Professional Documents

Culture Documents

Brake Test On DC Compound Motor

Uploaded by

kudupudinageshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brake Test On DC Compound Motor

Uploaded by

kudupudinageshCopyright:

Available Formats

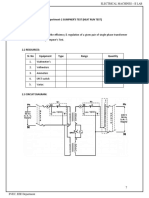

CIRCUIT DIAGRAM FOR BRAKE TEST ON D.C.

COMPOUND MOTOR

EM1LAB,BVCR,RAJAHMUNDRY ,Prepared by K. Nagesh & V.D.Neelima

BRAKE TEST ON D.C. COMPOUND MOTOR

AIM: To conduct brake test on D.C. Compound Motor and to draw its performance curves. APPARATUS REQUIRED: S. No 1 2 3 4 5 6 THEORY: The series field may be connected in the circuit so as to help the shunt field or oppose.,in first case the motor is cumulatively compounded and in the second case differentially compounded. If the series field of the differentially compounded motor is so adjusted that at full load, the decrease in flux produced by it is just sufficient to make the full load speed and to no-load speed, then for and other load with in its range, its speed will be approximately constant. The cumulative compounded motor experiences an increase in flux so that, as load increase, the speed decreases, the fall in speed affords relief to the motor. When differentially compounded motor is started. First series field flux will be established and the motor start is wrong direction, when the shunt field is fully established, the total flux is so small that the motor draws a large current from the supply. When the motor is overloaded speed will increase like a series motor on no-load. It is a direct method and consists of applying a brake to a water cooled pulley mounted on the motor shaft. The brake band is fixed with the help of wooden blocks gripping the pulley. One end of the band is fixed to earth via a spring balance S1 and the other is connected to a suspended weight W1. The motor is running and the load on the motor is adjusted till it carries its full load current. The net pull on the band due to friction at the pulley is ( S1 S2 ) Kg Wt. Shaft torque T sh = 9.81 ( S1 - S2 ) R N- M R = Radius of brake drum in Mt Motor output Power = T sh x 2N Watt. Efficiency = Output Input PROCEDURE: 1. 2. 3. 4. 5. 6. 7. 8. 9. Make the connections as per the circuit Give Supply to the motor, by closing DPST switch Start the motor with the help of 3- Point starter. Adjust the speed of the motor to its rated value by varying either field or armature rheostat as per the requirement. Note down the no load readings. Apply load on the motor by tighting the belt of the pulley. Note down the readings. Take the readings for different loads. Do the necessary calculations and draw the graphs. Name of the Equipment Type Range Ammeter M.C 02A Voltmeter M.C 0 300V Ammeter M.C 0 20 A Rheostat Wire wound 50 / 5A Rheostat Wire wound 360 / 1.2A Tachometer Digital 0 10,000 rpm Qty. 1No. 1No. 1No. 1No. 1No. 1No.

EM1LAB,BVCR,RAJAHMUNDRY ,Prepared by K. Nagesh & V.D.Neelima

TABULATION: Line Curr ent IL ( A ) Volta ge (v ) Field Current If (A) N (rpm) Ia= IL+If Spring Net Balance Balance S= S1 S2 S1 S2 Torque = S x Rx 9.81 Power ( O/P) Power Efficiency 2NT (I/P) = O/P 60 VIL I/ P

S.No

R=0.1034M Model Graph:-

PRECAUTIONS: 1) Readings must be noted without any parallax error. 2) The pulley of the brake drum must be filled with cool water. 3) Before stop the motor, load should be removed. 4) Connections must be tight. 5) Fuses should be properly rated . 6) The operation of the 3-Point starter. Should be slow and uniform. 7) Armature rheostat should be connected in maximum position initially. 8) Field rheostat should be minimum resistance position.

EM1LAB,BVCR,RAJAHMUNDRY ,Prepared by K. Nagesh & V.D.Neelima

RESULT:Brake Test on D.C Compound Motor is conducted and its performance curves are drawn.

VIVA QUESTIONS

1) What is the difference between cumulative and differential compound motor connections? 2) What happen, if the field circuit of a loaded cumulative compound motor is suddenly opened? 3) At the time of starting of motor the rheostat of the field circuit kept, in which position (maximum or minimum)? 4) What are the applications of DC compound motor? 5) What is the necessity of the starter?

EM1LAB,BVCR,RAJAHMUNDRY ,Prepared by K. Nagesh & V.D.Neelima

You might also like

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Brake Test On DC Shunt MotorDocument4 pagesBrake Test On DC Shunt Motorkudupudinagesh87% (31)

- Load Test On DC Compund GeneratorDocument4 pagesLoad Test On DC Compund Generatorkudupudinagesh50% (12)

- Electrical Machines II Lab ManualDocument28 pagesElectrical Machines II Lab ManualAnith Krishnan83% (6)

- Brake Test On DC Shunt MotorDocument5 pagesBrake Test On DC Shunt MotorkudupudinageshNo ratings yet

- Field TestDocument5 pagesField Testkudupudinagesh100% (3)

- Load Test On Series GeneratorDocument3 pagesLoad Test On Series Generatorkudupudinagesh88% (8)

- Swinburne'S Test: AIM: To Pre-Determine The Efficiency of A D.C Shunt Machine by PerformingDocument6 pagesSwinburne'S Test: AIM: To Pre-Determine The Efficiency of A D.C Shunt Machine by PerformingAshutosh SharmaNo ratings yet

- 7.noload and Blocked Rotor Test On Singlephase Induction MotorDocument5 pages7.noload and Blocked Rotor Test On Singlephase Induction Motormandadi_sailesh100% (2)

- Brake Test On 3 Phase Slip Ring Induction MotorDocument5 pagesBrake Test On 3 Phase Slip Ring Induction MotorRajeev Sai0% (1)

- 8.determination of XD and XQ of A Salient Pole Synchronous MachineDocument4 pages8.determination of XD and XQ of A Salient Pole Synchronous Machinemandadi_sailesh60% (5)

- Brake Test On The 3-Phase Induction MotorDocument2 pagesBrake Test On The 3-Phase Induction MotorAravind Babu68% (37)

- Calibration of LPF WattmeterDocument2 pagesCalibration of LPF WattmeterSingam Sridhar100% (3)

- EMF and MMF MethodDocument6 pagesEMF and MMF MethodBritto Tiger100% (2)

- 4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor TestsDocument4 pages4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor Testsmandadi_sailesh50% (2)

- 2.sumpner's Test On A Pair of Single Phase TransformersDocument5 pages2.sumpner's Test On A Pair of Single Phase Transformerschandrakanth100% (2)

- 1.O.C. & S.C. Tests On Single Phase TransformerDocument6 pages1.O.C. & S.C. Tests On Single Phase Transformerchandrakanth100% (3)

- Synchronizing 3-Phase AlternatorDocument5 pagesSynchronizing 3-Phase AlternatorHaritha RkNo ratings yet

- Load Test DC Shunt GeneratorDocument3 pagesLoad Test DC Shunt Generatormani100% (2)

- Speed Control of DC Shunt MotorDocument7 pagesSpeed Control of DC Shunt MotorAakash0% (1)

- Exp. No: Date: Formation of Y-Bus Matrice by Direct Inspection Method Aim: To Determine The Admittance Matrices For The Given Power System NetworkDocument5 pagesExp. No: Date: Formation of Y-Bus Matrice by Direct Inspection Method Aim: To Determine The Admittance Matrices For The Given Power System NetworkSnehil ChandraNo ratings yet

- REGULATION TESTING OF SYNCHRONOUS MACHINESDocument10 pagesREGULATION TESTING OF SYNCHRONOUS MACHINESAbhishEk Singh67% (3)

- Z and Y ParametersDocument6 pagesZ and Y Parameterskudupudinagesh100% (12)

- Speed Control of DC Shunt MotorDocument6 pagesSpeed Control of DC Shunt MotorSubham Basu100% (4)

- Sreekavithaengineerig College: Scott Connection of TransformersDocument4 pagesSreekavithaengineerig College: Scott Connection of Transformersmandadi_saileshNo ratings yet

- Energy Audit Lab Experiments GuideDocument23 pagesEnergy Audit Lab Experiments GuideNayandeep Gulhane100% (1)

- Load Test On Three Phase Induction Motor: Experiment No: 1Document4 pagesLoad Test On Three Phase Induction Motor: Experiment No: 1Bodhayan PrasadNo ratings yet

- Speed Control of Three Phase Slip Ring Induction Motor at Variable Load ConditionDocument3 pagesSpeed Control of Three Phase Slip Ring Induction Motor at Variable Load Conditionhi100% (1)

- Pe Lab Viva QuestionsDocument15 pagesPe Lab Viva Questionssujithmrinal100% (5)

- Turn ON and Off Characteristics of SCRDocument17 pagesTurn ON and Off Characteristics of SCRVedant .Chavan100% (2)

- AbcdDocument5 pagesAbcdkumarchaturvedulaNo ratings yet

- 2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control MethodDocument4 pages2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control Methodbhavesh1863100% (1)

- Formation of Ybus matrix using singular transformationDocument10 pagesFormation of Ybus matrix using singular transformationsepidmehr0% (1)

- D.C Motor StarterDocument4 pagesD.C Motor Starterkarthime0857% (7)

- Numerical Problems Induction MotorsDocument3 pagesNumerical Problems Induction Motorsloke06235No ratings yet

- EEP851 POWER ELECTRONICS LAB- SCR, IGBT & MOSFET CHARACTERISTICSDocument16 pagesEEP851 POWER ELECTRONICS LAB- SCR, IGBT & MOSFET CHARACTERISTICSGaurav Verma100% (2)

- Study of Step Up & Step Down Transformer: Experiment 9Document3 pagesStudy of Step Up & Step Down Transformer: Experiment 9Apna VeerNo ratings yet

- Electrical Drive - LAB-ManualDocument31 pagesElectrical Drive - LAB-Manualanil patelNo ratings yet

- Experiment 10 - Calibration of Wattmeter by Phantom LoadingDocument2 pagesExperiment 10 - Calibration of Wattmeter by Phantom LoadingFALSERNo ratings yet

- Viva Questions On AlternatorsDocument6 pagesViva Questions On AlternatorsKashif Hussain RazwiNo ratings yet

- Negative Sequence RelaysDocument10 pagesNegative Sequence Relayssudheerreddy115100% (1)

- Half and Full Wave RectifierDocument12 pagesHalf and Full Wave Rectifierlucy lucy50% (2)

- Electric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandDocument15 pagesElectric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandjaya mishraNo ratings yet

- Electrical Machines - II (Unit 4)Document13 pagesElectrical Machines - II (Unit 4)kumararguruNo ratings yet

- Swinburne S Test On DC Shunt MotorDocument5 pagesSwinburne S Test On DC Shunt Motortamann2004No ratings yet

- Single Phase Series InverterDocument9 pagesSingle Phase Series InverterDhivya NNo ratings yet

- Applications of DC Generators & MotorsDocument1 pageApplications of DC Generators & MotorsSureshNo ratings yet

- 9.speed Control of DC Motor Using Chopper DriveDocument8 pages9.speed Control of DC Motor Using Chopper DriveDhivya N100% (1)

- Three-phase alternator load test and OCC characteristics determinationDocument7 pagesThree-phase alternator load test and OCC characteristics determinationKailash Jagarwal100% (1)

- Lab ManualDocument41 pagesLab ManualSyaoran7Li80% (5)

- Characteristics of Over Voltage RelayDocument3 pagesCharacteristics of Over Voltage RelaySasindran SNo ratings yet

- MA-415 Industrial Drives Lab IndexDocument19 pagesMA-415 Industrial Drives Lab IndexMayankJainNo ratings yet

- Single Phase Dual ConverterDocument15 pagesSingle Phase Dual ConverterBhavin Bhanushali100% (11)

- Circuit Diagram For Brake Test On D.C.Shunt Motor: EM1 LAB, BVCR, RAJAHMUNDRY Prepared by K. Nagesh & V.D.NeelimaDocument4 pagesCircuit Diagram For Brake Test On D.C.Shunt Motor: EM1 LAB, BVCR, RAJAHMUNDRY Prepared by K. Nagesh & V.D.NeelimaPrabhu MoorthyNo ratings yet

- 1.load Test On DC Shut MotorDocument5 pages1.load Test On DC Shut Motorg3v5No ratings yet

- EE LAB MANUAL FOR ELECTRICAL EXPERIMENTSDocument45 pagesEE LAB MANUAL FOR ELECTRICAL EXPERIMENTSSai Karthi100% (1)

- EE6365 – ELECTRICAL ENGINEERING LABORATORY MANUALDocument58 pagesEE6365 – ELECTRICAL ENGINEERING LABORATORY MANUALjk100% (1)

- Lab 11 - Capacitor Start and Capasitor Run MotorsDocument4 pagesLab 11 - Capacitor Start and Capasitor Run MotorscostpopNo ratings yet

- Experiment #7: Slip Ring Motor: Alasala CollegesDocument5 pagesExperiment #7: Slip Ring Motor: Alasala CollegesabdullahNo ratings yet

- Power Systems and Simulation Laboratory: Department of Electrical and Electronics EngineeringDocument48 pagesPower Systems and Simulation Laboratory: Department of Electrical and Electronics EngineeringkudupudinageshNo ratings yet

- On of Stray LossesDocument5 pagesOn of Stray LosseskudupudinageshNo ratings yet

- Presentation 1Document1 pagePresentation 1kudupudinageshNo ratings yet

- Z and Y ParametersDocument6 pagesZ and Y Parameterskudupudinagesh100% (12)

- Speed Control& Swinburns TestDocument9 pagesSpeed Control& Swinburns TestkudupudinageshNo ratings yet

- Hop Kin Sons TestDocument4 pagesHop Kin Sons Testkudupudinagesh100% (1)

- Em Lab1Document1 pageEm Lab1kudupudinageshNo ratings yet

- OCCDocument4 pagesOCCkudupudinageshNo ratings yet

- Load Test On Series GeneratorDocument3 pagesLoad Test On Series Generatorkudupudinagesh88% (8)

- Thevinin and NortonDocument4 pagesThevinin and Nortonkudupudinagesh100% (1)

- Time Responseof RL and RC NetworksDocument5 pagesTime Responseof RL and RC Networkskudupudinagesh100% (1)

- Regulation of AlternatorDocument6 pagesRegulation of Alternatorkudupudinagesh100% (1)

- Super Position and ReciprocityDocument6 pagesSuper Position and ReciprocitykudupudinageshNo ratings yet

- O.C & S.C of Single Phase TransformerDocument8 pagesO.C & S.C of Single Phase Transformerkudupudinagesh50% (2)

- Swinburne S Test On DC Shunt MotorDocument5 pagesSwinburne S Test On DC Shunt Motortamann2004No ratings yet

- N&ET Lab SyllabusDocument1 pageN&ET Lab SyllabuskudupudinageshNo ratings yet

- Max Power TransferDocument5 pagesMax Power TransferkudupudinageshNo ratings yet

- The Poor Man's Super ComputerDocument12 pagesThe Poor Man's Super ComputerkudupudinageshNo ratings yet

- Magnetization Characterisitcs of Dcshunt GeneratorDocument4 pagesMagnetization Characterisitcs of Dcshunt GeneratorkudupudinageshNo ratings yet

- Maglev Trains: Trains That Fly On AirDocument21 pagesMaglev Trains: Trains That Fly On AirkudupudinageshNo ratings yet

- Global System For Mobile CommunicationDocument21 pagesGlobal System For Mobile CommunicationPulkit AroraNo ratings yet

- Control SystemsDocument8 pagesControl SystemsprakashjntuNo ratings yet

- Final Fuzzy ReportDocument19 pagesFinal Fuzzy ReportBhagyashree SoniNo ratings yet

- Maglev Trains: Rajamah EndriDocument9 pagesMaglev Trains: Rajamah EndrikudupudinageshNo ratings yet

- Journal of Travel & Tourism MarketingDocument19 pagesJournal of Travel & Tourism MarketingSilky GaurNo ratings yet

- Mid SemDocument1 pageMid SemvidulaNo ratings yet

- SECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSDocument2 pagesSECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSMuhammad Tahir QamarNo ratings yet

- Advance Distributed ComputingDocument2 pagesAdvance Distributed ComputingValia Centre of ExcellenceNo ratings yet

- A Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukhDocument6 pagesA Comparative Study of Different Image Denoising Methods: Afreen Mulla, A.G.Patil, Sneha Pethkar, Nishigandha DeshmukherpublicationNo ratings yet

- Statistics Interview QuestionsDocument5 pagesStatistics Interview QuestionsARCHANA R100% (1)

- CH - 1Document4 pagesCH - 1Phantom GamingNo ratings yet

- Sculptures by The SeaDocument1 pageSculptures by The Seaapi-457802597No ratings yet

- Aw MD700 Manual G10 150706Document73 pagesAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraNo ratings yet

- 1 Clock Domain CrossingDocument35 pages1 Clock Domain CrossingRamakrishnaRao SoogooriNo ratings yet

- NCP 1014Document24 pagesNCP 1014rodricaldasNo ratings yet

- MCCB SchneiderDocument2 pagesMCCB SchneiderkumontholNo ratings yet

- Planning Dirty FrameworkDocument62 pagesPlanning Dirty FrameworkHoàng Hoa Dương100% (1)

- w5 Philo Module 5Document24 pagesw5 Philo Module 5prestonvela15No ratings yet

- +GF+ Pressure Retaining Valve Type 586Document4 pages+GF+ Pressure Retaining Valve Type 586ROMNANo ratings yet

- Calmark - Birtcher 44 5 10 LF L DatasheetDocument2 pagesCalmark - Birtcher 44 5 10 LF L DatasheetirinaNo ratings yet

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang SetiawanNo ratings yet

- Listening Script 11Document11 pagesListening Script 11harshkumarbhallaNo ratings yet

- Green Screen Background Remover Using CV SystemDocument20 pagesGreen Screen Background Remover Using CV SystemSubhamNo ratings yet

- OSC - 2015 - Revised - Oct (Power Cables) PDFDocument118 pagesOSC - 2015 - Revised - Oct (Power Cables) PDFIván P. MorenoNo ratings yet

- Sist-En-6101-2016 .Document9 pagesSist-En-6101-2016 .lokelooksNo ratings yet

- Toolbox Meeting Or, TBT (Toolbox TalkDocument10 pagesToolbox Meeting Or, TBT (Toolbox TalkHarold PonceNo ratings yet

- 07-02-2023 MS QLNDocument3 pages07-02-2023 MS QLNSummaaaaNo ratings yet

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- Basf Masteremaco Application GuideDocument15 pagesBasf Masteremaco Application GuideSolomon AhimbisibweNo ratings yet

- Renal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaDocument9 pagesRenal Angina Index in Pediatric Septic Patients As A Predictor of Acute Kidney Injury in Remote AreaFarhanNo ratings yet

- Schippers and Bendrup - Ethnomusicology Ecology and SustainabilityDocument12 pagesSchippers and Bendrup - Ethnomusicology Ecology and SustainabilityLuca GambirasioNo ratings yet

- Ethics in ResearchDocument21 pagesEthics in Researchmukku_raviNo ratings yet

- CanReg5 InstructionsDocument150 pagesCanReg5 InstructionsdiyafersanNo ratings yet