Professional Documents

Culture Documents

Non Traditional Manufacturing Assignment: Topic:-Laser Beam Maching

Uploaded by

Vinay Vinay0 ratings0% found this document useful (0 votes)

3 views8 pagesThe document discusses laser beam machining, a non-traditional machining process. Laser beam machining uses a focused laser beam to remove material from a workpiece through thermal melting or vaporization. The laser produces an intense monochromatic light beam that can be focused onto a very small spot using optical lenses. When the laser beam hits the workpiece surface, the extremely high energy density causes localized melting and vaporization of the material. Some advantages are high precision machining of any material, including non-metals, and little heat affected zone. Disadvantages include low overall efficiency, limited to thin sheets, and high cost.

Original Description:

Original Title

LASER%20BEAM%20MACHINING

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses laser beam machining, a non-traditional machining process. Laser beam machining uses a focused laser beam to remove material from a workpiece through thermal melting or vaporization. The laser produces an intense monochromatic light beam that can be focused onto a very small spot using optical lenses. When the laser beam hits the workpiece surface, the extremely high energy density causes localized melting and vaporization of the material. Some advantages are high precision machining of any material, including non-metals, and little heat affected zone. Disadvantages include low overall efficiency, limited to thin sheets, and high cost.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views8 pagesNon Traditional Manufacturing Assignment: Topic:-Laser Beam Maching

Uploaded by

Vinay VinayThe document discusses laser beam machining, a non-traditional machining process. Laser beam machining uses a focused laser beam to remove material from a workpiece through thermal melting or vaporization. The laser produces an intense monochromatic light beam that can be focused onto a very small spot using optical lenses. When the laser beam hits the workpiece surface, the extremely high energy density causes localized melting and vaporization of the material. Some advantages are high precision machining of any material, including non-metals, and little heat affected zone. Disadvantages include low overall efficiency, limited to thin sheets, and high cost.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 8

NON TRADITIONAL

MANUFACTURING

ASSIGNMENT

TOPIC:- LASER BEAM MACHING

Submitted By:- Submitted to:-

JUGRAJ SINGH

11903201

LASER BEAM MACHINING

The ‘LASER ‘word is for Light Amplification by

Stimulated Emission of Radiation.

Laser beam machining is a non-conventional machining

process, in which a laser is directed towards the work piece

for machining. This process uses thermal energy to remove

metal from metallic or nonmetallic surfaces. The laser is

electromagnetic radiation. It produces monochromatic light

which is in the form of an almost collimated beam that can be

focused optically on to very small spots of less than 0.002

mm dia.

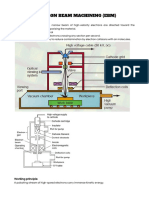

Working Principle of Laser Beam Machining

■ In this process, the Laser Beam is called monochromatic

light, which is made to focus on the workpiece to be

machined by a lens to give extremely high energy density to

melt and vaporize any material.

■ The Laser Crystal (Ruby) is in the form of a cylinder as

shown in the above figure or Diagram with flat reflecting

ends which are placed in a flash lamp coil of about 1000W.

■ The Flash is simulated with the high-intensity white light

from Xenon. The Crystal gets excited and emits the laser

beam which is focused on the work piece by using the lens.

■ The beam produced is extremely narrow and can be focused

to a pinpoint area with a power density of 1000 kW/cm2.

Which produces high heat and the portion of the metal

is melted and vapourise.

Working of Laser Beam Machining

■ At first laser material CO2 or other laser material is filled into discharge

tube.

■ After that the power supply is switched on which is used to light up the

flash lamp. The light from flash lamp is used to excite the electrons of

atom.

Then the atoms of laser material absorbs energy from the light energy

produced by flash lamp. Due to absorption of energy, the electron of atom

jump from lower energy level to higher energy level. But this is unstable

condition of atom.

■ When the atom reaches its absorption limit, it starts emitting energy

continuously. This energy is emitted in the form of highly amplified same

frequency and same wavelength coherent light.

■ This laser light released by atom is collected in the convex lens and is

directed towards the work piece.

■ As the laser falls on work piece, it starts the machining process by melting

or vaporizing material from contact surface of work piece.

Advantages of Laser Beam Machining

■ There is direct contact between the tool and the work

piece.

■ Machining of any material including nonmetal is

possible.

■ Drilling and cutting of areas not readily accessible are

possible.

■ The heat-affected zone is small because of the

collimated beam.

■ Extremely small holes can be machined.

■ There is no tool wear.

■ Soft materials like rubber and plastics can be machined.

Disadvantages of Laser Beam Machining

■ Its overall efficiency extremely low (10 to 15%).

■ The process is limited to thin sheets.

■ It has a very low material removal rate.

■ The machined holes are not round and straight.

■ The laser system is quite inefficient since the life of the lash

lamp is short.

■ Cost is high.

THANKYOU

You might also like

- Laser Beam Machining Definition Working Process Principle Advantages Disadvantages Application NotesDocument4 pagesLaser Beam Machining Definition Working Process Principle Advantages Disadvantages Application NotesMD Al-AminNo ratings yet

- Non Traditional Machining: Murthy Raj R 1MV19MCM02 M Tech Cim Sir. MvitDocument20 pagesNon Traditional Machining: Murthy Raj R 1MV19MCM02 M Tech Cim Sir. MvitMURTHY RAJNo ratings yet

- Laser Beam: MachiningDocument52 pagesLaser Beam: MachiningraghurockramNo ratings yet

- Laser Beam MEACHINING PPT Final 2Document16 pagesLaser Beam MEACHINING PPT Final 2hari ananthagiri67% (3)

- Ucm Assignment Sahil Tanweer 30-10-23Document56 pagesUcm Assignment Sahil Tanweer 30-10-23Sahil TanweerNo ratings yet

- Lecture 6 7 Non Traditional Machining ProcessesDocument32 pagesLecture 6 7 Non Traditional Machining ProcessesRishika Viral PatelNo ratings yet

- Digital Assigment-2: Name - Mukund Misra REG NO.-17BEM0134Document7 pagesDigital Assigment-2: Name - Mukund Misra REG NO.-17BEM0134mukund misNo ratings yet

- Laser Beam MachiningDocument25 pagesLaser Beam MachiningtrimohitNo ratings yet

- Non-Traditional Machining: Laser Beam Machining (LBM)Document17 pagesNon-Traditional Machining: Laser Beam Machining (LBM)Satish SatiNo ratings yet

- 1:electron Beam Welding:: PrincipleDocument17 pages1:electron Beam Welding:: PrincipleArafath JazeebNo ratings yet

- Manufacturing Technology: Unit - IDocument18 pagesManufacturing Technology: Unit - Iapi-271354682100% (1)

- Unit-4 LBM & EBMDocument44 pagesUnit-4 LBM & EBMbaaskararcher506No ratings yet

- Laser Beam Welding-1Document8 pagesLaser Beam Welding-1Karthik KarthikNo ratings yet

- 6-Laser Beam Welding MFTDocument11 pages6-Laser Beam Welding MFTRamu AmaraNo ratings yet

- Seminar ReportDocument13 pagesSeminar ReportRohith RajeevNo ratings yet

- LBM PPT Vga 2022-23-23-27Document5 pagesLBM PPT Vga 2022-23-23-27Sherazi AshrafiNo ratings yet

- Unit - 3Document23 pagesUnit - 3Dhileepan KumarasamyNo ratings yet

- UNIT-5 Thermal Energy Based Processes: ExamplesDocument8 pagesUNIT-5 Thermal Energy Based Processes: ExamplesRamanvlrNo ratings yet

- Laser Beam Machining: Definition, Construction, Working Principle, Advantages, Application (Notes & PDF)Document6 pagesLaser Beam Machining: Definition, Construction, Working Principle, Advantages, Application (Notes & PDF)ShubhamNo ratings yet

- NTM Unit4Document8 pagesNTM Unit4saravana kumarNo ratings yet

- Lazer Beam MechiningDocument18 pagesLazer Beam MechiningBiresh RoyNo ratings yet

- Laser Beam MachiningDocument3 pagesLaser Beam MachiningpankajNo ratings yet

- Manufacturing Technology-: Instructor: Shantanu BhattacharyaDocument34 pagesManufacturing Technology-: Instructor: Shantanu BhattacharyaSahil Sunda100% (1)

- Working Principle: Laser Beam WeldingDocument14 pagesWorking Principle: Laser Beam WeldingAkash KumarNo ratings yet

- Laser Beam WeldingDocument13 pagesLaser Beam WeldingAadip KushwahaNo ratings yet

- Document 1Document8 pagesDocument 1sadiqali4244No ratings yet

- Work Theory of The Laser Cutting MachineDocument5 pagesWork Theory of The Laser Cutting MachineHe OfweekNo ratings yet

- Laser CuttingDocument9 pagesLaser CuttingPrabir Kumar PatiNo ratings yet

- Laser WeldingDocument11 pagesLaser WeldingnkalaiNo ratings yet

- D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarDocument28 pagesD.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarVinith ArasuNo ratings yet

- UNIT 5 LBM Min MinDocument36 pagesUNIT 5 LBM Min MinVinith ArasuNo ratings yet

- Laser WeldingDocument17 pagesLaser WeldingSaurabh GuptaNo ratings yet

- LaserDocument6 pagesLaserhmoa2050No ratings yet

- EDM KTU AMT Notes Module 4Document37 pagesEDM KTU AMT Notes Module 4Safeer MNo ratings yet

- 18 Applications in Material ProcessingDocument38 pages18 Applications in Material Processingkaushik4208No ratings yet

- Laser Beam Welding: By, Ramu RajendranDocument19 pagesLaser Beam Welding: By, Ramu RajendranAmal Vikram100% (1)

- Laser Beam MachiningDocument41 pagesLaser Beam MachiningAiswarya Ramesh me21b011No ratings yet

- CH7 - Non Traditional Manufacturing ProcessesDocument21 pagesCH7 - Non Traditional Manufacturing ProcessesYash OramNo ratings yet

- Laser Beam Machining LBMDocument33 pagesLaser Beam Machining LBMPPSwainNo ratings yet

- Laser Beam MachiningDocument12 pagesLaser Beam MachiningSaipavan EmmadiNo ratings yet

- Laser Cutting - Wikipedia PDFDocument46 pagesLaser Cutting - Wikipedia PDFSandeep KumarNo ratings yet

- Laser Beam WeldingDocument14 pagesLaser Beam Weldingpatel mihirNo ratings yet

- LBM - New Edited VersionDocument25 pagesLBM - New Edited VersionTasdik TasinNo ratings yet

- Module 4Document33 pagesModule 4Mohammed aslamNo ratings yet

- LASER: Light Amplification by Stimulated Emission of RadiationDocument11 pagesLASER: Light Amplification by Stimulated Emission of RadiationVINAY BHASKARNo ratings yet

- Laser Beam MachiningDocument33 pagesLaser Beam MachiningVishalNo ratings yet

- Laser Beam Machining (LBM)Document16 pagesLaser Beam Machining (LBM)nashk18No ratings yet

- Laser CuttingDocument13 pagesLaser CuttingSatish KumarNo ratings yet

- Lect 32Document25 pagesLect 32shashankmay18No ratings yet

- Seminar Paper Laser Cutting: University of Maribor Faculty of Mechanical EngineeringDocument8 pagesSeminar Paper Laser Cutting: University of Maribor Faculty of Mechanical EngineeringPrimož BrglezNo ratings yet

- Some Information About Edm EBM and LBMDocument6 pagesSome Information About Edm EBM and LBMRuchin ChahwalaNo ratings yet

- Laser CuttingDocument8 pagesLaser CuttingSharath KumarNo ratings yet

- Ion Beam Machining (Ibm) Ion Itching, Ion Milling, or Ion PolishingDocument5 pagesIon Beam Machining (Ibm) Ion Itching, Ion Milling, or Ion PolishingShubhamNo ratings yet

- Research Paper On Laser Beam MachiningDocument4 pagesResearch Paper On Laser Beam Machininggw131ads100% (1)

- MMFM Unit 3 - EBMDocument4 pagesMMFM Unit 3 - EBMadhav1avi0804No ratings yet

- Laser Beam MachiningDocument30 pagesLaser Beam MachiningcpamechaNo ratings yet

- Electron Beam MachiningDocument7 pagesElectron Beam MachiningsatyanitwNo ratings yet

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Course Outline ReviewerDocument12 pagesCourse Outline Reviewerjmd.besanaNo ratings yet

- Gabuyer Oct13Document72 pagesGabuyer Oct13William Rios0% (1)

- Employee Conduct Policy StpsoDocument57 pagesEmployee Conduct Policy StpsoWWLTVWebteamNo ratings yet

- MSA & Destructive TestDocument4 pagesMSA & Destructive Testanon_902607157100% (1)

- Resume ObjectiveDocument2 pagesResume Objectiveapi-12705072No ratings yet

- Siemens Power Engineering Guide 7E 223Document1 pageSiemens Power Engineering Guide 7E 223mydearteacherNo ratings yet

- WI-824-003 First Article InspectionDocument2 pagesWI-824-003 First Article InspectionAndreas Schlager100% (1)

- Public Instructions For Death CorrectionsDocument4 pagesPublic Instructions For Death CorrectionsMukuru TechnologiesNo ratings yet

- JJDocument119 pagesJJAnonymous 5k7iGyNo ratings yet

- 1849 1862 Statutes at Large 601-779Document200 pages1849 1862 Statutes at Large 601-779ncwazzyNo ratings yet

- Forty Years Ago, December 1, 1980 - PM On Prices - The Indian ExpressDocument8 pagesForty Years Ago, December 1, 1980 - PM On Prices - The Indian ExpresshabeebNo ratings yet

- Report - Summary - Group 3 - MKT201Document4 pagesReport - Summary - Group 3 - MKT201Long Nguyễn HảiNo ratings yet

- Ruggedbackbone Rx1500 Rx1501Document13 pagesRuggedbackbone Rx1500 Rx1501esilva2021No ratings yet

- Frsky L9R ManualDocument1 pageFrsky L9R ManualAlicia GordonNo ratings yet

- 2017 Directory WO Member PagesDocument112 pages2017 Directory WO Member PagessberkowitzNo ratings yet

- Orange Stripe # 57 EnglishDocument2 pagesOrange Stripe # 57 EnglishShahid RazaNo ratings yet

- White and Yellow Reflective Thermoplastic Striping Material (Solid Form)Document2 pagesWhite and Yellow Reflective Thermoplastic Striping Material (Solid Form)FRANZ RICHARD SARDINAS MALLCONo ratings yet

- Diagrama Electronico EGED 285Document2 pagesDiagrama Electronico EGED 285Carlos Juarez Chunga100% (1)

- Brief On Safety Oct 10Document28 pagesBrief On Safety Oct 10Srinivas EnamandramNo ratings yet

- Compound Wall Design (1) - Layout1Document1 pageCompound Wall Design (1) - Layout1SandeepNo ratings yet

- Reliability EngineerDocument1 pageReliability EngineerBesuidenhout Engineering Solutions and ConsultingNo ratings yet

- Daily Price Monitoring: Retail Prices of Selected Agri-Fishery Commodities in Selected Markets in Metro ManilaDocument3 pagesDaily Price Monitoring: Retail Prices of Selected Agri-Fishery Commodities in Selected Markets in Metro ManilaRio CorralNo ratings yet

- Termsconditions of JionetDocument3 pagesTermsconditions of JionetskNo ratings yet

- Serious Game Overview PDFDocument28 pagesSerious Game Overview PDFjuanan.peterNo ratings yet

- Comparison of The Gasification Performance in The Downdraftfixed-Bedgasifier Fed by Different Feedstocks Rice Husk, Sawdust, and Their MixtureDocument8 pagesComparison of The Gasification Performance in The Downdraftfixed-Bedgasifier Fed by Different Feedstocks Rice Husk, Sawdust, and Their MixturechaniefNo ratings yet

- Salary Data 18092018Document5,124 pagesSalary Data 18092018pjrkrishna100% (1)

- CreatorsXO JuneDocument9 pagesCreatorsXO JuneGaurav KarnaniNo ratings yet

- PX4211 2Document3 pagesPX4211 2kalpanaNo ratings yet

- Social Media Engagement and Feedback CycleDocument10 pagesSocial Media Engagement and Feedback Cyclerichard martinNo ratings yet

- Microstrip Antennas: How Do They Work?Document2 pagesMicrostrip Antennas: How Do They Work?Tebogo SekgwamaNo ratings yet