Professional Documents

Culture Documents

Dissolved Air Floation

Uploaded by

HARI PRASATH0 ratings0% found this document useful (0 votes)

11 views25 pagesDissolved air flotation is a process used to treat waste activated sludge and other suspended solids. Small air bubbles become attached to solids particles, causing them to float to the surface where they form a sludge blanket. The air is dissolved into the wastewater under pressure and released upon depressurization, forming microscopic bubbles that adhere to solids. Proper ratios of air to solids and surface loading rates must be determined to optimize removal efficiency.

Original Description:

DAF design

Original Title

3.DAF (25.04.2020)

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDissolved air flotation is a process used to treat waste activated sludge and other suspended solids. Small air bubbles become attached to solids particles, causing them to float to the surface where they form a sludge blanket. The air is dissolved into the wastewater under pressure and released upon depressurization, forming microscopic bubbles that adhere to solids. Proper ratios of air to solids and surface loading rates must be determined to optimize removal efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views25 pagesDissolved Air Floation

Uploaded by

HARI PRASATHDissolved air flotation is a process used to treat waste activated sludge and other suspended solids. Small air bubbles become attached to solids particles, causing them to float to the surface where they form a sludge blanket. The air is dissolved into the wastewater under pressure and released upon depressurization, forming microscopic bubbles that adhere to solids. Proper ratios of air to solids and surface loading rates must be determined to optimize removal efficiency.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 25

DISSOLVED AIR FLOATION

• Suitable for treatment of waste activated

sludge.

• Minute air bubble get attached to solids and

cause the solids to separate from the water in

an upward direction.

• This happens because solids particle with

attached bubble have lower specific gravity

than water.

• The degree of adhesion depends on the

surface properties of the solids.

• The upward moving particles form a sludge

blanket on the surface of the flotation

thickener.

• Addition of alum, Polyelectrolytes can

increase the efficiency of the flotation unit.

• Particles that have a higher density than the

liquid can thus be made to rise.

• The rising of particles with lower density than

the liquid can also be facilitated (e.g., oil

suspension in water).

Dissolved-Air Flotation

• In dissolved-air flotation (DAF) systems, air is

dissolved in the wastewater under a pressure

of several atmospheres, followed by release of

the pressure to the atmospheric level.

• In small pressure systems, the entire flow may

be pressurized by means of a pump to 275 to

350 kPa with compressed air added at the

pump suction

• The entire flow is held in a retention tank

under pressure for several minutes to allow

time for the air to dissolve.

• It is then admitted through a pressure-

reducing valve to the flotation tank the air

comes out of solution in very fine bubbles.

Design Considerations for Dissolved-Air

Flotation Systems

• Factors that must be considered in the design

of flotation units include

– The concentration of particulate matter,

– The quantity of air used,

– The particle-rise velocity, and

– The solids loading rate.

• The performance of a dissolved-air flotation

system depends primarily on the ratio of the

volume of air to the mass of solids (A/S)

required to achieve a given degree of

clarification.

• The ratio will vary with each type of

suspension and must be determined

experimentally using a laboratory flotation

cell.

• Typical A/S ratios encountered in the

thickening of solids and biosolids in

wastewater-treatment plants vary from about

0.005 to 0.060.

• The relationship between the A/S ratio and

the solubility of air, the operating pressure,

and the concentration of solids for a system in

which all the flow is pressurized

SOLID LOADING RATE

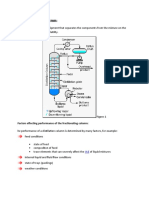

DAF Process

• A typical DAF system is designed to recirculate

a portion of clarified effluent through a

pressurization system by means of a

centrifugal recycle pump.

• The recycled effluent flow is pumped into an

air saturation tank where compressed air is

dissolved into the flow under pressure.

• The air saturated recycle is then fed under

pressure to the center of the DAF tank where

it thoroughly mixes with the DAF influent flow.

• The sudden release of pressure by means of a

back pressure control valve causes the

dissolved air to come out of solution and form

microscopic bubbles

• These microscopic bubbles adhere to

incoming solids and form a buoyant blanket

which rises to the surface for mechanical

removal.

• Floating solids are skimmed into a float box by

rotating skimmer arms.

• Any settled solids are scraped to the center of

the tank by sludge rake arms for removal from

the DAF sludge hopper.

• Clarified effluent exits the tank under a float

retention baffle and into a peripheral effluent

launder.

Industrial Flotation

• Refineries

• Food Processing and Food Packaging

• Chemical Processing

• Laundry

• Pulp and Paper

• Tanneries

• Industrial Water Treatment

Air Solubility in Water

• Amount of air that can be dissolved in water -

decreases with temperature and increases

with pressure

A/S RATIO

• Air/Solids (A/S) ratio has important influence

on dissolved air flotation.

• Higher A/S ratio is required for maintenance

of removal efficiency for wastewater

containing lower suspended solids.

• A/S ratio 0.05 is required for wastewater

containing suspended solids lower than 1000

mg L-1.

SURFACE LOADING RATE

• The surface loading rate is a

hydraulic loading factor expressed in terms of

flow per surface area. This factor is also

referred to as the “surface settling rate” or

“surface overflow rate.”

GAUGE PRESSURE

• The amount by which the pressure measured

in a fluid exceeds that of the atmosphere

• 1 atm = 101.35 kpa

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Water DAF IAF pp305 308Document4 pagesWater DAF IAF pp305 308lehuy1210No ratings yet

- Inertization and Fire SafetyDocument19 pagesInertization and Fire SafetysaikumarNo ratings yet

- Difloat - BrochureDocument8 pagesDifloat - Brochurejpsingh75100% (1)

- Biotower 001 PDFDocument3 pagesBiotower 001 PDFIsmael KhalilNo ratings yet

- Dissolved Air Flotation HandoutDocument5 pagesDissolved Air Flotation HandoutJen Astoveza0% (1)

- Sarvajanik College of Engineering & Technology Chemical Engineering DepartmentDocument11 pagesSarvajanik College of Engineering & Technology Chemical Engineering DepartmentFack AccountNo ratings yet

- Air Generation and DistributionDocument55 pagesAir Generation and DistributionJespher Adam AndalNo ratings yet

- AssignmentDocument57 pagesAssignmentsadaf munirNo ratings yet

- Unit Operations in ProcessingDocument27 pagesUnit Operations in ProcessingkindenewNo ratings yet

- Stripping Column: Haldia Institute of TechnologyDocument14 pagesStripping Column: Haldia Institute of TechnologyArnab DasNo ratings yet

- Pneumatic SystemsDocument74 pagesPneumatic SystemsInzamam Ul HaqueNo ratings yet

- 1 - Introduction To EORDocument56 pages1 - Introduction To EORSaroo BastkyNo ratings yet

- MT L19 DistillationDocument32 pagesMT L19 DistillationShiavm PatelNo ratings yet

- DAF ProcessDocument4 pagesDAF ProcessJoce88888No ratings yet

- Air PumpDocument12 pagesAir Pumpalfa89pNo ratings yet

- Chapter 2Document60 pagesChapter 2Solomon DesalegnNo ratings yet

- Eimco Dissairflotation MLDocument13 pagesEimco Dissairflotation MLfatima ezzahra rafiNo ratings yet

- Chapter 7 PDFDocument76 pagesChapter 7 PDFNurfatini CheNo ratings yet

- Mass Transfer Lab Presentation: By-Shubham Sachan Rajdeep Singh Shashwat Tiwari Sahil YadavDocument21 pagesMass Transfer Lab Presentation: By-Shubham Sachan Rajdeep Singh Shashwat Tiwari Sahil Yadavbadshah sharmaNo ratings yet

- Sterilization of AirDocument5 pagesSterilization of AirBeena KakranNo ratings yet

- L 36 Air Blowing Process For Manufacture of BitumenDocument12 pagesL 36 Air Blowing Process For Manufacture of Bitumena.faramarziNo ratings yet

- Separation DocumentDocument46 pagesSeparation DocumentAbdul AzizNo ratings yet

- Air BindingDocument8 pagesAir BindingRishabh SethiNo ratings yet

- Gas Liquid Separators Sizing Parameter MM083015Document42 pagesGas Liquid Separators Sizing Parameter MM083015Mubarik AliNo ratings yet

- Lecture 13Document31 pagesLecture 13Anas Nasir officalNo ratings yet

- Perdidas de Produccion DesgasificacionDocument8 pagesPerdidas de Produccion DesgasificacionWil Vasquez CNo ratings yet

- Daf ManualDocument4 pagesDaf ManualRATHNA KUMARNo ratings yet

- Ar-Coarse Bubble SystemsDocument1 pageAr-Coarse Bubble Systemskeikei22No ratings yet

- Technical Skills Workshop On Effluent Treatment Plant At: HindustanDocument33 pagesTechnical Skills Workshop On Effluent Treatment Plant At: HindustanDuggineni RamakrishnaNo ratings yet

- What Is Vacuum: Vacuum Refers To The Degree of Emptiness of A Process SystemDocument38 pagesWhat Is Vacuum: Vacuum Refers To The Degree of Emptiness of A Process Systemrnsasikumar100% (1)

- Flotation: P M. A NjitDocument26 pagesFlotation: P M. A NjitSri Endah WahyuniNo ratings yet

- Air DrillingDocument69 pagesAir Drillingshahin500No ratings yet

- 10...... Trickling Filter & AspDocument29 pages10...... Trickling Filter & AspLeo ThomasNo ratings yet

- Equipment For Gas Absorption: Instructor: Zafar ShakoorDocument34 pagesEquipment For Gas Absorption: Instructor: Zafar ShakoorMALIK ZARYABBABARNo ratings yet

- Humidity: Humidity Is The Amount ofDocument96 pagesHumidity: Humidity Is The Amount ofArjhay GironellaNo ratings yet

- Table: Uses of Different Products From Vacuum ColumnDocument5 pagesTable: Uses of Different Products From Vacuum ColumnLakshya SaxenaNo ratings yet

- Preparation of Compressed Air: - Therefore, Relative Humidity Absolute Humidity X 100 Saturation HumidityDocument16 pagesPreparation of Compressed Air: - Therefore, Relative Humidity Absolute Humidity X 100 Saturation HumidityvinayakNo ratings yet

- Air DryerDocument55 pagesAir DryerriajulNo ratings yet

- Oily Water Separators: Dissolved Air Flotation Units (DAF)Document2 pagesOily Water Separators: Dissolved Air Flotation Units (DAF)blondtumbalaNo ratings yet

- Humidity: Humidity Is The Amount ofDocument96 pagesHumidity: Humidity Is The Amount ofArjhay GironellaNo ratings yet

- Selection of Column Type: Plate or PackedDocument52 pagesSelection of Column Type: Plate or Packedsai charanNo ratings yet

- 409 - 8 RO Plant Deck MCDocument18 pages409 - 8 RO Plant Deck MCisrat jahanNo ratings yet

- Spray Drying 31.8.16Document22 pagesSpray Drying 31.8.16shutterbugsadiNo ratings yet

- VacuumDocument27 pagesVacuumVarsha PraburamNo ratings yet

- Air Drilling PDFDocument135 pagesAir Drilling PDFAndrés LópezNo ratings yet

- CPD Lecture 9Document40 pagesCPD Lecture 9nivedhithaNo ratings yet

- Chapter 1 2021Document83 pagesChapter 1 2021DEM4AF1026No ratings yet

- Cheat Sheet For Separation Processes - Chemical EngineeringDocument100 pagesCheat Sheet For Separation Processes - Chemical EngineeringMitchell Grierson0% (1)

- Bioreactor Configuration: Submitted To-Dr.R.S.Singh Submitted By-Benaf Kathuria MSC (Hon'S) Biotechnology Roll No-18010013Document35 pagesBioreactor Configuration: Submitted To-Dr.R.S.Singh Submitted By-Benaf Kathuria MSC (Hon'S) Biotechnology Roll No-18010013Jot SainiNo ratings yet

- Factors Effecting Performance of The Fractionating ColumnDocument4 pagesFactors Effecting Performance of The Fractionating ColumnHasieb Alam KhanNo ratings yet

- K Brian & E RochaisDocument16 pagesK Brian & E RochaisLuigi Andrew MercadoNo ratings yet

- Reflux Problems: CH Venkatesh 13021A2536Document14 pagesReflux Problems: CH Venkatesh 13021A2536Venkatesh ChNo ratings yet

- Condenser Cooling Towers 216Document28 pagesCondenser Cooling Towers 216rajushamla9927No ratings yet

- Types of Distillation ColumnDocument3 pagesTypes of Distillation ColumnKornelis OlaNo ratings yet

- Drive MechanismDocument48 pagesDrive MechanismtalhahafeezmNo ratings yet

- Flotation 21Document62 pagesFlotation 21Jamel CayabyabNo ratings yet

- Choosing Trays and Packings For Distillation: Back To BasicsDocument7 pagesChoosing Trays and Packings For Distillation: Back To Basicsmsn1981No ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Sludge ManagementDocument81 pagesSludge ManagementHARI PRASATHNo ratings yet

- Advanced Oxidation ProcessesDocument29 pagesAdvanced Oxidation ProcessesHARI PRASATHNo ratings yet

- Chemical OxidationDocument50 pagesChemical OxidationHARI PRASATHNo ratings yet

- 6.chemical Precipitation (07.04.2020)Document70 pages6.chemical Precipitation (07.04.2020)HARI PRASATHNo ratings yet

- 2.neutralization (25.04.2020)Document31 pages2.neutralization (25.04.2020)HARI PRASATHNo ratings yet

- Electrodialysis (23.04.2020)Document22 pagesElectrodialysis (23.04.2020)HARI PRASATHNo ratings yet

- Adsorption (25.04.2020)Document41 pagesAdsorption (25.04.2020)HARI PRASATHNo ratings yet

- Membrane Seperation (10.04.20)Document57 pagesMembrane Seperation (10.04.20)HARI PRASATHNo ratings yet

- STOCHIOMETRYDocument13 pagesSTOCHIOMETRYHARI PRASATHNo ratings yet

- Rio DeclarationDocument93 pagesRio DeclarationHARI PRASATHNo ratings yet

- Rio DeclarationDocument93 pagesRio DeclarationHARI PRASATHNo ratings yet

- AN610 - Using 24lc21Document9 pagesAN610 - Using 24lc21aurelioewane2022No ratings yet

- Invoice Acs # 18 TDH Dan Rof - Maret - 2021Document101 pagesInvoice Acs # 18 TDH Dan Rof - Maret - 2021Rafi RaziqNo ratings yet

- Contemp World Module 2 Topics 1 4Document95 pagesContemp World Module 2 Topics 1 4Miguel EderNo ratings yet

- Jainithesh - Docx CorrectedDocument54 pagesJainithesh - Docx CorrectedBala MuruganNo ratings yet

- Faida WTP - Control PhilosophyDocument19 pagesFaida WTP - Control PhilosophyDelshad DuhokiNo ratings yet

- SWOT AnalysisDocument6 pagesSWOT AnalysisSSPK_92No ratings yet

- Tajima TME, TMEF User ManualDocument5 pagesTajima TME, TMEF User Manualgeorge000023No ratings yet

- Modeling and Fuzzy Logic Control of A Quadrotor UAVDocument5 pagesModeling and Fuzzy Logic Control of A Quadrotor UAVAnonymous kw8Yrp0R5rNo ratings yet

- Applications of MathematicsDocument35 pagesApplications of MathematicsRamdas Sonawane100% (1)

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Document3 pagesSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaNo ratings yet

- Chap 06 Ans Part 2Document18 pagesChap 06 Ans Part 2Janelle Joyce MuhiNo ratings yet

- Developments in Prepress Technology (PDFDrive)Document62 pagesDevelopments in Prepress Technology (PDFDrive)Sur VelanNo ratings yet

- Dbms UPDATED MANUAL EWITDocument75 pagesDbms UPDATED MANUAL EWITMadhukesh .kNo ratings yet

- Relay Interface ModulesDocument2 pagesRelay Interface Modulesmahdi aghamohamadiNo ratings yet

- ODF-2 - Learning MaterialDocument24 pagesODF-2 - Learning MateriallevychafsNo ratings yet

- How Can You Achieve Safety and Profitability ?Document32 pagesHow Can You Achieve Safety and Profitability ?Mohamed OmarNo ratings yet

- Immovable Sale-Purchase (Land) ContractDocument6 pagesImmovable Sale-Purchase (Land) ContractMeta GoNo ratings yet

- Risk and Uncertainty in Estimating and TenderingDocument16 pagesRisk and Uncertainty in Estimating and TenderingHaneefa ChNo ratings yet

- Dreamfoil Creations & Nemeth DesignsDocument22 pagesDreamfoil Creations & Nemeth DesignsManoel ValentimNo ratings yet

- Ks 1609Document5 pagesKs 1609krish dabhiNo ratings yet

- Frito Lay AssignmentDocument14 pagesFrito Lay AssignmentSamarth Anand100% (1)

- Business Plan GROUP 10Document35 pagesBusiness Plan GROUP 10Sofia GarciaNo ratings yet

- Toshiba Satellite L200 M200 M203 M206 KBTIDocument59 pagesToshiba Satellite L200 M200 M203 M206 KBTIYakub LismaNo ratings yet

- DPC SEMESTER X B Project ListDocument2 pagesDPC SEMESTER X B Project ListVaibhav SharmaNo ratings yet

- Analysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)Document11 pagesAnalysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)AJHSSR JournalNo ratings yet

- T&B Detailed Plan: Ceiling LineDocument1 pageT&B Detailed Plan: Ceiling LineKuthbert NoceteNo ratings yet

- Bell WorkDocument26 pagesBell WorkChuột Cao CấpNo ratings yet

- Oops in PythonDocument64 pagesOops in PythonSyed SalmanNo ratings yet

- Rundown Rakernas & Seminar PABMI - Final-1Document6 pagesRundown Rakernas & Seminar PABMI - Final-1MarthinNo ratings yet

- SPIE Oil & Gas Services: Pressure VesselsDocument56 pagesSPIE Oil & Gas Services: Pressure VesselsSadashiw PatilNo ratings yet