Professional Documents

Culture Documents

S R - Poster

Uploaded by

Elbanhawy4EverOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S R - Poster

Uploaded by

Elbanhawy4EverCopyright:

Available Formats

Computational model to predict the pressure change

inside a pressure cooker

Priyadarshini S R, K. S Yoha, Moses JA, Anandharamakrishnan C*

Computational Modeling and Nano Scale Processing Unit,

*Indian Institute of Food Processing Technology (IIFPT),Ministry of Food Processing Industries, Government of India,

Pudukkottai Road, Thanjavur- 613005, Tamil Nadu, India

*anandharamakrishnan@iifpt.edu.in

Introduction: Results: The model estimated a

•A conventional domestic pressure cooker maximum pressure inside the pressure

is a sealed vessel which uses an external cooker of about 0.098 MPa when the

heat source that can maintain pressure cooking time reached 10 minutes.

approximately up to 0.1 MPa.

•The cooking time and pressure

distribution pattern during cooking is

essential for the selection of operating

conditions of the equipment.

•A computational model was developed to

predict the pressure distribution during the

cooking process.

a b

Computational Methods: The unsteady Figure 2. Pressure distribution pattern after 10 minutes

a) 3D view b) top view

equations for fluid flow was solved using the

finite element method

Figure 3 . Time dependant pressure profile

Conclusion: The predicted values from

the model helps in selection of operating

conditions for the cooking process

Reference:

Rocca-Poliméni, R., Flick, D., & Vasseur, J. (2011). A model of

heat and mass transfer inside a pressure cooker. Journal of

Figure 1.Pressure cooker geometry Food Engineering, 107(3-4), 393-404.

Acknowledgement:

This work was funded by Science and Engineering Research

Board (SERB), Government of India

You might also like

- Mark Vie Controller: Standard Block LibraryDocument287 pagesMark Vie Controller: Standard Block LibraryImad BouchaourNo ratings yet

- 5.eng-Parametric Analysis of Kerosene Pressure Cooker ADocument8 pages5.eng-Parametric Analysis of Kerosene Pressure Cooker AImpact JournalsNo ratings yet

- HP Heater Tube LKG CauseDocument4 pagesHP Heater Tube LKG CauseDebabrata GhoshNo ratings yet

- Simulation Study of LPG Cooking BurnerDocument3 pagesSimulation Study of LPG Cooking BurnerBensinghdhas Sathiya Dhas100% (1)

- Oop Lab ManualDocument12 pagesOop Lab ManualVijay T100% (1)

- Mcp401 Report 3 Team 2dDocument16 pagesMcp401 Report 3 Team 2dRakesh SharmaNo ratings yet

- Mcp401 Report-3 Template v1Document19 pagesMcp401 Report-3 Template v1Rakesh SharmaNo ratings yet

- Optimization and Control of Pressure Swing Adsorption SystemsDocument7 pagesOptimization and Control of Pressure Swing Adsorption SystemsKatiaPeraltaNo ratings yet

- Amasado PDFDocument13 pagesAmasado PDFDiego AlfredoNo ratings yet

- CFD Simulation of A Co-Rotating Twin-Screw Extruder: Validation of A Rheological Model For A Starch-Based Dough For Snack FoodDocument7 pagesCFD Simulation of A Co-Rotating Twin-Screw Extruder: Validation of A Rheological Model For A Starch-Based Dough For Snack FoodMuscalu GheorgheNo ratings yet

- Journal of Food Engineering: Si Zhu, Bing Li, Guibing ChenDocument10 pagesJournal of Food Engineering: Si Zhu, Bing Li, Guibing ChenYaniNo ratings yet

- Temperature Prediction For Reheating Furnace by Gated Recurrent Unit ApproachDocument8 pagesTemperature Prediction For Reheating Furnace by Gated Recurrent Unit ApproachRodrigo LimaNo ratings yet

- Dsign FornosDocument10 pagesDsign Fornosjhony telekenNo ratings yet

- Design and Scaling of Wheat Dough Extrusion by Numerical Simulation of Ow and Heat TransferDocument10 pagesDesign and Scaling of Wheat Dough Extrusion by Numerical Simulation of Ow and Heat TransferJose perezNo ratings yet

- Validation of Plate Heat Exchanger Design Using CFDDocument9 pagesValidation of Plate Heat Exchanger Design Using CFDTUTUNo ratings yet

- Influenceof Rest Periodand Confinement Pressureonthe Measurementof Dynamic Modulusof Bituminous MixturesDocument8 pagesInfluenceof Rest Periodand Confinement Pressureonthe Measurementof Dynamic Modulusof Bituminous MixturesGianfranco PellicanoNo ratings yet

- TribunaloLo Ex#6Document14 pagesTribunaloLo Ex#6Jaylou OpondaNo ratings yet

- Smart Mold: Real-Time In-Cavity Data AcquisitionDocument8 pagesSmart Mold: Real-Time In-Cavity Data AcquisitionSơn NgưuNo ratings yet

- Food Control: Bouchra Lamrini, Guy Della Valle, Ioan Cristian Trelea, Nathalie Perrot, Gilles TrystramDocument13 pagesFood Control: Bouchra Lamrini, Guy Della Valle, Ioan Cristian Trelea, Nathalie Perrot, Gilles TrystramEvelyn AmorimNo ratings yet

- TSD 02 PDFDocument5 pagesTSD 02 PDFgeetanjaliNo ratings yet

- Pencel Pressuremeter Testing To Determining P-Y Curves For Laterally Loaded Deep FoundationsDocument14 pagesPencel Pressuremeter Testing To Determining P-Y Curves For Laterally Loaded Deep FoundationsMaira Alessandra ChaparroNo ratings yet

- Dhanasekharan 2000Document11 pagesDhanasekharan 2000Vicky PolychronidouNo ratings yet

- A Case Study On Cooling Load Calculation For Lecture Halls (First Floor) of Engineering InstituteDocument5 pagesA Case Study On Cooling Load Calculation For Lecture Halls (First Floor) of Engineering InstituteSarath Philip Mathew VenkadathNo ratings yet

- Energy Efficiency Analysis of An Entire Ceramic KilnDocument8 pagesEnergy Efficiency Analysis of An Entire Ceramic Kilnduyen nguyen chi luongNo ratings yet

- Boiler Efficiency Monitoring and Boiler Losses Analysis: A ReviewDocument4 pagesBoiler Efficiency Monitoring and Boiler Losses Analysis: A ReviewaliNo ratings yet

- CFD Drying SimulationDocument6 pagesCFD Drying SimulationAdonis A. ClosasNo ratings yet

- Laporan Draft wK6Document16 pagesLaporan Draft wK6Anthony Kurnia JayaNo ratings yet

- Simulation of Blow Molding Using Ansys PolyflowDocument6 pagesSimulation of Blow Molding Using Ansys PolyflowAnonymous PufNjgNo ratings yet

- Research Article: Design of Intelligent Self-Tuning GA ANFIS Temperature Controller For Plastic Extrusion SystemDocument8 pagesResearch Article: Design of Intelligent Self-Tuning GA ANFIS Temperature Controller For Plastic Extrusion SystemOmprakash VermaNo ratings yet

- Ijet 16257Document3 pagesIjet 16257Gayathri VenkatNo ratings yet

- JHE 21 1 043 046 2007 1545 Kishtwaria J TTDocument4 pagesJHE 21 1 043 046 2007 1545 Kishtwaria J TTShreef EntsarNo ratings yet

- Simulation of Blow Molding Using Ansys PolyflowDocument7 pagesSimulation of Blow Molding Using Ansys PolyflowDANISHPREET SINGHNo ratings yet

- J Buildenv 2006 04 027Document6 pagesJ Buildenv 2006 04 027Yetana WubnehNo ratings yet

- Integrated Kitchen Design and Optimization Based On The Improved Particle Swarm Intelligent AlgorithmDocument12 pagesIntegrated Kitchen Design and Optimization Based On The Improved Particle Swarm Intelligent AlgorithmAnnihilationNo ratings yet

- The Use of Solar Thermal Systems in Piglet NurseriesDocument7 pagesThe Use of Solar Thermal Systems in Piglet NurseriesViktor ErdélyiNo ratings yet

- Analytical Solution of 1-D Multilayer Heat Conduction Problem With Time Varying AmbientsDocument9 pagesAnalytical Solution of 1-D Multilayer Heat Conduction Problem With Time Varying Ambientslolopopo28No ratings yet

- Dimensional AnalysisDocument20 pagesDimensional AnalysisKhiara Claudine EspinosaNo ratings yet

- 1 s2.0 S0360544217318947 MainDocument9 pages1 s2.0 S0360544217318947 MainDr.Chakrit MEMUNo ratings yet

- Characteristics Air Flow in Room Chamber Test Refrigerator Household Energy Consumption With Inlet Flow VariationDocument8 pagesCharacteristics Air Flow in Room Chamber Test Refrigerator Household Energy Consumption With Inlet Flow VariationEdy MesinNo ratings yet

- 1 s2.0 S2214157X22004452 MainDocument13 pages1 s2.0 S2214157X22004452 MainONo ratings yet

- Susanto 2018 IOP Conf. Ser. Mater. Sci. Eng. 316 012002 PDFDocument8 pagesSusanto 2018 IOP Conf. Ser. Mater. Sci. Eng. 316 012002 PDFEdy MesinNo ratings yet

- Exp2 Result ReportDocument10 pagesExp2 Result Report성제박No ratings yet

- Drying - Mass Transfer OperationDocument6 pagesDrying - Mass Transfer OperationShivani PatelNo ratings yet

- Flow Analysis of Intake Manifold Using Computational Fluid DynamicsDocument5 pagesFlow Analysis of Intake Manifold Using Computational Fluid DynamicserpublicationNo ratings yet

- Energy: Nathalie Cauchi, Karel Macek, Alessandro AbateDocument10 pagesEnergy: Nathalie Cauchi, Karel Macek, Alessandro AbateLuis ZambranoNo ratings yet

- Design, Fabrication and Performance Evaluation of Multipurpose Dryer (Room Heater)Document22 pagesDesign, Fabrication and Performance Evaluation of Multipurpose Dryer (Room Heater)sneha sahuNo ratings yet

- Design of Adaptive Pid Controller For Continuous Stirred Tank Heater (CSTH) ProcessDocument8 pagesDesign of Adaptive Pid Controller For Continuous Stirred Tank Heater (CSTH) ProcesssanthoshramrNo ratings yet

- Heat Transfer and Heating Rate of Food Stuffs in Commercial Shop OvensDocument10 pagesHeat Transfer and Heating Rate of Food Stuffs in Commercial Shop Ovensaziz ahmedNo ratings yet

- Jurnal Review Acara 1Document8 pagesJurnal Review Acara 1uswatun karimaNo ratings yet

- Model Based Controller With Internal Model Control (IMC) Which Tunning by Set Point and Disturbance On Power Plant Based HYSYSDocument2 pagesModel Based Controller With Internal Model Control (IMC) Which Tunning by Set Point and Disturbance On Power Plant Based HYSYSDoni SujanaNo ratings yet

- 10 1115@isec2003-44060 PDFDocument9 pages10 1115@isec2003-44060 PDFjorge ibañezNo ratings yet

- Measurement Quality and Uncertainty EvaluationDocument8 pagesMeasurement Quality and Uncertainty Evaluationحسام رسميNo ratings yet

- Setting The Processing Parameters in InjDocument8 pagesSetting The Processing Parameters in InjLuminita GeorgetaNo ratings yet

- Modeling of Temperature Distributions in Canned Tomato Based Dip During Industrial PasteurizationDocument7 pagesModeling of Temperature Distributions in Canned Tomato Based Dip During Industrial PasteurizationHugo GermaniNo ratings yet

- Mechanical Properties of S355 Under Extreme Coupled Effect of High Temperatures and High Strain RatesDocument8 pagesMechanical Properties of S355 Under Extreme Coupled Effect of High Temperatures and High Strain RatesCaline NunesNo ratings yet

- PRUKWARUN Et Al (2013) ArtigoDocument12 pagesPRUKWARUN Et Al (2013) ArtigoAndersonNo ratings yet

- Mems Bubble AccelDocument4 pagesMems Bubble AccelHua Hidari YangNo ratings yet

- Design and Testing of Thrust Measurement System For Rotary EngineDocument9 pagesDesign and Testing of Thrust Measurement System For Rotary EnginePepito PerezNo ratings yet

- AhnafFadhlurRahmanBinAwangHanib CB200143 T2 HOQDocument9 pagesAhnafFadhlurRahmanBinAwangHanib CB200143 T2 HOQAhnaf Fadhlur Rahman Bin Awang HanibNo ratings yet

- Designof Model Predictive Controllerfor Pasteurization ProcessDocument9 pagesDesignof Model Predictive Controllerfor Pasteurization ProcessMaman GocekNo ratings yet

- A Novel Method For Error Analysis in Radiation Thermometry With ApplicationDocument12 pagesA Novel Method For Error Analysis in Radiation Thermometry With ApplicationHaniele Santos RochaNo ratings yet

- Computer-Based Energy management systems: Technology and Applications: Technology and ApplicationsFrom EverandComputer-Based Energy management systems: Technology and Applications: Technology and ApplicationsNo ratings yet

- Bisceglia PosterDocument1 pageBisceglia PosterElbanhawy4EverNo ratings yet

- Intermittent Hypoxia Produces Alzheimer Disease?: Sosuke Yagishita and Akira HirasawaDocument2 pagesIntermittent Hypoxia Produces Alzheimer Disease?: Sosuke Yagishita and Akira HirasawaElbanhawy4EverNo ratings yet

- Second EditionDocument41 pagesSecond EditionElbanhawy4EverNo ratings yet

- Processes 09 00234 v3Document18 pagesProcesses 09 00234 v3Elbanhawy4EverNo ratings yet

- Energies 14 08503Document15 pagesEnergies 14 08503Elbanhawy4EverNo ratings yet

- Energies 16 02032Document14 pagesEnergies 16 02032Elbanhawy4EverNo ratings yet

- Sustainability 12 08990 v3Document25 pagesSustainability 12 08990 v3Elbanhawy4EverNo ratings yet

- 3CV.1.35 Paper 21st 2013Document11 pages3CV.1.35 Paper 21st 2013Elbanhawy4EverNo ratings yet

- Fullpdfenergies 14 06406Document14 pagesFullpdfenergies 14 06406Elbanhawy4EverNo ratings yet

- A Comprehensive Review of Renewable Energy Production From Biomass-Derived Bio-OilDocument16 pagesA Comprehensive Review of Renewable Energy Production From Biomass-Derived Bio-OilElbanhawy4EverNo ratings yet

- Original PaperDocument7 pagesOriginal PaperElbanhawy4EverNo ratings yet

- Auger Design For Uniform Unloading of Granular Material: I. Rectangular Cross-Section ContainersDocument7 pagesAuger Design For Uniform Unloading of Granular Material: I. Rectangular Cross-Section ContainersRobin RomarateNo ratings yet

- 11.2 Function Generation, Path Generation, AND Body GuidanceDocument1 page11.2 Function Generation, Path Generation, AND Body Guidanceg316281No ratings yet

- DC Transient Analysis Using SimulationDocument6 pagesDC Transient Analysis Using SimulationJanani RangarajanNo ratings yet

- Algebra: Addition and Subtraction Equations: Directions: Solve Each Equation. Show All Work in The Space ProvidedDocument26 pagesAlgebra: Addition and Subtraction Equations: Directions: Solve Each Equation. Show All Work in The Space ProvidedJen2sons100% (1)

- ML Geometry 3-3 Parallel Lines and TransversalsDocument7 pagesML Geometry 3-3 Parallel Lines and Transversalsmadhuraju778797No ratings yet

- Cs507 Quiz Solved #2Document18 pagesCs507 Quiz Solved #2Power GirlsNo ratings yet

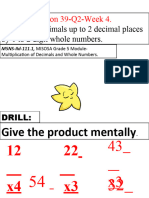

- Lesson 39 Multiplies Decimals Up To 2 Decimal Places by 1 To 2 Digit Whole Numbers.Document23 pagesLesson 39 Multiplies Decimals Up To 2 Decimal Places by 1 To 2 Digit Whole Numbers.Rugenie DomingoNo ratings yet

- Gopertz Growth Curve, Linear Co-EfficientDocument17 pagesGopertz Growth Curve, Linear Co-EfficientAmal DattaNo ratings yet

- My Final FileDocument54 pagesMy Final Fileharshit gargNo ratings yet

- Clusters and Semistable Models of Hyperelliptic Curves in The Wild CaseDocument84 pagesClusters and Semistable Models of Hyperelliptic Curves in The Wild CasenagiNo ratings yet

- Bacon Design of CitiespdfDocument18 pagesBacon Design of CitiespdfYounes AlamiNo ratings yet

- Lesson 3 Hypothesis Test Concerning MeansDocument30 pagesLesson 3 Hypothesis Test Concerning MeansMaimai PanaNo ratings yet

- Paper No 05 Edexcel PrimaryDocument13 pagesPaper No 05 Edexcel Primarymathsolutions.etcNo ratings yet

- OOP Java ArraysDocument60 pagesOOP Java ArraysIm Just A SimplexDNo ratings yet

- Full Test 04 - Test Paper (SOF IMO) - (PDF ONLY) - Mega Mock Test 9thDocument7 pagesFull Test 04 - Test Paper (SOF IMO) - (PDF ONLY) - Mega Mock Test 9thsatyamkeshari90807060No ratings yet

- Gen Physics 1 Wk3Document10 pagesGen Physics 1 Wk3Hannah Bianca RegullanoNo ratings yet

- Quantity Takeoff MethodDocument3 pagesQuantity Takeoff MethodPinoHellfrogNo ratings yet

- CorrectionDocument24 pagesCorrectionDeepa RameshNo ratings yet

- Rational Numbers RubricDocument1 pageRational Numbers Rubricapi-316929727No ratings yet

- BAerodynamics 1Document23 pagesBAerodynamics 1Charm YakuzaNo ratings yet

- OEE Calculation NorozionsDocument8 pagesOEE Calculation NorozionsNewhame DagneNo ratings yet

- IDEA LE Q2 Week 8Document4 pagesIDEA LE Q2 Week 8Pauline Erika CagampangNo ratings yet

- Math Sample Paper-1 (With Solutions)Document21 pagesMath Sample Paper-1 (With Solutions)Veeresh SavadiNo ratings yet

- Ortho PDFDocument1 pageOrtho PDFAlex OliveiraNo ratings yet

- Seawater Leaching of Caliche Mineral in Column ExperimentsDocument9 pagesSeawater Leaching of Caliche Mineral in Column ExperimentsCamila ContrerasNo ratings yet

- Maxwell's Relations PDFDocument12 pagesMaxwell's Relations PDFAsif MahmoudNo ratings yet

- 6th Semester SyllabusDocument20 pages6th Semester SyllabusVishal BhargavaNo ratings yet

- Data of CompilerDocument5 pagesData of CompilerramachandraNo ratings yet