Professional Documents

Culture Documents

Handle Your Hand Tools The Right Way

Uploaded by

Benjamin Fallet0 ratings0% found this document useful (0 votes)

15 views11 pagesOriginal Title

Handle Your Hand Tools the Right Way –

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views11 pagesHandle Your Hand Tools The Right Way

Uploaded by

Benjamin FalletCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 11

Handle your Hand Tools the

Right Way – Basic Safety Rules

and Operational Techniques

1. Inspect Your Tools before the Job

•Never use a damaged or defective hand

tool. Make sure that the tool you are about

to use is in good working condition.

Practice the habit of inspecting your tools

both before and after use. If you are re-

sharpening or re-fitting tools, make sure

that you follow the manufacturer’s

instructions.

2. Choose the Right Tool for the Job

•Make sure you are using the correct

tool for the task. Different tools are

specifically designated for specific

tasks. Replacing one tool for another

is dangerous and could lead to

accidents.

3. Always wear the Right PPE

•Personal protective equipment like

hard hats, safety goggles, and overalls

are a must to protect you while using

hand tools. This gear helps you from

sustaining injuries in case you lose grip

of the tool during operation.

4. Don’t Modify/Alter your Tools on

Your Own

•Removing safety clips or finger guards

from hand tools can prove to be

disastrous. Don’t cover up or paint

tools on your own, as this prevents

you from noticing cracks and chips in

it.

5. Handle your Tools with Care

•Tools aren’t toys. Don’t throw or

toss it to a co-worker. While

passing tools between co-

workers, ensure that you let them

know that you are passing it.

6. Transport and Store Tools the Right

Way

• When carrying tools up a ladder, don’t pass it from

one person to another or lift it by hand. Instead, use a

bag or bucket to hoist tools from the ground to the

workers above. While working at heights, ensure that

you don’t leave tools lying out in the open. This could

present a fatal hazard to the workers below.

• Wherever possible, use clamps and bench vices to

secure tools to a steady surface, to avoid slipping.

Don’t carry pointed tools in your pocket. Always use a

cart or a toolbox. Instead, of keeping extra tools lying

around, store them in a handy tool case.

7. Have Space

•When working with hand tools, ensure

that you have sufficient room to operate

without dashing against other objects,

walls or co-workers. Plant your feet on a

stable surface, provide yourself with

adequate support, while using hand

tools.

8. Clean your Workspace

•Don’t leave idle tools lying around

the job site. A cluttered and messy

workplace is one of the main

reasons for tripping, falls and

accidentally dropping tools on

one’s hands and legs.

9. Get the Right Training

• While hand tools like wrenches, chisels,

bench vices, hacksaws, hammers,

pricks, pry bars, scrapers, and others

seem easy to use, several proper

techniques must be followed. Ensure

that your employees are provided with

the right training to handle these tools.

10. Above all, Buy Quality Tools

• This cannot be stressed enough. Any

hand tool you choose should be made of

high-quality steel, heat-treated and

properly built.

You might also like

- Safe Hand Tool Use TipsDocument3 pagesSafe Hand Tool Use TipsMary Grace CatubiganNo ratings yet

- Hand Tools & Safety PracticesDocument4 pagesHand Tools & Safety PracticesRecel Ann RiveraNo ratings yet

- Hand Tools SafetyDocument2 pagesHand Tools SafetyAlfred PabloNo ratings yet

- Hand Tool SafetyDocument2 pagesHand Tool SafetyNelson ShatiNo ratings yet

- OSHA hand tool safety standardsDocument8 pagesOSHA hand tool safety standardsAlma Tomas-CafeNo ratings yet

- 22 Hand Tool SafetyDocument8 pages22 Hand Tool SafetyAlma Tomas-CafeNo ratings yet

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 pagesSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerNo ratings yet

- Hand and Power Tool Safety Tips: UC Monthly Safety Spotlight, February 2012Document6 pagesHand and Power Tool Safety Tips: UC Monthly Safety Spotlight, February 2012mallickss97No ratings yet

- Grantley Adams Memorial School: General Safety NotesDocument4 pagesGrantley Adams Memorial School: General Safety NotesPaul SealyNo ratings yet

- QuizDocument3 pagesQuizusman0280038No ratings yet

- Hand Tools and Portable ToolsDocument29 pagesHand Tools and Portable Toolsvino rubanNo ratings yet

- 4.1 2 Hand Tools and Its Uses Full PermissionDocument12 pages4.1 2 Hand Tools and Its Uses Full PermissionLathea Daiser TheaNise TesalunaNo ratings yet

- Hand Tools: Training GuideDocument5 pagesHand Tools: Training GuideHamza NoumanNo ratings yet

- Hand Power ToolsDocument1 pageHand Power Toolskalkalina63No ratings yet

- Hand Tools SOPDocument3 pagesHand Tools SOPAchmad Faisal FaputriNo ratings yet

- Dos and Donts in Using Hand ToolsDocument20 pagesDos and Donts in Using Hand ToolsMary Jane Blanco FioNo ratings yet

- Handle Tools For Your Safety (EN and SP)Document3 pagesHandle Tools For Your Safety (EN and SP)pruncu.alianmNo ratings yet

- Hand Tools: Safety TalkDocument1 pageHand Tools: Safety Talkahmer09No ratings yet

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 pagesSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerNo ratings yet

- Hand - Power Tools SafetyDocument49 pagesHand - Power Tools SafetySanjana Ganesh100% (3)

- 4thquarter CarpentryDocument13 pages4thquarter CarpentryhalemahpacoteNo ratings yet

- FY06 46c6-Ht21 English B 7 Hand Power ToolsDocument35 pagesFY06 46c6-Ht21 English B 7 Hand Power Toolstu100% (1)

- Basic Tips When Selecting Hand Tools PDFDocument1 pageBasic Tips When Selecting Hand Tools PDFfrederic asejoNo ratings yet

- 2010-1105 11 Hand & Power ToolsDocument35 pages2010-1105 11 Hand & Power Toolsbinas nasarNo ratings yet

- Student Shop Safety PresentationDocument39 pagesStudent Shop Safety PresentationAnnabelle DukaNo ratings yet

- Hand Safety (A) - 1Document44 pagesHand Safety (A) - 1Mohammad AbdullahNo ratings yet

- Comm Malfunction Grade 8Document7 pagesComm Malfunction Grade 8Leonard100% (1)

- TLEDocument4 pagesTLEEspano FaithNo ratings yet

- Workshop SafetyDocument21 pagesWorkshop SafetyEm Cama100% (1)

- Safety Rules for Power ToolsDocument1 pageSafety Rules for Power ToolsJaseel KanhirathingalNo ratings yet

- Prepared by A.Prasad RoshanDocument102 pagesPrepared by A.Prasad Roshansaswati roy barmanNo ratings yet

- 20-Tools SafetyDocument6 pages20-Tools SafetyismailinesNo ratings yet

- Workshop Rules and Safety ConsiderationsDocument4 pagesWorkshop Rules and Safety ConsiderationsCleng LaynesNo ratings yet

- Hand Tool TrainingDocument7 pagesHand Tool TrainingtuNo ratings yet

- Safety in RoboticsDocument28 pagesSafety in RoboticsOmar Shuja SiddiquiNo ratings yet

- Blue Doodle Project Presentation 20240214 123527 0000Document7 pagesBlue Doodle Project Presentation 20240214 123527 0000reglincaputolanNo ratings yet

- Objectives: Learn About It!Document7 pagesObjectives: Learn About It!AmpakNo ratings yet

- Hand ToolsDocument1 pageHand Toolspruncu.alianmNo ratings yet

- 6 Tools SafetyDocument6 pages6 Tools SafetyBarkat UllahNo ratings yet

- C - 3 Job Skills & Craft Competency Training ProgramDocument5 pagesC - 3 Job Skills & Craft Competency Training ProgramJamal Mohamed RahamathullahNo ratings yet

- Occupational Health and Safety: Learning OutcomesDocument15 pagesOccupational Health and Safety: Learning OutcomesEricson GarciaNo ratings yet

- Module 2Document117 pagesModule 2Henzo AguistinNo ratings yet

- Hand Injury PreventionDocument45 pagesHand Injury PreventionAjithNo ratings yet

- K to 12 Shop Safety RulesDocument13 pagesK to 12 Shop Safety RulesJocelyn C. DinampoNo ratings yet

- Electric Power Tools: Workforce Safety & InsuranceDocument2 pagesElectric Power Tools: Workforce Safety & InsuranceDocholosoNo ratings yet

- Farm tools and equipment safety precautionsDocument30 pagesFarm tools and equipment safety precautionsMarie Joy MadriagaNo ratings yet

- Hand Tools AND Portable Power Tools SafetyDocument40 pagesHand Tools AND Portable Power Tools SafetyBernadeth-beneth Salenga100% (1)

- ZAMBIA AIR SERVICES TRAINING INSTITUTE (ZASTI) A.E.E WORKSHOP THEORY and PRACTICE Safety and Preventive Maintenance UPLOADED BY CHIMWEKADocument7 pagesZAMBIA AIR SERVICES TRAINING INSTITUTE (ZASTI) A.E.E WORKSHOP THEORY and PRACTICE Safety and Preventive Maintenance UPLOADED BY CHIMWEKAChimweka Isaac MasompeNo ratings yet

- Common 5 - Using Hand ToolsDocument36 pagesCommon 5 - Using Hand ToolsDehrben FloresNo ratings yet

- You Need Hands": Teekay - The Marine Midstream CompanyDocument20 pagesYou Need Hands": Teekay - The Marine Midstream CompanyAdhimas ErlambangNo ratings yet

- Hand and Power ToolsDocument25 pagesHand and Power ToolsVishwash Goyal100% (1)

- Engineering & Technology: General Safety RulesDocument20 pagesEngineering & Technology: General Safety Rulesbeijingdaxing510No ratings yet

- Procedure For Hand Tools and Powered ToolsDocument2 pagesProcedure For Hand Tools and Powered ToolsrgmNo ratings yet

- Hand & Power Tools - SARA ADocument20 pagesHand & Power Tools - SARA ANIJESHNo ratings yet

- Jeddah South Thermal Power Plant Toolbox TalkDocument1 pageJeddah South Thermal Power Plant Toolbox TalkBassemGamalNo ratings yet

- CHAPTER 2: Health and SafetyDocument23 pagesCHAPTER 2: Health and SafetyTeague BreslinNo ratings yet

- Jigsaw PuzzleDocument25 pagesJigsaw PuzzleLALA MAHALNo ratings yet

- css1 Lesson5 LO3 USE APPROPRIATE HAND TOOLS AND TEST EQUIPMENTDocument9 pagescss1 Lesson5 LO3 USE APPROPRIATE HAND TOOLS AND TEST EQUIPMENTGen GonNo ratings yet

- 2011 Office Safety GuidelinesDocument4 pages2011 Office Safety GuidelinesMuhammad Fahmi AnbNo ratings yet

- Hazards, Risk Assessment and Control Classroom ActivityDocument1 pageHazards, Risk Assessment and Control Classroom ActivityMNMNo ratings yet

- Hazard IdentificationDocument10 pagesHazard IdentificationMarissa MarianoNo ratings yet

- 2016 Excel Part 4Document10 pages2016 Excel Part 4Wasim Ahmad KhanNo ratings yet

- TLE 9 EIM 9 Q3 M2revDocument5 pagesTLE 9 EIM 9 Q3 M2revBenjamin FalletNo ratings yet

- Level 1 - Excel - TipsDocument10 pagesLevel 1 - Excel - TipsRick GrimesNo ratings yet

- Electrical wiring diagram guideDocument12 pagesElectrical wiring diagram guideBenjamin Fallet100% (1)

- Q3-Lesson 4Document4 pagesQ3-Lesson 4Benjamin FalletNo ratings yet

- M1-General Requirements For Electrical InstallationDocument4 pagesM1-General Requirements For Electrical InstallationBenjamin FalletNo ratings yet

- Hand Tool BestDocument14 pagesHand Tool BestBenjamin FalletNo ratings yet

- Floor Plan LessonDocument3 pagesFloor Plan LessonBenjamin FalletNo ratings yet

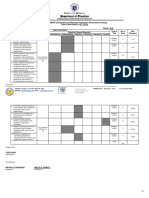

- TOS Q1 TLEICTCSS 9 - Jonalyn AmbronaDocument2 pagesTOS Q1 TLEICTCSS 9 - Jonalyn AmbronaBenjamin FalletNo ratings yet

- TLE10 - Ia - Electronicproductsassembly&servicing - q2 - Mod1 - Servicingconsumerelectronicproducts&systems... - v3 (85 Pages)Document85 pagesTLE10 - Ia - Electronicproductsassembly&servicing - q2 - Mod1 - Servicingconsumerelectronicproducts&systems... - v3 (85 Pages)Benjamin FalletNo ratings yet

- Access Information Using ComputerDocument7 pagesAccess Information Using ComputerBenjamin FalletNo ratings yet

- Facebook GuideDocument7 pagesFacebook GuideBenjamin FalletNo ratings yet

- Responding to Unplanned EventsDocument4 pagesResponding to Unplanned EventsBenjamin FalletNo ratings yet

- Technology and Livelihood Education: Industrial Arts-Electrical Installation and Maintenance Quarter 2 - Module 1Document35 pagesTechnology and Livelihood Education: Industrial Arts-Electrical Installation and Maintenance Quarter 2 - Module 1Benjamin Fallet100% (6)

- Basic Concepts in Electronics ServicingDocument13 pagesBasic Concepts in Electronics ServicingBenjamin FalletNo ratings yet

- NB-CPR 17-722r8 - General Guidance On AVCP (Working Copy)Document25 pagesNB-CPR 17-722r8 - General Guidance On AVCP (Working Copy)halexing5957No ratings yet

- OSCEs For Dentistry Third Edition-With-AnswersDocument365 pagesOSCEs For Dentistry Third Edition-With-AnswersAnkita Arora100% (6)

- 2022 Consumer Trends ReportDocument29 pages2022 Consumer Trends Reportadelin litan100% (1)

- Energy Savings White PaperDocument14 pagesEnergy Savings White PapersajuhereNo ratings yet

- Basic French ConversationDocument7 pagesBasic French Conversationeszti kozmaNo ratings yet

- Between Empire and GlobalizationDocument5 pagesBetween Empire and Globalizationazert yuiopNo ratings yet

- A High Capacity Floating LNG Design by Barend - PekDocument15 pagesA High Capacity Floating LNG Design by Barend - PekShaka Shalahuddin Shantika PutraNo ratings yet

- Media ExercisesDocument24 pagesMedia ExercisesMary SyvakNo ratings yet

- MDD FormatDocument6 pagesMDD FormatEngineeri TadiyosNo ratings yet

- Well Plug and Abandonment Using HwuDocument1 pageWell Plug and Abandonment Using HwuJuan Pablo CassanelliNo ratings yet

- Victory Over Sin Through Total ConsecrationDocument3 pagesVictory Over Sin Through Total ConsecrationJhon Ray OtañesNo ratings yet

- Module #5 Formal Post-Lab ReportDocument10 pagesModule #5 Formal Post-Lab Reportaiden dunnNo ratings yet

- International Journal of Infectious DiseasesDocument3 pagesInternational Journal of Infectious DiseasesDetti FahmiasyariNo ratings yet

- CPG Prevention, Diagnosis & Management of IE PDFDocument182 pagesCPG Prevention, Diagnosis & Management of IE PDFsigitNo ratings yet

- Arlington Value's 2013 LetterDocument7 pagesArlington Value's 2013 LetterValueWalk100% (7)

- Audit of Intangible AssetDocument3 pagesAudit of Intangible Assetd.pagkatoytoyNo ratings yet

- Salary Survey (Hong Kong) - 2022Document7 pagesSalary Survey (Hong Kong) - 2022Nathan SmithNo ratings yet

- RGB PDFDocument35 pagesRGB PDFGestion Medios Zamba ColorsNo ratings yet

- 200+ Selenium Interview QuestionsDocument40 pages200+ Selenium Interview QuestionsdhanaNo ratings yet

- 3D Solar System With Opengl and C#Document4 pages3D Solar System With Opengl and C#Shylaja GNo ratings yet

- Product Brand Management 427 v1Document484 pagesProduct Brand Management 427 v1Adii AdityaNo ratings yet

- WRITTEN ASSIGNMENT Unit 2 - The Peer Assessment Strategy - 1Document2 pagesWRITTEN ASSIGNMENT Unit 2 - The Peer Assessment Strategy - 1asdsafsvvsgNo ratings yet

- Complete Notes On 9th Physics by Asif RasheedDocument82 pagesComplete Notes On 9th Physics by Asif RasheedAsif Rasheed Rajput75% (28)

- BTechSyllabus EC PDFDocument140 pagesBTechSyllabus EC PDFHHNo ratings yet

- Montageanleitung sf25 35 enDocument20 pagesMontageanleitung sf25 35 enPaulo santosNo ratings yet

- VRF, MPLS and MP-BGP FundamentalsDocument55 pagesVRF, MPLS and MP-BGP FundamentalsIVAN TANEV100% (2)

- DTMF Relay and Interworking On CUBE PDFDocument18 pagesDTMF Relay and Interworking On CUBE PDFEngin KartalNo ratings yet

- Section10 - POST-DRILLING ACTIVITIESDocument16 pagesSection10 - POST-DRILLING ACTIVITIESMohamed ElshoraNo ratings yet

- Ayushi HR DCXDocument40 pagesAyushi HR DCX1048 Adarsh SinghNo ratings yet

- 0000 0000 0335Document40 pages0000 0000 0335Hari SetiawanNo ratings yet