0% found this document useful (0 votes)

115 views60 pagesMachine Design: Cutting and Finishing Techniques

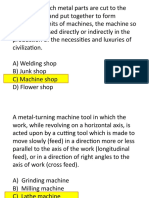

The document contains multiple choice questions about various machining, metalworking and engineering topics. Some questions test knowledge of materials like aluminum, nickel and cast iron. Other questions cover machining processes like centerless grinding, chemical milling and babbitt pouring. Additional concepts addressed include tool life equations, cutting fluids, heat treatment processes and mechanical properties.

Uploaded by

Jaypee BucatcatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

115 views60 pagesMachine Design: Cutting and Finishing Techniques

The document contains multiple choice questions about various machining, metalworking and engineering topics. Some questions test knowledge of materials like aluminum, nickel and cast iron. Other questions cover machining processes like centerless grinding, chemical milling and babbitt pouring. Additional concepts addressed include tool life equations, cutting fluids, heat treatment processes and mechanical properties.

Uploaded by

Jaypee BucatcatCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd