Professional Documents

Culture Documents

MEM 1-LF-4 Boilers

Uploaded by

Akash KandwalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MEM 1-LF-4 Boilers

Uploaded by

Akash KandwalCopyright:

Available Formats

ED 2017/ REV.

MEM 1-3

Design of Marine Machinery

Marine Steam Boilers

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 1 of 21

ED 2017/ REV. 0

Learning objectives

Marine Steam Boilers:

Types of Boilers

• Smoke tube boilers & Water tube boilers

• Composite Boilers

Superheaters & Attemperators

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 2 of 21

Smoke tube Boilers ED 2017/ REV. 0

• The hot gases

pass though the

tubes that are

surrounded by

water, which is

Fig 1 heated up and

converted into

• It is usually chosen for low- steam.

pressure steam production on • Examples:

vessels requiring steam for Cochran boiler,

auxiliary purposes. Thimble tube

• Operation is simple and feed boiler, Spanner

water of medium quality is used. boiler.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 3 of 21

Smoke tube Boilers

ED 2017/ REV. 0

• It’s a tank boiler of Cochran boiler

vertical type suitable Steam Stop Valve

for producing small Pressure gauge

amounts of low

pressure steam for

aux. purposes.

• Combustion products

pass from furnace into

combustion chamber

Fusible plug

Combustion chamber

lined with refractory Smoke

material, and then Box

through smoke tubes

into the smoke box at Fig 2

the front of the boiler. Slide No. 4 of 21

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery

Water tube boilers

ED 2017/ REV. 0

• The basic design

consists of a larger

steam drum placed

above the smaller

water drum.

• It is usually chosen

for producing large

quantities of high-

pressure steam.

Fig 3

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 5 of 21

Water tube boilers

ED 2017/ REV. 0

• Steam drum reservoir of relatively cool water as

it recieves feed, gives necessary head to displace

high temp. mixture of steam & water from heated

tube surfaces.

• Steam drum provides space for the seperation of

mixture of steam & water.

• Water flow: steam drum water drum via

downcomers (not passing through furnace). From

water drum distributes to generating tubes and

headers.

• Water rises up through generating tubes, providing

positive circulation. (water density ↓ on heating)

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 6 of 21

Water tube boilers

ED 2017/ REV. 0

• Water drum, provides accumulation space for

suspended solids precipitating from boiler water.

• Blowdown connection at bottom for blowing down

such impurities.

• Drums are connected directly by generating tubes

and by others via headers.

• Waterwall tubes used on roof side and rear of the

furnace are connected to drums or headers as

required.

• The gases leaving the furnace pass external to

the tubes, imparting heat to the water inside them.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 7 of 21

Water tube boilers

ED 2017/ REV. 0

• A multiloop superheater is placed in the lower part

of the uptake.

• Here steam is superheated i.e., it is raised above

its saturation temperature for use in turbines.

• The exhaust gases heat up an economiser (where

incoming feedwater is heated) after passing

through the superheater.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 8 of 21

ED 2017/ REV. 0

Composite Boilers

The figure shows a composite Cochran boiler.

• Can be used in port

and also at sea.

• In port it is fired with

Diesel oil or Heavy

oil(as per regulations).

• Waste heat in diesel

engine exh. varies

between 20 to 25% of

total heat energy

being supplied. Fig 4

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 9 of 21

ED 2017/ REV. 0

Composite Boilers

• Upto 50% of this waste heat is recoverable in

Exhaust Gas Boiler.

• Bypass line may be provided for the exh. gases to

bypass the boiler at sea, if required.

• At sea the burner is shut off or on ‘Auto’ and

Exh. gases from main engine heat up water.

• Burner cuts in if engine slows down/ steam

pressure falls. Hence during long hours of

maneuvring, boiler is set on ‘Auto’.

• The steam produced is led off through a main

steam stop valve for auxiliary services.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 10 of 21

ED 2017/ REV. 0

Superheated Steam

• If dry saturated

steam is further

heated at constant

pressure, its

temperature

increases.

• Thus it stores more Fig 5

energy without

increasing the boiler

scantlings.

• Allowing it to perform more work on– turbines.

• The onset of condensation is also delayed, the

steam having to drop to the evaporation temperature

corresponding to the pressure.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 11 of 21

Superheater

ED 2017/ REV. 0

Construction:

• Header type water tube

boiler’s Superheater consist

of a series of U-tubes,

expanded and bell-mouthed

into two separate cylindrical/

rectangular section, forged

steel headers. Fig 6

• Headers distribute steam to the superheater tubes

and direct it from the inlet to outlet piping. These

both either vertically or horizontally mounted.

• The super heater tubes in the case of the Inter deck

type, are carried by superheat support tubes.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 12 of 21

Superheater

ED 2017/ REV. 0

• Super heater in a

D-type Boiler

• The super heater

tubes, Ф 32- 38 mm

are supported by

means of

transverse support

plates.

Fig 7

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 13 of 21

Superheater

ED 2017/ REV. 0

• Internal baffles are

welded inside headers,

so steam makes the

required number of

passes through the gas Fig 8

stream.

Position-orientation of Superheater:

• Placed out of the gas stream, to one side of the

boiler, in a plane parallel to the inclined generating

tube bank.

• It’s tubes project horizontally across the gas stream,

being placed at right angles to the generating tubes.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 14 of 21

Attemperator

ED 2017/ REV. 0

They are fitted to keep the steam temperature in final

stages of the superheater within certain desired

limits.

This is done for two main reasons:

1. Most important protection of the super heater

tube material from the effects of overheating.

Steam temperature governs the tube metal

surface temperature rather than the temperature

of the gas flowing over them .

Example: Mild Steel superheater tubes should not

be subjected to steam temperatures in excess of

455°C.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 15 of 21

Attemperator

ED 2017/ REV. 0

2. Secondly, formation of bonded deposits on

superheater tubes can be reduced if steam and

gas streams within certain temperature ranges are

prevented from coming into contact with each

other.

• Two basic types of Attemperators are available:

– Water cooled

– Air cooled

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 16 of 21

Water cooled Attemperator

ED 2017/ REV. 0

• These are constructed in a manner similar to that of

a surface type de-super heater.

• Placed below the water level in the steam drum. Or,

• As an alternative , placed in an external chamber

connected by balance connections to the

circulation circuit of the boiler.

Fig 9

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 17 of 21

Water cooled Attemperator

ED 2017/ REV. 0

• With this type, some of the steam leaving the

primary super heater passes directly to the

secondary super heater , while the remainder

passes through the attemperator before rejoining

the rest of the steam to enter the secondary super

heater.

• Control valves, fitted to the steam line leaving the

primary superheater, regulate the final superheat

temperature by varying the proportion of steam

flowing direct to the secondary super heater to

that passing to it via the attemperator.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 18 of 21

Air cooled Attemperator

ED 2017/ REV. 0

• Usually fitted

in the double

casing of the

boiler, consists

of inlet and

outlet headers

connected

together by a

series of multi-

loop tube

elements. Fig 10

• Enables superheated steam to make several passes

across the path of combustion air flowing to furnace.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 19 of 21

Air cooled Attemperator

ED 2017/ REV. 0

• Here steam leaving the primary superheater passes

through the attemperator before entering the

secondary superheater.

• Final steam temperature is obtained by regulating

the amount of combustion air flowing over

attemperator through control dampers & air by-pass.

• Air cooled is much larger than a corresponding

water cooled type due to poor heat exchange

efficiency between the air and steam.

• Reduction in size possible if finned tubes used.

• A steam air heater is usually fitted to heat the by-

passed combustion air.

APPLIED RESEARCH INTERNATIONAL MEM 1 : Design of Marine Machinery Slide No. 20 of 21

ED 2017/ REV. 0

Thank You

APPLIED RESEARCH INTERNATIONAL MEM 22 : Diesel Engine Control and Safety Slide No. 21 of 21

You might also like

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Thermal Power Plant Offsite: Krishnamohan Marpina Manager - OperationDocument107 pagesThermal Power Plant Offsite: Krishnamohan Marpina Manager - OperationPrakash PatelNo ratings yet

- CH-14 Design Fundamentals of BoilerDocument15 pagesCH-14 Design Fundamentals of BoilerRavi ShankarNo ratings yet

- Boiler Construction Part-1Document130 pagesBoiler Construction Part-1tareas1978100% (2)

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- PPN 2018 - Clase 19 - Calderas Parte 3 PDFDocument43 pagesPPN 2018 - Clase 19 - Calderas Parte 3 PDFJuan Cruz TauterysNo ratings yet

- Circulating Fluidized Bed Boilers: Design and OperationsFrom EverandCirculating Fluidized Bed Boilers: Design and OperationsRating: 4.5 out of 5 stars4.5/5 (6)

- Thermal Engineering Unit-IiDocument67 pagesThermal Engineering Unit-IiAyush SinghalNo ratings yet

- Boiler With Mountings and AccessoriesDocument67 pagesBoiler With Mountings and AccessoriesYashvir Singh100% (1)

- Vacuum SystemDocument49 pagesVacuum Systemssmith2007100% (3)

- 12-Design Fundamentals of BoilerDocument12 pages12-Design Fundamentals of BoilerVishalVaishNo ratings yet

- Steam Boilers, MountingsDocument63 pagesSteam Boilers, Mountingsswarg patelNo ratings yet

- Boilers and Steam GenerationDocument86 pagesBoilers and Steam GenerationArzo KhanNo ratings yet

- Designing of A Fire Tube Boiler: Author Name/sDocument7 pagesDesigning of A Fire Tube Boiler: Author Name/sMohit JagtapNo ratings yet

- Fossil Fuel Steam GeneratorDocument33 pagesFossil Fuel Steam Generatorchaiya sonwongNo ratings yet

- Basic Design Concepts of Industrial Plants System and EquipmentDocument30 pagesBasic Design Concepts of Industrial Plants System and EquipmentEam EvieNo ratings yet

- Department of Collegiate and Technical Education: Unit 2: Steam BoilersDocument38 pagesDepartment of Collegiate and Technical Education: Unit 2: Steam BoilersItha veeranjaneyuluNo ratings yet

- Week 8 - Steam and BoilersDocument29 pagesWeek 8 - Steam and BoilersSandino Michael Angelo AguilarNo ratings yet

- BoilerDocument7 pagesBoilerKunal SupekarNo ratings yet

- Amna-1Document25 pagesAmna-1Amna liaquatNo ratings yet

- Atd Boilers Unit-4Document78 pagesAtd Boilers Unit-4Solanki YagnikNo ratings yet

- For BoilerDocument71 pagesFor BoilerSonal PotdarNo ratings yet

- 1.1 Background of The Project 1.2 Problem Statement 1.3 Objectives of The Project 1.4 Project ScopeDocument21 pages1.1 Background of The Project 1.2 Problem Statement 1.3 Objectives of The Project 1.4 Project ScopeAbdi samad MohamedNo ratings yet

- UntitledDocument46 pagesUntitledBuriro HayatNo ratings yet

- Boilersand Steam GenerationDocument86 pagesBoilersand Steam GenerationUyen LeNo ratings yet

- CondenserDocument33 pagesCondenserSatyam KumarNo ratings yet

- Industrial Boilers Our Objective: To Describe and Explain The Boilers' Functions and The Two MainDocument33 pagesIndustrial Boilers Our Objective: To Describe and Explain The Boilers' Functions and The Two MainKhairulNo ratings yet

- THERMAL-1 Experiment 1 Part ADocument7 pagesTHERMAL-1 Experiment 1 Part Anishith ranaNo ratings yet

- Boiler Power Plant PDFDocument91 pagesBoiler Power Plant PDFRejaul AnsaryNo ratings yet

- Power Plant: CondensersDocument7 pagesPower Plant: CondensersMustafam98No ratings yet

- Experiment No. 2: Page 1 of 7Document7 pagesExperiment No. 2: Page 1 of 7Kunal SupekarNo ratings yet

- Chapter 4 BoilerDocument66 pagesChapter 4 BoilerAnonymous YSdtimxAbNo ratings yet

- COE Phase 2 Partial Requirement: Operation and Maintenance of BoilersDocument11 pagesCOE Phase 2 Partial Requirement: Operation and Maintenance of BoilersMico CampoNo ratings yet

- Chap 31 PDFDocument14 pagesChap 31 PDFnelson escuderoNo ratings yet

- Applied Thermal Engineering: Unit - 1: Steam GeneratorsDocument30 pagesApplied Thermal Engineering: Unit - 1: Steam Generatorsnitya santoshNo ratings yet

- Experiment One-To Study The Cochran and Babcock and Wilcox BoilersDocument8 pagesExperiment One-To Study The Cochran and Babcock and Wilcox BoilersHasib IslamNo ratings yet

- Basic Boiler Construction: Front Fired Studded Wall Refractory Covered BoilerDocument12 pagesBasic Boiler Construction: Front Fired Studded Wall Refractory Covered BoilerAnand JinoNo ratings yet

- Steam Generators (EEE)Document39 pagesSteam Generators (EEE)RakibNo ratings yet

- Mechanical BoilersDocument26 pagesMechanical BoilersaymanNo ratings yet

- ME-321 Steam GeneratorDocument51 pagesME-321 Steam Generatormuhammad umarNo ratings yet

- Steam BoilersDocument43 pagesSteam BoilersHolly CrossNo ratings yet

- Boiler 1Document44 pagesBoiler 1Emmanuel AyisiNo ratings yet

- Basic Mechanical Engineering Lab Manual: April 2011Document34 pagesBasic Mechanical Engineering Lab Manual: April 2011ankit trivediNo ratings yet

- Department of Collegiate and Technical Education: Unit 2: Steam BoilersDocument38 pagesDepartment of Collegiate and Technical Education: Unit 2: Steam BoilerscacaNo ratings yet

- Steam CondensersDocument32 pagesSteam CondensersaadhithyarajasekaranNo ratings yet

- BoilerDocument109 pagesBoilerArijit Debroy100% (6)

- Tank Heating DiscussionsDocument26 pagesTank Heating DiscussionsTHERMAX007No ratings yet

- Flow Regime: - Heat Ex Performance Failure (Counter Flow Check)Document30 pagesFlow Regime: - Heat Ex Performance Failure (Counter Flow Check)Ahmed AymanNo ratings yet

- Vacuum SystemDocument25 pagesVacuum SystemIntelligence News BureauNo ratings yet

- Heat ExchangerDocument37 pagesHeat Exchangerdhairya1725100% (5)

- EPT REPORT 1 (Group Izza)Document15 pagesEPT REPORT 1 (Group Izza)yj55jzhdn9No ratings yet

- Basic Mechanical Engineering Lab Manual: April 2011Document34 pagesBasic Mechanical Engineering Lab Manual: April 2011Pradyot DeoliaNo ratings yet

- Fire Water Tube BoilerDocument12 pagesFire Water Tube BoilerFatma HelalNo ratings yet

- Assignment On BoilerDocument26 pagesAssignment On BoilerARKONo ratings yet

- BoilersDocument38 pagesBoilersAshlin Augusty92% (24)

- Power Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)Document28 pagesPower Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)نهاد نهادNo ratings yet

- In Simple A Boiler May Be Defined As A Closed Vessel in Which Steam Is Produced From Water by Combustion of FuelDocument9 pagesIn Simple A Boiler May Be Defined As A Closed Vessel in Which Steam Is Produced From Water by Combustion of FuelJomari Tobes SatorreNo ratings yet

- Ship-Tug InteractionDocument4 pagesShip-Tug InteractionAkash KandwalNo ratings yet

- ESP CodeDocument7 pagesESP CodeAkash KandwalNo ratings yet

- Girting of TugDocument4 pagesGirting of TugAkash KandwalNo ratings yet

- Meg 5-LF-37 Aux Steam TurbinesDocument36 pagesMeg 5-LF-37 Aux Steam TurbinesAkash KandwalNo ratings yet

- Meg 5-LF-38-39 Boiler and Turbine Defects and RepairDocument42 pagesMeg 5-LF-38-39 Boiler and Turbine Defects and RepairAkash KandwalNo ratings yet

- Contingency PlanningDocument18 pagesContingency PlanningAkash KandwalNo ratings yet

- Meg 5-LF-35-36 Aux Steam SystemDocument23 pagesMeg 5-LF-35-36 Aux Steam SystemAkash KandwalNo ratings yet

- The Pivot Point - ARHDocument3 pagesThe Pivot Point - ARHAkash KandwalNo ratings yet

- Meg 5-LF-33 Operation Surveillance and AssessmentDocument65 pagesMeg 5-LF-33 Operation Surveillance and AssessmentAkash KandwalNo ratings yet

- Main Differences Between Hague N Visby & Hamburg Rules-ARHDocument5 pagesMain Differences Between Hague N Visby & Hamburg Rules-ARHAkash KandwalNo ratings yet

- Noida MMDDocument9 pagesNoida MMDAkash KandwalNo ratings yet

- Decision MakingDocument14 pagesDecision MakingAkash KandwalNo ratings yet

- Part A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves FurnacesDocument25 pagesPart A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves Furnacesfujiman35100% (1)

- Lesson 5 - Thermal Power PlantsDocument16 pagesLesson 5 - Thermal Power PlantsHafsa AlhaddabiNo ratings yet

- Questions and AnswersDocument22 pagesQuestions and AnswersMuhammad NasimNo ratings yet

- Emerging Industries 96 105 PDFDocument10 pagesEmerging Industries 96 105 PDFglisoNo ratings yet

- Boiler Safety Checklist &Document185 pagesBoiler Safety Checklist &Steve WanNo ratings yet

- Biasi Wood and Coal Boiler BrochureDocument2 pagesBiasi Wood and Coal Boiler Brochuree-ComfortUSANo ratings yet

- Marine Study: Coc Oral Exam Preparation (Part-5) - BoilerDocument8 pagesMarine Study: Coc Oral Exam Preparation (Part-5) - BoilerSalwan ShubhamNo ratings yet

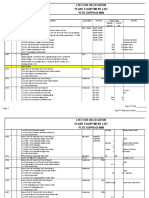

- Priced Bill of Quantities: Boq Mechanical InstalationDocument8 pagesPriced Bill of Quantities: Boq Mechanical InstalationHayri Bahadır UzunoğluNo ratings yet

- Marcyrl 8662 (Offer)Document51 pagesMarcyrl 8662 (Offer)Mina Maher MikhailNo ratings yet

- TERMOHIDRAULIKA CEVNIH SISTEMA KOTLOVA NA BLOKOVIMA B1 I B2 TERMOELEKTRANE „NIKOLA TESLA B” _ THERMALHYDRAULICS OF TUBE SYSTEMS IN STEAM BOILERS AT UNITS B1 AND B2 OF THERMAL POWER PLANT „NIKOLA TESLA B“Document10 pagesTERMOHIDRAULIKA CEVNIH SISTEMA KOTLOVA NA BLOKOVIMA B1 I B2 TERMOELEKTRANE „NIKOLA TESLA B” _ THERMALHYDRAULICS OF TUBE SYSTEMS IN STEAM BOILERS AT UNITS B1 AND B2 OF THERMAL POWER PLANT „NIKOLA TESLA B“Nikola MilovanovićNo ratings yet

- Experiment No. 1-To Study Cochran and Babcock and Wilcox BoilersDocument8 pagesExperiment No. 1-To Study Cochran and Babcock and Wilcox BoilersFerdaus Hasan BappiNo ratings yet

- Shuaiba North HRSG ManualDocument91 pagesShuaiba North HRSG Manualmartinp17171100% (7)

- PMDDocument1 pagePMDJesse OhNo ratings yet

- 2m Dev BrochureDocument2 pages2m Dev BrochureXandria Jane PerelloNo ratings yet

- Power Boilers-A Guide To Section I of The Asme Bpvc-2nd Ed.-2011Document332 pagesPower Boilers-A Guide To Section I of The Asme Bpvc-2nd Ed.-2011hainguyenbkvhv100% (6)

- Coaching 150 PipeDocument150 pagesCoaching 150 Piperobert carbungcoNo ratings yet

- 5000 TCD Sugar Plant 35 MW Co-Generation Power Plant Along With 80 KLPD DistilleryDocument24 pages5000 TCD Sugar Plant 35 MW Co-Generation Power Plant Along With 80 KLPD DistilleryServinorca, C.A.No ratings yet

- Material Balances Ethylene Oxide Production: O H C O H C O H CO O H CDocument26 pagesMaterial Balances Ethylene Oxide Production: O H C O H C O H CO O H CmoheedNo ratings yet

- LE4 PracticeDocument2 pagesLE4 PracticeLester Jason T. ChengNo ratings yet

- Industrial SafetyDocument180 pagesIndustrial SafetyvinodNo ratings yet

- Chapter VII Boiler Operation (Compatibility Mode)Document13 pagesChapter VII Boiler Operation (Compatibility Mode)Kiên GiangNo ratings yet

- Eme MCQ Question Bank: B) Work Is Done by The SystemDocument10 pagesEme MCQ Question Bank: B) Work Is Done by The Systemvims1248993No ratings yet

- PLTD Suppa Equipment List For Relokasi Review Rev1Document112 pagesPLTD Suppa Equipment List For Relokasi Review Rev1'PeRsona NoUn GraTa'No ratings yet

- Satyendra ' S ReportDocument24 pagesSatyendra ' S ReportSatyendra Singh100% (1)

- Thermal Power PlantDocument15 pagesThermal Power PlantAnonymous HyOfbJ6100% (1)

- Power Generation ProcessDocument8 pagesPower Generation ProcessIndra PanchalNo ratings yet

- Power Plant Operation Turbine & Auxiliaries: 8 January 2013 H K Sethi 1Document43 pagesPower Plant Operation Turbine & Auxiliaries: 8 January 2013 H K Sethi 1rohit_0123100% (2)

- 01 Asme Seci Index 04Document7 pages01 Asme Seci Index 04ManuelNo ratings yet

- Furnace 01490Document83 pagesFurnace 01490JKKNo ratings yet

- Wartsilla Power Plant 6.3MW X 3Document38 pagesWartsilla Power Plant 6.3MW X 3Cvita CvitićNo ratings yet