Professional Documents

Culture Documents

การทดสอบสมรรถนะหน้างานของ cooling tower

Uploaded by

Rapee PuaksungnoenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

การทดสอบสมรรถนะหน้างานของ cooling tower

Uploaded by

Rapee PuaksungnoenCopyright:

Available Formats

1

CTI

Field Performance Testing of Cooling Tower by CTI (Bulletin ATP105

and Form ATP-107R )

1 2

Montri Pirunkaset and Santi Laksitanonta

(CTI)

, KaV/L ,L/G

L/G

L/G L/G 100

,

Abstract

The performance testing of mechanical draft cooling tower in the field of tower installation,

the supplier and purchaser should understand in the standards of field testing and calculations of

tower capability in the same way by following the Cooling Tower Institute standards(CTI

standards).The supplier should summit this testing tower characteristic curves in the form of a plot

of tower characteristics, KaV/L versus water to air flow ratio, L/G under the design approach to the

purchaser. From the design data and test data of the same tower, the design and test values of L/G

can be determined from the standard procedure. The ratio of test value of L/G to the design value of

L/G and multiplying by 100 (percentage tower capability) represents the design circulating flow

which can be cooled at the design range, approach, and inlet air conditions. It is important to

standardize the field testing of cooling tower and verify the technical concerning guarantees for

agreement of the purchaser and supplier eventually.

Key Words : Field testing, Mechanical draft cooling tower, CTI

_________________________________________________________________________________________________

1 2

10900

Department of Mechanical Engineering, Faculty of Engineering, Kasetsart University, Bangkok 10900

A NF ,m2

A NF = (DF2 DPIPE2)/4

Cw

,kJ/kg-K

ha1

t wb1 ,

kJ/kg-dry air

ha2

,kJ/kg-dry air

h S1

,kJ/kg-dry

air

KaV/L

L/G

T1

T2

t wb1

t a2

vel AVG

va2

V&W

V&

W

2

, oC

, oC

, oC

, oC

, m/s

, m 3 /kg

,L/min

,m 3/min

, kg/m 3

CTI

CTI-Bulletin ATP-105

And Form ATP-107R

CTI

(L/G)design

(specification)

m 3 /min

L/min CTI (L/G)designBulletin ATP-105Form

ATP-107CTI

,

V&w = ______ L/min , V&a = ______ m3/min

,

T1 = ______ oC , T2 = ______ oC

,twb1 = ______ oC

, R = (T1-T2) = ______oC

L/G KaV/L

4.175V w w R v a 2

ha2 = ha1 +

1000 V a

(1)

1. ha1

twb1

2.

va2 2

3. (1) ha2

4. 2 ha2 2 3

, t a2

5. 1

4

1 4

V w w / 1000 V w w v a 2

L

=

=

G design

V a /v a2

1000 V a

(2)

(L/G)design (KaV/L ) design

,T1 ,T2

, twb1

(KaV/L ) design CTI

1 1 ,T1

,T2 ,twb1 ,(L/G)design

1 KaV/L CTI

hS

ha

h

(oC)

(kJ/kg)

(kJ/kg)

, T2= ______

_

twb1,ha1 = _______

_

TA=T2+0.1(T1-T2) = ______ _____ h = h +0.1C L (T -T ) = _______ _______

1 2

G

hB = ha1+0.4CW L (T1-T2) = _______

G

hC = ha2-0.4CW L (T1-T2) = _______

G

hD = ha2-0.1CW L (T1-T2) = _______

G

ha2 = ha1+ CW L (T1-T2) = _______

G

A

TB=T2+0.4(T1-T2) = ______

_____

TC=T1-0.4(T1-T2) = ______

_____

TD=T1-0.1(T1-T2) = ______

_____

, T1 = ______

a1

(1/h) =

(1/h) 1

1/h

_

_______

_______

_______

_______

_______

_______

_______

_

_______

(KaV/L ) design

( 1 / h )

KaV

= C w (T 1 T 2 )

4

L design

(3)

L/G KaV/L

(L/G)design (KaV/L)design

L/G (L/G)test CTI

, V&w,test (L/min)

, V&a ,test (m3/min)

V&w,test HPdesign

L

L

x

x

=

&

G test G design Vw,design HPtest

1/ 3

(4)

L

L

=

G test G design

V&

x a ,test

V&

a , design

(5)

, (L/G)test (4) ( 5 )

KaV/L

,T1 ,T2 ,twb1

( (L/G)test , (KaV/L)test )

CTI PFM-143:

1994 Recommend Practice for Airflow Testing of Cooling Tower

CTI DF DPIPE

2

2

A NF A NF = (DF DPIPE )/4 A F

= DF2/4 5 ,Aratio

A ratio = A NF /10

5 A5 = AF Aratio

, R5 = A5 /

, R4 = A4 /

4 A4 = A5 2 Aratio

3 A3 = A4 2 Aratio

, R3 = A3 /

2 A2 = A3 2 Aratio

, R2 = A2 /

1 A1 = A2 2 Aratio

, R1 = A1 /

20

,vel AVG

V&a = ANF vel AVG

( L / G) design ( KaV / L) design

,C KaV / L = C ( L / G) 0.6 (CTI)

( L / G ) test ( KaV / L) test ,C

KaV / L = C ( L / G ) 0.6

L/G 0< L/G

<(L/G)max (L/G)max

HWT

(L/G)max =

hS1 ha1

CW (T1 T2 )

(6)

CTI

1.) T1 = oC , T2 = oC , twb1=oC

2.) L/G 0 L/G (L/G) max (L/G) max ( 6 )

3.) T1 = oC , T2 = oC , twb1=oC 1.)

L/G 2.) L/G KaV/L

1

4.) L/G KaV/L3

( L / G ) design ( L / G) int er sec

Cooling Capacity =

( L / G ) int er sec

100

( L / G ) design

(7)

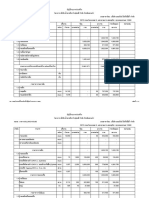

T1 (oC)

43

42.2

T2(oC)

34

32

twb1(oC)

29

27.5

V&W (L/min)

58,333

47,100

V&a ( m3/min)

28,665

31,250

(volt)

3,300

3,300

( amp)

34.7

29

(hp)

215

208.6

( HP = (1.73xAxVxPower _ FactorxMotor _ Efficiency) / 746 )

2 3

3 CTI

L/G

1.938

1.538

KaV/L

1.548

1.774

,C

2.3024

2.335

KaV/L=2.3024(L/G)-0.6 KaV/L=2.335(L/G)-0.6

T1 = 43 oC , T2 = 34 oC , twb1 = 29 oC

L/G

1.938

1.960

( L / G ) int er sec = 1.96

1

Cooling Capacity =

( L / G ) int er sec

1.96

100 = 101.14%

100 =

1.938

( L / G ) design

101.14%

101.14%

KaV/L

1.581

test

Approach 43-34-29 oC

Intersection point

1.559

design

1.548

Curve through test point

KaV/L=2.335(L/G) -0.6

Characteristic

KaV/L=2.3024(L/G) -0.6

1.774

1.938

1.96

L/G

[ 1 ] Mills , A. F., Heat and Mass Transfer, Richard D. Irwin Inc., Chicago, 1995.

[ 2 ] Hill , G.B ., Pring E.J. and Osborn P.D. ,Cooling Towers Principles and Practice, ButterworthHeinemann Ltd, London, 3 rd ed .,1990.

[ 3 ] Nicholas P.Ch. and Paul N.Ch., Cooling Tower (Selection ,Design and practice), Ann arbor

Science Publishers, the Butterworth-Group, Michigan, 2 nd ed.,1983.

[ 4 ] British Standard Institution, British Standard Specification for Water Cooling Towers ,Method for

Performance Testing ,BS 4485 ; Part 2,1988.

[ 5 ] Cooling Tower Institute, Acceptance Test Code for Water Cooling Towers. CTI Code ATC105,1982.

[ 6 ] Cooling Tower Institute, Cooling Tower Performance Curves, 1967.

[ 7 ] Cooling Tower Institute, Cooling Tower Manual Chapter 5, July, 1983.

10

You might also like

- แก๊สDocument16 pagesแก๊สPoonnaphaNo ratings yet

- ข้อสอบสามัญเครื่องกล Power Plant 3/2547Document13 pagesข้อสอบสามัญเครื่องกล Power Plant 3/2547wetchkrubNo ratings yet

- ข้อสอบสามัญเครื่องกล Air Conditioning 1/2549Document11 pagesข้อสอบสามัญเครื่องกล Air Conditioning 1/2549wetchkrub67% (3)

- ข้อสอบสามัญเครื่องกล Main 1/2547Document11 pagesข้อสอบสามัญเครื่องกล Main 1/2547wetchkrub100% (1)

- Heat Transfer in BoilerDocument12 pagesHeat Transfer in BoilermanatchaiNo ratings yet

- แบบฟอร์มแผนธุรกิจDocument11 pagesแบบฟอร์มแผนธุรกิจนางสาวธนัชพร พินิจชัยNo ratings yet

- ข้อสอบสามัญเครื่องกล Plant 2/2549Document10 pagesข้อสอบสามัญเครื่องกล Plant 2/2549wetchkrubNo ratings yet

- ข้อสอบสามัญเครื่องกล poweplant 2/2547Document16 pagesข้อสอบสามัญเครื่องกล poweplant 2/2547wetchkrub100% (1)

- ข้อสอบสามัญเครื่องกล Air Condition 1/2550Document11 pagesข้อสอบสามัญเครื่องกล Air Condition 1/2550wetchkrub100% (4)

- การปรับอากาศและระบายอากาศDocument303 pagesการปรับอากาศและระบายอากาศPrachak Laemlak100% (1)

- ข้อสอบสามัญเครื่องกล Automotive 1/2550Document5 pagesข้อสอบสามัญเครื่องกล Automotive 1/2550wetchkrubNo ratings yet

- การทำความเย็น PDFDocument212 pagesการทำความเย็น PDFjamjam1062100% (1)

- ตารางแนบหนังสือการปรับอากาศ 1Document63 pagesตารางแนบหนังสือการปรับอากาศ 1Rider Thailand100% (1)

- ข้อสอบสามัญเครื่องกล Air Conditioning 3/2548Document9 pagesข้อสอบสามัญเครื่องกล Air Conditioning 3/2548wetchkrub100% (1)

- การหาประสิทธิภาพเครื่องทำความเย็นDocument39 pagesการหาประสิทธิภาพเครื่องทำความเย็นChoedwut Sangboon80% (10)

- การออกแบบระบบระบายน้ำDocument35 pagesการออกแบบระบบระบายน้ำchainun252925% (4)

- วสท มาตรฐานการป้องกันอัคคีภัยDocument334 pagesวสท มาตรฐานการป้องกันอัคคีภัยมธุรส สังข์วรรณะ100% (1)

- MEA Harmonic StandardsDocument19 pagesMEA Harmonic StandardstjnoonNo ratings yet

- Design of Steam Piping-ColorDocument70 pagesDesign of Steam Piping-Colorallouche_abd100% (3)

- CH3 Thailand Boiler RegulationDocument48 pagesCH3 Thailand Boiler RegulationTchai Siri0% (1)

- H8 การหุ้มฉนวนท่อไอน้ำและวาล์วDocument6 pagesH8 การหุ้มฉนวนท่อไอน้ำและวาล์วจิรศักดิ์ อิเล็กทรอนิกส์No ratings yet

- 1. ระบบส่งจ่ายไอน้ำ - SSI3 - R2Document22 pages1. ระบบส่งจ่ายไอน้ำ - SSI3 - R2Osu AmpawanonNo ratings yet

- PTT - การผุกร่อนของท่อก๊าซภายในโรงงานDocument2 pagesPTT - การผุกร่อนของท่อก๊าซภายในโรงงานchockanan suwanprasertNo ratings yet

- AST Co.,LTD ThailandDocument13 pagesAST Co.,LTD ThailandIB IsmadyNo ratings yet

- Lecture 02Document56 pagesLecture 02Sirilak KlakwongNo ratings yet

- ความรู้พื้นธานระบบปรับอากาศDocument24 pagesความรู้พื้นธานระบบปรับอากาศPeppy Kung100% (2)

- Control Welding ElectrodesDocument21 pagesControl Welding Electrodesคุณพ่อน้อง บิ๊กบอสNo ratings yet

- VCKDocument59 pagesVCKEng Advance100% (3)

- BLDG Act 33 - EngDocument3 pagesBLDG Act 33 - EngThomas Or100% (1)

- Air-Condition Calculation BasisDocument96 pagesAir-Condition Calculation BasisSupat Love MamNo ratings yet

- Presentการเลือกใช้ระบบบำบัดน้ำเสีย ให้เหมาะกั PDFDocument71 pagesPresentการเลือกใช้ระบบบำบัดน้ำเสีย ให้เหมาะกั PDFJack VongmontyNo ratings yet

- BOQ โรงงานน้ำตาลนิวกว้างสุ้นหลี detailDocument11 pagesBOQ โรงงานน้ำตาลนิวกว้างสุ้นหลี detail2508127No ratings yet

- ใบเสนอราคาระบบสปริงเกอร์ (บางปะกง)Document6 pagesใบเสนอราคาระบบสปริงเกอร์ (บางปะกง)Panus Pattamasarawuth100% (1)

- Wet Scrubber Presentation 1Document47 pagesWet Scrubber Presentation 1DonbandanNo ratings yet

- Pulsator Clarifier Vacuum TypeDocument20 pagesPulsator Clarifier Vacuum TypeMambo_Junus_5783No ratings yet

- DRSDFSDFDocument126 pagesDRSDFSDFJeffrey TooNo ratings yet

- Pporn 280965 ADocument179 pagesPporn 280965 Aดาราพร นามประสพNo ratings yet

- 10 - Refrigeration and Air ConditioningDocument55 pages10 - Refrigeration and Air Conditioningpiya_engineer2786100% (1)

- 6 Screw ConveyorDocument28 pages6 Screw Conveyormaherianto 29No ratings yet

- Verify Calculation Method of Gas LeakDocument6 pagesVerify Calculation Method of Gas LeakNguyenThanhdungNo ratings yet

- Thermodynamics Wk2 1stLawOfThermodynamics AfterclassDocument23 pagesThermodynamics Wk2 1stLawOfThermodynamics AfterclassBall SarunNo ratings yet

- Lab 2 CheckDocument10 pagesLab 2 Checkpannita.kNo ratings yet

- คำนวณระบบอัดอากาศDocument6 pagesคำนวณระบบอัดอากาศภูมิรพี ศรีโวทานัยNo ratings yet

- Book GasLaw 2022 v4 DoneDocument7 pagesBook GasLaw 2022 v4 DonePongsathon PINPUEKNo ratings yet

- HVDocument6 pagesHVNattapon TangnithikunNo ratings yet

- Cal Chiller4Document33 pagesCal Chiller4SAKDA MAPRADITKULNo ratings yet

- Plan Lab 10 - G.4 PDFDocument10 pagesPlan Lab 10 - G.4 PDFSariya HorpisuttisanNo ratings yet

- Ch9 Power and Refrig Cycle - ThermodynamicsI SommaiPripremDocument33 pagesCh9 Power and Refrig Cycle - ThermodynamicsI SommaiPripremThanachot ThiangthamNo ratings yet

- ความรู้เกี่ยวกับระบบปรับอากาศDocument134 pagesความรู้เกี่ยวกับระบบปรับอากาศPrachak LaemlakNo ratings yet

- นิวเมติก PneumaticDocument5 pagesนิวเมติก Pneumaticmon012No ratings yet

- การทดลองที่ 2 การใช้งานอุปกรณ์ทดลองและการต่อวงจรDocument10 pagesการทดลองที่ 2 การใช้งานอุปกรณ์ทดลองและการต่อวงจรkittitat PongsapanNo ratings yet

- UntitledDocument15 pagesUntitledThanaphat SeangnkewNo ratings yet

- เครื่องปรับอากาศแบบรวมศูนย์และการปรับปรDocument17 pagesเครื่องปรับอากาศแบบรวมศูนย์และการปรับปรกรวิก กนกนาคNo ratings yet

- TSF24 MenettDocument11 pagesTSF24 MenetttanpradithNo ratings yet

- M 3 X 2Document3 pagesM 3 X 2minknakrabNo ratings yet

- วงจรอะสเตเบิลDocument4 pagesวงจรอะสเตเบิลภาณุมาส มาลาNo ratings yet

- Lab 03Document12 pagesLab 03AimNo ratings yet

- Heat ExchangerDocument24 pagesHeat ExchangerYingyote LubphooNo ratings yet

- Part1 CCTDocument107 pagesPart1 CCTChirawat KotchasarnNo ratings yet

- Less Ee MethDocument27 pagesLess Ee MethKobchai ChoorithNo ratings yet