Professional Documents

Culture Documents

Inert Gas System

Inert Gas System

Uploaded by

Mdshaji0 ratings0% found this document useful (0 votes)

2 views20 pagesIG System

Original Title

INERT GAS SYSTEM

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIG System

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views20 pagesInert Gas System

Inert Gas System

Uploaded by

MdshajiIG System

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 20

INERT GAS SYSTEM

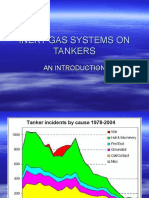

• INERT GAS means a gas or mixture of gases containing insufficient

oxygen to support combustion

• Inert condition means a condition in which the oxygen content

throughout the atmosphere of a controlled space has been

reduced to les than 8 % by volume

• Oil tankers carry oil of different grades and quality, having

property to produce flammable vapors and gases when

loaded for transportation. Even with no cargo on board, there

can be harmful flammable gases present in the hold. When

the vapor produced by an oil cargo is mixed with certain

concentration of air primarily containing oxygen, it can result

in exploison

FLAMABLE LIMITS

• A mixture of hydrocarbon gas and air cannot ignite unless its

composition lies with a range of gas in air concentration as

Flamable range

• The lower limit of this range is known as Lower Flamable Limit

is any hydrocarbon concentration below which there is insufficient

hydrocarbon gas to support combustion

The Upper limit of the range is known as Upper Flamable Limit

•

• When Inert Gas is added to hydrocarbon air /gas mixture the result

is to increase the lower flammable limit concentration and decrease

upper flammable limit concentration

• Methods of Gas replace ment- Inerting , Purging & Gas freeing

• Inerting means introduction of Inert Gas in to tank with the

object of attaining a condition in which the oxygen content

throughout the atmosphere has been reduced to 8 percent or less by

volume

FLAMABLE LIMITS

Sources of Inert Gas on Board

• Up take from Ships Main or Aux Boiler

• Independent Inert Gas Generator

• Gas turbine plant equipped with after burner

• Nitrogen Generators( Chemical Tanker)

• Gas freeing : Introduction of fresh air in to the tank with object of

toxic flammable and inert gases and increasing the oxygen content

to 21%

• Purging means introduction of inert gas in to a tank already in inert

condition with the object of Further reducing the existing oxygen

content and or Reducing the existing hydrocarbon gas content to a

level below which combustion cannot be supported if air is

subsequently introduced in to the tank

Scrubber

Inert Gas Blowers

• Blowers are used to deliver the scrubbed flue gas to cargo tanks

• At least two blowers shall be provided which together shall be

capable of delivering inert gas to cargo tanks at the rate of at least

125% maximum cargo discharge capacity

• Blower casing and impeller should be constructed using corrosion

resistant material

• Means should be provided for water washing to remove build up of

deposit

Non return Devices

• Regulation requires that the inert gas system is equipped

with two non-return devices, one of which shall be a water

seal, to prevent the return of hydrocarbon vapour to the gas-

safe spaces.

• The deck water seal and Mechanical non return valve

together form means of automatically preventing back flow

of cargo gases from the cargo tank to machinery space

Deck water seal

• The dry type deck water seal has an upper reservoir (drop tank) and a lower

reservoir (sealing tank). The flow of water from the drop tank to the sealing

tank and from the sealing tank to the overboard discharge is controlled

automatically via level sensors and other control equipment.

• The upper reservoir is filled with water at all times and supplies water to the

lower reservoir.

• The lower reservoir is empty during system operation (gas flowing to tanks)

and filled with water when the inert gas blower is shut down, either because

of normal stopping or because of automatic system shutdown activated by

off-design conditions. The filling and drainage of the upper and lower

reservoirs is triggered automatically by the sensing of levels in the sealing

tank and drop tanks, by the on/off status of the blowers or by the gas-to-tank

push button switch. The upper and lower reservoirs are usually equipped

with float-type level sensors.

Pressure Vaccum Breaker

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Nitric Acid ProductionDocument46 pagesNitric Acid Productionbotolwa80% (5)

- Carburettor PDFDocument20 pagesCarburettor PDFDeepak MehtaNo ratings yet

- Inert Gas SystemDocument9 pagesInert Gas Systemdj22500100% (3)

- IG SystemDocument29 pagesIG SystemAPURV YASHWARDHANNo ratings yet

- Inert Gas SystemDocument45 pagesInert Gas Systempiliyandalaleos100% (5)

- Change of Cargo Grades or Preparation For Drydock - LPG Tanker ProcedureDocument6 pagesChange of Cargo Grades or Preparation For Drydock - LPG Tanker ProcedureLukasz ZablockiNo ratings yet

- Sistema de Gas Inerte en InglesDocument18 pagesSistema de Gas Inerte en Inglespaola sotoNo ratings yet

- Inert Gas Systems FDocument66 pagesInert Gas Systems Fkumar100% (3)

- Unit - 5 IG SystemsDocument74 pagesUnit - 5 IG SystemsRagunath Palanichamy100% (1)

- Cargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureDocument8 pagesCargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureLukasz ZablockiNo ratings yet

- Crude Oil TankerDocument31 pagesCrude Oil TankerJoseph GraciousNo ratings yet

- Tank AtmosphereDocument28 pagesTank AtmosphereBhupender RamchandaniNo ratings yet

- Inert Gas On Board Tankers - All You Need To Know!Document11 pagesInert Gas On Board Tankers - All You Need To Know!Giorgi KandelakiNo ratings yet

- IG System 2Document17 pagesIG System 2Sergioi IndurainNo ratings yet

- IG SystemDocument23 pagesIG SystemMr. Nehal Solanki100% (2)

- Solutions: TankersDocument7 pagesSolutions: TankersKirtishbose ChowdhuryNo ratings yet

- Inert Gas SystemDocument3 pagesInert Gas Systemmehedi2636No ratings yet

- Type of OperationsDocument17 pagesType of OperationsEmil-Junior IordacheNo ratings yet

- Gas-Freeing For Cargo Tank EntryDocument6 pagesGas-Freeing For Cargo Tank EntryPanagiotis Mouzenidis100% (1)

- Inert Gas PresentationDocument17 pagesInert Gas PresentationRahmat RanggonangNo ratings yet

- Inert Gas System With Its Alarms and Trips Are Compulsory Safety Equipment On Oil Tankers Under SOLAS ConventionDocument5 pagesInert Gas System With Its Alarms and Trips Are Compulsory Safety Equipment On Oil Tankers Under SOLAS Conventionvihaan100% (1)

- IG SysDocument59 pagesIG SysSergioi Indurain100% (1)

- Inert Gas SystemDocument10 pagesInert Gas SystemAnonymous qwhZLv4OINo ratings yet

- Inert Gas SystemDocument13 pagesInert Gas SystemKaushal KumarNo ratings yet

- 1.6 Inert Gas SystemDocument8 pages1.6 Inert Gas SystemAbcdNo ratings yet

- Safety & Fire Safety and Fire Fighting OperationDocument81 pagesSafety & Fire Safety and Fire Fighting OperationD kuiNo ratings yet

- 1) What Is Crude Oil Washing and Its Purpose and Requirement ?Document20 pages1) What Is Crude Oil Washing and Its Purpose and Requirement ?Sujeet sharma100% (1)

- Marine Piping SystemDocument75 pagesMarine Piping SystemNguyễn Hoàng Thành100% (1)

- Crude Oil Tank CleaningDocument7 pagesCrude Oil Tank CleaningSandip Mahata100% (1)

- Inert Gas SystemDocument274 pagesInert Gas SystemReynante P. Consul100% (3)

- Chapter 3 - Emission ControlDocument38 pagesChapter 3 - Emission Controlmohamad fitri F2008No ratings yet

- Phase 1 - Tanker Notes As Per Syllabus & MMD PapersDocument59 pagesPhase 1 - Tanker Notes As Per Syllabus & MMD PapersJiby John Joseph100% (2)

- PART 2 of 2.01 INTERVIEW Вопросы-ответы v.2.01Document30 pagesPART 2 of 2.01 INTERVIEW Вопросы-ответы v.2.01Максим Романов100% (1)

- Change of Cargo Grades or Preparation For DrydockDocument3 pagesChange of Cargo Grades or Preparation For DrydockAlice Mano JiamaNo ratings yet

- Inert Gas SystemDocument9 pagesInert Gas Systemchristian popeNo ratings yet

- Boiler - FinalDocument73 pagesBoiler - FinalMohit GauttamNo ratings yet

- Otf CourseDocument324 pagesOtf Coursebandar almalkiNo ratings yet

- Publications PDF Petroleum FarmDocument3 pagesPublications PDF Petroleum FarmKuldeepsingh ChandelNo ratings yet

- Flare Gas Recovery Using Gas EjectorDocument8 pagesFlare Gas Recovery Using Gas Ejectoremmanuel limaNo ratings yet

- MIDSTREAMDocument28 pagesMIDSTREAMKhairul IrfanNo ratings yet

- Cargo Theory (2m)Document148 pagesCargo Theory (2m)manish singh negiNo ratings yet

- Oxygen SystemsDocument19 pagesOxygen SystemsSasi aeroNo ratings yet

- Cargo Tank Venting & Inert Gas System & EquipmentDocument64 pagesCargo Tank Venting & Inert Gas System & EquipmentferkmNo ratings yet

- Tank Truck Loading of Crude Oil or CondensateDocument4 pagesTank Truck Loading of Crude Oil or CondensateNakkolopNo ratings yet

- GT Gas Fuel and Air FlowDocument38 pagesGT Gas Fuel and Air Flowhina100% (1)

- DEAERATORDocument14 pagesDEAERATORHassan Faraz0% (1)

- LNG CARGO HANDLING EQUIPMENT (εργασία)Document22 pagesLNG CARGO HANDLING EQUIPMENT (εργασία)ΒΑΣΙΛΕΙΟΣ ΜΑΡΑΖΙΩΤΗΣNo ratings yet

- Oxygen 1Document61 pagesOxygen 1Vignesh DuraiNo ratings yet

- Perdidas de Produccion DesgasificacionDocument8 pagesPerdidas de Produccion DesgasificacionWil Vasquez CNo ratings yet

- Pnematic SystemDocument17 pagesPnematic SystemFaisal AwaisNo ratings yet

- Emission Control: Hydrocarbons (HC)Document18 pagesEmission Control: Hydrocarbons (HC)eldhopaul19894886No ratings yet

- 5 107 Vaporizers and DemisterDocument7 pages5 107 Vaporizers and DemisterLeonidas PetrouNo ratings yet

- Exogas™ Exothermic Generators: Product BulletinDocument9 pagesExogas™ Exothermic Generators: Product BulletinJhon ChitNo ratings yet

- Oil Tankers: Siddharth Sid' ChandrasekarDocument72 pagesOil Tankers: Siddharth Sid' ChandrasekarGermán Ruiz100% (1)

- Week 2Document33 pagesWeek 2Justin CaliguiaNo ratings yet

- Tanker OperationsDocument11 pagesTanker OperationsLynton MenezesNo ratings yet

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- EmergenciesDocument15 pagesEmergenciesMdshajiNo ratings yet

- PUMPSDocument20 pagesPUMPSMdshajiNo ratings yet

- Bil of LadingDocument61 pagesBil of LadingMdshajiNo ratings yet

- Ship RegistrationDocument24 pagesShip RegistrationMdshajiNo ratings yet

- Operational Activity: Port TypesDocument46 pagesOperational Activity: Port TypesMdshajiNo ratings yet

- IMO - The International Maritime Organization: The Organization Consists of An Assembly, A Council and Five MainDocument24 pagesIMO - The International Maritime Organization: The Organization Consists of An Assembly, A Council and Five MainMdshajiNo ratings yet

- Indian Maritime UniversityDocument3 pagesIndian Maritime UniversityMdshajiNo ratings yet

- PF CalculatorDocument3 pagesPF CalculatorMdshajiNo ratings yet

- NatConv Chap7Document20 pagesNatConv Chap7MdshajiNo ratings yet

- Maternity Benifit ActDocument9 pagesMaternity Benifit ActMdshajiNo ratings yet

- Gratuity ActDocument11 pagesGratuity ActMdshajiNo ratings yet

- Important Facts About PM Svanidhi For UpscDocument2 pagesImportant Facts About PM Svanidhi For UpscMdshajiNo ratings yet

- Sarva Shiksha Abhiyan SSADocument4 pagesSarva Shiksha Abhiyan SSAMdshajiNo ratings yet

- Maternitybenifit ActDocument20 pagesMaternitybenifit ActMdshajiNo ratings yet

- FAQs IPMDocument2 pagesFAQs IPMMdshajiNo ratings yet

- Edexcel A Biology A-Level: Core Practical 3Document4 pagesEdexcel A Biology A-Level: Core Practical 3htbfdgNo ratings yet

- Iwaki Chemical ResistanceDocument16 pagesIwaki Chemical ResistanceBenjamin MillerNo ratings yet

- Waste Incineration TechnologyDocument22 pagesWaste Incineration TechnologyJoao MinhoNo ratings yet

- 03-SOLID STATE-Solution-Final-EDocument5 pages03-SOLID STATE-Solution-Final-EAmit BansalNo ratings yet

- 523V Pressure Vacuum Vent PDFDocument1 page523V Pressure Vacuum Vent PDFBaraka LetaraNo ratings yet

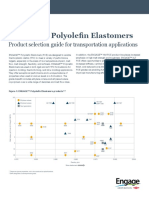

- 777 088 01 Engage Polyolefin Elastomer Product Selection GuideDocument4 pages777 088 01 Engage Polyolefin Elastomer Product Selection GuideAparesh GantaitNo ratings yet

- Alkaline Water Stomach Acid DR Jerry TennantDocument2 pagesAlkaline Water Stomach Acid DR Jerry TennantCesar OrantesNo ratings yet

- Pengaruh Suhu Terhadap Laju ReaksiDocument22 pagesPengaruh Suhu Terhadap Laju Reaksiayrajiu alexanderNo ratings yet

- Distillation of Prunella Vulgaris Paper1vs7 - SeanDocument24 pagesDistillation of Prunella Vulgaris Paper1vs7 - SeanWilson MakNo ratings yet

- 6 Buffer Zones FINAL RGK V2Document4 pages6 Buffer Zones FINAL RGK V2Moses AyoadeNo ratings yet

- The Objective of This Project Is To Study of Effect of Potassium Bisulphite As A Food Preservative Under Various ConditionsDocument11 pagesThe Objective of This Project Is To Study of Effect of Potassium Bisulphite As A Food Preservative Under Various ConditionsTee BeeNo ratings yet

- 17-Superheated Water ExtractionDocument43 pages17-Superheated Water ExtractionJayanath Nuwan SameeraNo ratings yet

- Layout of A Conventional Water Treatment Location of Treatment PlantsDocument6 pagesLayout of A Conventional Water Treatment Location of Treatment PlantsSajil KrishnaNo ratings yet

- MFL47317017 LG LFX25975ST Refrigerator Service Manual PDFDocument53 pagesMFL47317017 LG LFX25975ST Refrigerator Service Manual PDFRick EvansNo ratings yet

- Class 12 Chemistry PracticalDocument21 pagesClass 12 Chemistry PracticalAnand YadavNo ratings yet

- Cumin (Cuminum Cyminum L.) From Traditional Uses To Potential PDFDocument10 pagesCumin (Cuminum Cyminum L.) From Traditional Uses To Potential PDFRabeea NasirNo ratings yet

- M3 Chemistry CSE Stream VDocument48 pagesM3 Chemistry CSE Stream Vayushsingh102005No ratings yet

- Assessment of Removal of Nitrate by Water Using Mosambi Peel Powder As AdsorbentDocument3 pagesAssessment of Removal of Nitrate by Water Using Mosambi Peel Powder As AdsorbentSakkeer A VNo ratings yet

- DLL - Science 3 - Q1 - W6Document3 pagesDLL - Science 3 - Q1 - W6Vonne Denesse MaganteNo ratings yet

- Cat Code Item Description Electrical Items & Spares: Oscom Chavara Manavalakuruchi REDDocument18 pagesCat Code Item Description Electrical Items & Spares: Oscom Chavara Manavalakuruchi REDManishDwivediNo ratings yet

- 1 s2.0 S0016236122017471 MainDocument26 pages1 s2.0 S0016236122017471 Mainhadush2002No ratings yet

- Kanepox Masticoat: 15550 KANEPOX MASTICOAT Is An Epoxy-Polyamine Based, Two Component, Zinc PhosphateDocument3 pagesKanepox Masticoat: 15550 KANEPOX MASTICOAT Is An Epoxy-Polyamine Based, Two Component, Zinc PhosphateSalih HASNo ratings yet

- Stain Removal Effect of Novel Papain-And Bromelain-Containing Gels Applied To EnamelDocument6 pagesStain Removal Effect of Novel Papain-And Bromelain-Containing Gels Applied To EnamelSultanPatuahonPanggabeanNo ratings yet

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- Integrated Science 2020Document7 pagesIntegrated Science 2020Jâmãçy BräthwåítèNo ratings yet

- Lesson 1 Introduction To Materials Science and EngineeringDocument33 pagesLesson 1 Introduction To Materials Science and EngineeringJone Zelita Culanculan Orlina100% (1)

- CEPE Inventory ListDocument153 pagesCEPE Inventory Listjai soniNo ratings yet

- Nippon Vinilex 2000 PDFDocument7 pagesNippon Vinilex 2000 PDFRezka RamindaNo ratings yet

- Thermal Oxidizer Technology SheetDocument1 pageThermal Oxidizer Technology SheetadrianioantomaNo ratings yet

- Assorted Practice Test 2Document11 pagesAssorted Practice Test 2Khánh Huyền NguyễnNo ratings yet