Professional Documents

Culture Documents

Autoleveller Carding

Autoleveller Carding

Uploaded by

Abhay Kumar0 ratings0% found this document useful (0 votes)

17 views6 pagesThe document discusses autolevellers, which are devices used to carefully control sliver uniformity in the spinning process. There are two main types of autolevellers: mechanical systems of control and electronic control systems. Mechanical autolevellers work by measuring sliver variations and correcting the delivery speed, and include long term autolevellers and short term autolevellers. Electronic autolevellers classify variations by length and include controllers for very short, short term, medium term, and very long variations. Careful control of sliver uniformity through autolevellers is important to minimize waste and improve efficiency in spinning.

Original Description:

Original Title

autoleveller carding

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses autolevellers, which are devices used to carefully control sliver uniformity in the spinning process. There are two main types of autolevellers: mechanical systems of control and electronic control systems. Mechanical autolevellers work by measuring sliver variations and correcting the delivery speed, and include long term autolevellers and short term autolevellers. Electronic autolevellers classify variations by length and include controllers for very short, short term, medium term, and very long variations. Careful control of sliver uniformity through autolevellers is important to minimize waste and improve efficiency in spinning.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views6 pagesAutoleveller Carding

Autoleveller Carding

Uploaded by

Abhay KumarThe document discusses autolevellers, which are devices used to carefully control sliver uniformity in the spinning process. There are two main types of autolevellers: mechanical systems of control and electronic control systems. Mechanical autolevellers work by measuring sliver variations and correcting the delivery speed, and include long term autolevellers and short term autolevellers. Electronic autolevellers classify variations by length and include controllers for very short, short term, medium term, and very long variations. Careful control of sliver uniformity through autolevellers is important to minimize waste and improve efficiency in spinning.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 6

Autoleveller

Careful control of sliver uniformity is necessary in the spinning process, to minimize the

production of streaky fabrics, waste of raw material and to waste of production time.

Need for Autoleveller:

Continuous checking of sliver weight together with

automatic correction of sliver weight variation at card is necessary.

Advantage of installing autoleveller at card draw frame:

They control the thickness of individual slivers.

They are followed by greater no. of doublings.

They are generally cheaper.

Classification of autoleveller:

1] Mechanical system of control

2] Electronic control

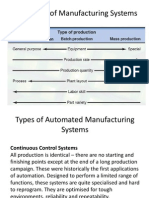

Control systems are classified into:

1] Open loop

2] Closed loop

Open loop:

- Variation is corrected in draft zone by varying speed of O/P

rollers (on card) or I/P rollers (on D/F).

- Correction follows measurement so there is no check that

correction was correctly applied.

Closed loop:

- Variations corrected in draft zone by varying speed of delivery

rollers.

- Correction precedes measurement so system check that

‘correction’ was correctly applied.

Mechanical system of control

Working principle:

Measurement of sliver variation

Correction rate and sliver variation

Correction rate and delivery speed Types:

Long term autoleveller [LTAL]

Short term autoleveller [STAL]

Short term autoleveller and dual

autoleveller

Fig. Mechanical Autolevelling System

Electrical System Of Control

They are classified as

follows: Very short : up to 25cm

variations Short term : from 25cm to 2.5m

variationsterm variations

Medium : from 25m

to 250 m Very long variations : more than

250 m

Types:

Long term autolevelling UCC-L Model L

Medium term autolevelling USTER-M controller

Short term autolevelling UCC-S

You might also like

- Servo-Drive-Systems Ch1 Outline PDFDocument12 pagesServo-Drive-Systems Ch1 Outline PDFcườngNo ratings yet

- Auto Levelling in SpinningDocument81 pagesAuto Levelling in SpinningArihara Sudhan73% (11)

- EE742 Chap2 System ComponentsDocument50 pagesEE742 Chap2 System Componentsrasim_m1146No ratings yet

- Optima: Improving The Production Process Through Better Web Tension ControlDocument9 pagesOptima: Improving The Production Process Through Better Web Tension ControlJulio C. SalinasNo ratings yet

- High-Speed and High-Precision Tracking Control Ofultrahigh-Acceleration Moving-Permanent-Magnetlinear Synchronous MotoDocument9 pagesHigh-Speed and High-Precision Tracking Control Ofultrahigh-Acceleration Moving-Permanent-Magnetlinear Synchronous MotoDoru DumitracheNo ratings yet

- Chapter-6 Hydro-Turbine Governing SystemDocument27 pagesChapter-6 Hydro-Turbine Governing SystemChristian Llanes-de la CruzNo ratings yet

- Baldor Linear Br1202!1!02Document62 pagesBaldor Linear Br1202!1!02Umm E KalsoomNo ratings yet

- Servo Hydraulic CTM 3000knDocument23 pagesServo Hydraulic CTM 3000knMIGUEL LOPEZNo ratings yet

- Adaptive ControlDocument30 pagesAdaptive ControlGanesh67% (3)

- Application Notes Bearing Monitoring Equipment For Gear Driven Paper Machines Bo0072Document4 pagesApplication Notes Bearing Monitoring Equipment For Gear Driven Paper Machines Bo0072AndysNo ratings yet

- ProcesscontrolDocument58 pagesProcesscontrolzakariareal623No ratings yet

- Fabric Inspection Machines For KnitsDocument2 pagesFabric Inspection Machines For KnitsGarima DhimanNo ratings yet

- Matec - VSR ManualDocument20 pagesMatec - VSR ManualPhung Tuan AnhNo ratings yet

- Loom OMEGA6 Part EngDocument81 pagesLoom OMEGA6 Part EngPhúc Vũ Viết Phúc67% (3)

- AD00375FLC - CIMV Brochure PDFDocument16 pagesAD00375FLC - CIMV Brochure PDFgpuzoneNo ratings yet

- Servo Drive Systems - Chapter 1 - 2021Document19 pagesServo Drive Systems - Chapter 1 - 2021Hang Duc ThinhNo ratings yet

- Control System of The Wiredrawing Machine1Document8 pagesControl System of The Wiredrawing Machine1Vadim CazacNo ratings yet

- Lab Manual of Pneumatics ControlDocument110 pagesLab Manual of Pneumatics ControlKhanNo ratings yet

- CSC Unit 1Document22 pagesCSC Unit 1aviitharu2472No ratings yet

- Cep 1.1Document11 pagesCep 1.1Qaim RizviNo ratings yet

- SSD Digital Technology in Speed ControlDocument23 pagesSSD Digital Technology in Speed ControlNitishNo ratings yet

- Introduction To B.H.E.L: 1.1 EstablishmentDocument35 pagesIntroduction To B.H.E.L: 1.1 EstablishmentSameer KapoorNo ratings yet

- W B48ev Emtem1specDocument6 pagesW B48ev Emtem1specDharmesh PatelNo ratings yet

- Subject - Mechatronics: Summer - 2018 SolutionDocument31 pagesSubject - Mechatronics: Summer - 2018 SolutionFaheem TirmiziNo ratings yet

- Speed Control of DC MotorDocument5 pagesSpeed Control of DC MotorAmit SinghNo ratings yet

- Slection of Motor Starter PDFDocument4 pagesSlection of Motor Starter PDFArun GuptaNo ratings yet

- Mekatronika - 4 - ControllersDocument51 pagesMekatronika - 4 - ControllersFahri FatturahmanNo ratings yet

- Chapter EightDocument35 pagesChapter EightMusaabNo ratings yet

- Condition MonitoringDocument10 pagesCondition MonitoringRoy Samia100% (1)

- On-Load Tap Changer Testing MethodsDocument8 pagesOn-Load Tap Changer Testing MethodsSanjay MahatoNo ratings yet

- DC Motor Position Control EMDAP CVTDocument11 pagesDC Motor Position Control EMDAP CVTzulfikarzaidNo ratings yet

- Underwater ROV Control SystemDocument20 pagesUnderwater ROV Control SystemPhanNamNo ratings yet

- Adaptive Bandwidth Approach ON DTC Controlled Induction MotorDocument9 pagesAdaptive Bandwidth Approach ON DTC Controlled Induction MotorijicsjournalNo ratings yet

- Mekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalDocument51 pagesMekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalYuneo NurcahyaNo ratings yet

- Automationof DrillingmachinesDocument7 pagesAutomationof Drillingmachinesdevang mishraNo ratings yet

- Pranjal WB 1Document39 pagesPranjal WB 1bvdasNo ratings yet

- Web Tension Control SystemsDocument24 pagesWeb Tension Control SystemsSudhakar Joshi0% (2)

- Technological Control For Cold Rolling ProcessesDocument4 pagesTechnological Control For Cold Rolling ProcessesBAHARO ALYAUMA IEDNo ratings yet

- Bab IiiDocument16 pagesBab IiiWingky ChannelNo ratings yet

- Circuitos ElectroneumaticosDocument31 pagesCircuitos ElectroneumaticosÁngeles Campaña OlmosNo ratings yet

- Study of Automatic Transmission Based On Electronic Control SystemDocument10 pagesStudy of Automatic Transmission Based On Electronic Control SystemHusseenNo ratings yet

- Section Low Voltage Power Circuit Breaker Part 1 - GeneralDocument5 pagesSection Low Voltage Power Circuit Breaker Part 1 - GeneralJose HernandezNo ratings yet

- Robust Adaptive Backstepping Control Design For A Nonlinear Hydraulic-Mechanical SystemDocument8 pagesRobust Adaptive Backstepping Control Design For A Nonlinear Hydraulic-Mechanical SystemlimakmNo ratings yet

- Automated Manufacturing SystemsDocument25 pagesAutomated Manufacturing SystemsSoto KunNo ratings yet

- Precision Machine DesignDocument56 pagesPrecision Machine DesignFelipe Soares MaiaNo ratings yet

- Salim Khan Electronic Information Engineering Super Visor Prof Bai LinDocument26 pagesSalim Khan Electronic Information Engineering Super Visor Prof Bai Linsaalim_khan1No ratings yet

- Introduction OnkeshDocument12 pagesIntroduction OnkeshPatricia JosephNo ratings yet

- Design of A New Non-Singular Robust Control Using Synergetic Theory For DC-DC Buck Converter (#403052) - 521332Document8 pagesDesign of A New Non-Singular Robust Control Using Synergetic Theory For DC-DC Buck Converter (#403052) - 521332Aisha Sir ElkhatemNo ratings yet

- Circuitos Electroneumaticos nrc2496Document29 pagesCircuitos Electroneumaticos nrc2496Ronnie LoboNo ratings yet

- Underwater ROV Control SystemDocument11 pagesUnderwater ROV Control SystemIain McCulloch100% (1)

- Dual Control CableDocument3 pagesDual Control CableHendra W GyaltshenNo ratings yet

- Unit 1 EDCDocument22 pagesUnit 1 EDCDr Harsha AnantwarNo ratings yet

- Centro-Matic Automated Lubrication Systems: System ControlsDocument8 pagesCentro-Matic Automated Lubrication Systems: System ControlsAlex Rivera RiveraNo ratings yet

- Automation in Ring Spinning Machines-KTTMDocument24 pagesAutomation in Ring Spinning Machines-KTTMkathirvelus940850% (2)

- Eurobloc®: Electric Wire Rope Hoist For Load From 800 Up To 100.000 KGDocument8 pagesEurobloc®: Electric Wire Rope Hoist For Load From 800 Up To 100.000 KGf157839No ratings yet

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)