Professional Documents

Culture Documents

Uee PPT Module-I

Uploaded by

shiva sai donthula0 ratings0% found this document useful (0 votes)

7 views89 pagesOriginal Title

UEE PPT MODULE-I

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views89 pagesUee PPT Module-I

Uploaded by

shiva sai donthulaCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 89

Utilization of Electrical Engineering

Direct Arc Furnance

Vertical Core Type Furnace

(Ajax- Wyatt Furnace)

The vertical core type induction furnace is also known as Ajax-Wyatt Furnace.

•This furnace has a vertical crucible instead of a horizontal one (as in case direct core type induction furnace) for the charge.

•The shell of the furnace is made of heavy steel, and the top of the furnace is closed by an insulated cover which can be

removed for charging the furnace. Therefore, the vertical core type induction furnace is convenient from metallurgical point of

view.

•In case of vertical core type induction furnace, the magnetic coupling is comparatively better and the power factor is also

high. Therefore, it can be operated from the supply of normal frequency.

•In this furnace, the molten metal is kept circulating round the vee-channel by convection currents. Since the vee-channel is

so narrow that a small quantity of charge keeps the secondary circuit closed. Although the vee-channel must be kept of full

of charge in order to maintain continuity of the secondary circuit.

•The output of the vertical core type induction furnace depends upon the shape and dimension of the channel. Apart from

the V-shaped channel, U-shaped channel and rectangular channel are also used in this type of induction furnace.

•The weight of the charge in the crucible counteracts the tendency of the secondary circuit to rupture due to pinch effect (i.e.

formation of bubbles and voids).

•The inner surface of the shell is lined with some refractory material. The type of lining depends upon the type of charge to

be melt. For example, the lining of clay is used for yellow brass, a mixture of magnesia and alumina or corundum is used for

red brass and bronze.

The chief advantages of the vertical core type induction furnaces are given as

follows −

•Vertical core type induction furnaces give consistent performance.

•They have simple and accurate temperature control.

•With the vertical core type induction furnace, we can obtain uniform castings,

reduced metal losses and reduction of rejects.

•The vertical core type induction furnaces have comparatively high power

factor, ranges from 0.8 to 0.85.

•They give highly efficient heat, low operating costs and improved production.

•Vertical core type induction furnaces give local working conditions in a cool

atmosphere with no dirt, noise and fuel.

•The crucible is absent in case of vertical core type induction furnace.

•There is absence of combustion gases resulting in elimination of the

common source of metal contamination.

You might also like

- Induction HeatingDocument22 pagesInduction Heatingaditya20012003No ratings yet

- R Satish Kumar: Rgmcet - NandyalDocument28 pagesR Satish Kumar: Rgmcet - NandyalGopi RamNo ratings yet

- Electric Arc Furnace: By:-Mukesh.J.Choudhari 3 Semester (D.M.E.) ROLL NO:-19Document15 pagesElectric Arc Furnace: By:-Mukesh.J.Choudhari 3 Semester (D.M.E.) ROLL NO:-19boopasangeeNo ratings yet

- Furnaces and Equipment Used in The Manufacture and Heat Treatment of Alloy SteelsDocument9 pagesFurnaces and Equipment Used in The Manufacture and Heat Treatment of Alloy SteelsChinmoyMondal0% (1)

- Industrial Furnace: Abishek S R - 22P432 Aravindhu Kumar - 22P438 Vijay - 22P440Document7 pagesIndustrial Furnace: Abishek S R - 22P432 Aravindhu Kumar - 22P438 Vijay - 22P440Abishek RajasekarNo ratings yet

- Lec 10 Commonly Used FurnacesDocument35 pagesLec 10 Commonly Used FurnacesSakunaPappuNo ratings yet

- The Electric Arc FurnaceDocument22 pagesThe Electric Arc FurnaceKingsley Posiyano100% (2)

- Electric Arc Furnace Operations and WorkingDocument40 pagesElectric Arc Furnace Operations and Workingpkn_pnt9950100% (7)

- 6 Type Induction FurnaceDocument6 pages6 Type Induction Furnacehodeegits9526No ratings yet

- Lecture BKC FurnacesDocument60 pagesLecture BKC FurnacesB K. ChoudhuryNo ratings yet

- Unit 2: BoilersDocument43 pagesUnit 2: Boilersommech2020No ratings yet

- Lect 1 FurnaceDocument42 pagesLect 1 FurnaceAyushNo ratings yet

- Spaft PresentationDocument29 pagesSpaft PresentationVaishnavi ShringiNo ratings yet

- Cast Iron Production & ClassificationDocument34 pagesCast Iron Production & ClassificationTanzir Musa100% (1)

- Induction FurnaceDocument23 pagesInduction Furnaceveenavee276No ratings yet

- Induction FurnacesDocument4 pagesInduction FurnacesGustavo EcheverriNo ratings yet

- Industrial Boilers Our Objective: To Describe and Explain The Boilers' Functions and The Two MainDocument33 pagesIndustrial Boilers Our Objective: To Describe and Explain The Boilers' Functions and The Two MainKhairulNo ratings yet

- Lect-Ns-Casting6 Melting FurnacesDocument14 pagesLect-Ns-Casting6 Melting FurnacesMohd AbrarNo ratings yet

- 3furnaces 120520160438 Phpapp01 130806162930 Phpapp02Document10 pages3furnaces 120520160438 Phpapp01 130806162930 Phpapp02Ashrav GuptaNo ratings yet

- Recap: in This Class You Have Learnt About - Different Methods of Temperature Control of Resistance HeatingDocument27 pagesRecap: in This Class You Have Learnt About - Different Methods of Temperature Control of Resistance HeatingDrVikas Singh BhadoriaNo ratings yet

- If & LRFDocument20 pagesIf & LRFMashiur RahmanNo ratings yet

- Figure 19.5.-Vertical Section of An Electric Arc Furnace ShopDocument61 pagesFigure 19.5.-Vertical Section of An Electric Arc Furnace ShopAries GunZadielNo ratings yet

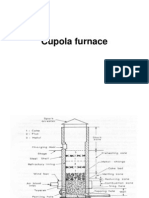

- Cupola Furnace-Iron MakingDocument32 pagesCupola Furnace-Iron MakingSameer MdNo ratings yet

- Types of Reheating FurnacesDocument4 pagesTypes of Reheating FurnacesziadNo ratings yet

- Induction HeatingDocument17 pagesInduction HeatingRam Kumar Gogada100% (1)

- Types Vgof Reheating FurnacesDocument5 pagesTypes Vgof Reheating FurnacesNiladri BhattacharyyaNo ratings yet

- 3furnaces 120520160438 Phpapp01 130806162930 Phpapp02Document10 pages3furnaces 120520160438 Phpapp01 130806162930 Phpapp02Amrik SinghNo ratings yet

- Lec 9 Introduction To FurnacesDocument18 pagesLec 9 Introduction To FurnacesSakunaPappuNo ratings yet

- Induction HeatingDocument5 pagesInduction HeatingPavan KumarNo ratings yet

- Crucible - Cupola Furnaces-2 PDFDocument81 pagesCrucible - Cupola Furnaces-2 PDFSaeed Aba ateNo ratings yet

- Electric HeatingDocument13 pagesElectric HeatingSarala NandanNo ratings yet

- Induction FurnaceDocument7 pagesInduction FurnaceDeepak Velusamy100% (2)

- Steam BoilersDocument35 pagesSteam BoilersMohammedAminShaikhNo ratings yet

- Induction HeatingDocument33 pagesInduction Heatingdallisrinivas14No ratings yet

- Electric Heating and WeldingDocument84 pagesElectric Heating and WeldingReddy Sekhar75% (16)

- Modern Steelmaking Processes: Topics To DiscussDocument17 pagesModern Steelmaking Processes: Topics To DiscussMir RafsanNo ratings yet

- Air University Islamabad: Materials and Manufacturing Assignment # 3Document11 pagesAir University Islamabad: Materials and Manufacturing Assignment # 3danial shehroz khanNo ratings yet

- Structure of The Blast FurnaceDocument28 pagesStructure of The Blast FurnaceAYIBONGWE SIZIBANo ratings yet

- Utilization of Electric PowerDocument12 pagesUtilization of Electric PowerAbhishek SharmaNo ratings yet

- Lecture 15 PDFDocument5 pagesLecture 15 PDFrahulNo ratings yet

- Electric Arc Furnace: RefractoryDocument5 pagesElectric Arc Furnace: RefractoryAbhilash MallikarjunaNo ratings yet

- Steel Making Using Open Hearth Furnace-1Document9 pagesSteel Making Using Open Hearth Furnace-1victorymusa45No ratings yet

- Types of Boilers and Types of Hydrostatic Test: Boiler ComponentsDocument10 pagesTypes of Boilers and Types of Hydrostatic Test: Boiler ComponentsIbrahim MustafaNo ratings yet

- Induction FurnaceDocument3 pagesInduction FurnaceSuman_SamadderNo ratings yet

- The Electric Arc FurnaceDocument21 pagesThe Electric Arc FurnaceKingsley Posiyano100% (1)

- Furances: Cupola FurnaceDocument7 pagesFurances: Cupola FurnaceMahmoud MerdanNo ratings yet

- Metal Melting FurnacesDocument11 pagesMetal Melting FurnacesPradeep Sankar100% (2)

- Boilers - Thermal EngineeringDocument45 pagesBoilers - Thermal Engineeringommech2020No ratings yet

- Induction Furnace Working Principle - Mechanical EngineeringDocument5 pagesInduction Furnace Working Principle - Mechanical Engineeringjalilemadi0% (1)

- Billets ProcessDocument5 pagesBillets ProcessWewey NuestroNo ratings yet

- Thermal Power Plant Layout and OperationDocument77 pagesThermal Power Plant Layout and OperationAlex100% (1)

- Uses of Ferrous Metals & Alloys SteelsDocument55 pagesUses of Ferrous Metals & Alloys SteelsNoel AngeloNo ratings yet

- Electric Arc FurnaceDocument60 pagesElectric Arc FurnacePatel Ki BahuNo ratings yet

- Meg 5-LF-29-30 Types of Aux BoilersDocument54 pagesMeg 5-LF-29-30 Types of Aux BoilersAkash KandwalNo ratings yet

- Principle of Transformers in The Transformer, Supply Is Utilized by SecondaryDocument25 pagesPrinciple of Transformers in The Transformer, Supply Is Utilized by SecondaryRajeshBasireddyNo ratings yet

- Melting TechniquesDocument3 pagesMelting TechniquesMicky SahuNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

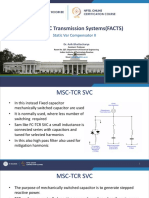

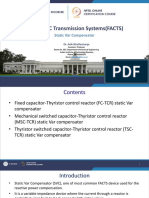

- 07 SVC 2 PDFDocument25 pages07 SVC 2 PDFshiva sai donthulaNo ratings yet

- 12 Series Compensator 1 PDFDocument29 pages12 Series Compensator 1 PDFshiva sai donthulaNo ratings yet

- 06 SVC 1 PDFDocument21 pages06 SVC 1 PDFshiva sai donthulaNo ratings yet

- Hei 2Document2 pagesHei 2shiva sai donthulaNo ratings yet

- Unit I (SM) PDFDocument89 pagesUnit I (SM) PDFshiva sai donthulaNo ratings yet

- Questions (FAQ)Document21 pagesQuestions (FAQ)shiva sai donthulaNo ratings yet

- HVE - Unit 1 - Oct 2022 - Handout PDFDocument12 pagesHVE - Unit 1 - Oct 2022 - Handout PDFshiva sai donthulaNo ratings yet

- Vamshi's InternshipDocument17 pagesVamshi's Internshipshiva sai donthulaNo ratings yet

- Groundwater Quality and Leachate Pollution Index inDocument15 pagesGroundwater Quality and Leachate Pollution Index inshiva sai donthulaNo ratings yet

- Cyber Security AssignmentDocument1 pageCyber Security Assignmentshiva sai donthulaNo ratings yet

- CCNA-Internship PresentationDocument19 pagesCCNA-Internship Presentationshiva sai donthulaNo ratings yet

- NishanthreportDocument28 pagesNishanthreportshiva sai donthulaNo ratings yet

- Hot Process Liquid SoapmakingDocument11 pagesHot Process Liquid SoapmakingPanacea PharmaNo ratings yet

- Short Moritz - LiverGB PDFDocument3 pagesShort Moritz - LiverGB PDFPetra JobovaNo ratings yet

- 33 SriSriTadepalliShastryGaru 1Document4 pages33 SriSriTadepalliShastryGaru 1Kiran GopalanNo ratings yet

- Ingles y Español Unidad 7Document9 pagesIngles y Español Unidad 7Pier Jhoani Ñañez LlanosNo ratings yet

- The Coffee Shop Easy Reading - 152542Document1 pageThe Coffee Shop Easy Reading - 152542Fc MakmurNo ratings yet

- Naskah Soal PeroranganDocument16 pagesNaskah Soal PeroranganRiza FatimahNo ratings yet

- Indian Standard: Application Guide For Voltage TransformersDocument16 pagesIndian Standard: Application Guide For Voltage TransformersGnanavel GNo ratings yet

- Brochure ISDocument4 pagesBrochure ISJAYESH VIKRAM RastogiNo ratings yet

- Purgatory and The AbsoluteDocument18 pagesPurgatory and The AbsoluteCarla MissionaNo ratings yet

- Yamaha rx-v395 v395rds htr-5130 5130rdsDocument55 pagesYamaha rx-v395 v395rds htr-5130 5130rdsdomino632776No ratings yet

- Dyson - Environmental AssesmentDocument16 pagesDyson - Environmental AssesmentShaneWilson100% (5)

- Danh M C AHTN 2017 - HS Code 2017 PDFDocument564 pagesDanh M C AHTN 2017 - HS Code 2017 PDFBao Ngoc Nguyen100% (1)

- The Lower Parts of The Lock Stitch Sewing MachineDocument3 pagesThe Lower Parts of The Lock Stitch Sewing MachineHazelAnnCandelarioVitug20% (5)

- Notes Ch. 4 - Folk and Popular CultureDocument7 pagesNotes Ch. 4 - Folk and Popular CultureVienna WangNo ratings yet

- Jerms B 2109 - 0BDocument10 pagesJerms B 2109 - 0BNothing is ImpossibleNo ratings yet

- PPP-B-676 e PDFDocument34 pagesPPP-B-676 e PDFffincher4203No ratings yet

- Dense NetDocument28 pagesDense NetFahad RazaNo ratings yet

- Msds - Lemon Detergent Acco BrandsDocument10 pagesMsds - Lemon Detergent Acco Brandsfitri widyaNo ratings yet

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageDocument6 pagesThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoNo ratings yet

- CJR Fisika Umum IDocument17 pagesCJR Fisika Umum IveronikaNo ratings yet

- Advanced Logic Synthesis: Multiple Choice QuestionsDocument16 pagesAdvanced Logic Synthesis: Multiple Choice QuestionsmanojkumarNo ratings yet

- Eurolite Led TMH 7 PDFDocument2 pagesEurolite Led TMH 7 PDFSarahNo ratings yet

- Part 66 B1 - MODULE 4 3 SERVOMECHANISMSDocument26 pagesPart 66 B1 - MODULE 4 3 SERVOMECHANISMSyaman91100% (1)

- The Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateDocument22 pagesThe Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateOkawa TakeshiNo ratings yet

- Fuk SecDocument1 pageFuk SecHirushan MenukaNo ratings yet

- Using A Wet Film ThicknessDocument2 pagesUsing A Wet Film ThicknesssanoopvkNo ratings yet

- Load ScheduleDocument8 pagesLoad SchedulemerebookNo ratings yet

- DPWH ReviewerDocument597 pagesDPWH Reviewercharles sedigoNo ratings yet

- Recipes G.garvin Copy1 Scribd 5Document7 pagesRecipes G.garvin Copy1 Scribd 5Peggy Bracken StagnoNo ratings yet

- Biomaterials in Restorative Dentistry and Endodontics: An OverviewDocument6 pagesBiomaterials in Restorative Dentistry and Endodontics: An Overviewmanzoor ul haq bukhariNo ratings yet