Professional Documents

Culture Documents

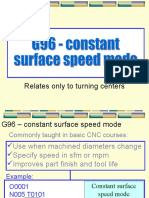

Relates To Machining and Turning Centers

Uploaded by

Suresh Rajagopal0 ratings0% found this document useful (0 votes)

10 views70 pagesG10-data setting command

Original Title

09Lesson_nine_presentaiton

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentG10-data setting command

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views70 pagesRelates To Machining and Turning Centers

Uploaded by

Suresh RajagopalG10-data setting command

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 70

Relates to machining and turning centers

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Example:

N001 G90 G10 L10 P1 R5.4433

N002 G10 L10 P2 R6.2827

N003 G10 L10 P3 R7.3432

Set offsets one, two, and three

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught in basic CNC courses:

Words involved:

Not often

L word tellsmentioned in basic

control what kind courses

of data

(values of L word vary based upon

Allowscontrol

programming

model and offsetof offset data

option)

Minimizes manual entry of offsets

For 10, 11, & 15 M series with tool offset memory A:

Not L2 – fixture

always offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you read offset values?

Setting parameters from within programs

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught in basic CNC courses:

Words involved:

Not often

P word - thementioned in being

offset number basicset

courses

AllowsP1:

programming

offset number of

oneoffset data

P5: offset

Minimizes manualnumber fiveof offsets

entry

Not always taught in basic courses:

How G10 works

L2 – fixture offsets

Entering offset values

L10 – geometry offsets(machining & radius)

(length and turning ctr)

Can

L11 –you readoffsets

wear offset (length

values?and radius)

Setting parametersentry

L50 – parameter from within programs

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught in basic CNC courses:

Words involved:

RNot often

word mentioned

– value in basic

of tool offsets courses

and parameters

X, Y, Z used

Allows for fixture offsets

programming of offset data

X, Z, R, T used

Minimizes for turning

manual centers

entry of offsets

Not always taught in basic courses:

L2 – fixture offsets

How G10 works

L10 – geometry offsets (length and radius)

Entering offset values (machining & turning ctr)

L11 – wear offsets (length and radius)

Can

L50 you read offset

– parameter values?

entry

Setting

P word parameters

- the offsetfrom within

number programs

being set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught in basic CNC courses:

Words involved:

Absolute mode

Not often – overwriteinoffset

mentioned basicvalue

courses

Incremental mode – modify offset value

Allows programming of offset data

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught

Examples for in basic

15M with CNC

offset courses:

memory A:

Not often mentioned in basic courses

G90 G10 L10 P1 R4.3876

Allows programming of offset data

Overwrite geometry offset number one

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught

Examples for in basic

15M with CNC

offset courses:

memory A:

Not often mentioned in basic courses

G91 G10 L11 P32 R0.005

Allows programming of offset data

Increase wear offset thirty-two by 0.005

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught

Examples for in basic

15M with CNC

offset courses:

memory A:

Not often mentioned in basic courses

G90 G10 L2 P1 X-12.32 Y-11.12 Z-9.45

Allows programming of offset data

Overwrite fixture offset number one

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught

A turning center in basic CNC courses:

example:

Not often mentioned in basic courses

G10 L10 P1 R0.0316 T3

Allows programming of offset data

Overwrite geometry offset number one R & T

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught

Another turning in basic

center CNC courses:

example:

Not often mentioned in basic courses

G10 L10 P1 X-10.2273 Z-12.9726

Allows programming of offset data

Overwrite geometry offset number one X & Z

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering offsets

Commonly taught

Another turning in basic

center CNC courses:

example:

Not often mentioned in basic courses

G10 L11 P1 U0.005

Allows programming of offset data

Increase wear offset number one’s X by 0.005

Minimizes manual entry of offsets

L2 –always

Not fixture offsets

taught in basic courses:

L10 – geometry offsets (length and radius)

How G10 works

L11 – wear offsets (length and radius)

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering parameters

Commonly

Parameterstaught

requireina basic

slightlyCNC courses:

different format

Not often mentioned in basic courses

G10 L50

Allows programming of offset data

N6218 R0030

Minimizes manual entry of offsets

N6219 R0002

NotN6220

alwaysR3

taught in basic courses:

G11

How G10 works

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering parameters

Commonly

Parameterstaught

requireina basic

slightlyCNC courses:

different format

Not often mentioned in basic courses

G10 L50

Allows programming of offset data

N6218 R0030 Set parameter

Minimizes manual entry of offsets

N6219 R0002 entry mode

NotN6220

alwaysR3

taught in basic courses:

G11

How G10 works

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering parameters

Commonly

Parameterstaught

requireina basic

slightlyCNC courses:

different format

Not often mentioned in basic courses

G10 L50

Allows programmingSet of offset data

parameter

N6218 R0030

Minimizes manual entry of offsets

number 6218

N6219 R0002

NotN6220

alwaysR3 to 0.0030

taught in basic courses:

G11

How G10 works

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering parameters

Commonly

Parameterstaught

requireina basic

slightlyCNC courses:

different format

Not often mentioned in basic courses

G10 L50

Allows programmingSet of offset data

parameter

N6218 R0030

Minimizes manual entry of offsets

number 6219

N6219 R0002

NotN6220

alwaysR3 to 0.0002

taught in basic courses:

G11

How G10 works

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering parameters

Commonly

Parameterstaught

requireina basic

slightlyCNC courses:

different format

Not often mentioned in basic courses

G10 L50

Allows programmingSet of offset data

parameter

N6218 R0030

Minimizes manual entry of offsets

number 6220

N6219 R0002

NotN6220

alwaysR3 to 3

taught in basic courses:

G11

How G10 works

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10

How– data

G10setting

workscommand

for entering parameters

Commonly

Parameterstaught

requireina basic

slightlyCNC courses:

different format

Not often mentioned in basic courses

G10 L50

Allows programming of offset

Cancel data

parameter

N6218 R0030

Minimizes manual entry of offsets

entry mode

N6219 R0002

NotN6220

alwaysR3

taught in basic courses:

G11

How G10 works

Entering offset values (machining & turning ctr)

L50 – parameter entry

Can you-read

P word offset number

the offset values? being set

Setting

R, X, Y,parameters

Z, T wordsfrom withinbeing

– values programs

set

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is a

mentioned in basic courses

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic of offsets

courses:

Tool length compensation

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Tool

Anylength

time compensation

you know example

the value

Commonly taught in basic CNC courses:

Notof an

Many offset

companies prior to setup

assemble

often mentioned in basic courses is

anda

good

measure time to

cutting use

Allows programming of offset datatoolsG10

while

Machining machines

centers: are in production

Minimizes

Not always manual

taught in entry

basic of offsets

courses:

Tool length compensation

In essence,

Cutter radiusthey’re getting ready for

compensation

future

Fixture setups, minimizing the

offsets

How G10 works between production runs

downtime

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Tool length

Any time compensation

you know example

the value

Commonly taught in basic CNC courses:

Notof an

Tool offset

setter prior

may to

write setup

down is a

offset

often mentioned in basic courses

good

values fortime

setupto use

peopleG10

to

Allows programming of offset dataenter

Machining centers:

Minimizes

1: 5.3837

Not always manual

taught entry

7:in5.3837

basic

Tool length compensation

of offsets

32:

courses: 0.500

2: 6.2837 8: 6.2837 35: 0.3745

Cutter radius compensation

3: 4.2376

Fixture offsets 9: 4.2376 31: 0.251

How 4:G10 works 10: 7.3763

7.3763

Turning centers:

Entering

5: offset

nose values

8.7662

Tool (machining & turning ctr)

11: 8.7662

radius compensation

Can you

6: read offset

5.3477

Geometry values?

12:

offsets5.3477

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Tool length

Any time compensation

you know example

the value

Commonly taught in basic CNC courses:

Use This

a template

template program

program

Notofoften

an offset prior

tomentioned

to setup

toin20basic

allows up entries:

minimize

is a

tools courses

Allows good time toG90

O5000 programming

use G10

of offset

G10 L10 P11data

R20.0

Machining

Minimizes centers:

G90 G10 L10 P1 R20.0 G90 G10 L10 P12 R20.0

Not always

G90 G10 L10 manual

taught in entry

basic G10of

L10offsets

courses:

Tool length compensation P13 R20.0

P2 R20.0 G90

G90 G10 L10 P3 R20.0 G90 G10 L10 P14 R20.0

Cutter

G90 radius

G10 L10 compensation

P4 R20.0 G90 G10 L10 P15 R20.0

G90 G10 L10

Fixture P5 R20.0

offsets G90 G10 L10 P16 R20.0

HowG90

G10 works

G10 L10 P6 R20.0 G90 G10 L10 P17 R20.0

Turning

G90 G10centers:

L10 P7 R20.0 G90 G10 L10 P18 R20.0

Entering

Tool

G90 offset

G10nose

L10 P8values

radius (machining

R20.0 compensation &P19

G90 G10 L10 turning

R20.0 ctr)

Can you readL10offset

G90 G10

Geometry values?G90 G10 L10 P20 R20.0

P9 R20.0

offsets

G90 G10 L10 P10 R20.0 M30

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Tool

Tool setter

Anylength

timewill:

compensation

you know example

the

Commonly taught in basic CNC courses: value

Use a Default tools

template length

program for all fashion

ofoften

an offset

1) Assemble

Not

& prior

measure to setup

in is

normal a

tomentioned

2) Modify 20.0minimize

value in basic

toolsforisentries:

20.0

each inches

tool courses

in text editor

Allows

O5000

good time

3) If theyprogramming

to use

can’t measure a of

G90

G10

offset

given

G10 tool,

L10 data

P11leave

R20.0 20.0

Machining

G90 G10 L10

Minimizes centers:

P1 R20.0 G90 G10 L10 P12 R20.0

Not 4) Delete

always anymanual

taught

G90 G10 L10 P2

unneeded

in

R20.0 entry

basic

G90 G10of

G10 L10offsets

commands

courses:

Tool length compensation P13 R20.0

5)

G90Save program

G10 L10 to DNC

P3 R20.0 system

G90 G10 L10directory

P14 R20.0

Cutter

G90 radius

G10 L10 compensation

P4 R20.0 G90 G10 L10 P15 R20.0

Setup person will:

G90 G10 L10

Fixture P5 R20.0

offsets G90 G10 L10 P16 R20.0

HowG90

G10 works

G10 L10 P6 R20.0 G90 G10 L10 P17 R20.0

Turning

1)

G90 G10centers:

Load offset

L10 setting

P7 R20.0 program

G90 G10from DNC

L10 P18 system

R20.0

Entering

Tool

G90 offset

G10nose values

L10 P8radius (machining

G90 G10 L10 P19 R20.0 ctr)

R20.0 compensation & turning

Can2) Run

you

G90 G10

itL10

Geometry

once

read offset

P9

to enter all offsets

values? G10 L10 P20 R20.0

R20.0

offsets G90

3) Check

G90 G10 L10to P10

seeR20.0

if any offsets

M30 are still set to 20.0

Setting parameters

Work shift from

offset within programs

4) Measure any tools having offset values of 20.0

G10 – data setting

Applications forcommand

G10 (offset setting)

Tool length

Any time compensation

you know example

the value

Commonly taught in basic CNC courses:

Notofoften

an offset

Note that manyprior to

tool setup is

measuring

mentioned in basic courses a

devices

goodhave

timecommunications

to use G10 ports

Allows programming of offset data

Machining

If yours centers:

does, itincan be interfaced with a

Minimizes

Not always manual

taught entry

basic

Tool length compensation

of offsets

courses:

personal computer to automatically

Cutter radius compensation

generate the G10 commands

Fixture offsets

How G10 Thisworks

eliminates the need for the tool

Turning centers:

Entering

Tooloffset

setter values

to modify

nose (machining

radiusthe & turning ctr)

template program,

compensation

Can you read offset

reducing

Geometry values?

potential

offsets for entry mistakes

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is a

mentioned in basic courses

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic of offsets

courses:

Tool length compensation

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Cutter

Any radius

time compensation

you know theexample

value

Commonly taught in basic CNC courses:

As

of stated,

an if you

offset know

prior to the values

setup is of

a

Notany often mentioned

offset prior to in basic

setup, don’t courses

force

Allows good time to use G10

yourprogramming

setup people to of offset

enter them!data

Machining centers:

Minimizes

1: 5.3837

Not always manual

taught 7:in5.3837

basic

Tool length compensation

entry of

32:

courses: offsets

0.500

2: 6.2837 8: 6.2837 35: 0.3745

Cutter radius compensation

3: 4.2376

Fixture offsets 9: 4.2376 37: 0.251

How 4:G10 works 10: 7.3763

7.3763

Turning centers:

Entering

5: offset

nose values

8.7662

Tool (machining & turning ctr)

11: 8.7662

radius compensation

Can you

6: read offset

5.3477

Geometry values?

12:

offsets 5.3477

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Fixture

Any offsets

time example

you knowCNC

the courses:

value

Commonly taught in basic

Notofoften

an offset

Manymentioned

prior to setup

in basic

machining center

is a

userscourses

Allows good time

programming to use G10

of offset data

make qualified setups

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

IfCutter

a setup is truly

radius qualified, the location of

compensation

fixture offset

Fixture values will be exactly the

offsets

How G10 works

same every time the setup is made

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Fixture

Any offsets

time example

you knowCNC

the courses:

value

Commonly taught in basic

Not ofoften

anyou

Since offset

need prior

the to setup

control to is a

execute

mentioned in basic courses

thegood

G10 time

commandsto usebut

Allows programming of offset data G10

once…

Machining

O0002 centers:

Minimizes

Not. always manual

taught Normal

in entry

basic

Tool length compensation

of

program

courses:offsets

.

Cutter radius compensation

(Normal cutting operations)

. Fixture offsets

How G10 works

Turning

. centers:

Entering

Tool

N505 offset

nose values

M30 (machining & turning ctr)

radius compensation

CanN999

you readG10

G90

Geometry offset

L2 values?

P1 X-10.2322 Y-12.2388 Z-9.2833

offsets

N1000

Setting M30

parameters from within programs

Work shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Fixture

Any offsets

time example

you knowCNC

the courses:

value

Commonly taught in basic

of

Sincean

Not often

Setup you

person offset

need prior

mentioned

will: the to setup

control to is a

execute

in basic courses

the

1)Allows good

G10 time

commands to use

but G10

once…

Scan toprogramming

N999 of offset data

Machining

O0002 centers: (fixture offset set)

Minimizes

2) Execute

Not. always manual

program

taught

Tool sequence

length in entry

basic

compensation

of

courses:offsets

3). N999 Program zero

will not assignment

be executed again!

Cutter radius compensation

(Normal cutting operations)

. Fixture offsets

How G10 works Remember-able sequence number

Turning

. centers:

Entering

Tool

N505 offset

nose values

M30 (machining & turning ctr)

radius compensation

CanN999

you readG10

G90

Geometry offset

L2 values?

P1 X-10.2322 Y-12.2388 Z-9.2833

offsets

N1000

Setting M30

parameters from within programs

Work shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time offsets

you know example

the courses:

value

Commonly taught in basic CNC

of Have

an you ever

offset priorwished

to you is a

setup

Not often

hadmentioned

more fixture in basic courses

offsets?

Allows good time to use G10

programming of offset data

Fanuc offers an option allowing 48 fixture

Machining centers:

Minimizes

offsets,

Not always but ifmanual

taught youin

Tool length compensation

don’t

basicentry

have of

theoffsets

courses: option…

O6001 (coord. system one)

Cutter

Create radiusG90

as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering you offset

need!

Tool nose radiusvalues

O6002 (machining

compensation & turning ctr)

(coord. system two)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

Always use fixture offset one

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time youoffsets

know example

the courses:

value

Commonly taught

In the main in basic CNC

program:

Notofoften

an offset

O0001 prior

mentioned to

insetup

basic is a

courses

N005 M98 P6001

Allows good time

N010programming

to

G00 X2.0 Y1.0

use G10

of offset data

Machining

. centers:

Minimizes

Not always manual

taught in entry

basic

. length compensation

Tool

of offsets

courses:

O6001 (coord. system one)

Cutter

Create radiusG90

as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering

you offset

need! values

Tool nose radius

O6002 (machining & turning

(coord. system two)

compensation ctr)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time youoffsets

know example

the courses:

value

Commonly taught

In the main in basic CNC

program:

Notofoften

an offset

O0001 prior

mentioned toinsetup

basic

Sets & is a

courses

invokes

N005 M98 P6001

Allows good time

N010programming

to

G00 X2.0 Y1.0

use G10

fixture offset one

of offset data

Machining

. centers:

Minimizes

Not always manual

taught in entry

basic

. length compensation

Tool

of

courses: offsets

O6001 (coord. system one)

Cutter

Create radiusG90

as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering

you offset

need! values

Tool nose radius

O6002 (machining & turning

(coord. system two)

compensation ctr)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time youoffsets

know example

the courses:

value

Commonly taught

In the main in basic CNC

program:

of an offset prior to setup

Not often mentioned in basic

O0001 iscourses

a

Move relative

N005 M98 P6001 to new origin

Allows good time

N010programming

to

G00 X2.0 Y1.0

use G10

of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic of offsets

courses:

. length compensation

Tool O6001 (coord. system one)

.

Cutter radiusG90

Create as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering

you offset

need! values

Tool nose radius

O6002 (machining & turning

(coord. system two)

compensation ctr)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time youoffsets

know example

the courses:

value

Commonly taught

In the main in basic CNC

program:

Notofoften

. an offset prior

mentioned to

insetup

basic is a

courses

.

Allows good time

N150programming

M98 P6002

to use G10

of offset data

Machining centers:

N155 G00 X4.0 Y2.0

Minimizes

Not always manual

taught in entry

basic

. length compensation

Tool

of offsets

courses:

O6001 (coord. system one)

Cutter

Create radiusG90

as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering

you offset

need! values

Tool nose radius

O6002 (machining & turning

(coord. system two)

compensation ctr)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time youoffsets

know example

the courses:

value

Commonly taught

In the main in basic CNC

program:

Notofoften

. an offset prior

mentioned to

in

Sets

setup

basic is a

courses

fixture offset

.

Allows good time

N150programming

M98 P6002

to useoneG10

(again)

of offset data

Machining centers:

N155 G00 X4.0 Y2.0

Minimizes

Not always manual

taught in entry

basic

. length compensation

Tool

of

courses: offsets

O6001 (coord. system one)

Cutter

Create radiusG90

as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering

you offset

need! values

Tool nose radius

O6002 (machining & turning

(coord. system two)

compensation ctr)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Another

Any fixture

time youoffsets

know example

the courses:

value

Commonly taught

In the main in basic CNC

program:

Notofoften

. an offset prior

mentioned to

insetup

basic is a

courses

Move relative

.

Allows good time

N150programming

M98 P6002

to use G10

to new origin

of offset data

Machining centers:

N155 G00 X4.0 Y2.0

Minimizes

Not always

Tool

manual

taught in entry

basic

. length compensation

of

courses:offsets

O6001 (coord. system one)

Cutter

Create radiusG90

as many compensation

G10 L2 P1 X-12.01 Y-10.18 Z-9.22

coordinate system G54

Fixture offsets

How G10 works M99

setting

Turning centers:

subprograms as

Entering

you offset

need! values

Tool nose radius

O6002 (machining & turning

(coord. system two)

compensation ctr)

G90 G10 L2 P1 X-10.32 Y-9.33 Z-10.47

Can you read offset

Geometry values?

offsets

G54

SettingWork

parameters M99

from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nosevalues

radius(machining & turning ctr)

compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Tool nose

Any timeradius

you compensation

knowCNC

the courses:

value

Commonly taught in basic

Notof an use

Ifoften

you offset

G41 prior

and to setup

G42, you is

know

mentioned in basic coursesa

the good

tool time

offset to

table use

must G10

contain

Allows programming of offset data the

Machiningnose radius and type of tool

centers:

Minimizes

Not always manual

taught in entry

basic of offsets

courses:

Tool length compensation

If the tool nose radius remains

Cutter radius

consistent compensation

throughout the production

Fixture offsets

How G10 worksG10 to enter TNR values!

run, use

Turning centers:

Entering

Tooloffset

nose values

radius (machining & turning ctr)

compensation

Can you G10 L10

read offset P1 R0.0316

values? T3

Geometry offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nosevalues

radius(machining & turning ctr)

compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Geometry offsets

Commonly taughtyou

Any time knowCNC

in basic the courses:

value

While

of an you canprior

offset manipulate

to geometry

setup is a

Not often

offsetsmentioned in basic

on turning centers, courses

it may

Allows good time

programmingto use G10

not be your bestofoption

offset data

Machining centers:

NotMinimizes

Since

always many manual

tools

taught in entry

remain

basic in of

the

courses:

Tool length compensation

offsets

turret

Cutterfrom jobcompensation

radius to job…

…and

Fixture since you need not manipulate

offsets

How G10 works

Turningoffsets for tools remaining in the turret

centers:

Entering offset

nose values

ToolIncludingradius (machining & turning ctr)

compensation

Can you G10s to set geometry

read offset

Geometry values?

offsets

offsets will overwrite working offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Work shift offset

Commonly taughtyou

Any time knowCNC

in basic the courses:

value

If you useoffset

of an the work shifttofunction…

prior setup is a

Not often mentioned in basic courses

…and

good iftime

you make

to qualified

use G10 setups

Allows programming of offset data

Machining

Use centers:

G10 to set the work shift values

Minimizes

Not always manual

taught in entry

basic

Tool length compensation

of

courses: offsets

Cutter radius

G10 compensation

P0 Z1.5

Fixture offsets

How G10Use works

the N999 technique to keep

Turning centers:

Entering offset

Toolthe values

control

nose (machining

from

radius executing&

compensation turning ctr)

this

Can you readcommand

Geometry offset values?

offsets in every cycle

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Work shift offset

Commonly taughtyou

Any time knowCNC

in basic the courses:

value

Multiple

of anworkpieces from

to asetup

slug:

Not often mentioned in basiciscourses

offset prior a

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

O1000

Cutter radius compensation

O0001

N001 (Cut part)

N005 G10 P0 Z0

Fixture offsets .

How G10 works

N010 M98 P1000 L3

.

Turning centers:

N015 M30

Entering offset values (machining

.

Tool nose radius compensation & turning ctr)

N035 G10 P0 W-1.25

Can you read offset

Geometry values?

offsets N040 M99

SettingWork

parameters from within programs

shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Work

Anyshift

timeoffset

you Set work shift to initial value

know the courses:

value

Commonly taught in basic CNC

Multiple

of anworkpieces from

to asetup

slug:

Not often mentioned in basiciscourses

offset prior a

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

O1000

Cutter radius compensation

O0001

N001 (Cut part)

N005 G10 P0 Z0

Fixture offsets .

How G10 works

N010 M98 P1000 L3

.

Turning centers:

N015 M30

Entering offset values (machining

.

Tool nose radius compensation & turning ctr)

N035 G10 P0 W-1.25

Can you read offset

Geometry values?

offsets N040 M99

SettingWork

parameters from within programs

shift offset

G10 – data setting command

Work

Anyshift

timeoffset

you Make three parts

know the courses:

value

Commonly taught in basic CNC

Multiple

of anworkpieces from

to asetup

slug:

Not often mentioned in basiciscourses

offset prior a

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

O1000

Cutter radius compensation

O0001

N001 (Cut part)

N005 G10 P0 Z0

Fixture offsets

N010 M98 P1000 L3

.

Turning centers: .

N015 M30

.

Tool nose radius compensation

N035 G10 P0 W-1.25

Geometry offsets N040 M99

Work shift offset

G10 – data setting command

Work

Anyshift

timeoffset

you Step work shift after each part

know the courses:

value

Commonly taught in basic CNC

Multiple

of anworkpieces from

to asetup

slug:

Not often mentioned in basiciscourses

offset prior a

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

O1000

Cutter radius compensation

O0001

N001 (Cut part)

N005 G10 P0 Z0

Fixture offsets

N010 M98 P1000 L3

.

Turning centers: .

N015 M30

.

Tool nose radius compensation

N035 G10 P0 W-1.25

Geometry offsets N040 M99

Work shift offset

G10 – data setting

Applications forcommand

G10 (offset setting)

Any time

Commonly taughtyou knowCNC

in basic the courses:

value

Notofoften

an offset prior to setup is

mentioned in basic coursesa

Allows good time to use G10

programming of offset data

Machining centers:

NotMinimizes

always manual

taught in entry

basic

Tool length compensation

of offsets

courses:

Cutter radius compensation

Fixture offsets

How G10 works

Turning centers:

Entering

Tooloffset

nose values (machining & turning ctr)

radius compensation

Can you read offset

Geometry values?

offsets

SettingWork

parameters from within programs

shift offset

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data

Read setting

offset command

values from within programs?

Commonly taught in basic CNC courses:

Unfortunately, this is impossible

Not

withoften mentioned

normal in basic courses

G code programming

Allows programming of offset data

But with parametric programming, you can…

Minimizes manual entry of offsets

Read and write offset values

Not always

Usetaught in basic courses:

variables

How G10works

Do arithmetic

Make

Applications tests

for G10

Can you Generate

read alarms

offset values?

Much more!

Setting parameters from within programs

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting

Applications for command

changing parameters

Commonly taught in basic CNC courses:

AsNot

stated,

oftenthere are many

mentioned parameters

in basic courses

that affect

Allows the way programs

programming of offsetbehave

data

Minimizes

There may manual entrywhen

be times of offsets

you

Notneed to taught

always changein a parameter

basic courses:setting

from within a program

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

G10 – data setting

Applications for command

changing parameters

Commonly taught

An example: in basic CNC courses:

Not all

With often

but mentioned

0T and 3T in basiccontrols,

Fanuc courses

Allows

you cannotprogramming

manipulate of offset

three data

important

variables

Minimizes formanual entry

the G76 of offsets

threading cycle

For 15T control:

Not always taught in basic courses:

Parameter 6218 Minimum depth of cut

How G10 works

Parameter 6219 Final depth of cut

Applications

Parameter 6220 for G10Number of spring passes

Can you read offset values?

SettingYetparameters

these arefromparameter settings

within programs

.

G10 – data

Applications

. setting

for command

changing parameters

G10 L50

Commonly

An example: taughtSet

N6218 R0030 in parameters

basic CNC courses:

N6219 R0002

Not all

With often

N6220 R3

for first thread

but mentioned

0T and 3T in basiccontrols,

Fanuc courses

Allows

you

G11

cannotprogramming

manipulate of offset

three data

important

N045 G00 X3.2 Z0.2

variables

Minimizes formanual entry

the G76 of offsets

threading cycle

N050 G76 X2.92 Z-0.75 K0.040 D0100 F0.0625

G10 L50

Not always taught in basic courses:

N6218 R0070

Say you have two very different

N6219 R0004

How G10

N6220works

R2

threads on the same workpiece…

G11

Applications

N055 G00for G10

X5.2

Can you read

N060 Z-2.8offset values?

N065 G76 X4.8 Z-0.75 K0.1 D0250 F0.1875

Setting

.

parameters from within programs

.

G10 – data

Applications

. setting

for command

changing parameters

G10 L50

Commonly

An example: taught in basic CNC courses:

N6218 R0030

N6219 R0002

Not all

With often

but mentioned

N6220 R3 0T and 3T in basiccontrols,

Fanuc courses

Allows

you

G11

cannotprogramming

manipulate of offset

three data

important

N045 G00 X3.2 Z0.2

variables

Minimizes formanual entry

the G76 of offsets

threading cycle

N050 G76 X2.92 Z-0.75 K0.040 D0100 F0.0625

G10 L50

Not always taught in basic

N6218 R0070 Machine first

courses:

Say you have two very different

N6219 R0004 thread

How G10

N6220works

R2

threads on the same workpiece…

G11

Applications

N055 G00for G10

X5.2

Can you read

N060 Z-2.8offset values?

N065 G76 X4.8 Z-0.75 K0.1 D0250 F0.1875

Setting

.

parameters from within programs

.

G10 – data

Applications

. setting

for command

changing parameters

G10 L50

Commonly

An example: taught in basic CNC courses:

N6218 R0030

N6219 R0002

Not all

With often

but mentioned

N6220 R3 0T and 3T in basiccontrols,

Fanuc courses

Allows

you

G11

cannotprogramming

manipulate of offset

three data

important

N045 G00 X3.2 Z0.2

variables

Minimizes formanual entry

the G76 of offsets

threading cycle

N050 G76 X2.92 Z-0.75 K0.040 D0100 F0.0625

G10 L50

Not always taught inSet

N6218 R0070 basic courses:

parameters for

Say you have two very different

N6219 R0004

second thread

How G10

N6220works

R2

threads on the same workpiece…

G11

Applications

N055 G00for G10

X5.2

Can you read

N060 Z-2.8offset values?

N065 G76 X4.8 Z-0.75 K0.1 D0250 F0.1875

Setting

.

parameters from within programs

.

G10 – data

Applications

. setting

for command

changing parameters

G10 L50

Commonly

An example: taught in basic CNC courses:

N6218 R0030

N6219 R0002

Not all

With often

but mentioned

N6220 R3 0T and 3T in basiccontrols,

Fanuc courses

Allows

you

G11

cannotprogramming

manipulate of offset

three data

important

N045 G00 X3.2 Z0.2

variables

Minimizes formanual entry

the G76 of offsets

threading cycle

N050 G76 X2.92 Z-0.75 K0.040 D0100 F0.0625

G10 L50

Not always taught in basic courses:

N6218 R0070

Say you have two very different

N6219 R0004

How G10

N6220works

R2

Machine

threads on the same workpiece…

G11

Applications

N055 G00for G10 second thread

X5.2

Can you read

N060 Z-2.8offset values?

N065 G76 X4.8 Z-0.75 K0.1 D0250 F0.1875

Setting

.

parameters from within programs

G10 – data setting command

Commonly taught in basic CNC courses:

Not often mentioned in basic courses

Allows programming of offset data

Minimizes manual entry of offsets

Not always taught in basic courses:

How G10 works

Applications for G10

Can you read offset values?

Setting parameters from within programs

You might also like

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesFrom EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesRating: 5 out of 5 stars5/5 (1)

- CNC Programming and OperationDocument42 pagesCNC Programming and OperationAlbert ArominNo ratings yet

- Digital Signal Processing: A Practical Guide for Engineers and ScientistsFrom EverandDigital Signal Processing: A Practical Guide for Engineers and ScientistsRating: 4.5 out of 5 stars4.5/5 (7)

- Earthing Calculation: A General Design DataDocument14 pagesEarthing Calculation: A General Design Dataمحمد الأمين سنوساوي100% (1)

- Intro to G-Code ProgrammingDocument55 pagesIntro to G-Code ProgrammingJusuf Kunic100% (1)

- CNC Programming Concepts and Commonly Used G-Codes inDocument54 pagesCNC Programming Concepts and Commonly Used G-Codes inMel ParasNo ratings yet

- G Code Programming G - Code Programming (PDFDrive) PDFDocument56 pagesG Code Programming G - Code Programming (PDFDrive) PDFhasan alsarrafNo ratings yet

- Centrifugal Compressors in Ethylene PlantsDocument5 pagesCentrifugal Compressors in Ethylene PlantsForcus onNo ratings yet

- CAD/CAM/CAE IntroductionDocument149 pagesCAD/CAM/CAE IntroductionalexiskandarNo ratings yet

- Mach4 G and M Code Reference ManualDocument81 pagesMach4 G and M Code Reference ManualMegi Setiawan SNo ratings yet

- Bess-Sm-3q90041-Qams-003 Method of Statement - Cable Termination PDFDocument5 pagesBess-Sm-3q90041-Qams-003 Method of Statement - Cable Termination PDFChristian BulaongNo ratings yet

- Artificial Intelligence Big Data 01 Research PaperDocument32 pagesArtificial Intelligence Big Data 01 Research PapermadhuraNo ratings yet

- Lecture of CNC ProgramDocument29 pagesLecture of CNC ProgramMargam Kiran KumarNo ratings yet

- CNC Programming For CNC MachinistsDocument6 pagesCNC Programming For CNC MachinistschampdilseNo ratings yet

- 5 - G-CodeDocument55 pages5 - G-CodefamilyumaNo ratings yet

- VMC ProgrammingDocument9 pagesVMC ProgrammingRatnakar Patil50% (10)

- Heidenhain 355Document237 pagesHeidenhain 355Favoreel PatrickNo ratings yet

- 11 Cad Cam CNC Programming MVVDocument37 pages11 Cad Cam CNC Programming MVVbassem smatiNo ratings yet

- Spare Parts and Project For Scheidt and BachmannDocument223 pagesSpare Parts and Project For Scheidt and Bachmannnachit01No ratings yet

- CNC Programming and OperationDocument80 pagesCNC Programming and OperationMohammed Habeeb100% (1)

- PLC Based Traffic Control System ReportDocument51 pagesPLC Based Traffic Control System ReportAbhijeet Shinde73% (26)

- NC, CNC & Robotics: An IntroductionDocument143 pagesNC, CNC & Robotics: An IntroductionshafiqNo ratings yet

- TNC360 User Manual ISO ProgrammingDocument227 pagesTNC360 User Manual ISO ProgrammingAnonymous Zzx3gRSE100% (1)

- Conceptual Programming: Conceptual Programming: Learn Programming the old way!From EverandConceptual Programming: Conceptual Programming: Learn Programming the old way!No ratings yet

- CNC AlphabetDocument23 pagesCNC AlphabetБоривоје Спасојевић50% (2)

- TNC 2500 IsoDocument204 pagesTNC 2500 Isobillyb53100% (1)

- Manual Part ProgrammingDocument38 pagesManual Part ProgrammingHot Shot100% (1)

- CNC Programming BasicsDocument17 pagesCNC Programming BasicszoranteicNo ratings yet

- CW60M CNC Controller ManualDocument50 pagesCW60M CNC Controller Manualfeliciajia100% (1)

- CNC TechDocument20 pagesCNC TechBharath KumarNo ratings yet

- Programming 1Document44 pagesProgramming 1shubhanshu kumarNo ratings yet

- Module 2Document87 pagesModule 2Daniel KetemawNo ratings yet

- 01 CNC Lab Manual NIT APDocument4 pages01 CNC Lab Manual NIT APDevesh RehanNo ratings yet

- Numerical ControlDocument30 pagesNumerical ControlSandeep PanditaNo ratings yet

- Cncprogrammingbasics 100101063548 Phpapp02Document17 pagesCncprogrammingbasics 100101063548 Phpapp02Kristan CedilloNo ratings yet

- Numerical ControlDocument30 pagesNumerical ControlKeshav AroteNo ratings yet

- Fanuc G10 GDocument2 pagesFanuc G10 GKristan CedilloNo ratings yet

- New Microsoft Word DocumentDocument19 pagesNew Microsoft Word DocumentŤhåýğųŢjNo ratings yet

- 7.1 CNCDocument35 pages7.1 CNCAkesh JohnNo ratings yet

- Part Programming: Unit II 2nd EvaluationDocument14 pagesPart Programming: Unit II 2nd EvaluationEduardo ResendizNo ratings yet

- Computer Numerical Control Machine: By-Er - Ved PrakashDocument28 pagesComputer Numerical Control Machine: By-Er - Ved Prakashyogesh borseNo ratings yet

- Chapter 3 English From The BookDocument16 pagesChapter 3 English From The BookAbdelhakim DORBANENo ratings yet

- Chapter 2 Part ProgrammingDocument33 pagesChapter 2 Part ProgrammingKarnal 0388No ratings yet

- Specific Codes: Letter AddressesDocument16 pagesSpecific Codes: Letter AddressesVijay KumarNo ratings yet

- Heidenhain Itnc 530 (Pilot)Document98 pagesHeidenhain Itnc 530 (Pilot)Reymondo BundocNo ratings yet

- Presentation Bhel PKMDocument19 pagesPresentation Bhel PKMAnonymous EjQbY1CNo ratings yet

- LAB 5 - Coding LectureDocument16 pagesLAB 5 - Coding LectureHusnain AliNo ratings yet

- CADCAM_CNC_Unit-3.1Document54 pagesCADCAM_CNC_Unit-3.1kiranchennoju2004No ratings yet

- The Basics of CNC Machining Programming (For Lathe) : Computerized Numerical Controller (CNC)Document38 pagesThe Basics of CNC Machining Programming (For Lathe) : Computerized Numerical Controller (CNC)Thanh Kieu Nguyen ThiNo ratings yet

- Programming guide for HEIDENHAIN TNC 407, 415, 425 controlsDocument71 pagesProgramming guide for HEIDENHAIN TNC 407, 415, 425 controlsvicjaviNo ratings yet

- CNC Basics 2 PDFDocument23 pagesCNC Basics 2 PDFRithwikNo ratings yet

- Sect 18 MacrosDocument64 pagesSect 18 MacrosChaker Ben MariemNo ratings yet

- Appeared in Designed By: (Citation Needed)Document18 pagesAppeared in Designed By: (Citation Needed)Akemi MurasakiNo ratings yet

- iTNC 530: User's Manual HEIDENHAIN Conversational FormatDocument552 pagesiTNC 530: User's Manual HEIDENHAIN Conversational FormatrastaeggNo ratings yet

- NC Programming GuideDocument25 pagesNC Programming GuideRaghuNo ratings yet

- Typical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingDocument82 pagesTypical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingAbdul RehmanNo ratings yet

- Unit 3 G-CodeDocument44 pagesUnit 3 G-CodeMohammed Fakhruddin Hasan NizamiNo ratings yet

- CNC Basics of G PDFDocument14 pagesCNC Basics of G PDFAli NorooziNo ratings yet

- Chapter 3. Cad, Cam CimDocument50 pagesChapter 3. Cad, Cam Cimahmed jemalNo ratings yet

- STM Ust Lecture4 - 0Document28 pagesSTM Ust Lecture4 - 0Choukoura AldfeerNo ratings yet

- Floating Point Multipliers: Simulation & Synthesis Using VHDLDocument40 pagesFloating Point Multipliers: Simulation & Synthesis Using VHDLmdzakir_hussainNo ratings yet

- Lathe GCode ProgrammingDocument83 pagesLathe GCode ProgrammingRemove NameNo ratings yet

- Basic Information of CNC ProgramDocument16 pagesBasic Information of CNC Programjawad khalidNo ratings yet

- Vadiraja Theertha Prabandha An Unique Travel Guide of 107 Holy Kshetras 1997Document128 pagesVadiraja Theertha Prabandha An Unique Travel Guide of 107 Holy Kshetras 1997Suresh RajagopalNo ratings yet

- 16lesson Sixteen PresentationDocument78 pages16lesson Sixteen PresentationSuresh RajagopalNo ratings yet

- 12lesson Twelve PresentationDocument77 pages12lesson Twelve PresentationSuresh RajagopalNo ratings yet

- Relates Only To Turning CentersDocument37 pagesRelates Only To Turning CentersSuresh RajagopalNo ratings yet

- Relates Only To Machining Centers & Turning Centers With Live ToolingDocument18 pagesRelates Only To Machining Centers & Turning Centers With Live ToolingSuresh RajagopalNo ratings yet

- Relates Only To Turning CentersDocument49 pagesRelates Only To Turning CentersSuresh RajagopalNo ratings yet

- Relates To Machining and Turning CentersDocument29 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- Relates Mostly To Machining Centers (Unless Turning Center Has Live Tooling)Document16 pagesRelates Mostly To Machining Centers (Unless Turning Center Has Live Tooling)Suresh RajagopalNo ratings yet

- G code fundamentals for CNC machiningDocument20 pagesG code fundamentals for CNC machiningSuresh RajagopalNo ratings yet

- Special Interpolation Types Helical MotionDocument141 pagesSpecial Interpolation Types Helical MotionSuresh Rajagopal100% (1)

- Relates To Machining and Turning CentersDocument28 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- 06lesson Six PresentationDocument81 pages06lesson Six PresentationSuresh RajagopalNo ratings yet

- Cutter Radius Compensation Relates To Machining Centers Tool Nose Radius Compensation Relates To Turning CentersDocument137 pagesCutter Radius Compensation Relates To Machining Centers Tool Nose Radius Compensation Relates To Turning CentersSuresh RajagopalNo ratings yet

- Relates To Machining and Turning CentersDocument26 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- Relates To Machining and Turning CentersDocument67 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- Relates Only To Machining CentersDocument7 pagesRelates Only To Machining CentersSuresh RajagopalNo ratings yet

- Relates To Machining and Turning CentersDocument18 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- Relates To Machining and Turning CentersDocument29 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- Catia Part10Document19 pagesCatia Part10Rajaram KamathNo ratings yet

- Relates To Machining and Turning CentersDocument22 pagesRelates To Machining and Turning CentersSuresh RajagopalNo ratings yet

- Catia Part11Document13 pagesCatia Part11luluNo ratings yet

- Catia Part05Document12 pagesCatia Part05Suresh RajagopalNo ratings yet

- Drawing an Auto Body Shape Using SurfacesDocument21 pagesDrawing an Auto Body Shape Using SurfacesSuresh RajagopalNo ratings yet

- Catia Part07Document19 pagesCatia Part07Suresh RajagopalNo ratings yet

- Advanced 3D modeling techniques for dress-up featuresDocument13 pagesAdvanced 3D modeling techniques for dress-up featuresSuresh RajagopalNo ratings yet

- Catia Part06Document15 pagesCatia Part06luluNo ratings yet

- Catia Part08Document17 pagesCatia Part08luluNo ratings yet

- Catia Part03Document16 pagesCatia Part03Suresh RajagopalNo ratings yet

- Catia Part02Document12 pagesCatia Part02luluNo ratings yet

- Samsung 2233sn Service Manual: Read/DownloadDocument2 pagesSamsung 2233sn Service Manual: Read/DownloadIordan Adrian0% (1)

- Vibrating ScreensDocument6 pagesVibrating Screensvarun_0512933No ratings yet

- Megahertz Internet Network Pvt. LTD.: Retail InvoiceDocument1 pageMegahertz Internet Network Pvt. LTD.: Retail InvoiceAyush ThapliyalNo ratings yet

- Maintenance Management Practices For Building Facility: A Case StudyDocument11 pagesMaintenance Management Practices For Building Facility: A Case StudyLeykun GebreselassieNo ratings yet

- Webinar BrochureDocument1 pageWebinar BrochurePruthweesha SalianNo ratings yet

- Job Vacancies AdvertisementDocument28 pagesJob Vacancies AdvertisementRobert AzihembaNo ratings yet

- Java Basics - Key Elements of a Java ProgramDocument21 pagesJava Basics - Key Elements of a Java ProgramAsh LeeNo ratings yet

- All Motor, &electrical Equipment in StorDocument8 pagesAll Motor, &electrical Equipment in StorMd. Saddam HossainNo ratings yet

- "Experimental Investigation On The Use of Coconut Shell As Partial Replacement of Coarse Aggregate in Concrete'' Nikhil M. DofeDocument18 pages"Experimental Investigation On The Use of Coconut Shell As Partial Replacement of Coarse Aggregate in Concrete'' Nikhil M. DofeKomal mankarNo ratings yet

- 2122 Mast M-Tech A2 Hoe Emship enDocument22 pages2122 Mast M-Tech A2 Hoe Emship enMohamed BoutmezoughetNo ratings yet

- Structure of A C++Document3 pagesStructure of A C++All TvwnzNo ratings yet

- Wireless Sensor Network Security A Critical Literature ReviewDocument4 pagesWireless Sensor Network Security A Critical Literature Reviewea6xrjc4No ratings yet

- 1019-Article Text-6238-1-10-20230525Document6 pages1019-Article Text-6238-1-10-20230525Keyara PutriNo ratings yet

- IA SampleDocument4 pagesIA SampleZaina KudchiwalaNo ratings yet

- How VFDs Improve Cane Mill Efficiency and Reduce Energy CostsDocument5 pagesHow VFDs Improve Cane Mill Efficiency and Reduce Energy CostsEdison EstrellaNo ratings yet

- Object-Oriented Programming Assignment 2 - Library Management SystemDocument13 pagesObject-Oriented Programming Assignment 2 - Library Management SystemMohamed AhmedNo ratings yet

- Quantifying The Seasonal Cooling Capacity of Green Infrastr 2020 LandscapeDocument21 pagesQuantifying The Seasonal Cooling Capacity of Green Infrastr 2020 Landscape熙槃No ratings yet

- Employee Payroll System ProjectDocument21 pagesEmployee Payroll System ProjectZeeshan Hyder BhattiNo ratings yet

- Contingency Tables Crosstabs Chi Square TestDocument48 pagesContingency Tables Crosstabs Chi Square TestAbii ShivuNo ratings yet

- Schwartz Space and Fourier AnalysisDocument10 pagesSchwartz Space and Fourier AnalysiseducatedyaserNo ratings yet

- Non Faculty Application FormDocument6 pagesNon Faculty Application FormBharat KumarNo ratings yet

- Role of Print Media in AdvertisementDocument14 pagesRole of Print Media in AdvertisementMoond0070% (1)

- Literacy Narrative Essay 1Document3 pagesLiteracy Narrative Essay 1api-644119616No ratings yet