Professional Documents

Culture Documents

Actuators and Valves: How To Marry' The Correct Actuator To The Correct Valve?

Uploaded by

Zakky Ibnu FadjrieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Actuators and Valves: How To Marry' The Correct Actuator To The Correct Valve?

Uploaded by

Zakky Ibnu FadjrieCopyright:

Available Formats

Actuators and Valves

How to ‘marry’ the correct actuator to the correct valve?

Confidence through Competence

ACTUATORS AND VALVES

What is an actuator? Why are actuators installed on valves?

An actuators is a type of motor use for moving or controlling a

mechanism or system.

The actuator can be operated using the following:

1)Pneumatic pressure (Air)

2)Electrical current

3)Hydraulic fluid

Confidence through Competence

ACTUATORS AND VALVES

What is the functions of actuated valves?

Typically, there are three main functions of actuated valves:

1)On/Off – The actuator is used to fully open or close the valve

2)Shutdown – The actuator together with help of springs will

open or close the valve in an event of an emergency.

3)Modulating – Precision control of either the flow rate or

pressure flowing through the valve.

Confidence through Competence

ACTUATORS AND VALVES

Pneumatic Actuators

There are two main designs of pneumatic actuators:

1)Rack and Pinion Design

2)Scotch and Yoke Design

Confidence through Competence

ACTUATORS AND VALVES

Rack and Pinion Actuators

• Rack and Pinion actuators are designed

for use in low and high cycle service. Used

for ball, plug and butterfly valves.

• Torque that a typical rack and pinion

actuator can generate – from as low as 6 Nm

to 4,000 Nm

• Two type of rack and pinion actuator:

- Double acting actuator

- Single acting actuator

Confidence through Competence

ACTUATORS AND VALVES

Double acting actuator

Operating principle of double acting actuator

- Air to port A Forces the piston outwards, causing the piston to

turn counter clockwise while air is being exhausted from Port B

Confidence through Competence

ACTUATORS AND VALVES

Single acting actuator

Operating principle of Single acting actuator

- Air is pumped into the port on the left forcing the piston

outwards, causing the springs to compress. The counter

clockwise action of the piston will open the valve. When air

pressure is stopped or lost, the release tension of the springs

will close the valve.

Confidence through Competence

ACTUATORS AND VALVES

Question:

What happens if you want the actuator to have a ‘fail open’

function?

Very simple – all you need to do is to switch the racks of the

actuator to the opposite ends!

Confidence through Competence

ACTUATORS AND VALVES

Scotch and Yoke actuators

Scotch Yoke actuators are designed to meet the higher torque

requirements of large sizes quarter turn valves

Confidence through Competence

ACTUATORS AND VALVES

Construction of a Scotch Yoke Actuator.

PTFE

Standardized Guide Reduced Safe Spring

Bar Roller Hydraulic

Mounting Wear Lock

Override

PTFE Replaceable Travel

Housing

Guide Bearings Adjustment

Vent

Ring

Confidence through Competence

ACTUATORS AND VALVES

Advantages of Pneumatic Actuators

.

• Generally cheaper than electric actuators if the number of

actuated valves is large

• Torque of the actuator can be increased by increasing the air

pressure entering the actuator

• Actuator has a faster response time, opening and closing of

valve is much faster compared to an electric actuator

• Able to continue working even when there is a power failure,

as long as the air line is working. Actuator will remain in ‘fail last’

position

Confidence through Competence

ACTUATORS AND VALVES

Hydraulic Actuators

.

Operation of hydraulic actuators is typically the same as the

operation of a pneumatic actuator, with the main difference

being that oil instead of air is used to pressurize the cylinder.

One unique difference that a spring return hydraulic actuator

can offer over a pneumatic actuator is that it can offer a ‘slower’

shutoff time for the valve if needed.

Confidence through Competence

ACTUATORS AND VALVES

Motor Operated Valves (MOV)

There are several reasons when electric actuators are used/

preferred over pneumatic actuators

• When there is an absence of an air line in the facility

• When the valve is linear and not quarter turn

• More cost efficient if the number of actuated valves is not

many as there will not be a need to install a compressor

• When both local and remote control is required

Confidence through Competence

ACTUATORS AND VALVES

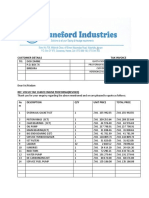

Motor Operated Valves (MOV)

One of the greatest fear when sizing a MOV is to

undersize it as unlike pneumatic actuators, there

is no way to increase the torque of the actuator.

This lead to many operators over sizing their

actuators!

< 24” CL150

actuated gate

valve sized by

others

32” CL 150>

actuated gate

valve sized by us

Confidence through Competence

ACTUATORS AND VALVES

Optimization for MOV

Optimization – to choose the most suitable actuator to match

the valve and produce the most cost effective outcome for the

customer.

• Lower hardware cost

• Lower risk of damage

• Over sizing of actuators – stem will bend over time,

increased cable cost, higher power consumption

• Under sizing of actuators – Overtime, actuator may not be

able to overcome fractional wear and tear in the valve and

result in leakage

Confidence through Competence

ACTUATORS AND VALVES

Heaton MOV Optimization Program

Confidence through Competence

ACTUATORS AND VALVES

Linear Actuators

Confidence through Competence

THANK YOU

INQ@mrctransmark.com

Confidence through Competence

You might also like

- Control ValvesDocument38 pagesControl ValvesSridhar GudapatiNo ratings yet

- Fisher Globe Valve Selection Guide PDFDocument12 pagesFisher Globe Valve Selection Guide PDFAmiroucheBenlakehalNo ratings yet

- Actuator Sizing for Butterfly Valves - Torque Requirements & CalculationsDocument2 pagesActuator Sizing for Butterfly Valves - Torque Requirements & CalculationsAntonio LebrunNo ratings yet

- Good-Comparison of Friction Models Applied To A Control ValveDocument13 pagesGood-Comparison of Friction Models Applied To A Control ValvesayproNo ratings yet

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftNo ratings yet

- Control Valve Manual - What is a Control Valve? Process Control TerminologyDocument55 pagesControl Valve Manual - What is a Control Valve? Process Control Terminologytxlucky80100% (1)

- Thrust and TorqueDocument41 pagesThrust and TorquevelusankarNo ratings yet

- Valve HandbookDocument52 pagesValve Handbookshivam100% (1)

- Control Valves - International Site For Spirax SarcoDocument12 pagesControl Valves - International Site For Spirax SarcoOzawa MagooNo ratings yet

- G-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionDocument12 pagesG-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionRoo Fa100% (1)

- Cci PDFDocument4 pagesCci PDFKamlesh DalavadiNo ratings yet

- Control Valve OpeningDocument3 pagesControl Valve OpeningConnor SailorNo ratings yet

- CH 5 Control ValvesDocument42 pagesCH 5 Control ValvesFelix LaraNo ratings yet

- SAMSON Valve Series 3250 & 3280 GuideDocument45 pagesSAMSON Valve Series 3250 & 3280 Guidepmmparana100% (1)

- API - Valve StandardsDocument38 pagesAPI - Valve StandardsK LandryNo ratings yet

- Esd Valve Actuator SizingDocument19 pagesEsd Valve Actuator Sizingshinojbaby4148No ratings yet

- CV Training InstDocument21 pagesCV Training Instxentrer100% (1)

- CV1Document47 pagesCV1Sridhar GudapatiNo ratings yet

- Gas Sizing PDFDocument36 pagesGas Sizing PDFChetan ChuriNo ratings yet

- ValvesDocument25 pagesValvesAlbertoNo ratings yet

- Overcoming Control Valve Trim Selection ChallengeDocument10 pagesOvercoming Control Valve Trim Selection Challengeprasad durgaNo ratings yet

- KV CV Flow Coefficient - ValviasDocument2 pagesKV CV Flow Coefficient - Valviasdevika11No ratings yet

- API 6A and 6D Ball ValvesDocument27 pagesAPI 6A and 6D Ball ValveszayerirezaNo ratings yet

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- Control Valve SelectionDocument50 pagesControl Valve SelectionSyed AhmedNo ratings yet

- Attachment M - John Fowler - AnnexXRevBDocument5 pagesAttachment M - John Fowler - AnnexXRevBBùi Văn HợpNo ratings yet

- Belimo Control ValveDocument106 pagesBelimo Control ValveAnderson SiqueiraNo ratings yet

- Valve Pressure Recovery Factor and its Impact on Cavitation, Flashing, and NoiseDocument45 pagesValve Pressure Recovery Factor and its Impact on Cavitation, Flashing, and NoiseVitória MarcenariaNo ratings yet

- DRESSER ControlValveCavitationDocument10 pagesDRESSER ControlValveCavitationLindsey PatrickNo ratings yet

- Topic 1 Valve and Instrumentation SymbolsDocument8 pagesTopic 1 Valve and Instrumentation SymbolshatiniNo ratings yet

- Valve SizingDocument1 pageValve SizingdlescribdNo ratings yet

- Control Valve PDFDocument26 pagesControl Valve PDFRoona Thankam VargheseNo ratings yet

- PRD Design FundamentalsDocument6 pagesPRD Design Fundamentalsnarayanan_anoobNo ratings yet

- Topworx Valvetop D-Series With GO Switches ManualDocument20 pagesTopworx Valvetop D-Series With GO Switches ManualJuan LuisNo ratings yet

- MAST CalculationDocument4 pagesMAST Calculationaniket100% (3)

- Bopp & Reuther Safety Valves RangeDocument24 pagesBopp & Reuther Safety Valves RangeLuka Borna100% (1)

- Face To Face Valve Dimensions En-558-1 - ValviasDocument3 pagesFace To Face Valve Dimensions En-558-1 - ValviasAntonio CeiNo ratings yet

- Control Valves 91000Document16 pagesControl Valves 91000ibharNo ratings yet

- Scotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Document2 pagesScotch Yoke or Rack-and-Pinion Quarter-Turn Actuator?Assured AutomationNo ratings yet

- Control Valve Theory & Sizing GuideDocument29 pagesControl Valve Theory & Sizing GuideSandeep KulathapallilNo ratings yet

- 6.6 Control Valve Actuators and Positioners PDFDocument20 pages6.6 Control Valve Actuators and Positioners PDFdanpolymathNo ratings yet

- Service Instructions PDFDocument13 pagesService Instructions PDFBrett GottliebNo ratings yet

- Open Thrust Calculation For ValveDocument177 pagesOpen Thrust Calculation For ValvePrashant Malve100% (2)

- Applications Guideline-Flashing (Water)Document2 pagesApplications Guideline-Flashing (Water)strahor7492No ratings yet

- Control Valve Characteristics - International Site For Spirax SarcoDocument19 pagesControl Valve Characteristics - International Site For Spirax SarcoRujisak MuangsongNo ratings yet

- Masoneilan Process Valves CNDNSD Catalog 0512Document20 pagesMasoneilan Process Valves CNDNSD Catalog 0512pauloferettiNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- Valves Terminology and SymbolsDocument1 pageValves Terminology and SymbolsHardik AcharyaNo ratings yet

- Focus On Control ValvesDocument5 pagesFocus On Control Valveswmolinac584366No ratings yet

- Control Valve Characteristics PDFDocument20 pagesControl Valve Characteristics PDFPrem SagarNo ratings yet

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Solenoid Valve - Which Insulation ClassDocument2 pagesSolenoid Valve - Which Insulation ClassMohd Firdaus100% (2)

- BS en Iso 6553-2017Document14 pagesBS en Iso 6553-2017GT-LUCAS BARCINo ratings yet

- ISA 2011 Fundamentals DistillationDocument30 pagesISA 2011 Fundamentals DistillationEr Mayur PatilNo ratings yet

- Bray - Valvulas Control RotativasDocument151 pagesBray - Valvulas Control RotativasAnnie De WildeNo ratings yet

- Scansteering CatDocument16 pagesScansteering CatosamaNo ratings yet

- Brochure RV Series Rotary Vane Actuators Shafer en 86698Document8 pagesBrochure RV Series Rotary Vane Actuators Shafer en 86698josecordova2014No ratings yet

- Shafer Rv-Series Brochure PDFDocument8 pagesShafer Rv-Series Brochure PDFSeaman NoNo ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Training Module THINKTANKcontrol Valve PDFDocument90 pagesTraining Module THINKTANKcontrol Valve PDFkam.kimou16No ratings yet

- Cryogenic ValvesDocument36 pagesCryogenic ValvesZakky Ibnu FadjrieNo ratings yet

- Limitorque QXM Smart Valve ActuatorDocument2 pagesLimitorque QXM Smart Valve ActuatorZakky Ibnu FadjrieNo ratings yet

- Mortar AmeiteDocument3 pagesMortar AmeiteZakky Ibnu FadjrieNo ratings yet

- Catalog PDFDocument24 pagesCatalog PDFskinkcrowNo ratings yet

- Limitorque QX Smart Valve ActuatorDocument2 pagesLimitorque QX Smart Valve ActuatorZakky Ibnu FadjrieNo ratings yet

- Specifications: Limitorque MX and L120 Series Product SpecificationsDocument42 pagesSpecifications: Limitorque MX and L120 Series Product SpecificationsZakky Ibnu FadjrieNo ratings yet

- Aveva Intouch Hmi: Formerly WonderwareDocument16 pagesAveva Intouch Hmi: Formerly WonderwareZakky Ibnu FadjrieNo ratings yet

- (FLS VA ECS 00006 EN EX A4 0217) Margherita - Quad - Yoke - Success - LRDocument3 pages(FLS VA ECS 00006 EN EX A4 0217) Margherita - Quad - Yoke - Success - LRZakky Ibnu FadjrieNo ratings yet

- Limitorque MX/QX: HART Field UnitDocument2 pagesLimitorque MX/QX: HART Field UnitZakky Ibnu FadjrieNo ratings yet

- LTRH/LTRM Valve Specs - Torque, Thrust, Diameter, Speed & PowerDocument1 pageLTRH/LTRM Valve Specs - Torque, Thrust, Diameter, Speed & PowerZakky Ibnu FadjrieNo ratings yet

- Valve and Actuator: An IntroductionDocument19 pagesValve and Actuator: An IntroductionZakky Ibnu FadjrieNo ratings yet

- Butterfly Valve Catalogue PDFDocument25 pagesButterfly Valve Catalogue PDFZakky Ibnu FadjrieNo ratings yet

- GateGlobeValveTorqueNM PDFDocument4 pagesGateGlobeValveTorqueNM PDFWanda Hafiz NurzamanNo ratings yet

- Valve and Actuator: An IntroductionDocument19 pagesValve and Actuator: An IntroductionZakky Ibnu FadjrieNo ratings yet

- The Torque Calculation Method For Ball ValvesDocument2 pagesThe Torque Calculation Method For Ball ValvesZakky Ibnu Fadjrie100% (2)

- Bottled Water in Indonesia - NielsenDocument30 pagesBottled Water in Indonesia - Nielsenme24370No ratings yet

- PT. Integra Automasi: An Automation and Control CompanyDocument8 pagesPT. Integra Automasi: An Automation and Control CompanyZakky Ibnu FadjrieNo ratings yet

- Retrofitting ActuatorsDocument25 pagesRetrofitting ActuatorsKamal SkNo ratings yet

- Bottled Water in Indonesia - NielsenDocument30 pagesBottled Water in Indonesia - Nielsenme24370No ratings yet

- Itung CableDocument2 pagesItung CableZakky Ibnu FadjrieNo ratings yet

- Bottled Water in Indonesia - NielsenDocument30 pagesBottled Water in Indonesia - Nielsenme24370No ratings yet

- Valve ActuatorDocument18 pagesValve ActuatorZakky Ibnu Fadjrie100% (1)

- Organizational Physic Lex SisneyDocument9 pagesOrganizational Physic Lex SisneyZakky Ibnu FadjrieNo ratings yet

- IELTS Reading Practice Test 16 Printable v2Document13 pagesIELTS Reading Practice Test 16 Printable v2javohirakmalov2No ratings yet

- Code Delphi InjectorsDocument4 pagesCode Delphi InjectorsLevaniMgebrishviliNo ratings yet

- Auto Suppliers Lean On Price Till Volume Ramps 2023 OutlookDocument10 pagesAuto Suppliers Lean On Price Till Volume Ramps 2023 OutlookEkambaram Thirupalli TNo ratings yet

- MID 128, SID 32 Waste Gate (D12-800) : MID 128: Engine Control Unit. Fault CodeDocument1 pageMID 128, SID 32 Waste Gate (D12-800) : MID 128: Engine Control Unit. Fault Codeuser1100% (1)

- Commutator in DC MotorDocument2 pagesCommutator in DC MotorArmy Joel MarianoNo ratings yet

- AW139 Fuel System ChapterDocument72 pagesAW139 Fuel System ChapterŞükrü ÇarkçiNo ratings yet

- 501 14 PDFDocument27 pages501 14 PDFTuan Tran100% (1)

- WheelHorse Charger 12 Manual 1-7241-PDocument14 pagesWheelHorse Charger 12 Manual 1-7241-PKevins Small Engine and Tractor Service100% (1)

- Advanced Driver-Assistance SystemsDocument15 pagesAdvanced Driver-Assistance Systemsfroggoand decrewNo ratings yet

- 2012 Annual Report (Complete Version) - Fiat SpADocument346 pages2012 Annual Report (Complete Version) - Fiat SpAMichele Luigi GrecoNo ratings yet

- Agitator Design and SpecificationsDocument6 pagesAgitator Design and SpecificationsJesseNo ratings yet

- Oral 2022-2023 Question BankDocument16 pagesOral 2022-2023 Question BankRAHUL SINGHNo ratings yet

- Electra-Saver SAV 350-500 HP Cut SheetDocument2 pagesElectra-Saver SAV 350-500 HP Cut SheetEsteban JaramilloNo ratings yet

- Front Hub/Freehub (Disc Brake) : Dealer's ManualDocument15 pagesFront Hub/Freehub (Disc Brake) : Dealer's ManuallizukyNo ratings yet

- 22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & CoDocument13 pages22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & Coshan shanzNo ratings yet

- 2017 Advanced Diagnostics Usa MVP Pro T Code Pro Manual Key Guide Ver 2017 2Document638 pages2017 Advanced Diagnostics Usa MVP Pro T Code Pro Manual Key Guide Ver 2017 2Anonymous 8To07bJFa50% (2)

- System Description - Lane Change Assist (Audi Side Assist)Document10 pagesSystem Description - Lane Change Assist (Audi Side Assist)ergdegNo ratings yet

- Nissan Sentra 1.8L A/C Circuit DiagramDocument106 pagesNissan Sentra 1.8L A/C Circuit DiagramJhonatan Yucra100% (1)

- SplendorDocument72 pagesSplendorandres parragaNo ratings yet

- Service Manual LS170Document741 pagesService Manual LS170nettlesman90% (39)

- GL XX Mobil ATF 220Document3 pagesGL XX Mobil ATF 220Muhammad SaputraNo ratings yet

- TIME AND DISTANCE (Trending Questions)Document12 pagesTIME AND DISTANCE (Trending Questions)Ranjan RajNo ratings yet

- 6BTAA5.9-G6: Fuel OptimizedDocument3 pages6BTAA5.9-G6: Fuel OptimizedArnaldo Macchi MillanNo ratings yet

- Rivian CEO RJ Scaringe E-Mail To Customers July 16, 2021Document1 pageRivian CEO RJ Scaringe E-Mail To Customers July 16, 2021CNBC.comNo ratings yet

- PSI Inspection SheetDocument9 pagesPSI Inspection SheetSalman BankariNo ratings yet

- General Purpose Tank Car ChartDocument2 pagesGeneral Purpose Tank Car ChartARMANDONo ratings yet

- 2024 Honda CR-V Specifications - enDocument3 pages2024 Honda CR-V Specifications - enAhmed GaballaNo ratings yet

- 40 Series SM 11026743Document40 pages40 Series SM 11026743gerallazo29No ratings yet

- Freda Rebecca Volvo Tad1340ve Engine Tax InvoiceDocument2 pagesFreda Rebecca Volvo Tad1340ve Engine Tax InvoiceHugh O'Brien GwazeNo ratings yet

- Mechatronic 2017 PadeepzDocument112 pagesMechatronic 2017 PadeepzSenthil Kumar PNo ratings yet