Professional Documents

Culture Documents

Sarvajanik College of Engineering & Technology Chemical Engineering Department

Uploaded by

Fack Account0 ratings0% found this document useful (0 votes)

8 views11 pagesOriginal Title

Flotation(2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views11 pagesSarvajanik College of Engineering & Technology Chemical Engineering Department

Uploaded by

Fack AccountCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

SARVAJANIK COLLEGE OF ENGINEERING & TECHNOLOGY

CHEMICAL ENGINEERING DEPARTMENT

SUBJECT:- WASTE WATER ENGINEERING(3160513)

SUBMITED TO:- PROF. ANAND UPADHYAY

SUBMITED BY:- YASH S. PRAJAPATI(200420105503)

HITESH M. VANZARA(190420105069)

Flotation

INTRODUCTION :

• Flotation is known as a separation process, based on the introduction

of gas bubbles as the transport medium.

• Suspended particulate matter, being hydrophobic or conditioned to be

so, is then attach to the bubbles and moves toward the water solution

surface.

-i.e., contrary to the direction of gravity

• Flotation may be used in place of sedimentation, primarily for treating

industrial waste waters containing finely divided suspended solids and oily

matter.

• It is used in paper industry to recover fine fibers from the screened effluent

and in the oil industry for the clarification of oil-bearing waste.

• It is also used for treating effluents from tanneries, metal finishing, cold-

rolling and pharmaceutical industries.

• Particles of density very close to that of water are very difficult to settle in

normal sedimentation tanks and take a long time for separation.In such

cases, the separation can be speeded up by aerating the effluent whereby

air bubbles are attached to the suspended matter.

• To aid in the flotation process, chemical coagulants such as aluminum

and ferric salts or polymer coagulant-aids are often used.

• These chemicals increase the flocculent structure of the floated

particles so that they can easily entrap the air bubbles.

Two methods of flotation are currently available:

1) Dissolved air flotation

2) Dispersed air flotation

1. Dissolved air flotation:

• The feed water to the DAF float tank is often dosed with a coagulant to

coagulate the colloidal particles into bigger clusters.

• The released air forms tiny bubbles which adhere to the suspended

matter causing the suspended matter to float to the surface of the water

where it can be removed.

• A portion of the clarified effluent water leaving the DAF tank is pumped

into a small pressure vessel called the air drum into which compressed

air is also introduced. This results in saturating the pressurized effluent

water with air.

• The air-saturated water stream is recycled to the front of the float tank

and flows through a pressure reduction valve just as it enters the front of

the float tank, which results in the air being released in the form of tiny

bubbles.

• The froth-free water exits the float tank as the clarified effluent from the

DAF unit. The suspended matter which float to the surface where it

forms a froth layer which is then removed by a skimmer.

2. Dispersed air flotation:

• In dispersed-air flotation, air is introduced directly into the liquid through

a revolving impeller or through diffusers.

• The air bubbles generated in dispersed air flotation systems are normally

about 1mm in diameter and they usually cause turbulence which breaks

up fragile floc particles.

• Dispersed air flotation is not a favored technique in the treatment of

municipal wastewater, although it finds a limited application in treating

industrial wastes containing oil, grease and fine powders.

https://www.youtube.com/watch?

v=8dJOiEyLyfg

Thank you!

You might also like

- FlotationDocument40 pagesFlotationAhmed Mohamed RedaNo ratings yet

- Lecture Slides CPE 676 - Absorption & AdsorptionDocument56 pagesLecture Slides CPE 676 - Absorption & AdsorptionLim Ying PeiNo ratings yet

- From Air Sparged Hydrocyclone To Gas Energy Mixing (GEM) Floration, Clean Water TechnologyDocument18 pagesFrom Air Sparged Hydrocyclone To Gas Energy Mixing (GEM) Floration, Clean Water TechnologyCamille Nunes LeiteNo ratings yet

- WWT in RefineryDocument32 pagesWWT in RefineryGodwin100% (1)

- Dissolved Air FloationDocument25 pagesDissolved Air FloationHARI PRASATHNo ratings yet

- Equipments Regarding AbsorptionDocument7 pagesEquipments Regarding AbsorptionGerry Lou QuilesNo ratings yet

- Layout of A Conventional Water Treatment Location of Treatment PlantsDocument6 pagesLayout of A Conventional Water Treatment Location of Treatment PlantsSajil KrishnaNo ratings yet

- Stripping Column: Haldia Institute of TechnologyDocument14 pagesStripping Column: Haldia Institute of TechnologyArnab DasNo ratings yet

- 2.1.13 Drum Washing, Crushing, Shredding and CuttingDocument3 pages2.1.13 Drum Washing, Crushing, Shredding and CuttingvzgscribdNo ratings yet

- أنتاج ثالثة 3Document6 pagesأنتاج ثالثة 3snariaNo ratings yet

- Treatment of Water: 4 Process Will Be Used To Treat Waste Water in Steel IndustryDocument19 pagesTreatment of Water: 4 Process Will Be Used To Treat Waste Water in Steel IndustryReshab SahooNo ratings yet

- Oily Water Separators: Dissolved Air Flotation Units (DAF)Document2 pagesOily Water Separators: Dissolved Air Flotation Units (DAF)blondtumbalaNo ratings yet

- Oil & Gas SeperationDocument34 pagesOil & Gas Seperationassatpute100% (2)

- Absorption Flue GasDocument62 pagesAbsorption Flue GasReza RhiNo ratings yet

- Basic Distillation Concept 1705563192Document10 pagesBasic Distillation Concept 1705563192rajesh_sgNo ratings yet

- Absorption (FGD)Document62 pagesAbsorption (FGD)Chaidir FajariNo ratings yet

- Drilling Fluid EssayDocument5 pagesDrilling Fluid EssayAyman MikailNo ratings yet

- 04 Feuillet Memento Degremont en N 4 Aquadaf BDDocument4 pages04 Feuillet Memento Degremont en N 4 Aquadaf BDSong Nguyen NguyenNo ratings yet

- Bubbles and Foam in Hydraulics - How It Happens, How To Avoid It - Hydraulics & PneumaticsDocument11 pagesBubbles and Foam in Hydraulics - How It Happens, How To Avoid It - Hydraulics & PneumaticsChandramohan MuruganNo ratings yet

- A Rotary EvaporatorDocument3 pagesA Rotary EvaporatorJuvy Anne LozanoNo ratings yet

- Wastewate TreatmentDocument68 pagesWastewate Treatment21pwche1592No ratings yet

- Biotower 001 PDFDocument3 pagesBiotower 001 PDFIsmael KhalilNo ratings yet

- Water DAF IAF pp305 308Document4 pagesWater DAF IAF pp305 308lehuy1210No ratings yet

- Chapter 2Document60 pagesChapter 2Solomon DesalegnNo ratings yet

- Submitted by Natthu Shrirame: Under The Guidance ofDocument48 pagesSubmitted by Natthu Shrirame: Under The Guidance ofKamran Rana100% (2)

- Sumber FileDocument16 pagesSumber FileONes 4686No ratings yet

- Residuals Processing and DisposalDocument30 pagesResiduals Processing and DisposalHeba YousifNo ratings yet

- Unit IV Wastewater Treatment II SEMDocument33 pagesUnit IV Wastewater Treatment II SEMDavid LalrinnungaNo ratings yet

- Types of Distillation ColumnDocument3 pagesTypes of Distillation ColumnKornelis OlaNo ratings yet

- Project Report 2013Document45 pagesProject Report 2013Bhupendrapal SinghNo ratings yet

- Separation of Oil From Water by Dissolved Air FlotationDocument12 pagesSeparation of Oil From Water by Dissolved Air FlotationMarcosChaprãoNo ratings yet

- Dissolved Air Flotation HandoutDocument5 pagesDissolved Air Flotation HandoutJen Astoveza0% (1)

- Froth FlotationDocument42 pagesFroth FlotationKeshav K Rangan100% (3)

- Industrial Chemical Cleaning MethodsDocument29 pagesIndustrial Chemical Cleaning MethodsTEZ ANALYSIS AND STORIESNo ratings yet

- Separator Vessel: Ms. Shreya SahajpalDocument6 pagesSeparator Vessel: Ms. Shreya SahajpalShreya Sahajpal KaushalNo ratings yet

- Mass Transfer: Unit OperationDocument4 pagesMass Transfer: Unit OperationazibanjumNo ratings yet

- Types FDFDocument2 pagesTypes FDFaymen telliNo ratings yet

- Sand Vac Ogj April 2002Document6 pagesSand Vac Ogj April 2002Aquiles CarreraNo ratings yet

- Effluent Treatmnt Plant (ETP) : Akash TikheDocument44 pagesEffluent Treatmnt Plant (ETP) : Akash TikheArvind ShuklaNo ratings yet

- Sand Vac OGJ-APRIL-2002 PDFDocument6 pagesSand Vac OGJ-APRIL-2002 PDFAquiles CarreraNo ratings yet

- Ww06 Solids Handling WBDocument69 pagesWw06 Solids Handling WBj17perezNo ratings yet

- Field Operations & Inlet ReceivingDocument38 pagesField Operations & Inlet ReceivingBalamurali BalamNo ratings yet

- Drilling Fluid OverviewDocument13 pagesDrilling Fluid OverviewAhmed SalahNo ratings yet

- Japan-Philippine Steel Manufacturing Corporation: Acid Fumes ScrubberDocument84 pagesJapan-Philippine Steel Manufacturing Corporation: Acid Fumes ScrubberLuis UrzoNo ratings yet

- Flotation 21Document62 pagesFlotation 21Jamel CayabyabNo ratings yet

- Assignment Water Supply (Individual)Document24 pagesAssignment Water Supply (Individual)eryky21No ratings yet

- Dissolved Air Flotation (DAF) SystemDocument8 pagesDissolved Air Flotation (DAF) Systemneeraj sharmaNo ratings yet

- Ar-Coarse Bubble SystemsDocument1 pageAr-Coarse Bubble Systemskeikei22No ratings yet

- Evaporator HistoryDocument7 pagesEvaporator History박우진No ratings yet

- ClarifiersDocument2 pagesClarifiersvijay kumar honnaliNo ratings yet

- Series 4000 Cyclosep Centrifugal SeparatorDocument7 pagesSeries 4000 Cyclosep Centrifugal SeparatorValiNo ratings yet

- Chapter OneDocument27 pagesChapter OneAyuob ElsharefNo ratings yet

- VWS Westgarth Specialises in The Turnkey Design and Build of Water Treatment Plants For Upstream Oil and Gas MarketsDocument4 pagesVWS Westgarth Specialises in The Turnkey Design and Build of Water Treatment Plants For Upstream Oil and Gas Marketskay50No ratings yet

- Separator InternalsDocument36 pagesSeparator InternalsCVACAPNo ratings yet

- Solutions For Reservoir DesignDocument7 pagesSolutions For Reservoir DesignSympatyagaNo ratings yet

- Zabel1984 Chapter FlotationInWaterTreatment PDFDocument29 pagesZabel1984 Chapter FlotationInWaterTreatment PDFjoseph ayronNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Waste Water Engineering Topic: Anarobic Fixed Film Reactor Submitted ToDocument11 pagesWaste Water Engineering Topic: Anarobic Fixed Film Reactor Submitted ToFack AccountNo ratings yet

- Boundary Layer Formation in Straight Tube PDFDocument1 pageBoundary Layer Formation in Straight Tube PDFFack AccountNo ratings yet

- Sarvajanik College of Engineering & TechnologyDocument27 pagesSarvajanik College of Engineering & TechnologyFack AccountNo ratings yet

- Applied Chemistry PDFDocument147 pagesApplied Chemistry PDFFack AccountNo ratings yet

- Boundary Layer Formation in Straight Tube PDFDocument1 pageBoundary Layer Formation in Straight Tube PDFFack AccountNo ratings yet

- AC BookDocument147 pagesAC BookFack AccountNo ratings yet

- Questions On Composite Wall PDFDocument1 pageQuestions On Composite Wall PDFFack AccountNo ratings yet

- Questions On Composite Wall PDFDocument1 pageQuestions On Composite Wall PDFFack AccountNo ratings yet

- Sewage Treatment OverviewDocument13 pagesSewage Treatment OverviewDr. Akepati Sivarami Reddy100% (3)

- 1.03 MLD Sbr-Process DesignDocument4 pages1.03 MLD Sbr-Process DesignHemant KaleNo ratings yet

- Water and Wastewater Engineering Prof. C. Venkobacher Department of Civil Engineering Indian Institute of Technology, Madras Lecture-16Document18 pagesWater and Wastewater Engineering Prof. C. Venkobacher Department of Civil Engineering Indian Institute of Technology, Madras Lecture-16kaushal patelNo ratings yet

- Ocy751 Waste Water TreatmentDocument13 pagesOcy751 Waste Water TreatmentDivyadharshinisekarNo ratings yet

- Activated Sludge Process 01Document42 pagesActivated Sludge Process 01fahmi rifaldiNo ratings yet

- 06-Wastewater TreatmentDocument29 pages06-Wastewater TreatmentAstra BeckettNo ratings yet

- Kleen: Koch 150 Membrane CleanerDocument2 pagesKleen: Koch 150 Membrane Cleanerdalton2004No ratings yet

- Water Treatment Lecture 1 PDFDocument27 pagesWater Treatment Lecture 1 PDFibruNo ratings yet

- KP Mam SsDocument12 pagesKP Mam Ssmarketing hydroNo ratings yet

- Penurunan Kadar BOD Dan COD Dalam Limbah Cair Laundry Menggunakan Kombinasi Adsorben Alam Sebagai Media FiltrasiDocument7 pagesPenurunan Kadar BOD Dan COD Dalam Limbah Cair Laundry Menggunakan Kombinasi Adsorben Alam Sebagai Media FiltrasiKadek andi dwi SaputraNo ratings yet

- Gulariya FSM BrochureDocument2 pagesGulariya FSM BrochureAnish GhimireNo ratings yet

- Ats BrochureDocument28 pagesAts BrochureQuốc Anh KhổngNo ratings yet

- Chapter 4 SepticTank Design and Construction by Haile.BDocument14 pagesChapter 4 SepticTank Design and Construction by Haile.BANDLENATUNo ratings yet

- Modified Cluster System Approach To WastDocument10 pagesModified Cluster System Approach To WastGraziella NavacciNo ratings yet

- CES ProfileDocument12 pagesCES ProfileGanesh VijaykumarNo ratings yet

- Environmental Pollution Control: BITS PilaniDocument26 pagesEnvironmental Pollution Control: BITS PilaniAnubhav NarwalNo ratings yet

- Questions STPDocument22 pagesQuestions STPRabindra SinghNo ratings yet

- SewageDocument34 pagesSewageMongolian MutuNo ratings yet

- Performance Evaluation of A Sewage Treatment Plant STP A Critical ReviewDocument3 pagesPerformance Evaluation of A Sewage Treatment Plant STP A Critical ReviewEditor IJTSRDNo ratings yet

- Question Paper Code:: Time: Three Hours Maximum: 100 Marks Answer ALL Questions Part - ADocument3 pagesQuestion Paper Code:: Time: Three Hours Maximum: 100 Marks Answer ALL Questions Part - ASrikrishnan DhanajiNo ratings yet

- Expansion Maraba Water - KSADocument1 pageExpansion Maraba Water - KSAHaseeb RazviNo ratings yet

- Lista Detalhada de Equipamentos ETADocument3 pagesLista Detalhada de Equipamentos ETADimitri DiogoNo ratings yet

- IPALDocument38 pagesIPALnamsayasriNo ratings yet

- PDF WTP - 18 September 2023Document3 pagesPDF WTP - 18 September 2023Agus WibowoNo ratings yet

- Product Spares RelationshipDocument962 pagesProduct Spares RelationshipebinNo ratings yet

- Chapter-1: Sewage Treatment PlantDocument24 pagesChapter-1: Sewage Treatment PlantanushkaNo ratings yet

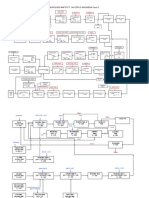

- Flowchart AllDocument11 pagesFlowchart Allasri nurulNo ratings yet

- Objective of Sanitation - Collection and Conveyence of Sewage and Different Tyoes of Refuse From SettelementsDocument18 pagesObjective of Sanitation - Collection and Conveyence of Sewage and Different Tyoes of Refuse From SettelementsThe White Beast YTNo ratings yet

- Quantity of Material (LPBS)Document8 pagesQuantity of Material (LPBS)Billy DNo ratings yet

- New Microsoft Word DocumentDocument6 pagesNew Microsoft Word DocumentalialshammaaNo ratings yet