottom around a metal

blow pin as the two halves of the mold come together; (3) the tube is

inflated so that it takes the shape of the mold cavity; and (4) mold is

opened to remove the solidified part

ISE 316 - Manufacturing Processes

Engineering

Figure 13.32 ‑ Injection blow molding: (1) parison is injected molded

around a blowing rod; (2) injection mold is opened and parison is

transferred to a blow mold; (3) soft polymer is inflated to conform to

the blow mold; and (4) blow mold is opened and blown product is

removed

ISE 316 - Manufacturing Processes

Engineering

Stretch Blow Molding

Variation of injection blow molding in which blowing rod

extends downward into parison in step 2, stretching

the soft plastic for a more favorable stressing of

polymer than conventional blow molding

• Resulting structure is more rigid, with higher

transparency and better impact resistance

• Most widely used material is polyethylene

terephthalate (PET) which has very low permeability

and is strengthened by stretch blow molding

• Combination of properties makes it ideal as container

for carbonated beverages

ISE 316 - Manufacturing Processes

Engineering

Figure 13.33 ‑ Stretch blow molding:

(1) injection molding of parison; (2) stretching; and (3) blowing

ISE 316 - Manufacturing Processes

Engineering

Materials and Products in Blow Molding

• Blow molding is limited to thermoplastics

• Materials: high density polyethylene,

polypropylene (PP), polyvinylchloride (PVC),

and polyethylene terephthalate

• Products: disposable containers for liquid

consumer goods, large shipping drums (55

gallon) for liquids and powders, large storage

tanks (2000 gallon), gasoline tanks, toys, and

hulls for sail boards and small boats

ISE 316 - Manufacturing Processes

Engineering

Thermoforming

Flat thermoplastic sheet or film is heated and

deformed into desired shape using a mold

• Heating usually accomplished by radiant electric

heaters located on one or both sides of starting

plastic sheet or film

• Widely used in packaging of products and to

fabricate large items such as bathtubs,

contoured skylights, and internal door liners for

refrigerators

ISE 316 - Manufacturing Processes

Engineering

Figure 13.35 ‑ Vacuum thermoforming:

(1) a flat plastic sheet is softened by heating

ISE 316 - Manufacturing Processes

Engineering

Figure 13.35 ‑ Vacuum thermoforming:

(2) the softened sheet is placed over a concave mold cavity

ISE 316 - Manufacturing Processes

Engineering

Figure 13.35 ‑ Vacuum thermoforming:

(3) a vacuum draws the sheet into the cavity

ISE 316 - Manufacturing Processes

Engineering

Figure 13.35 ‑

(4) the plastic

hardens on

contact with the

cold mold

surface, and the

part is removed

and

subsequently

trimmed from

the web

ISE 316 - Manufacturing Processes

Engineering

Negative Molds vs. Positive Molds

Negative mold – concave cavity

Positive mold - convex shape

• Both types are used in thermoforming

• For positive mold, heated sheet is draped over

convex form and negative or positive pressure

forces plastic against mold surface

ISE 316 - Manufacturing Processes

Engineering

Figure 13.37 ‑ Use of a positive mold in vacuum thermoforming:

(1) the heated plastic sheet is positioned above the convex mold

ISE 316 - Manufacturing Processes

Engineering

Figure 13.37 ‑ Use of a positive mold in vacuum thermoforming:

(2) the clamp is lowered into position, draping the sheet over the mold as

a vacuum forces the sheet against the mold surface

ISE 316 - Manufacturing Processes

Engineering

Materials for Thermoforming

• Only thermoplastics can be thermoformed,

since extruded sheets of thermosetting or

elastomeric polymers have already been

cross‑linked and cannot be softened by

reheating

• Common TP polymers: polystyrene, cellulose

acetate, cellulose acetate butyrate, ABS, PVC,

acrylic (polymethylmethacrylate),

polyethylene, and polypropylene

ISE 316 - Manufacturing Processes

Engineering

Applications of Thermoforming

• Thin films: blister packs and skin packs for packaging

commodity products such as cosmetics, toiletries,

small tools, and fasteners (nails, screws, etc.)

– For best efficiency, filling process to containerize item(s)

is placed immediately downstream from thermoforming

• Thicker sheet stock: boat hulls, shower stalls,

advertising displays and signs, bathtubs, certain

toys, contoured skylights, internal door liners for

refrigerators

ISE 316 - Manufacturing Processes

Engineering

Casting

Pouring liquid resin into a mold, using gravity to

fill cavity, where polymer hardens

• Both thermoplastics and thermosets are cast

– Thermoplastics: acrylics, polystyrene, polyamides

(nylons) and PVC

– Thermosetting polymers: polyurethane, unsaturated

polyesters, phenolics, and epoxies

• Simpler mold

• Suited to low quantities

ISE 316 - Manufacturing Processes

Engineering

Polymer Foam

A polymer‑and‑gas mixture that gives the

material a porous or cellular structure

• Most common polymer foams: polystyrene

(Styrofoam, a trademark), polyurethane

• Other polymers: natural rubber ("foamed

rubber") and polyvinylchloride (PVC)

ISE 316 - Manufacturing Processes

Engineering

Characteristic Properties of a Foamed

Polymer

• Low density

• High strength per unit weight

• Good thermal insulation

• Good energy absorbing qualities

ISE 316 - Manufacturing Processes

Engineering

Classification of Polymer Foams

• Elastomeric - matrix polymer is a rubber, capable

of large elastic deformation

• Flexible - matrix is a highly plasticized polymer

such as soft PVC

• Rigid - polymer is a stiff thermoplastic such as

polystyrene or a thermoset such as a phenolic

• Depending on chemical formulation and degree

of cross‑linking, polyurethanes can range over all

three categories

ISE 316 - Manufacturing Processes

Engineering

Applications of Polymer Foams

• Characteristic properties of polymer foams, and

the ability to control elastic behavior by

selection of base polymer, make these

materials suitable for certain applications

• Applications: hot beverage cups, heat insulating

structural materials, cores for structural panels,

packaging materials, cushion materials for

furniture and bedding, padding for automobile

dashboards, and products requiring buoyancy

ISE 316 - Manufacturing Processes

Engineering

Figure 13.40 ‑ Two polymer foam structures:

(a) closed cell and (b) open cell

ISE 316 - Manufacturing Processes

Engineering

Extrusion of Polystyrene Foams

• Polystyrene is a thermoplastic polymer

• A physical or chemical blowing agent is fed

into polymer melt near die end of extruder

barrel; thus, extrudate consists of expanded

polymer

• Products: large sheets and boards that are

subsequently cut to size for heat insulation

panels and sections

ISE 316 - Manufacturing Processes

Engineering

Molding Processes for

Polystyrene Foams

• Expandable foam molding - molding material

usually consists of prefoamed polystyrene

beads

• Prefoamed beads are fed into mold cavity

where they are further expanded and fused

together to form molded product

• Products: hot beverage cups of polystyrene

foam are produced in this way

ISE 316 - Manufacturing Processes

Engineering

Shaping Processes for

Polyurethane Foams

• Polyurethane can be thermosetting, elastomer or

thermoplastic (less common)

• Polyurethane foam products are made in a one‑step

process in which the two liquid ingredients are mixed

and immediately fed into a mold or other form

– Polymer is synthesized and part geometry is created at

the same time

• Shaping processes for polyurethane foam:

– Spraying

– Pouring

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines for Plastics –

General - I

• Strength and stiffness

– Plastics are not as strong or stiff as metals

– Avoid applications where high stresses will be

encountered

– Creep resistance is also a limitation

– Strength‑to‑weight ratios for some plastics are

competitive with metals in certain applications

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines for Plastics –

General - II

• Impact Resistance

– Capacity of plastics to absorb impact is generally

good; plastics compare favorably with most metals

• Service temperatures

– Plastics are limited relative to engineering metals

and ceramics

• Thermal expansion

– Dimensional changes due to temperature changes

much more significant than for metals

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines for Plastics –

General - III

• Many plastics are subject to degradation from

sunlight and other forms of radiation

• Some plastics degrade in oxygen and ozone

atmospheres

• Plastics are soluble in many common solvents

• Plastics are resistant to conventional corrosion

mechanisms that afflict many metals

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Extruded Plastics - I

• Wall thickness

– Uniform wall thickness is desirable in an extruded

cross‑section

– Variations in wall thickness result in nonuniform

plastic flow and uneven cooling which tend to

warp extrudate

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Extruded Plastics - II

• Hollow sections

– Hollow sections complicate die design and plastic

flow

– Desirable to use extruded cross‑sections that are

not hollow yet satisfy functional requirements

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Extruded Plastics III

• Corners

– Sharp corners, inside and outside, should be

avoided in extruded cross‑sections, since they

result in uneven flow during processing and stress

concentrations in the final product

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Molded Parts - I

• Economic production quantities

– Each part requires a unique mold, and the mold

for any molding process can be costly, particularly

for injection molding

– Minimum production quantities for injection

molding are usually around 10,000 pieces

– For compression molding, minimum quantities are

1000 parts, due to simpler mold designs

– Transfer molding lies between other two

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Molded Parts - II

• Part complexity

– Although more complex part geometries mean

more costly molds, it may nevertheless be

economical to design a complex molding if the

alternative involves many individual components

that must be assembled

– An advantage of plastic molding is that it allows

multiple functional features to be combined into

one part

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Molded Parts - III

• Wall thickness

– Thick cross‑sections are wasteful of material, more

likely to cause warping due to shrinkage, and take

longer to harden

• Reinforcing ribs

– Achieves increased stiffness without excessive wall

thickness

– Ribs should be made thinner than the walls they

reinforce to minimize sink marks on outside wall

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Molded Parts - IV

• Corner radii and fillets

– Sharp corners, both external and internal, are

undesirable in molded parts; they interrupt

smooth flow of the melt, tend to create surface

defects, and cause stress concentrations in the

part

• Holes

– Holes are quite feasible in plastic moldings, but

they complicate mold design and part removal

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Molded Parts - V

• Draft

– A molded part should be designed with a draft on

its sides to facilitate removal from mold

– Especially important on inside wall of a

cup‑shaped part because plastic contracts against

positive mold shape

– Recommended draft:

• For thermosets, around 1/2 to 1

• For thermoplastics, between 1/8 and 1/2

ISE 316 - Manufacturing Processes

Engineering

Product Design Guidelines –

Molded Parts - VI

• Tolerances

– Although shrinkage is predictable under closely

controlled conditions, generous tolerances are

desirable for injection moldings because of

• Variations in process parameters that affect shrinkage

• Diversity of part geometries encountered

ISE 316 - Manufacturing Processes

Engineering

You might also like

- Lesson 3 Extrusion Blow MoldingDocument34 pagesLesson 3 Extrusion Blow MoldingAnonymous ExWAN2xjFJNo ratings yet

- PATTERN ALLOWANCE AND CASTING PROCESS FUNDAMENTALSDocument19 pagesPATTERN ALLOWANCE AND CASTING PROCESS FUNDAMENTALSimamuddeen100% (3)

- Checklist of Mandatory Documents Required by ISO IEC 17025 2017 EN PDFDocument14 pagesChecklist of Mandatory Documents Required by ISO IEC 17025 2017 EN PDFkheng chanbormeiNo ratings yet

- Plastic Design Guidelines For Automotive ComponentsDocument26 pagesPlastic Design Guidelines For Automotive Componentsvumrane100% (12)

- EIRI Provides Integrated Technical and Financial Consultancy ServicesDocument166 pagesEIRI Provides Integrated Technical and Financial Consultancy ServicesRaghuvaran SmartNo ratings yet

- PlasticsDocument48 pagesPlasticsPavan MehataNo ratings yet

- FormingAndShapingPlasticsDocument30 pagesFormingAndShapingPlasticsM PraveenNo ratings yet

- Zones of ScrewDocument111 pagesZones of Screwzubi0585100% (2)

- Forming & Shaping Processes For Plastics: Manufacturing Processes Manufacturing Processes ME ME - 222 222Document41 pagesForming & Shaping Processes For Plastics: Manufacturing Processes Manufacturing Processes ME ME - 222 222shahnawaz875No ratings yet

- Forming and Shaping Plastics & Composite Materials: Chapter - 18Document35 pagesForming and Shaping Plastics & Composite Materials: Chapter - 18Muddu AlaparthiNo ratings yet

- Plastic Shaping Processes GuideDocument82 pagesPlastic Shaping Processes GuideMrinal BachulkarNo ratings yet

- Teknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Document62 pagesTeknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Aszhari AszhariNo ratings yet

- Module 2Document21 pagesModule 2ABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- Ch13 1 PolymerMelt&ExtrusionDocument32 pagesCh13 1 PolymerMelt&ExtrusionPrabhu MechNo ratings yet

- Tek Pol Usai UTS - 2020Document91 pagesTek Pol Usai UTS - 2020raihan dzakyNo ratings yet

- Lecture 7 - Common Manufacturing Processes IIDocument41 pagesLecture 7 - Common Manufacturing Processes IIKamal SurenNo ratings yet

- Plastic Proc 28 May 09 FinalDocument59 pagesPlastic Proc 28 May 09 FinalAinun ZulfikarNo ratings yet

- U-2 Mechanical Working of MetalsDocument76 pagesU-2 Mechanical Working of Metalsapi-271354682No ratings yet

- Deep Drawing and Super-Plastic Forming Processes ComparedDocument83 pagesDeep Drawing and Super-Plastic Forming Processes ComparedYasir HussainNo ratings yet

- Flat Film Forming: Andrew Leithead Chris Barr Nick AntonakosDocument32 pagesFlat Film Forming: Andrew Leithead Chris Barr Nick AntonakosHOANGVUNL1988No ratings yet

- Material Selection: Process & Process Selections: Materials Selection and Design EBT 447 SEMESTER I, 2014/2015Document38 pagesMaterial Selection: Process & Process Selections: Materials Selection and Design EBT 447 SEMESTER I, 2014/2015fatinzalilaNo ratings yet

- Material Selection: Process & Process Selections: Materials Selection and Design EBT 447 SEMESTER I, 2014/2015Document123 pagesMaterial Selection: Process & Process Selections: Materials Selection and Design EBT 447 SEMESTER I, 2014/2015fatinzalilaNo ratings yet

- MFG Pro 1 (1) - 2Document25 pagesMFG Pro 1 (1) - 2Uzair AzziNo ratings yet

- BTM4723 Plastic Composite FormingDocument55 pagesBTM4723 Plastic Composite FormingMas Ayu HassanNo ratings yet

- Investment Casting Process and ApplicationsDocument28 pagesInvestment Casting Process and ApplicationsKristin Louise Agbulos100% (1)

- Matrix MaterialDocument51 pagesMatrix MaterialA-13-M Ibrahim OMARNo ratings yet

- Bulk Deformation ProcessDocument80 pagesBulk Deformation ProcessSam ChaduaryNo ratings yet

- Chapter 11Document102 pagesChapter 11223399No ratings yet

- CH 19 Plastics and Composite Materials1Document28 pagesCH 19 Plastics and Composite Materials1Cham AmirruddinNo ratings yet

- Injection molding machine schematics and process guideDocument29 pagesInjection molding machine schematics and process guideTamirat NemomsaNo ratings yet

- Metal Forming: Extrusion, Wire Drawing and RollingDocument71 pagesMetal Forming: Extrusion, Wire Drawing and RollingSatyajeet SahooNo ratings yet

- JFDD Assignment No - 04Document7 pagesJFDD Assignment No - 04LowEnd GamerNo ratings yet

- Chapter 3 Metal Forming Rev1Document42 pagesChapter 3 Metal Forming Rev1Dinie Zulhusni ArsadNo ratings yet

- Polymers PPT PDFDocument47 pagesPolymers PPT PDFShivani RajeevNo ratings yet

- Pult Rusi OnDocument60 pagesPult Rusi OnmechanicalsrivasansNo ratings yet

- Ch3 Forming Shaping Plastics and CompositeDocument64 pagesCh3 Forming Shaping Plastics and CompositeRusydi JamainNo ratings yet

- Manufacturing Processes for Metal DeformationDocument83 pagesManufacturing Processes for Metal DeformationlihinNo ratings yet

- Plastics: Extrusion MoldingDocument21 pagesPlastics: Extrusion Moldingluan_baNo ratings yet

- Injection Molding Explained: The Essential Process for Plastic ManufacturingDocument23 pagesInjection Molding Explained: The Essential Process for Plastic ManufacturingAditya DhikaNo ratings yet

- Plastic ProcessesDocument27 pagesPlastic Processesnitouch3564No ratings yet

- UnitVI Injection - Compressiona ND Blow MoldingDocument48 pagesUnitVI Injection - Compressiona ND Blow Moldingharrywilson.harish77No ratings yet

- Extrusion Die DesignDocument67 pagesExtrusion Die DesignShubham Chaudhary100% (1)

- 02 Multilayercompositefilms 110322072335 Phpapp02Document48 pages02 Multilayercompositefilms 110322072335 Phpapp02naveenjeswaniNo ratings yet

- Lecture # 4 Investment CastingDocument53 pagesLecture # 4 Investment CastingAbdulRehman Ahmed SoomroNo ratings yet

- 6 - Bulk Deformation ProcessesDocument34 pages6 - Bulk Deformation ProcessesMaida NurhidayahNo ratings yet

- 6 - Bulk Deformation ProcessesDocument34 pages6 - Bulk Deformation ProcessesZack MalikNo ratings yet

- Extrusion 180709144910 PDFDocument78 pagesExtrusion 180709144910 PDFkathiravanpr_6744097No ratings yet

- Week 9 - Shaping Process For PlasticsDocument139 pagesWeek 9 - Shaping Process For PlasticsFattihi EkhmalNo ratings yet

- Mold DesignDocument68 pagesMold DesignBagus Bramantya bagusbramantya.2019No ratings yet

- Forging Processes GuideDocument51 pagesForging Processes GuideShovan KarmakarNo ratings yet

- Global Academy of Technology: (Accredited by Naac With "A" Grade)Document37 pagesGlobal Academy of Technology: (Accredited by Naac With "A" Grade)James Prajwal PrajuNo ratings yet

- 20IN027 - Arslan AhmedDocument12 pages20IN027 - Arslan AhmedArsalan SidikiNo ratings yet

- Plastics PDFDocument18 pagesPlastics PDFV Phanindra BoguNo ratings yet

- Plastics: by Dr. V Phanindra Bogu Dept. of Mech. EnggDocument18 pagesPlastics: by Dr. V Phanindra Bogu Dept. of Mech. EnggV Phanindra BoguNo ratings yet

- Extruder: Poly-Al Al Corrugation Lead SheathDocument45 pagesExtruder: Poly-Al Al Corrugation Lead SheathnasikroadNo ratings yet

- Processes Used To Form Metallic MaterialsDocument23 pagesProcesses Used To Form Metallic MaterialsHimanshu GuptaNo ratings yet

- Lecture 03 - Bulk-Forming Processes PDFDocument22 pagesLecture 03 - Bulk-Forming Processes PDFMohamed Galal MekawyNo ratings yet

- Metal Forming ProcessDocument27 pagesMetal Forming ProcessAravind MohanNo ratings yet

- m243 ch08Document26 pagesm243 ch08Kuscar GasperNo ratings yet

- Advance MF in ICMDocument11 pagesAdvance MF in ICMJhaPraNo ratings yet

- CompositesDocument24 pagesCompositesjrevanthmaniNo ratings yet

- Learn Critical Aspects of Pattern and Mould Making in FoundryFrom EverandLearn Critical Aspects of Pattern and Mould Making in FoundryNo ratings yet

- List Your Processes Here: Enter Full Name of CAR Form Here Enter Abbreviated Name of Your CAR Form HereDocument5 pagesList Your Processes Here: Enter Full Name of CAR Form Here Enter Abbreviated Name of Your CAR Form HereSaAhRaNo ratings yet

- 51 - List of HazardsDocument1 page51 - List of HazardsSaAhRaNo ratings yet

- Aptitude TestDocument1 pageAptitude TestSaAhRaNo ratings yet

- Clause-By-Clause Explanation of ISO 17025:2017Document26 pagesClause-By-Clause Explanation of ISO 17025:2017Xany Santos100% (1)

- External Audit Checklist: Supplier: Location: Lead Auditor: DateDocument8 pagesExternal Audit Checklist: Supplier: Location: Lead Auditor: DateSaAhRaNo ratings yet

- 0 ISO 17025 2017 TransDocument10 pages0 ISO 17025 2017 TransdanielmugaboNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- ISO 17025 Project PlanDocument6 pagesISO 17025 Project Planamirq4No ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

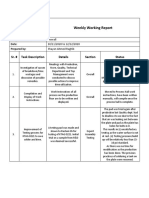

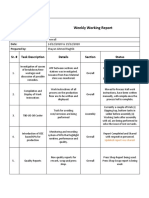

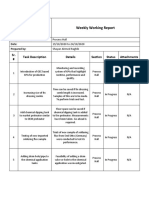

- Weekly Working Report: Sr. # Task Description Details Section StatusDocument2 pagesWeekly Working Report: Sr. # Task Description Details Section StatusSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Weekly Working Report (Week 12)Document1 pageWeekly Working Report (Week 12)SaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Weekly Working Report (Week 9)Document2 pagesWeekly Working Report (Week 9)SaAhRaNo ratings yet

- Weekly Working Report (Week 2)Document1 pageWeekly Working Report (Week 2)SaAhRaNo ratings yet

- Weekly Working Report (Week 5)Document2 pagesWeekly Working Report (Week 5)SaAhRaNo ratings yet

- Weekly Working Report: Sr. # Task Description Details Section Status AttachmentsDocument2 pagesWeekly Working Report: Sr. # Task Description Details Section Status AttachmentsSaAhRaNo ratings yet

- Weekly Working Report (Week 5)Document2 pagesWeekly Working Report (Week 5)SaAhRaNo ratings yet

- Weekly Working Report (Week 3)Document1 pageWeekly Working Report (Week 3)SaAhRaNo ratings yet

- Weekly Report - Feeding Section (Week 1)Document2 pagesWeekly Report - Feeding Section (Week 1)SaAhRaNo ratings yet

- Weekly Working Report (Week 5)Document2 pagesWeekly Working Report (Week 5)SaAhRaNo ratings yet

- Daily Orientation Report: Learning OutcomesDocument1 pageDaily Orientation Report: Learning OutcomesSaAhRaNo ratings yet

- Weekly Feeding Section Report 03/10/2020 to 10/10/2020Document2 pagesWeekly Feeding Section Report 03/10/2020 to 10/10/2020SaAhRaNo ratings yet

- FORTRON® 1140L4 - PPS - Glass Reinforced: DescriptionDocument7 pagesFORTRON® 1140L4 - PPS - Glass Reinforced: DescriptionAdam GordonNo ratings yet

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaNo ratings yet

- Gravimetric Blenders: The World's Most Popular Blender Range With Close ToDocument20 pagesGravimetric Blenders: The World's Most Popular Blender Range With Close Toanon_78840813No ratings yet

- IMD Equipment GuideDocument159 pagesIMD Equipment GuideInternational Milling Directory100% (1)

- DV03PUB23 Study GuideDocument4 pagesDV03PUB23 Study GuidesobheysaidNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Zeonex (Various MaterialsDocument7 pagesZeonex (Various Materialsdave judayaNo ratings yet

- Injection Moulding TechniqueDocument14 pagesInjection Moulding Techniquedrpooja.kaloniyaNo ratings yet

- Hydrocerol HKDocument1 pageHydrocerol HKKrzysztof NowakNo ratings yet

- 2162 - Tutorial 3 - AY20202021Document17 pages2162 - Tutorial 3 - AY20202021JunJieNo ratings yet

- Haitian Series: Haitian Partner: Haitian International Holdings LimitedDocument6 pagesHaitian Series: Haitian Partner: Haitian International Holdings LimitedsandulupeniNo ratings yet

- An Experimental Analysis On Overall Equipment EffectivenessDocument16 pagesAn Experimental Analysis On Overall Equipment EffectivenessInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CPX Series Pet Rotary Stretch Blow Molding Machine: English V ErsionDocument32 pagesCPX Series Pet Rotary Stretch Blow Molding Machine: English V ErsionIMPRESIONES CARLOSNo ratings yet

- 1 s2.0 S2590048X22001030 MainDocument17 pages1 s2.0 S2590048X22001030 MainJeff DatinguinooNo ratings yet

- Important Thesis in CADDocument23 pagesImportant Thesis in CADMohammad TooneerNo ratings yet

- Trouble Shooting For Injection Moulding 2014 PDFDocument24 pagesTrouble Shooting For Injection Moulding 2014 PDFchemikas8389No ratings yet

- ShankarDocument5 pagesShankaranon-940175100% (2)

- Spectacle Frame Materials Guide - Learn About Popular Plastics and Metals UsedDocument14 pagesSpectacle Frame Materials Guide - Learn About Popular Plastics and Metals Usedjaslinda_jamalNo ratings yet

- 305.033 PULSE 2100LG Process Guide - TrinseoDocument2 pages305.033 PULSE 2100LG Process Guide - TrinseoEnrique ChavezNo ratings yet

- Sasol Polymers PP HNR100Document3 pagesSasol Polymers PP HNR100Albert FortunatoNo ratings yet

- Iso 20430 2020Document15 pagesIso 20430 2020Rocio PerezNo ratings yet

- National Skill Qualification Framework (NSQF) Qualification FileDocument28 pagesNational Skill Qualification Framework (NSQF) Qualification FileKeshavesaiNo ratings yet

- Company Profile - Ningbo Zhenfei Injection Molding Machine Manufacturing Co., LTDDocument3 pagesCompany Profile - Ningbo Zhenfei Injection Molding Machine Manufacturing Co., LTDzhenfeimoldcnNo ratings yet

- Design in Brass: Properties and ApplicationsDocument16 pagesDesign in Brass: Properties and Applicationsjohn_progecoNo ratings yet

- Cambridge International A Level: Design & Technology 9705/33Document16 pagesCambridge International A Level: Design & Technology 9705/33Maya PopoNo ratings yet

- Pead - Nova Chemicals - Ig 464 U 8000uvDocument2 pagesPead - Nova Chemicals - Ig 464 U 8000uvs0n1907No ratings yet

- Emerald Emerging Markets Case Studies: Article InformationDocument16 pagesEmerald Emerging Markets Case Studies: Article InformationAaqib JokhioNo ratings yet

- Astm D4812 05Document6 pagesAstm D4812 05Faiz IbrahimNo ratings yet