100% found this document useful (1 vote)

344 views67 pagesHydrostatic Transmission Guide

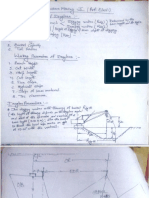

Hydrostatic transmissions, also known as hydraulic transmissions, offer several advantages over other transmission types including compact size, wide torque-speed ratios, controlled speed regardless of load, and ability to transmit power to multiple locations. They consist of hydraulic components like pumps, motors, valves and reservoirs. Hydraulic fluids are used to transmit power and must have properties like good lubrication, stable viscosity, compatibility with system materials, and heat dissipation. Common types of hydraulic motors include axial piston, radial piston, and gear motors, which convert hydraulic pressure and flow into mechanical motion.

Uploaded by

Anshul yadavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

344 views67 pagesHydrostatic Transmission Guide

Hydrostatic transmissions, also known as hydraulic transmissions, offer several advantages over other transmission types including compact size, wide torque-speed ratios, controlled speed regardless of load, and ability to transmit power to multiple locations. They consist of hydraulic components like pumps, motors, valves and reservoirs. Hydraulic fluids are used to transmit power and must have properties like good lubrication, stable viscosity, compatibility with system materials, and heat dissipation. Common types of hydraulic motors include axial piston, radial piston, and gear motors, which convert hydraulic pressure and flow into mechanical motion.

Uploaded by

Anshul yadavCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd