Professional Documents

Culture Documents

Weekly Report - Feeding Section (Week 1)

Uploaded by

SaAhRaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weekly Report - Feeding Section (Week 1)

Uploaded by

SaAhRaCopyright:

Available Formats

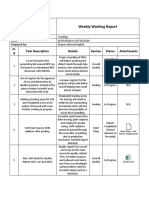

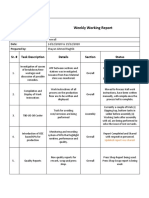

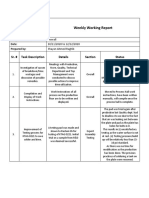

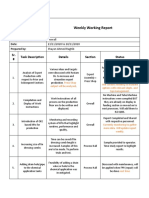

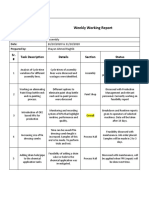

Weekly Working R

Assigned Section: Feeding

Date: 26/09/2020 to 03/10/2020

Prepared by: Shayan Ahmed Raghib

Sr. # Task Description Details

Proper recording of DPRs will help in analyzing

A new format for the prexisting but unused DPR

the defect trends through data analysis, thus

1 Log Document was developed after discussion

indicating the areas where improvements can be

with Abid Sb.

made.

Use of register for the approval of size and

dimensions by Quality Inspector, instead of the A proper register for this purpose will provide

2

piece of paper currently used. Discussed with better record keeping than small pieces of paper.

Uzair.

Designated stacking areas for each jig will result

Defining stacking areas for WIP and Completed

in relatively less transporting of material which

3 Cores at JIG section. Discussed with Uzair. Further

working in progress. will also decrease the possibilty of issues due to

handling.

Currently used Enamel (low bake stoving) paint

requires oven baking for proper curing. OEM

4 Wet Paint issue in OEM radiators after packing. radiators cannot be passed through the oven

after re-painting due to production constraints.

Detailed report attached.

Quality reports for rework and scrap are the main

source for quality related KPIs. For better analysis

New VBA Sheet for Quality Report entry was

5 and reduced work load a new form was

provided.

developed and provided to Abid Sb. Currently

being used on a trial basis.

Weekly Working Report

Section Status Attachments

Completed (DPR

Overall Quality C:\Users\

Logging has started)

process.engineer\

Desktop\DPR

Working\DPRs

Working log sheet

new 1.xlsx

Feeding In Progress N/A

Feeding In Progress N/A

Report Completed

Paint Shop (Formal decision to C:\Users\

be made) process.engineer\

Desktop\Paint

Shop\Paint Shop -

Wet Paint

Complaint.pdf

Overall Quality In Progress C:\Users\

process.engineer\

Desktop\Quality

Reports\New

folder\Format.xlsm

You might also like

- Weekly Working Report: Sr. # Task Description Details Section Status AttachmentsDocument1 pageWeekly Working Report: Sr. # Task Description Details Section Status AttachmentsSaAhRaNo ratings yet

- Weekly Working Report (Week 2)Document1 pageWeekly Working Report (Week 2)SaAhRaNo ratings yet

- Weekly Working Report (Week 12)Document1 pageWeekly Working Report (Week 12)SaAhRaNo ratings yet

- Weekly Working Report: Sr. # Task Description Details Section StatusDocument2 pagesWeekly Working Report: Sr. # Task Description Details Section StatusSaAhRaNo ratings yet

- Weekly Working Report (Week 8)Document2 pagesWeekly Working Report (Week 8)SaAhRaNo ratings yet

- Weekly Working Report (Week 9)Document2 pagesWeekly Working Report (Week 9)SaAhRaNo ratings yet

- Kaizen Idea Sheet: CountermeasureDocument1 pageKaizen Idea Sheet: CountermeasurerahulNo ratings yet

- Sridharkumar, Thangaperumal IFS139Document12 pagesSridharkumar, Thangaperumal IFS139sridharkumar0% (1)

- Cam SoftwareDocument5 pagesCam SoftwareSyafiqah ShahuriNo ratings yet

- Orbit V32N3 2012 Q3Document68 pagesOrbit V32N3 2012 Q3huliplay100% (1)

- Rework Process FlowDocument6 pagesRework Process FlowIsaac Samuel100% (1)

- APQP MatrixDocument2 pagesAPQP Matrixkumar QA100% (2)

- Weekly Working Report (Week 5)Document2 pagesWeekly Working Report (Week 5)SaAhRaNo ratings yet

- ANPQP - DRBFM (Design Review Based On Failure Mode) WORKSHEETDocument1 pageANPQP - DRBFM (Design Review Based On Failure Mode) WORKSHEETrenato fabbri100% (1)

- 20-QMSP Change Control-Product-ECNDocument5 pages20-QMSP Change Control-Product-ECNDhananjay PatilNo ratings yet

- ANPQP Version 3.2 RevisionDocument33 pagesANPQP Version 3.2 RevisionFaby Mendoza50% (2)

- Ge Energy: Infrastructure General Electric Apex Global R12I Implementation Ibs To ApDocument32 pagesGe Energy: Infrastructure General Electric Apex Global R12I Implementation Ibs To ApbishwabengalitolaNo ratings yet

- Cognex Deep Learning Release NotesDocument64 pagesCognex Deep Learning Release NotesBasil SoulouknaNo ratings yet

- Navsari Div - Box Culvert On Hansapore Flag Station RoadDocument14 pagesNavsari Div - Box Culvert On Hansapore Flag Station RoadartiNo ratings yet

- QuizletDocument4 pagesQuizletJaceNo ratings yet

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocument6 pagesDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNo ratings yet

- Weekly Working Report (Week 3)Document1 pageWeekly Working Report (Week 3)SaAhRaNo ratings yet

- Font Style: Courier Font Size: 12 Margins: Left 1.5, RBT 1Document1 pageFont Style: Courier Font Size: 12 Margins: Left 1.5, RBT 1Rodson TinioNo ratings yet

- PC vs. Thin Client Performance in Typical Office Application Scenarios Executive SummaryDocument35 pagesPC vs. Thin Client Performance in Typical Office Application Scenarios Executive SummaryDr.Kamlesh BariNo ratings yet

- DemoPurposeOnlyPerformanceTest PlanDocument9 pagesDemoPurposeOnlyPerformanceTest Planraja gouravNo ratings yet

- WPI Form1 Jignesh TRNG320Document12 pagesWPI Form1 Jignesh TRNG320Vishal FundingNo ratings yet

- WPI Form2 Jignesh TRNG320Document12 pagesWPI Form2 Jignesh TRNG320Vishal FundingNo ratings yet

- Introduction To Databases (Week 1) : Remedios de Dios BulosDocument68 pagesIntroduction To Databases (Week 1) : Remedios de Dios BulosEdmar Sta MariaNo ratings yet

- Mesha Engineering Industry Pvt. Ltd. Unit-Ii: Oee Action Plan (2019)Document4 pagesMesha Engineering Industry Pvt. Ltd. Unit-Ii: Oee Action Plan (2019)Fabian BellNo ratings yet

- AN44 Creating Automated ReportsDocument5 pagesAN44 Creating Automated ReportsSaid MabroukNo ratings yet

- Lessons Log: LL# Lesson Type EventDocument13 pagesLessons Log: LL# Lesson Type EventCQMS 5S DivisionNo ratings yet

- QAQC Procedure For Fabrication - Flare KOD Rev ADocument9 pagesQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- Job Information: Job No Sheet No RevDocument1 pageJob Information: Job No Sheet No RevEduardo Murguía De NigrisNo ratings yet

- New Prod-DB and KPI 22Document5 pagesNew Prod-DB and KPI 22Senthilmani MuthuswamyNo ratings yet

- Lab2 Unit Test Case RRS Group 5Document10 pagesLab2 Unit Test Case RRS Group 5Thanh TùngNo ratings yet

- Go Live Readiness AssessmentDocument8 pagesGo Live Readiness Assessmentarun2sasi100% (1)

- Supplier 8D Report: D 1. Description of The ProblemDocument7 pagesSupplier 8D Report: D 1. Description of The ProblemDearRed FrankNo ratings yet

- FRM-WS-11 DWM Check Sheet (Weld SHP)Document2 pagesFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalNo ratings yet

- Project Defect TrackerDocument5 pagesProject Defect TrackersachokNo ratings yet

- Project Defect TrackerDocument5 pagesProject Defect TrackerAnil KumarNo ratings yet

- Chapter 4 - Process CostingDocument40 pagesChapter 4 - Process CostingMuhammad Ali KazmiNo ratings yet

- Samcis - Ae212 - Module 7 Process Costing Lost UnitsDocument17 pagesSamcis - Ae212 - Module 7 Process Costing Lost UnitsMamaril John NathanielNo ratings yet

- (PPT) Activity Based Management (Part 3)Document11 pages(PPT) Activity Based Management (Part 3)Trisha Mae DacusinNo ratings yet

- Divisions: Transportation Decorated Products Plating & Enameling Southern OperationsDocument9 pagesDivisions: Transportation Decorated Products Plating & Enameling Southern OperationsMuralidhara BangaloreNo ratings yet

- Network PC and Server Audit ChecklistDocument7 pagesNetwork PC and Server Audit Checklistsmile4ever54100% (1)

- BJN S4hana2022 BPD en deDocument22 pagesBJN S4hana2022 BPD en deabdeltifNo ratings yet

- NX - Upgrading and Ugmanager - Refile Some Ideas To Manage The Basic Risks!Document4 pagesNX - Upgrading and Ugmanager - Refile Some Ideas To Manage The Basic Risks!cad cadNo ratings yet

- Revit Paint Tool ParameterDocument4 pagesRevit Paint Tool ParameterI Gede Bayu Chandra NathaNo ratings yet

- Quality Excellence in Textile Industry Case Study: IndiaDocument3 pagesQuality Excellence in Textile Industry Case Study: IndiafarooquintuNo ratings yet

- TP01 Calculation PPM Claims QuotaDocument3 pagesTP01 Calculation PPM Claims QuotaTATI TorresNo ratings yet

- Responsibility Matrix 1of ApqpDocument4 pagesResponsibility Matrix 1of ApqpanuailddNo ratings yet

- Daily Activity Report: - KSA TeamDocument2 pagesDaily Activity Report: - KSA TeamHaidar Ali ZaidiNo ratings yet

- Business Section: Jmcs Project StatusDocument4 pagesBusiness Section: Jmcs Project StatusatilabayatNo ratings yet

- Model Appraisal Template 2022Document3 pagesModel Appraisal Template 2022DerrickNo ratings yet

- Year End Closing ProcessDocument17 pagesYear End Closing ProcessdasradreddyNo ratings yet

- 4M: Corrective Action Plan: No Name Set Date: Fty Area Product TypeDocument1 page4M: Corrective Action Plan: No Name Set Date: Fty Area Product TypeBayu IrawanNo ratings yet

- 1 Upgrading Jasper 7.5.1 Client Configuration Functionality Implementation in ExpenseDocument19 pages1 Upgrading Jasper 7.5.1 Client Configuration Functionality Implementation in ExpenseSreevidya KanumallaNo ratings yet

- Internal Software Quality Assurance Plan: Enter Project Specific Information HereDocument18 pagesInternal Software Quality Assurance Plan: Enter Project Specific Information Herececep rusdiNo ratings yet

- Automating Revit 2 Create More Flexible Scripts to Share for REVIT Productivity: Automating Revit, #2From EverandAutomating Revit 2 Create More Flexible Scripts to Share for REVIT Productivity: Automating Revit, #2No ratings yet

- External Audit Checklist: Supplier: Location: Lead Auditor: DateDocument8 pagesExternal Audit Checklist: Supplier: Location: Lead Auditor: DateSaAhRaNo ratings yet

- Mantis Coral Red Resume TemplateDocument1 pageMantis Coral Red Resume TemplateSaAhRaNo ratings yet

- Weekly Working Report (Week 3)Document1 pageWeekly Working Report (Week 3)SaAhRaNo ratings yet

- Weekly Working Report (Week 9)Document2 pagesWeekly Working Report (Week 9)SaAhRaNo ratings yet

- Weekly Working Report (Week 5)Document2 pagesWeekly Working Report (Week 5)SaAhRaNo ratings yet

- Weekly Working Report: Sr. # Task Description Details Section Status AttachmentsDocument2 pagesWeekly Working Report: Sr. # Task Description Details Section Status AttachmentsSaAhRaNo ratings yet

- Weekly Report - Feeding Section (Week 2)Document2 pagesWeekly Report - Feeding Section (Week 2)SaAhRaNo ratings yet

- Throttling Calorimeter 2015ME08Document6 pagesThrottling Calorimeter 2015ME08SaAhRaNo ratings yet

- PP MidsDocument42 pagesPP MidsSaAhRaNo ratings yet

- Daily Orientation Report: Learning OutcomesDocument1 pageDaily Orientation Report: Learning OutcomesSaAhRaNo ratings yet

- Experiment No - 5 Power Plants: Name: - Shayan Ahmed Raghib - Regd. No. - 2015-ME-08 - Date: - 26/02/19Document2 pagesExperiment No - 5 Power Plants: Name: - Shayan Ahmed Raghib - Regd. No. - 2015-ME-08 - Date: - 26/02/19SaAhRaNo ratings yet

- Compiled Lab ReportDocument25 pagesCompiled Lab ReportSaAhRaNo ratings yet

- Principle of Virtual Work PVMDocument23 pagesPrinciple of Virtual Work PVMSaAhRaNo ratings yet

- Statically Indeterminate Beams: Mechanics of Materials - 2Document36 pagesStatically Indeterminate Beams: Mechanics of Materials - 2SaAhRaNo ratings yet

- 17 - Procedure - Control of Records ProcessDocument4 pages17 - Procedure - Control of Records ProcessSaAhRaNo ratings yet

- Mechanics of Materials - IiDocument43 pagesMechanics of Materials - IiSaAhRaNo ratings yet

- GCS Troubleshooting&Applications1v0 (3.23.01)Document101 pagesGCS Troubleshooting&Applications1v0 (3.23.01)Jesús A Guerrero MNo ratings yet

- Stars Rwy 29 EpgdDocument3 pagesStars Rwy 29 EpgdMateusz HeinNo ratings yet

- 74LS08 PDFDocument5 pages74LS08 PDFsirgeorge1987No ratings yet

- Adm2 FR Operating Manual 15 07 02Document160 pagesAdm2 FR Operating Manual 15 07 02Avs Electron100% (2)

- Cold Climate Application Guideline DuctlessDocument1 pageCold Climate Application Guideline DuctlessZineddine AlicheNo ratings yet

- Final QBDocument15 pagesFinal QBShubham Anil KambleNo ratings yet

- BS 4422 2005Document84 pagesBS 4422 2005Dave WilliamsNo ratings yet

- Verburg, Babette Linnet, Bjørn - The Black Box of Netflix - A Qualitative Study of Consumers Perception of Netflix and Its Recommendation SystemDocument116 pagesVerburg, Babette Linnet, Bjørn - The Black Box of Netflix - A Qualitative Study of Consumers Perception of Netflix and Its Recommendation SystemMarcos CurvelloNo ratings yet

- 2006 2008 Chrysler PT Cruiser Bulldog Security DiagramsDocument2 pages2006 2008 Chrysler PT Cruiser Bulldog Security DiagramsRubenNo ratings yet

- Blender Cit SitDocument9 pagesBlender Cit SitbilekgwejNo ratings yet

- Fire DetectionDocument88 pagesFire DetectionReza BabriNo ratings yet

- Shivank Singh Baghel - 2020Document2 pagesShivank Singh Baghel - 2020Shivank BaghelNo ratings yet

- Future of Robotics Agriculture 1Document36 pagesFuture of Robotics Agriculture 1Asma RafiqNo ratings yet

- Fuzzy Logic ControllerDocument7 pagesFuzzy Logic ControllermeenaNo ratings yet

- Computer Hardware Technology PowerPoint TemplatesDocument48 pagesComputer Hardware Technology PowerPoint TemplatesMugiwara no LuffyNo ratings yet

- Chapter 7 Manual TransmissionDocument25 pagesChapter 7 Manual TransmissioncckasNo ratings yet

- Thesis Using ArduinoDocument6 pagesThesis Using Arduinofjdxfc4v100% (2)

- Integrity of Subsea Control UmbilicalDocument11 pagesIntegrity of Subsea Control Umbilicalxinlin.cppNo ratings yet

- Page 1 of 2: Improved Features IncludeDocument2 pagesPage 1 of 2: Improved Features IncludeVovchik VovchikNo ratings yet

- Design and Fabrication of Horizontal Axis Wind TurbineDocument5 pagesDesign and Fabrication of Horizontal Axis Wind TurbineLorenzo YapNo ratings yet

- Catalogo Piñones SatiDocument308 pagesCatalogo Piñones SatiFrancisco GalindoNo ratings yet

- Bug Bounty DorksDocument3 pagesBug Bounty Dorkshomaw57No ratings yet

- 231 Preventive Check Sheet of Hps Mechanical PressDocument4 pages231 Preventive Check Sheet of Hps Mechanical PressAjayNo ratings yet

- CV Muhammad Rizal KhoirulDocument9 pagesCV Muhammad Rizal Khoirularie.febryanNo ratings yet

- Lab 1-Introduction To Packet Tracer - BBIT3-FTDocument2 pagesLab 1-Introduction To Packet Tracer - BBIT3-FTOpenda mitchNo ratings yet

- No Tech Name: Current Value/ Simulated For NSNDocument7 pagesNo Tech Name: Current Value/ Simulated For NSNFazlee KanNo ratings yet

- Annual Report 2020 PDFDocument165 pagesAnnual Report 2020 PDFNRNo ratings yet

- Lawson Industries, IncDocument4 pagesLawson Industries, IncTony DiStasioNo ratings yet

- Karthikeyan K: Job ObjectiveDocument3 pagesKarthikeyan K: Job ObjectiveKarthikeyan RK SwamyNo ratings yet

- Power BI OutsetDocument11 pagesPower BI Outsetmkshmistry100% (1)