Professional Documents

Culture Documents

Introduction To Power Generation

Uploaded by

pawan deep0 ratings0% found this document useful (0 votes)

3 views36 pagesThe document provides an overview of the plant cycle in a power generation system. It discusses how various systems like feedwater preheaters, deaerators, and boiler feedwater pumps are interconnected and how heat is extracted at different turbine stages to preheat feedwater before it reaches the boiler. Staged feedwater heating using multiple extraction points improves efficiency by minimizing wasted heat. Deaeration is also discussed as the process of removing oxygen and other gases from boiler feedwater to prevent corrosion in the boiler.

Original Description:

Original Title

_PlantCycle

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides an overview of the plant cycle in a power generation system. It discusses how various systems like feedwater preheaters, deaerators, and boiler feedwater pumps are interconnected and how heat is extracted at different turbine stages to preheat feedwater before it reaches the boiler. Staged feedwater heating using multiple extraction points improves efficiency by minimizing wasted heat. Deaeration is also discussed as the process of removing oxygen and other gases from boiler feedwater to prevent corrosion in the boiler.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views36 pagesIntroduction To Power Generation

Uploaded by

pawan deepThe document provides an overview of the plant cycle in a power generation system. It discusses how various systems like feedwater preheaters, deaerators, and boiler feedwater pumps are interconnected and how heat is extracted at different turbine stages to preheat feedwater before it reaches the boiler. Staged feedwater heating using multiple extraction points improves efficiency by minimizing wasted heat. Deaeration is also discussed as the process of removing oxygen and other gases from boiler feedwater to prevent corrosion in the boiler.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 36

Introduction to Power Generation

Lesson 1: Energy Conversion Process

Lesson 2: Boiler Steam Water Cycle

Lesson 3: Basic Turbine Overview

Lesson 4: Plant Cycle

Lesson 4 - Plant Cycle

The Plant Cycle discusses the interrelation of the

systems we’ve already talked about. Specifically, it

addresses the issues of heat, cooling, and plant

startup and shutdown. This lesson provides basic

information only.

Lesson 4 - Plant Cycle: Feedwater Preheaters

We discussed boiler makeup water purity requirements

earlier. In addition to purity, the temperature of

water sent to the boiler is also important. Water sent

to the boiler must be preheated.

Lesson 4 - Plant Cycle: Feedwater Preheaters

Cold water added directly to the boiler creates two

problems:

– It’s inefficient. Cold water reduces the boiler water

temperature as it flows into the drum. This cooling effect

requires higher boiler firing rates for the same amount of

steam production.

– Thermal stress caused by the cold water can damage

economizer and boiler internals.

Lesson 4 - Plant Cycle: Feedwater Preheaters

Preheaters minimize stress and improve efficiency by

heating the feedwater to near the boiler operating

temperature before the water actually reaches the

boiler.

Lesson 4 - Plant Cycle: Feedwater Preheaters

POP QUIZ - True or False

– Preheating incoming boiler feedwater creates thermal stress

that can damage economizer and boiler internals.

FALSE

Lesson 4 - Plant Cycle: Feedwater Preheaters

To improve efficiency, the

heat source usually comes

from the turbine. Steam

(called “extract” steam) is

sent to the feedwater

heater from one or more

of the turbine stages.

Since the goal is to heat

the feedwater as much as

possible, it would make

sense to take the steam

from the turbine stage

that’s nearest the boiler

operating temperature.

Lesson 4 - Plant Cycle: Feedwater Preheaters

Although that makes sense for preheating boiler feedwater, it robs the

turbine of the most efficient steam for power production. Cycle

efficiency improves as the extract steam source moves closer to the

turbine exhaust end. Unfortunately, steam close the to the turbine

exhaust is at a much lower temperature than the boiler circulating

water.

Lesson 4 - Plant Cycle: Feedwater Preheaters

As a compromise, incoming feedwater is normally

heated in stages. For example, using two feedwater

heaters:

Lesson 4 - Plant Cycle: Feedwater Preheaters

The first heater is a low-pressure, low-temperature

heater extracting steam close to the exhaust end of

the turbine.

Lesson 4 - Plant Cycle: Feedwater Preheaters

The second heater is a high-pressure, high-temperature

heater extracting steam closer to the high-pressure

end of the turbine.

Lesson 4 - Plant Cycle: Feedwater Preheaters

Staged feedwater heating improves efficiency by minimizing

wasted heat. The low-grade heat present at the turbine

exhaust can’t be used to generate power, but it can be used to

preheat water. Any heat extracted prior to the turbine exhaust

improves the cycle efficiency. Any heat remaining in the turbine

exhaust must be removed by the condenser. This remaining

heat is dumped to the cooling tower circulating water and

eventually to atmosphere. It’s wasted.

Lesson 4 - Plant Cycle: Feedwater Preheaters

POP QUIZ: The most efficient way to heat feedwater in

a feedwater heater is to utilize:

– A. A separate fuel-fired furnace

– B. Extract steam from the turbine stages

– C. Utilize an air heater

– D. Take steam directly from the boiler steam drum

Lesson 4 - Plant Cycle: Feedwater Preheaters

POP QUIZ: The most efficient way to heat feedwater in

a feedwater heater is to utilize:

– A. A separate fuel-fired furnace

– B. Extract steam from the turbine stages

– C. Utilize an air heater

– D. Take steam directly from the boiler steam drum

Lesson 4 - Plant Cycle: Feedwater Preheaters

The condensate (or hotwell) pump sends recovered condensate to

the first heater where low-grade heat from the turbine low-

pressure extraction passes through one side of the exchanger

and condensate through the other side. The low-pressure

extraction steam heats the returned condensate 10 to 20

degrees F above the hotwell temperature.

Lesson 4 - Plant Cycle: Feedwater Preheaters

Next, steam from a higher-pressure, higher-temperature point on

the turbine flows to finish the heating process. This staged

process, called Regenerative Heating, uses steam from multiple

extraction points on the turbine.

Lesson 4 - Plant Cycle: Feedwater Preheaters

Some plants have as many as 16 feedwater heaters fed

from eight different extraction points on the turbine

generator.

Lesson 4 - Plant Cycle: Feedwater Preheaters

POP QUIZ - Utilizing several points of extraction from

the turbine is called __________ heating.

– A. Degenerative

– B. Convection

– C. Regenerative

– E. Extraction

Lesson 4 - Plant Cycle: Feedwater Preheaters

POP QUIZ - Utilizing several points of extraction from

the turbine is called __________ heating.

– A. Degenerative

– B. Convection

– C. Regenerative

– E. Extraction

Lesson 4 - Plant Cycle: Deaerators

Both the low-pressure and high-pressure feedwater

heaters in the previous examples are called “closed

feedwater heaters” because they’re closed to

atmosphere. Open feedwater preheaters, called

deaerators, also exist. Their purpose is to remove air

and other noncondensable gases from the boiler

feedwater

Lesson 4 - Plant Cycle

Deaeration is the process of removing dissolved oxygen and other

gases from the boiler feedwater. Removal of dissolved oxygen is

critical to safe and reliable boiler operation. The corrosion rate

of mild steel doubles for every 18 degree F increase in

temperature in the presence of oxygen. If the oxygen is not

removed, oxygen corrosion occurs rapidly. Corrosion is

especially severe in the economizer because that’s where boiler

makeup water temperature increases the most. All oxygen must

be removed from the feedwater. For this reason, chemical

oxygen scavengers are added to the water leaving the deaerator

to ensure that any residual oxygen is scavenged before the

feedwater reaches the boiler.

Lesson 4 - Plant Cycle

Deaeration occurs in two

stages. The first is

Mechanical Deaeration. Air

and non-condensable gases

are scrubbed out of the

deaerator to atmosphere

through a vent on top of

the pressure vessel. The

extraction steam and

condensate come in

contact with each other

inside the deaerator vessel,

so the deaerator is called

an open feedwater heater.

Lesson 4 - Plant Cycle

POP QUIZ - The process of Mechanical Deaeration

– A. Removes air and other non-condensable gases from

boiler feedwater

– B. Mixes extraction steam from the turbine with the

feedwater

– C. Takes place in an “open heater”

– D. All of the above

Lesson 4 - Plant Cycle

POP QUIZ - The process of Mechanical Deaeration

– A. Removes air and other non-condensable gases from

boiler feedwater

– B. Mixes extraction steam from the turbine with the

feedwater

– C. Takes place in an “open heater”

– D. All of the above

Lesson 4 - Plant Cycle

Chemical deaeration removes any remaining dissolved

oxygen from the boiler feedwater. No mechanical

deaeration process is perfect. Some dissolved

oxygen will always remain. For this reason, a

chemical oxygen scavenger is fed, usually to the

storage section of the deaerator, to react with and

scavenge any dissolved oxygen that remains in the

boiler feedwater after mechanical deaeration.

Lesson 4 - Plant Cycle

The deaerator is usually fed from an intermediate extraction on the

turbine. The steam and feedwater mix in the dome or upper

section of the deaerator where mechanical deaeration occurs.

The water then falls into the lower or storage section of the

deaerator where the chemical oxygen scavenger is added.

Lesson 4 - Plant Cycle

POP QUIZ - The deaerator is _________ type of feedwater heater.

– A. A closed

– B. A shell-and-tube

– C. An open

– D. An unfiltered

Lesson 4 - Plant Cycle

POP QUIZ - The deaerator is _________ type of feedwater heater.

– A. A closed

– B. A shell-and-tube

– C. An open

– D. An unfiltered

Lesson 4 - Plant Cycle: BFW Pumps

After deaeration, the oxygen-free

water is pumped on by the

boiler feedwater water pumps.

These pumps are usually the

largest capacity pumps in the

plant. They must be capable

of supplying full water flow to

the boiler at a pressure high

enough to overcome the

maximum boiler operating

pressure. The highest

pressure in the plant is found

at the discharge of the boiler

feedwater pumps.

Lesson 4 - Plant Cycle

Why use a condensate pump and a boiler feedwater pump? If the

hotwell (condensate) pump were designed as a boiler feedwater

pump, then the entire boiler makeup water system would have

to be built to withstand extremely high pressure. By placing the

boiler feedwater pumps after some of the equipment, only a

portion of the feedwater system is subject to high pressure.

Lesson 4 - Plant Cycle

POP QUIZ - True or False

– The highest pressure in the plant is at the boiler steam

outlet header.

FALSE

Lesson 4 - Plant Cycle

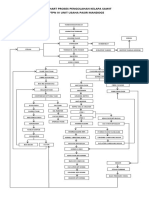

The following diagram shows the basic plant cycle. Proper

operation of every component is essential. Failure of any link in

the chain will result in a plant shutdown.

Lesson 4 - Plant Cycle

The arrows show basic cycle flow paths. Specific

configurations will vary from plant to plant, but this

introduction provides a basic overview.

Lesson 4 - Plant Cycle

POP QUIZ - True or False

– The boiler feedwater pump is located between the hotwell

(condensate) pump and the low pressure feedwater heater.

FALSE

Lesson 4 - Plant Cycle

This introduction discusses plant equipment generally,

but provides no specifics on the individual

components. Additional site training will address

specific plant designs and equipment.

Lesson 4 - Plant Cycle

End of Lesson

You might also like

- What Are Boiler AccessoriesDocument7 pagesWhat Are Boiler AccessoriesTHEOPHILUS ATO FLETCHERNo ratings yet

- JJ308 REPORT Layout and Piping of The Steam Power Plant SystemDocument9 pagesJJ308 REPORT Layout and Piping of The Steam Power Plant SystemAh Tiang86% (7)

- PPS Steam Boiler Operation and AuxiliariesDocument9 pagesPPS Steam Boiler Operation and AuxiliariesAraNo ratings yet

- Esquema Principal de 3500 Cat PDFDocument2 pagesEsquema Principal de 3500 Cat PDFClever Negrete NovaNo ratings yet

- Physical Study of A Steam Generating UnitDocument13 pagesPhysical Study of A Steam Generating Unitashier dave calulot80% (5)

- Basic Mech Lab BE-203Document27 pagesBasic Mech Lab BE-203ravindrapathak123100% (1)

- TRG Module PPT - Flow MeasurementsDocument30 pagesTRG Module PPT - Flow Measurementspawan deepNo ratings yet

- Experiment No. 1 Measurement of Heating Surface of A Firetube BoilerDocument16 pagesExperiment No. 1 Measurement of Heating Surface of A Firetube BoilerAli Requiso MahmudNo ratings yet

- Boiler Mounting & AccessoriesDocument14 pagesBoiler Mounting & Accessoriesshiraj36100% (1)

- Power Plant Engg (Two Mark Question With Answer, Big Question)Document19 pagesPower Plant Engg (Two Mark Question With Answer, Big Question)Lionus LeoNo ratings yet

- Boiler-Turbine Operation Start Up ExplainedDocument35 pagesBoiler-Turbine Operation Start Up ExplainedSteven100% (1)

- S 1 EngineDocument231 pagesS 1 EnginePSNo ratings yet

- Perform Nursery OperationsDocument71 pagesPerform Nursery OperationsAllen Jade Pateña100% (1)

- Integrated Environmental Solutions (IES) - IES ConsultingDocument5 pagesIntegrated Environmental Solutions (IES) - IES ConsultingSyed Moazzam Ali AliNo ratings yet

- Steam BoilerDocument62 pagesSteam BoilerLofi RadioNo ratings yet

- Vapor and Combined Power Cycles: Mehmet KanogluDocument27 pagesVapor and Combined Power Cycles: Mehmet KanogluRodrigo Patiño100% (1)

- LNG Centrifugal Compressors BrochureDocument12 pagesLNG Centrifugal Compressors BrochurehacenescribdNo ratings yet

- Lab 3 Experiment 2Document10 pagesLab 3 Experiment 2Jads CayabyabNo ratings yet

- CFB Presentation and Power Plant OverviewDocument31 pagesCFB Presentation and Power Plant OverviewPrasenjit AdakNo ratings yet

- Thermal Power Generation Plant or Thermal Power StationDocument157 pagesThermal Power Generation Plant or Thermal Power Stationgteklay100% (1)

- Unit - 1 Coal Based Thermal Power Plants Layout of Thermal Power Plant and Its Working PrincipleDocument154 pagesUnit - 1 Coal Based Thermal Power Plants Layout of Thermal Power Plant and Its Working PrincipleMadhu Mitha100% (1)

- Mr. Hassan Alam: Heat Recovery Boiler of SNPC Power PlantDocument11 pagesMr. Hassan Alam: Heat Recovery Boiler of SNPC Power PlantYashal Syed, AhmedNo ratings yet

- E. Steam Power Plant - Lecture PDFDocument20 pagesE. Steam Power Plant - Lecture PDFSafaa Hameed Al NaseryNo ratings yet

- Water Tube Boiler: Babcock and WilcoxDocument8 pagesWater Tube Boiler: Babcock and WilcoxJosue Carubio Ricalde Jr.No ratings yet

- Research Paper On ME LabDocument12 pagesResearch Paper On ME LabJherel BerinNo ratings yet

- Egypowpd-Module2 2Document22 pagesEgypowpd-Module2 2Jas PayaNo ratings yet

- Schmidt Hartmann Boiler 1Document24 pagesSchmidt Hartmann Boiler 1Varun KarriNo ratings yet

- Boiler Draught and Its TypesDocument4 pagesBoiler Draught and Its TypesHamza AbdullahNo ratings yet

- Reasons For Considering Rankine Cycle As An Ideal Cycle For Steam Power PlantsDocument5 pagesReasons For Considering Rankine Cycle As An Ideal Cycle For Steam Power Plantsrajesh kumarNo ratings yet

- Me152l - Experiment 6 - AmahmudDocument25 pagesMe152l - Experiment 6 - AmahmudAli Requiso MahmudNo ratings yet

- Boiler PDFDocument24 pagesBoiler PDFrajishrajan1983No ratings yet

- Institute of Technology & Management Universe: Mechanical Engineering DepartmentDocument7 pagesInstitute of Technology & Management Universe: Mechanical Engineering DepartmentEr Samkit ShahNo ratings yet

- A Boiler Is Defined As "A Closed Vessel in Which Water or Other Liquid Is Heated, Steam or VaporDocument3 pagesA Boiler Is Defined As "A Closed Vessel in Which Water or Other Liquid Is Heated, Steam or VaporAsim aliNo ratings yet

- Boiler: Function of A Steam BoilerDocument6 pagesBoiler: Function of A Steam BoilerGR FaisalNo ratings yet

- Objective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutDocument5 pagesObjective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutSuraj KumarNo ratings yet

- Introduction To CFPPDocument34 pagesIntroduction To CFPPVenkat CherukuriNo ratings yet

- Format 1Document12 pagesFormat 1mobile legend practiceNo ratings yet

- Presentation1 170509173340Document20 pagesPresentation1 170509173340jeremygilbertNo ratings yet

- AduDocument8 pagesAduAdil AminNo ratings yet

- Thermal LabDocument38 pagesThermal LabKRRISH MAHESHWARINo ratings yet

- Analysis of Steam CycleDocument87 pagesAnalysis of Steam CycleKibrom GmichaelNo ratings yet

- Safety Operating Procedure of A Fire Tube BoilerDocument10 pagesSafety Operating Procedure of A Fire Tube BoilerJan Marvin Tamse0% (1)

- Chapter 2 Power CycleDocument44 pagesChapter 2 Power CycleBese Mat100% (1)

- Unit - I Steam Power PlantsDocument32 pagesUnit - I Steam Power Plantsrsankarganesh MECH-HICET100% (1)

- ATD Unit-4 NotesDocument44 pagesATD Unit-4 NotesSanjay KatreddyNo ratings yet

- Power Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)Document28 pagesPower Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)نهاد نهادNo ratings yet

- Dry Cooling Systems1.2Document40 pagesDry Cooling Systems1.2paragmishra1986No ratings yet

- Chapter 10 LectureDocument22 pagesChapter 10 LectureBala MuruganNo ratings yet

- Ppe 2m - OptDocument15 pagesPpe 2m - OptAnonymous gAVMpR0aNo ratings yet

- Power Plant Engineering PDFDocument15 pagesPower Plant Engineering PDFVengadasubramanianNo ratings yet

- Power Plant Engineering - Meng 4115 Chapter 2 - Analysis of Steam CyclesDocument39 pagesPower Plant Engineering - Meng 4115 Chapter 2 - Analysis of Steam CyclesBruktawit SharewNo ratings yet

- Handout FinalDocument254 pagesHandout FinalMalik ForbesNo ratings yet

- Chapter 2-Power CyclesDocument23 pagesChapter 2-Power CyclesbaseakelNo ratings yet

- CHAPTER 1 STEAM GENERATION (Complete Slide)Document25 pagesCHAPTER 1 STEAM GENERATION (Complete Slide)nisasoberiNo ratings yet

- Steam Boiler Operation and AuxiliariesDocument9 pagesSteam Boiler Operation and Auxiliariesshin deiruNo ratings yet

- Power Plant Interview Questions & AnswersDocument33 pagesPower Plant Interview Questions & AnswersSantosh Kumar JaiswalNo ratings yet

- BoilerDocument5 pagesBoilerUmar Farouq Mohammed GalibNo ratings yet

- Turbine NotesDocument4 pagesTurbine NotesQuinton Tendai NyamhungaNo ratings yet

- Experiment # 7 Objective:: Fig: 7.1 (Steam Boiler)Document4 pagesExperiment # 7 Objective:: Fig: 7.1 (Steam Boiler)AkramNo ratings yet

- Lesson 2.4 Sketch Types of Turbine Plant Arrangement - Bleeder Turbine (Extraction Turbine) - Regenerative Turbine - Reheat TurbineDocument3 pagesLesson 2.4 Sketch Types of Turbine Plant Arrangement - Bleeder Turbine (Extraction Turbine) - Regenerative Turbine - Reheat TurbinemarpelNo ratings yet

- 10air Con04Document7 pages10air Con04mister pogiNo ratings yet

- High Pressure BoilerDocument10 pagesHigh Pressure Boilershpaly67% (6)

- SystemsDocument25 pagesSystemsTissa1969No ratings yet

- ON Internship IN Boiler House & Coal Plant: AT Aurobindo Pharma Ltd. Unit V PashmylaramDocument13 pagesON Internship IN Boiler House & Coal Plant: AT Aurobindo Pharma Ltd. Unit V PashmylaramKesari VelamanchiNo ratings yet

- Modern Steam Plant 2022Document28 pagesModern Steam Plant 2022Mahlatse Morongwa MalakaNo ratings yet

- STG Trip MatrixDocument11 pagesSTG Trip Matrixpawan deepNo ratings yet

- 165 MW Captive Power Plant Training Session Evaluation Sheet Training SubjectDocument2 pages165 MW Captive Power Plant Training Session Evaluation Sheet Training Subjectpawan deepNo ratings yet

- 165 MW Captive Power Plant Training Session Evaluation Sheet Training SubjectDocument2 pages165 MW Captive Power Plant Training Session Evaluation Sheet Training Subjectpawan deepNo ratings yet

- FLOW MEASUREMENT - Course NotesDocument38 pagesFLOW MEASUREMENT - Course Notespawan deepNo ratings yet

- Level Measurement - Course NotesDocument19 pagesLevel Measurement - Course Notespawan deepNo ratings yet

- Hardware Guide: Distributed Processing Unit FunctionalityDocument8 pagesHardware Guide: Distributed Processing Unit Functionalitypawan deepNo ratings yet

- 2-GT IntroDocument70 pages2-GT Intropawan deep100% (1)

- System ProtectionDocument60 pagesSystem Protectionarshadanjum12No ratings yet

- Question Bank of PecDocument4 pagesQuestion Bank of PecSudip SaketNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakaJefry KusumaNo ratings yet

- Danfoss Compressors: Quick ReferenceDocument6 pagesDanfoss Compressors: Quick Referencemuhammad irfanNo ratings yet

- Turbo Machines: Chapter Two: Velocity Vector DiagramDocument17 pagesTurbo Machines: Chapter Two: Velocity Vector DiagramayushNo ratings yet

- Summer Training IN Andhra Pradesh Power Generation Corporation - (Apgenco)Document17 pagesSummer Training IN Andhra Pradesh Power Generation Corporation - (Apgenco)Goutham ReddyNo ratings yet

- Tidal PowerDocument16 pagesTidal PowermanjuNo ratings yet

- Class10 Science IOS SampleDocument3 pagesClass10 Science IOS Samplemaneesh5No ratings yet

- Nhom 10 - Chuong 6Document18 pagesNhom 10 - Chuong 6Alfie StacyNo ratings yet

- 800H-UR29 Spec PDFDocument11 pages800H-UR29 Spec PDFManuel AlcudiaNo ratings yet

- INT69 Motor Protector: ® ApplicationDocument2 pagesINT69 Motor Protector: ® ApplicationmrcndoruNo ratings yet

- Final Year Project Report Chapter 1,2Document13 pagesFinal Year Project Report Chapter 1,2Dhanush NNo ratings yet

- Ee Computer Application: EecompDocument27 pagesEe Computer Application: EecompJas PayaNo ratings yet

- FlsmidthrotarypackersventocemDocument2 pagesFlsmidthrotarypackersventocemytjtNo ratings yet

- Laptop Battery Instruction ManualDocument1 pageLaptop Battery Instruction ManualEdwin ElectricoNo ratings yet

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) November 2019Document8 pagesHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) November 2019Adnan NstNo ratings yet

- Flow Chart Proses Pengolahan Kelapa Sawit Di PTPN Iv Unit Usaha Pasir MandogeDocument1 pageFlow Chart Proses Pengolahan Kelapa Sawit Di PTPN Iv Unit Usaha Pasir MandogehariNo ratings yet

- Turbine - 1Document80 pagesTurbine - 1Vineet Gupta100% (1)

- Kpi'S Environment, Health and SafetyDocument7 pagesKpi'S Environment, Health and SafetyRobby DamanikNo ratings yet

- Lecture 1 To 9Document90 pagesLecture 1 To 9anuragkumartiwari3No ratings yet

- Datasheet - Rack - Mounted - 48V - 51 - 2V - Li - Ion - Battery RitarDocument7 pagesDatasheet - Rack - Mounted - 48V - 51 - 2V - Li - Ion - Battery RitarCesar VasquezNo ratings yet

- Tecumseh Tpa0413yxa Technical Data Sheet 691676Document1 pageTecumseh Tpa0413yxa Technical Data Sheet 691676SERVICIO TÉCNICO 4 SOTONo ratings yet

- Goodman PC Series Package Air Conditioner (50 HZ)Document8 pagesGoodman PC Series Package Air Conditioner (50 HZ)Luis Rosales gNo ratings yet

- ELEG 530 - Project 1 - Fall 2014Document4 pagesELEG 530 - Project 1 - Fall 2014dr_biltNo ratings yet

- Actividad Mecanica Diesel SenaDocument5 pagesActividad Mecanica Diesel SenaMiguel Angelito Martinez EscuderoNo ratings yet