Professional Documents

Culture Documents

T-Shirt Operation Breakdown

Uploaded by

ArnavpaitandyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T-Shirt Operation Breakdown

Uploaded by

ArnavpaitandyCopyright:

Available Formats

Operation Breakdown

of a T-shirt

Paper:

Garment Manufacturing Technology

Faculty:

Ms. Garima Srivastava

Submitted by:

Akansha Choudhary | MFM, Sem 1, 03

Anurodh Agnihotri | MFM, Sem 1, 05

Arnav Paitandy | MFM, Sem 1, 06

Natasha Dhawan | MFM, Sem 1, 16

National Institute of Fashion technology, Mumbai

November, 2008

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

T-shirts are multi-functional garment worn by all age groups as innerwear and outerwear. They are simply

constructed garments that consist of a front and a back, sleeves and a neckline. A few styles may also have

pockets. Many styles are now considered unisex.

Fashion maybe reflected in oversize styling, deep armhole, cutoff lengths and fitted body. Seasonal changes in T-

shirts maybe reflected in sleeve length, color and fabric weight. Reversible T-shirts may be made with two layers

of fabric. Plain T-shirts are often referred to as Blanks for the imprint market. Printed T-shirt, which appeal to

both males and females, provide humor, ideas or interests. They provide identity through screen printed or heat

transfer applications of lettering, logos and licensed designs. Designs provide intrinsic appeal beyond the

intrinsic value of the garment.

SIZING AND FIT

T-shirts are produced in al size ranges. Infant and toddler shirts are sized by month and weight. Youth and adult

sizes are small, medium, big, extra large and so on. T-shirt fit is concerned with length and circumference of a

garment body, cut of sleeves and neckline shape and depth. Sleeve fit is often determined by styling. Set-in

sleeves which fit close to the body require room for movement and arm expansion.

Necklines of T-shirts should lay flat against the body regardless of styling, depth of the neck band or method of

assembly. During application, neckband is stretched slightly to fit neck edges. One of the causes for poor

neckline fit is banding the stretches but never recovers. This maybe due to, incorrect stitch selection or too

many stitches per inch.

Product testing and complete product specifications can help prevent poor fit. Differences in body proportions

must be accommodated in the styling and fit of garments.

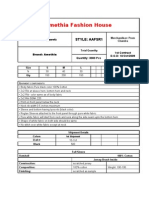

Example of a T-shirt size chart:

Garment Manufacturing Technology 2

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

MATERIALS

Fabrics used for T-shirts are primarily 100% cotton or cotton /polyester blends. All cotton is generally used in

producing better quality garments, though yarn type, fabrication and fabric finished also affect quality. Fiber

length and alignment affect durability and appearance. Ring-spun yarns provide long-range performance.

Heavier fabrics are often 100 percent cotton and require more yarn which leads to increase in costs. Trims used

on T-shirts consist of neckbands, cuffs, bindings; screen printed designs, embroidery, etc.

Trims maybe matching or contrasting. Tubular neckbands do not require seaming and are often used for better

turtlenecks and crew necks. Other trims used are braids,

stripes and bindings Trims must be compatible with other

materials, garment performance care and use.

Tape maybe used on back necklines, to stabilize and enclose

the seams and improve durability and performance. Narrow

twill tape or stable strips maybe sewn in shoulder seams to

prevent breaking of the stitch line. Elastic application

ensures recovery of stretched seams. Threads of many types

are used in sewing T – shirt .Budget shirts are stitched with

white thread, while top-stitching is usually done with color-

matched threads.

SPREADING AND CUTTING

Tubular knit fabric, which is frequently used in adult T-

Shirts, creates some challenges in preproduction that are

different than products being spread and cut from flat

goods. Closed markers are usually used to cut tubular goods

to be able to utilize the full width of the fabric. Tubular

goods may be cut with an open marker but primarily for

children’s clothing. Fabric may be knife cut or die cut. If it is

die cut, lengths of the fabric cut to the lengths of the die

must be cross or section from the new fabric. Sections or

blocks of knife are stacked until they meet the specified ply

height and the spread is moved to the die cutter.

Better T-shirt will have a tubular goods turns ¼ turn before cross cutting and stacking. This will transfer the

crease lines from sides of the spread to the centre. This moves the fold from what would be centre front and

center back to the underarm area.turning the fabric although automated, provides a less distorted surface for

centre front. Die cutting usually causes less distortion problems in the cutting process.

Garment Manufacturing Technology 3

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

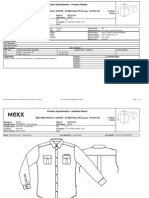

COMPONENTS AND ASSEMBLY OF A T-SHIRT

Final T-shirt

Garment Manufacturing Technology 4

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

Garment Manufacturing Technology 5

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

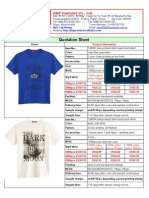

Garment Operation Breakdown List Form Date: 28 November 2008

Style Number: _________________________ Sketch:

Description: T-shirt. Casual wear. Knitted

fabric .

Op. # Description Stitch Seam

1 Seams

Most T-shirt seams are superimposed seams, stitched with overedge 504 Superimposed

stitch. This stitch/seam combination produces a narrow, finished seam

with good stretch and flexibility if properly executed. Knitted fabrics do

not need a wide seam allowance for good performance. However,

seaming of knit fabrics needs to be monitored to prevent yarn

severance. Broken yarn caused by faulty needles or the wrong needles

type may allow runs to start at seams.

2 Sleeve

Because of automation and ease in handling, sleeves are often finished 504 Superimposed

prior to setting into T-shirts. Automated seaming allows sleeves to be

carried by conveyer to the sewing head for hemming. For tubular T-

shirts, sleeves are seamed before setting. For other cut and sewn T-

shirts, the sleeve is set into the garment and the sleeves and the side

seam are closed in one operation.

Edge treatments, weather band or hems, are easiest to apply while

sleeves are flat. Bands may be applied as binding (BSb) or as

superimposed seam (SSa).

3 Hemline

Better quality T-shirt 406 Efa

Budget T-shirt 503 EFc

Hems must be stretchy, flat and wide enough to avoid rolling when the

fabric is stretched. A narrow hem on a jersey is likely to curl when

tension is applied to the edge of the garment. Stitch tension should be

loose and the stitches not visible on the right side. Hems may be the

first operation on a t-shirt or the last depending how the production

line is set up.

Garment Manufacturing Technology 6

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

4 Patch Pockets

Patch pockets are found on some outwear T-shirts. Pocket hems of

better t-shirts have filler or interlining in the pocket hem to retain

shape and prevent stretching. Support material is fed in as hems are

stitched to the pocket. Automatic pocket setters may be used to attach

pocket to shirt fronts. With automation, an operator places a pocket

and shirt and shirt front and engages the machine. The machine aligns

and stitches the pocket. If pockets are applied, it may be one of the first

operations because it is easier to manipulate a flat open piece.

5 Shoulder Seams

Budget garments may only be seamed, while better garments have the 504 SSa Superimposed

shoulders taped or elastic applied. This approach may be closed before

the neckbone is applied.

6 Neckline

Bound Seam Neckline 406 Bsb

Bound seam neckline applications stitched with a cover stitch are fast

and easy to apply. They may be used to finish neckline of crew necks,

scoops, tanks and so on. Bound seams are flat except where joined at

shoulder(s), and provide a neat topstitch appearance. Neckbands, when

applied as bound seams, are strips of rib knit fed off rolls through

tensioning devices and folders. When neckbands are applied and the

shoulder seams(s) closed, the neckline is completed.

Neckbands may be applied separately to the neckline back and front or

to the neckline after one shoulder seam is closed. Closure of the

shoulder seam(s) after trim is applied leaves exposed seam(s) at the

neckline edge. This method is fast, minimizes handling, amd is widely

used on budget and moderate shirts.

Tubular Neckband 504 SSa Superimposed

Neckbands in tubular form require both shoulder seams to be closed

before application. Tubular neckbands may be cut from appropriately

sized tubular knits or cut and sewn from piece goods. Tubular

neckbands are folded with wrong sides together, positioned on top of

the neckline in a superimposed seam, and attaching tubular neckbands

to necklines with closed shoulder seams requiring manual application.

Sewing operators fold, stretch, and align neckbands and shirt necklines

while sewing them together.

Garment Manufacturing Technology 7

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

7 Taping of Shoulder and Neckline

Superimposed neckline seam, are often taped, cover stitched or 406 SSf, Superimposed

topstitched to improve comfort, aesthetic appeal, and durability. SSag, LSbn

Unfinished super imposed seam at the neckline may not remain flat

during wear or may not stretch and not cover. More durable T-shirts

are taped continuously around the back neckline and shoulder seam to

flatten the seams, maintain shape, and provide hanger appeal.

Continuous taping reinforces the junction of shoulder and neckline

seams, which is subject to high stress. Only back neckline seams may be

taped when neckbands are applied with both shoulder seams open.

This gives the appearance of a better-quality shirt when only the back

neck is stabilized. Topstitching may also be used on better-quality

garments in areas where the neckline is not taped.

8 Label Stitching

Label setting is often combined with neckline with neckline seaming.

Most T-shirts have neckline labels to provide information and appeal

while some shirts have a second label sewn to the outside lower front

in a separate operation. This is intended to add fashion appeal and

differentiation to some types of shirts.

9 Optional Features

Some T-shirts will have trim or screen prints added for decorative

purposes. Special T-shirts for infants have larger openings at the head.

The shoulder seams are left open near the neck, and buttons or other

fasteners are attached.

10 Finishing Operations

T-shirts are inspected for flaws in the fabric, stitching, and thread. High-

quality T-shirts may be pressed through steam tunnels before they are

packaged. Packaging depends on the type of T-shirt and the intended

distribution outlet.

11 Quality Control

Most of the operations in manufacturing clothing are regulated by

federal and inter-national guidelines. Manufacturers may also set

guidelines for the company. There are standards that apply specifically

to the T-shirt industry, which include proper sizing and fit, appropriate

needles and seams, types of stitches, and the number of stitches per

inch. Stitches must be loose enough to allow the garment to stretch

without breaking the seam. Hems must be flat and wide enough to

prevent curling. T-shirts must also be inspected for proper application

of neck-lines, which should rest flat against the body. The neckline

should also recover properly after being slightly stretched.

Garment Manufacturing Technology 8

Operation Breakdown of a T-shirt MFM, Sem 1 | NIFT, Mumbai | 2008

BOTTLENECK OPERATION

We have identified the stitching of the neckline of the T-shirt as a major bottleneck operation. This is a still a

manual and time consuming process. There are many variations of attaching the neckline and each of these

methods effect the appearance, quality and cost of t-shirts.

Attaching the neckline is a very time consuming process and leads to accumulation of WIP. This can be avoided

by employing 2 operators instead of one for attaching neckbands. It will add to the cost but there will be a

certain cost benefit advantage.

Garment Manufacturing Technology 9

You might also like

- Fabric ScienceDocument67 pagesFabric Sciencemansiagrawal63% (8)

- How To Spec A Garment PDFDocument9 pagesHow To Spec A Garment PDFBeky ManNo ratings yet

- Tech Pack TemplateDocument5 pagesTech Pack Templatechickungpao21No ratings yet

- BSCIC Factory ListDocument381 pagesBSCIC Factory ListMd. Abid Hossain Tapu88% (8)

- Aran KnittingDocument30 pagesAran Knittingsjn110% (7)

- Tech PackDocument9 pagesTech PackAnoop Singh67% (3)

- Tech Pack of T Shirt OrderDocument7 pagesTech Pack of T Shirt Orderamethiaexport75% (4)

- Seam and Stitch Analysis of A GarmentDocument1 pageSeam and Stitch Analysis of A GarmentArnavpaitandy100% (2)

- Tech Pack of ShirtDocument14 pagesTech Pack of ShirtJai Sharma50% (2)

- Seam and Stitch Analysis of A GarmentDocument1 pageSeam and Stitch Analysis of A GarmentArnavpaitandy100% (2)

- Garment ManufacturingDocument9 pagesGarment ManufacturingSauumye Chauhan0% (1)

- Jean Tech Pack ExampleDocument8 pagesJean Tech Pack ExampleJin NguyễnNo ratings yet

- Final Report PDFDocument204 pagesFinal Report PDFES MaxternNo ratings yet

- Assignment Report On Quality Inspection of Shirt ManufacturingDocument17 pagesAssignment Report On Quality Inspection of Shirt ManufacturingJuborazIV78% (9)

- Time and Action Calendar or TNADocument17 pagesTime and Action Calendar or TNAruchi ratan100% (1)

- Operation Breakdown of A JacketDocument16 pagesOperation Breakdown of A JacketSakshi Khurana25% (4)

- Operation Breakdown and SAM of The Full Sleeve Formal Men's ShirtDocument56 pagesOperation Breakdown and SAM of The Full Sleeve Formal Men's ShirtKumera HaileyesusNo ratings yet

- Costing of Men's Formal ShirtDocument8 pagesCosting of Men's Formal ShirtHaqiqat Ali94% (17)

- How To MeasureDocument73 pagesHow To MeasureVarun Mehrotra100% (1)

- Apparel Dictionary Very UsefulDocument9 pagesApparel Dictionary Very Usefulmorshed_mahamud7055No ratings yet

- Garment Sewing DepartmentDocument22 pagesGarment Sewing DepartmentSauumye Chauhan100% (1)

- Branded T ShirtDocument36 pagesBranded T ShirtSourav RoyNo ratings yet

- Max Lifestyle: Women's Wear Summer 2020 Ribbed Short Sleeves Red T-Shirt MRP Rs599Document2 pagesMax Lifestyle: Women's Wear Summer 2020 Ribbed Short Sleeves Red T-Shirt MRP Rs599SWATI DAS0% (1)

- Kidzania Business Model (Autosaved)Document8 pagesKidzania Business Model (Autosaved)ArnavpaitandyNo ratings yet

- Operation Breakdown & Machinery Required For: Formal TrouserDocument18 pagesOperation Breakdown & Machinery Required For: Formal Trouserashishgcti8175% (8)

- Tech PackDocument9 pagesTech PackKartik Singh100% (5)

- Template of Tech Pack (SHIRT)Document10 pagesTemplate of Tech Pack (SHIRT)Apurva NidhiNo ratings yet

- Spec SheetDocument15 pagesSpec SheetRAJESH KUMARNo ratings yet

- TechpackDocument27 pagesTechpackShalini Yadav33% (3)

- Tech PackDocument15 pagesTech PackAbhijit BiswasNo ratings yet

- SheenaMaria TechPack DressDocument10 pagesSheenaMaria TechPack DressChetna Shetty Dikkar100% (1)

- Final Tech PackDocument11 pagesFinal Tech Packapi-464890134No ratings yet

- Tech Pack 2Document7 pagesTech Pack 2Sanya Nagpal100% (1)

- Sonal Apparel Pvt. LTD Apparel Document FinalDocument160 pagesSonal Apparel Pvt. LTD Apparel Document FinalAkanksha GuptaNo ratings yet

- Winning Spirit - WorkwearDocument64 pagesWinning Spirit - WorkwearJasper Hazlett100% (1)

- Stitch TypesDocument4 pagesStitch TypesJeffry Junkeer83% (12)

- Brands Analysis and Tech PackDocument21 pagesBrands Analysis and Tech PackRabi KantNo ratings yet

- Sewing Room GuidelinesDocument56 pagesSewing Room Guidelinesmalikzeeshanaliawan100% (6)

- Sampling and Tech PacksDocument23 pagesSampling and Tech PacksMaham AnwarNo ratings yet

- Process Flow Chart of Garments Sample MakingDocument5 pagesProcess Flow Chart of Garments Sample MakingRana Muhammad Arif Khan100% (1)

- Garment Inspection GuidelineDocument132 pagesGarment Inspection Guidelinestudent1291No ratings yet

- T Shirt Printing BakeryDocument39 pagesT Shirt Printing Bakeryalassadi09100% (1)

- T-Shirt Manufacturing Business-394665 PDFDocument70 pagesT-Shirt Manufacturing Business-394665 PDFMonish VenkatNo ratings yet

- US Standard Clothing SizeDocument28 pagesUS Standard Clothing Sizeinama33100% (1)

- Denim Garment IndustryDocument98 pagesDenim Garment Industryroshaero67% (3)

- Assg6 Techpack TrousersDocument17 pagesAssg6 Techpack Trousersanshushah_144850168100% (2)

- CuttingDocument30 pagesCuttingsatish.121180% (5)

- Final Tech Pack RacerbackDocument11 pagesFinal Tech Pack Racerbackapi-232043623No ratings yet

- Catelouge and Price List of Men T-ShirtDocument7 pagesCatelouge and Price List of Men T-ShirtMicky Singh Aswal100% (2)

- Garment Manufacturing Process Fabric To Finished ProductDocument12 pagesGarment Manufacturing Process Fabric To Finished ProductEmmanuel Tunde Renner100% (1)

- Operation Breakdown Formal ShirtDocument2 pagesOperation Breakdown Formal ShirtSevesh75% (16)

- Albha Oberoi-Graduation ProjectDocument156 pagesAlbha Oberoi-Graduation Projectalbha oberoiNo ratings yet

- Denim Jean ProductionDocument34 pagesDenim Jean Productionsaharabid100% (2)

- TrousersDocument6 pagesTrousersJeremy Charles100% (1)

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- NPD Assignment 1 - Development of A T-ShirtDocument4 pagesNPD Assignment 1 - Development of A T-ShirtNikhil SriramNo ratings yet

- Apparel Industry Construction MethodsDocument42 pagesApparel Industry Construction MethodsSachin Roy0% (1)

- Hid - Pattern Making II-Mens Handout 1Document45 pagesHid - Pattern Making II-Mens Handout 1Mohammed Khalid100% (3)

- 02 - FAD QuestionsDocument16 pages02 - FAD Questionsmaya_muthNo ratings yet

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Document25 pagesKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaNo ratings yet

- PatternDocument5 pagesPatternsporti1412No ratings yet

- Quick and Easy T ShirtDocument5 pagesQuick and Easy T ShirtCammy870% (1)

- Southeast University: Department of Textile EngineeringDocument23 pagesSoutheast University: Department of Textile EngineeringtabassumpunomNo ratings yet

- Consumer Behavior of McDonalds ConsumersDocument48 pagesConsumer Behavior of McDonalds ConsumersArnavpaitandy88% (8)

- Genetically Modified CottonDocument8 pagesGenetically Modified CottonArnavpaitandy100% (2)

- ZAPP - Marketing Mix & PositioningDocument8 pagesZAPP - Marketing Mix & PositioningArnavpaitandyNo ratings yet

- Knitting Technology IntroductionDocument72 pagesKnitting Technology IntroductionDr Muhammad Mushtaq Mangat100% (3)

- HM Group Supplier List APR 2022Document461 pagesHM Group Supplier List APR 2022Emdad HossainNo ratings yet

- Knitting Faults Causesand Remediesof Knit FabricsDocument14 pagesKnitting Faults Causesand Remediesof Knit FabricsDivya SuryavanshiNo ratings yet

- Top 350 RMG Exporters of BangladeshDocument17 pagesTop 350 RMG Exporters of BangladeshCommercial Wing, Bangladesh Embassy Madrid, SpainNo ratings yet

- What Is KnittingDocument21 pagesWhat Is KnittingAkhilendra Pratap100% (1)

- Fashion School FacilitiesDocument4 pagesFashion School FacilitiesClaire NecesitoNo ratings yet

- SCHMETZ HH Catalogue Version 01 2014 GB PDFDocument24 pagesSCHMETZ HH Catalogue Version 01 2014 GB PDFKukyong LeeNo ratings yet

- Knitwear Design and Technology: January 2018Document23 pagesKnitwear Design and Technology: January 2018RAFIAHAMMEDNo ratings yet

- Computers and Flat Bed Knitting MachinesDocument4 pagesComputers and Flat Bed Knitting MachinesSunil Kumar PuriNo ratings yet

- 04.kniterate - AboutDocument10 pages04.kniterate - AboutluisricardosantosNo ratings yet

- Fabric KnittingDocument8 pagesFabric KnittingRahul RajNo ratings yet

- Warp KnittingDocument44 pagesWarp KnittingEngineer WaleedNo ratings yet

- Textile Vision - Fayyaz Industry Support CellDocument596 pagesTextile Vision - Fayyaz Industry Support CellTaimur Shan100% (1)

- FASH2000 Garment and The Body Semester 1 2022 Bentley Perth Campus INTDocument14 pagesFASH2000 Garment and The Body Semester 1 2022 Bentley Perth Campus INTArchVFXNo ratings yet

- Profitable Machine Knitting Magazine 1991.08 300dpi ClearScan OCRDocument64 pagesProfitable Machine Knitting Magazine 1991.08 300dpi ClearScan OCRRaimundo Pereira Paiva JúniorNo ratings yet

- Business Directory Samples 301 400Document100 pagesBusiness Directory Samples 301 400Pranav GuptaNo ratings yet

- A Typical Testing Performance For CommercialDocument6 pagesA Typical Testing Performance For CommercialKhandaker Sakib FarhadNo ratings yet

- Types of Stitches and SeamDocument52 pagesTypes of Stitches and Seam58-Suhani Shekh100% (1)

- Placement Brochure 2021Document49 pagesPlacement Brochure 2021Saksham GoelNo ratings yet

- Spandex Lycra Cotton Heat UsesDocument34 pagesSpandex Lycra Cotton Heat UsesarkcgemNo ratings yet

- Industrial Attachment On Rahman Knit Garments LTDDocument131 pagesIndustrial Attachment On Rahman Knit Garments LTDMehediHasan100% (2)

- Nur Group Company ProfileDocument22 pagesNur Group Company Profilesamin3shohelNo ratings yet

- Knitting Off The Axis BLADDocument8 pagesKnitting Off The Axis BLADInterweaveNo ratings yet

- A Study About Garment Industry in Indian Senario AT M.S Knitting Mills in TirupurDocument26 pagesA Study About Garment Industry in Indian Senario AT M.S Knitting Mills in TirupurSuresh KumarNo ratings yet

- Bangladesh Factory ListDocument1,781 pagesBangladesh Factory ListMd: Rashedul IslamNo ratings yet

- Assignment: Corse Name: Course CodeDocument8 pagesAssignment: Corse Name: Course CodeSaHaria SajibNo ratings yet

- Research and DesignDocument31 pagesResearch and DesignIyasu Tade SseNo ratings yet

- Report On RMG Industry Bangladesh - Economic PerspectiveDocument87 pagesReport On RMG Industry Bangladesh - Economic PerspectiveRuhin Afrin Joyee100% (1)