Professional Documents

Culture Documents

Plywood: Exceeding 2 Pages Per Material (Front and Back)

Uploaded by

Bmssa 2017B0 ratings0% found this document useful (0 votes)

17 views4 pagesThis document provides information about plywood, including its properties, sizes, thicknesses, grades, applications, and joinery details. Plywood is strong and stable due to its cross-laminated construction, which resists expansion, shrinkage, and impacts. It is flexible and available in a wide range of sizes, thicknesses, and facings. Common applications include subflooring, wall paneling, roof sheathing, mezzanine decks, shuttering, and furniture. Grades include moisture resistant, boiling water resistant, and marine plywood. The document also lists demerits such as plywood's susceptibility to water damage if exposed to leaks over time.

Original Description:

Details of Ply Board

Original Title

1. PLYWOOD

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about plywood, including its properties, sizes, thicknesses, grades, applications, and joinery details. Plywood is strong and stable due to its cross-laminated construction, which resists expansion, shrinkage, and impacts. It is flexible and available in a wide range of sizes, thicknesses, and facings. Common applications include subflooring, wall paneling, roof sheathing, mezzanine decks, shuttering, and furniture. Grades include moisture resistant, boiling water resistant, and marine plywood. The document also lists demerits such as plywood's susceptibility to water damage if exposed to leaks over time.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views4 pagesPlywood: Exceeding 2 Pages Per Material (Front and Back)

Uploaded by

Bmssa 2017BThis document provides information about plywood, including its properties, sizes, thicknesses, grades, applications, and joinery details. Plywood is strong and stable due to its cross-laminated construction, which resists expansion, shrinkage, and impacts. It is flexible and available in a wide range of sizes, thicknesses, and facings. Common applications include subflooring, wall paneling, roof sheathing, mezzanine decks, shuttering, and furniture. Grades include moisture resistant, boiling water resistant, and marine plywood. The document also lists demerits such as plywood's susceptibility to water damage if exposed to leaks over time.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 4

PLYWOOD

NOTE: All material assignments to be hand written on A4 size sheets, not

exceeding 2 pages per material (front and back).

PROPERTIES ACTIVITY-01 COST per sq.ft BRANDS

Design an office/home use product,

STRENGTH AND STABILITY:

with optimum utilization of a

8’x4’plywood sheet.

R

– 45 – 130 IN

MR PLY

SIZES THICKNESS

NR

LY – 90 I

The direction of grain in layers are perpendicular to

8’ X 4’ 4mm BWR P

6mm R

each other which resists expansion and shrinkage. 8’ X 3’ - 120 IN

LY – 50

7’ X 4’ 9mm BWP P

FLEXIBILITY : 12mm

Plywood is a manufactured 7’ X 3’

19mm

product, they are available 6’ X 4’

25mm

in wide range of sizes,

facings and thickness.

6’ X 3’ 32mm APPLICATION

SUBFLOORING: MEZZANINE

DECKS :

PLYWOOD

HIGH IMPACT RESISTANCE :

Plywood has high tensile strength due to the

Thin sheets of cross laminated veneer bonded under

cross lamination of panels which distributes

heat and pressure with strong adhesive.

force over a large area and reduces tensile

stress. WALL PANELLING AND ROOF SHEATHING:

FIRE, WATER AND CHEMICAL RESISTANT

MERITS

STRENGTH AND STABILITY:

HIGH

IMPACT RESISTANCE: SHUTTERING: FURNITURES:

CHEMICAL RESISTANCE:

GRADES OF PLYWOOD

SURFACE DIMENSIONAL STABILITY:

MOISTURE RESISTANT PLYWOOD (MR)

STRENGTH TO WEIGHT RATIO: BOILING WATER RESISTANT (BWR)

MARINE PLY OR BOILING WATER PROOF (BWP)

DE-MERITS

While plywood's layered property has many advantages, it actually also makes the wood porous and

susceptible to water damage if exposed to leaks over time.

JOINERY DETAILS

GROOVE CUTTING EDGE BANDING

THANK YOU

You might also like

- Block Board: Exceeding 2 Pages Per Material (Front and Back)Document3 pagesBlock Board: Exceeding 2 Pages Per Material (Front and Back)Bmssa 2017BNo ratings yet

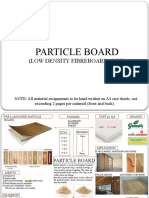

- Particle Board: (Low Density Fibreboard - LDF)Document3 pagesParticle Board: (Low Density Fibreboard - LDF)Bmssa 2017BNo ratings yet

- Hr+Oxspec+ +Laser+Cut+Screen+SetupsDocument10 pagesHr+Oxspec+ +Laser+Cut+Screen+SetupstibisortNo ratings yet

- Hr+Oxspec+ +Laser+Cut+Screen+SetupsDocument10 pagesHr+Oxspec+ +Laser+Cut+Screen+SetupstibisortNo ratings yet

- Timber and Plywood 1Document22 pagesTimber and Plywood 1yash goyalNo ratings yet

- Vibration Pads: Mason Industries, IncDocument2 pagesVibration Pads: Mason Industries, Incbman0051401No ratings yet

- Aanchal Rode BoardsDocument10 pagesAanchal Rode Boardsanchal rodeNo ratings yet

- Aastha BC Sheet 5Document1 pageAastha BC Sheet 5ajNo ratings yet

- Cedar Shakes Shingles Application enDocument20 pagesCedar Shakes Shingles Application enAlex IacobNo ratings yet

- Lumber For YaDocument4 pagesLumber For Yadktravels85No ratings yet

- FlooringDocument57 pagesFlooringGayatri SharmaNo ratings yet

- Tis 0002 Timber DunnageDocument2 pagesTis 0002 Timber DunnageMustaffa HoodMusNo ratings yet

- Wall Guard CatalogDocument12 pagesWall Guard CatalogJavier NúñezNo ratings yet

- Cedar Shingles GuideDocument20 pagesCedar Shingles GuideSimonNo ratings yet

- Lexan Fabrication GuideDocument7 pagesLexan Fabrication Guidenew_sub_energyNo ratings yet

- Section S 02Document1 pageSection S 02Awadhi SuleimanNo ratings yet

- Jurong Port - Steel Stowage InitiativeDocument22 pagesJurong Port - Steel Stowage Initiativeenigma102No ratings yet

- Vibro e BrochureDocument24 pagesVibro e BrochureAr Aayush Goel0% (1)

- Catalogue Polishing AbrasivesDocument12 pagesCatalogue Polishing AbrasivesMuhammad ShafiqueNo ratings yet

- Fabric-Reinforced Vibration-Damping Pad, For Heavy Machinery, 12 - Long, 12 - Wide, 1 - Thick - McMaster-Carr PDFDocument1 pageFabric-Reinforced Vibration-Damping Pad, For Heavy Machinery, 12 - Long, 12 - Wide, 1 - Thick - McMaster-Carr PDFHassan HelmyNo ratings yet

- Harper Independent Distributor Tri FoldDocument2 pagesHarper Independent Distributor Tri FoldYipper ShnipperNo ratings yet

- IR - FF4 IR.S2 Proprietary Custom 250mm High Rubber Skirting With Resilient Sealing Lip IR - WF7 IR - CF1Document12 pagesIR - FF4 IR.S2 Proprietary Custom 250mm High Rubber Skirting With Resilient Sealing Lip IR - WF7 IR - CF1Kesanam SpNo ratings yet

- Vol 4Document24 pagesVol 4Manish GuptaNo ratings yet

- STEICO Construction Guide LVL en IDocument32 pagesSTEICO Construction Guide LVL en IHarrison LangNo ratings yet

- Thermo Lite BoardDocument1 pageThermo Lite BoardRamon SellersNo ratings yet

- 004 Ottimo Collection SimpoloDocument43 pages004 Ottimo Collection SimpoloDimple BachaniNo ratings yet

- Gerflor Brochure Finishing Solutions Special LVT en PDF 348Document24 pagesGerflor Brochure Finishing Solutions Special LVT en PDF 348corzeaNo ratings yet

- Market SurveyDocument9 pagesMarket Surveypriti kochetaNo ratings yet

- 2023 03 - EN - Pollmeier LVL SDocument16 pages2023 03 - EN - Pollmeier LVL Sphani.dubaiNo ratings yet

- Triple Density Extra Slim Extra SlimDocument1 pageTriple Density Extra Slim Extra Slimfennec100% (1)

- Marigold Indore Sign OffDocument8 pagesMarigold Indore Sign OffNandini SawalkarNo ratings yet

- Interiors FlooringDocument47 pagesInteriors FlooringjacobNo ratings yet

- Ss Drum Mulcher Brochure 2019Document4 pagesSs Drum Mulcher Brochure 2019KuhnNo ratings yet

- Heavy Duty 8 MIL - 10x10 WEAVEDocument2 pagesHeavy Duty 8 MIL - 10x10 WEAVEAditya Tetra FirdaussyahNo ratings yet

- Arauco Ficha Tecnica Melamina Vesto Ing18ene 21Document6 pagesArauco Ficha Tecnica Melamina Vesto Ing18ene 21Rosa Marie GreenNo ratings yet

- Armtec Structural Plate Mini Span BridgesDocument8 pagesArmtec Structural Plate Mini Span BridgesAmos ChikwengoNo ratings yet

- NortonCatalog - Abrasive CA - CompositeDocument2 pagesNortonCatalog - Abrasive CA - CompositeJohn Pham NgocNo ratings yet

- Step 6-10 Tissue ProcessingDocument12 pagesStep 6-10 Tissue ProcessingNisa Claire ParpanNo ratings yet

- Heavy-Duty Vibrating FeedersDocument4 pagesHeavy-Duty Vibrating FeedersErsin SucuNo ratings yet

- DEKSTRIP Expandable Edged Flashing Product Data 661408Document2 pagesDEKSTRIP Expandable Edged Flashing Product Data 661408luisNo ratings yet

- Wood and Its DerivativesDocument35 pagesWood and Its DerivativesA 04 Ankit SharmaNo ratings yet

- Öko Skin: Slat Wall Panels Made of Glassfibre Reinforced ConcreteDocument4 pagesÖko Skin: Slat Wall Panels Made of Glassfibre Reinforced ConcreteChristian HutterNo ratings yet

- Steico Construction Guide LVL en IDocument29 pagesSteico Construction Guide LVL en Iapi-237820992No ratings yet

- PolygraniteDocument26 pagesPolygranitemistiavi7No ratings yet

- False CeilingDocument5 pagesFalse CeilingHitprakash Mohanty0% (1)

- The Zone Nailing Area & Color Selector GuideDocument3 pagesThe Zone Nailing Area & Color Selector GuideHoeNo ratings yet

- The Roofing SheetsDocument17 pagesThe Roofing SheetsAtul BhagwatNo ratings yet

- Linard Modular Anti-Abrasion Panels (MAP) Spec SheetDocument2 pagesLinard Modular Anti-Abrasion Panels (MAP) Spec SheetIgor JovanovićNo ratings yet

- Flap DiscsDocument3 pagesFlap DiscsPiyush A JoshiNo ratings yet

- IR - FF4 Norament' 992 Solid Colour Rubber Tiles With Classical Round Pastille 1002 X 1002 X 9mm THK Colour 0862 Blue IR - WF7 IR - CF2Document6 pagesIR - FF4 Norament' 992 Solid Colour Rubber Tiles With Classical Round Pastille 1002 X 1002 X 9mm THK Colour 0862 Blue IR - WF7 IR - CF2siva prasadNo ratings yet

- Passive & Active Fire System Market SurveyDocument5 pagesPassive & Active Fire System Market SurveyBhakti WanaveNo ratings yet

- Planum ENDocument20 pagesPlanum ENAmihay HararyNo ratings yet

- Terram - PipelineUtility - Brochure - June - 20pp 3Document1 pageTerram - PipelineUtility - Brochure - June - 20pp 3amoghimiNo ratings yet

- Building Technology Market SurveyDocument21 pagesBuilding Technology Market SurveyParmeet KaurNo ratings yet

- Rim Board Technical Guide CanadaDocument4 pagesRim Board Technical Guide CanadaAimad LarabiNo ratings yet

- Roll Covers For The Paper Making Industry: Size Presses, Film PressesDocument1 pageRoll Covers For The Paper Making Industry: Size Presses, Film PressesvenkNo ratings yet

- Doka Birch Plywood Specs - 18 MMDocument2 pagesDoka Birch Plywood Specs - 18 MMAnupam GhoshNo ratings yet

- When It Matters: Malarkey ShinglesDocument2 pagesWhen It Matters: Malarkey ShinglesHoeNo ratings yet

- Presentation 2Document8 pagesPresentation 2Md AatifNo ratings yet

- Bromide Printing and Enlarging A Practical Guide to the Making of Bromide Prints by Contact and Bromide Enlarging by Daylight and Artificial Light, With the Toning of Bromide Prints and EnlargementsFrom EverandBromide Printing and Enlarging A Practical Guide to the Making of Bromide Prints by Contact and Bromide Enlarging by Daylight and Artificial Light, With the Toning of Bromide Prints and EnlargementsNo ratings yet

- Ar. Leslie Dias School of Architecture S.I.T - MangaloreDocument22 pagesAr. Leslie Dias School of Architecture S.I.T - MangaloreBmssa 2017BNo ratings yet

- Ar. Leslie Dias School of Architecture S.I.T - MangaloreDocument20 pagesAr. Leslie Dias School of Architecture S.I.T - MangaloreBmssa 2017BNo ratings yet

- Ar. Leslie Dias School of Architecture S.I.T - MangaloreDocument15 pagesAr. Leslie Dias School of Architecture S.I.T - MangaloreBmssa 2017BNo ratings yet

- Shallow Foundation Deep FoundationDocument39 pagesShallow Foundation Deep FoundationBmssa 2017BNo ratings yet

- Wood Wool: Exceeding 2 Pages Per Material (Front and Back)Document3 pagesWood Wool: Exceeding 2 Pages Per Material (Front and Back)Bmssa 2017BNo ratings yet

- False Ceiling: MMBC 7Th SemDocument54 pagesFalse Ceiling: MMBC 7Th SemBmssa 2017BNo ratings yet

- Building Materials InteriorsDocument45 pagesBuilding Materials InteriorsBmssa 2017BNo ratings yet

- Tower - WikipediaDocument6 pagesTower - WikipediaNameNo ratings yet

- Stone Mastic Asphalt: A Seminar Report OnDocument17 pagesStone Mastic Asphalt: A Seminar Report Onprajakta chaudhari100% (1)

- Sample CHB InstallationDocument11 pagesSample CHB Installationjmhike_1050% (2)

- Comparative Study of Framed StructureDocument17 pagesComparative Study of Framed StructureSrimanNo ratings yet

- Barber, T. (2007) A Study of Water Surface Deformation Due To Tip Vortices Wing-In-Ground Effect, Journal of Ship Research, 51 (02), Pp. 182-186.Document5 pagesBarber, T. (2007) A Study of Water Surface Deformation Due To Tip Vortices Wing-In-Ground Effect, Journal of Ship Research, 51 (02), Pp. 182-186.Samson Paul PintoNo ratings yet

- A Study On Positive Separating Bulbous BowDocument9 pagesA Study On Positive Separating Bulbous BowamNo ratings yet

- A Brief History of Beam-Column DesignDocument11 pagesA Brief History of Beam-Column DesigntaosyeNo ratings yet

- Structural Analysis Report of Residential BuildingDocument40 pagesStructural Analysis Report of Residential BuildingPrakash Singh RawalNo ratings yet

- SE. 2014 Result PDFDocument421 pagesSE. 2014 Result PDFAnonymous GAtDm8No ratings yet

- Reinforced Concrete Structures Design and Drawing PDFDocument2 pagesReinforced Concrete Structures Design and Drawing PDFAnkitNo ratings yet

- Life Cycle of Civil Engineering ProjectsDocument28 pagesLife Cycle of Civil Engineering ProjectsMarvin Bryant MedinaNo ratings yet

- Kiswok Pipe Layout AdDocument1 pageKiswok Pipe Layout AdaroonkumaarvNo ratings yet

- Matrox EX 60 TDSDocument1 pageMatrox EX 60 TDSrajanarenderNo ratings yet

- Ijsetr Vol 3 Issue 10 2868 2872Document5 pagesIjsetr Vol 3 Issue 10 2868 2872Deva IsmayaNo ratings yet

- Pump BasicsDocument18 pagesPump BasicssparthaelfNo ratings yet

- Mayorarca TormentaDocument36 pagesMayorarca TormentaAndres AngelesNo ratings yet

- New Zealand Design Guide Version 2.2 May 2017 PDFDocument57 pagesNew Zealand Design Guide Version 2.2 May 2017 PDFYCNo ratings yet

- Offshore PlatformsDocument48 pagesOffshore Platformsmasoud132100% (3)

- Supercast PVC WaterstopDocument4 pagesSupercast PVC WaterstopArun KumarNo ratings yet

- Construction and Building Materials: Negasi N. Gebremichael, Moses Karakouzian, Kazem JadidiDocument8 pagesConstruction and Building Materials: Negasi N. Gebremichael, Moses Karakouzian, Kazem JadidisandroNo ratings yet

- Commercial Electrical Inspection ChecklistsDocument23 pagesCommercial Electrical Inspection Checklists08Sanjay ShivaNo ratings yet

- Construction Engineering: Start With The Name of Allah Who Is Most Rehman and RaheemDocument6 pagesConstruction Engineering: Start With The Name of Allah Who Is Most Rehman and RaheemUmair Masood MemonNo ratings yet

- CLT HandbookDocument38 pagesCLT HandbookMikeNo ratings yet

- First Quarter Module 4-Grade10-DraftingDocument18 pagesFirst Quarter Module 4-Grade10-DraftingMaCel VMNo ratings yet

- Expansive SoilsDocument20 pagesExpansive Soilstemesgen yohannesNo ratings yet

- Main Project PROJECTDocument84 pagesMain Project PROJECTMeraj AlamNo ratings yet

- Phillips & Temro - Silencer Installation Guidelines JMM 12-2Document1 pagePhillips & Temro - Silencer Installation Guidelines JMM 12-2Jorge ContrerasNo ratings yet

- 14) Webinar Content - Stone Columns For Improving Weak GroundsDocument110 pages14) Webinar Content - Stone Columns For Improving Weak GroundsEswara PrasadNo ratings yet

- Design Guide For SHSCFCDocument73 pagesDesign Guide For SHSCFCDebajit SahaNo ratings yet

- Slope Stability Study of External Dump of Sonepur-Bazari Opencast Coal Mine IndiaDocument6 pagesSlope Stability Study of External Dump of Sonepur-Bazari Opencast Coal Mine IndialohitsnNo ratings yet