Professional Documents

Culture Documents

Safety Alert

Uploaded by

jo123nOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Alert

Uploaded by

jo123nCopyright:

Available Formats

SAFETY ALERT (ALT-017)

Excavators Used as Cranes

BACKGROUND

Using excavators as cranes is a high risk activity because lifting is not the primary design function of these machines. A number of dangerous occurrences have recently occurred where chains, shackles or master links have either deformed or broken whilst loaded. Such incidents occur primarily because the load is not freely suspended from the lifting point. Instead, lifting equipment is wrapped over the lift point therefore creating rotational forces that multiply the load many times over (depending upon the geometry of the machine and its lifting equipment). Forces created are invariably many times greater than the rating of the slings or chains used. Load swing whilst a machine is travelling, or unexpected movement of the machine whilst lifting gear is attached, are other commonly reported problems that cause contact with, or crushing, injuries and fatalities.

On-track Multimedia

PRACTICAL GUIDANCE

SAFE OPERATOR Excavators should only be driven by fully trained, competent operators who have been authorised to do so and any operation should be accompanied by a suitable risk assessment. The nationally recognised qualification for competence within Britain is a Scottish/National Vocational Qualification (S/NVQ) Level II Plant Operations. For lifting operations, operators must also provide proof of both training and competence for using excavators as cranes. This will include knowledge and skills relating to: pre-lift checks; differences between various lifting accessories or machine attachments (e.g. quick hitches); load connection procedures; interpreting the machines lifting duties limitations at varying radii, over the front, side and rear of the machine (dozer blade up or down); travelling with a load; and load disconnection procedures. SAFE SITE Pedestrians must be segregated from the operational area of the excavator and its transport routes; these routes should have good clear signage and appropriate traffic control measures. The use of hands-free mobile technology should be considered to maintain good communication at a safe distance with site management and/or slingers during any lift or carry operations. Site managers should be knowledgeable with regards to safe lifting operations and must take an active role in planning, monitoring, controlling and managing all lifting operations on site. The lift plan and method statement should be communicated to all operatives involved. Vehicle routes should avoid significant obstacles, uneven ground and inclines, particularly if across the direction of travel. Where the route is near to a drop, such as an excavation or embankment, extra support or barriers should be provided for the edge of the route.

For further guidance refer to: BS EN 474: 2006 Earth-moving Machinery, BS 7121:2006 Code of Practice for Safe Use of Cranes, the Lifting Operations and Lifting Equipment Regulations 1998, the Provision and Use of Work Equipment Regulations 1998 and other safety alerts issued by OPERC (www.operc.com).

SAFE MACHINE Before using an excavator as a crane, a thorough risk assessment should be undertaken to determine whether alternative work processes could be used to avoid lifting operations or whether a different item of equipment would represent a safer choice. The operator has a duty to conduct maintenance and inspection at the start of each working shift (for example, of chains, shackles, hooks and slings) to ensure they are suitable for the lift, clearly marked with a safe working load and in good working condition. A full and complete record of all maintenance and inspection undertaken must be kept and any defective machinery or lifting gear found should not be used under any circumstance. The excavator must always be operated within its capability and if in any doubt, the operator should consult with the operations and maintenance manual supplied by the Original Equipment Manufacturer (OEM). Excavators that are used for lifting are subject to a thorough examination and test at least every 12 months. Machines must also be fitted with an audio-visual safe load indicator and lift capacity at various radii should be clearly stated. Lifting eyes should be closed, not open and rated by the OEM. When travelling, machine stability will be improved by reducing travel speeds, crowding the load into the machine as far as is safe/practicable and keeping the load low to the ground. When placing the load into position, engine revs should be lowered to tortoise mode and the machines boom and dipper manipulated to move the load into position. At all times, the load must remain freely suspended.

Images for illustrative purposes only

OPERC: The home of plant and equipment professionals www.operc.com

SAFETY ALERT (ALT-017)

Excavators Used as Cranes

BACKGROUND

Using excavators as cranes is a high risk activity because lifting is not the primary design function of these machines. A number of dangerous occurrences have recently occurred where chains, shackles or master links have either deformed or broken whilst loaded. Such incidents occur primarily because the load is not freely suspended from the lifting point. Instead, lifting equipment is wrapped over the lift point therefore creating rotational forces that multiply the load many times over (depending upon the geometry of the machine and its lifting equipment). Forces created are invariably many times greater than the rating of the slings or chains used. Load swing whilst a machine is travelling, or unexpected movement of the machine whilst lifting gear is attached, are other commonly reported problems that cause contact with, or crushing, injuries and fatalities.

On-track Multimedia

PRACTICAL GUIDANCE

SAFE OPERATOR Excavators should only be driven by fully trained, competent operators who have been authorised to do so and any operation should be accompanied by a suitable risk assessment. The nationally recognised qualification for competence within Britain is a Scottish/National Vocational Qualification (S/NVQ) Level II Plant Operations. For lifting operations, operators must also provide proof of both training and competence for using excavators as cranes. This will include knowledge and skills relating to: pre-lift checks; differences between various lifting accessories or machine attachments (e.g. quick hitches); load connection procedures; interpreting the machines lifting duties limitations at varying radii, over the front, side and rear of the machine (dozer blade up or down); travelling with a load; and load disconnection procedures. SAFE SITE Pedestrians must be segregated from the operational area of the excavator and its transport routes; these routes should have good clear signage and appropriate traffic control measures. The use of hands-free mobile technology should be considered to maintain good communication at a safe distance with site management and/or slingers during any lift or carry operations. Site managers should be knowledgeable with regards to safe lifting operations and must take an active role in planning, monitoring, controlling and managing all lifting operations on site. The lift plan and method statement should be communicated to all operatives involved. Vehicle routes should avoid significant obstacles, uneven ground and inclines, particularly if across the direction of travel. Where the route is near to a drop, such as an excavation or embankment, extra support or barriers should be provided for the edge of the route.

For further guidance refer to: BS EN 474: 2006 Earth-moving Machinery, BS 7121:2006 Code of Practice for Safe Use of Cranes, the Lifting Operations and Lifting Equipment Regulations 1998, the Provision and Use of Work Equipment Regulations 1998 and other safety alerts issued by OPERC (www.operc.com).

SAFE MACHINE Before using an excavator as a crane, a thorough risk assessment should be undertaken to determine whether alternative work processes could be used to avoid lifting operations or whether a different item of equipment would represent a safer choice. The operator has a duty to conduct maintenance and inspection at the start of each working shift (for example, of chains, shackles, hooks and slings) to ensure they are suitable for the lift, clearly marked with a safe working load and in good working condition. A full and complete record of all maintenance and inspection undertaken must be kept and any defective machinery or lifting gear found should not be used under any circumstance. The excavator must always be operated within its capability and if in any doubt, the operator should consult with the operations and maintenance manual supplied by the Original Equipment Manufacturer (OEM). Excavators that are used for lifting are subject to a thorough examination and test at least every 12 months. Machines must also be fitted with an audio-visual safe load indicator and lift capacity at various radii should be clearly stated. Lifting eyes should be closed, not open and rated by the OEM. When travelling, machine stability will be improved by reducing travel speeds, crowding the load into the machine as far as is safe/practicable and keeping the load low to the ground. When placing the load into position, engine revs should be lowered to tortoise mode and the machines boom and dipper manipulated to move the load into position. At all times, the load must remain freely suspended.

Images for illustrative purposes only

OPERC: The home of plant and equipment professionals www.operc.com

You might also like

- 2.5 - FAT - C1574 - FAT Procedure PDFDocument7 pages2.5 - FAT - C1574 - FAT Procedure PDFGeorge Jhonson100% (2)

- Case Studies in Project Management - The Shard Top Down Construction - Draft (Individual) E - GencbayDocument16 pagesCase Studies in Project Management - The Shard Top Down Construction - Draft (Individual) E - GencbayErdem Gencbay100% (1)

- Drilling Operation Practices Manual (ONGC) (2007)Document368 pagesDrilling Operation Practices Manual (ONGC) (2007)Karun Nooney100% (4)

- Pathfinder User ManualDocument73 pagesPathfinder User ManualMartinez Andryj89% (9)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Final Notes 23110 Safety in Construction IndustryDocument201 pagesFinal Notes 23110 Safety in Construction IndustryAmitkumar Singh67% (6)

- Suspended Load SafetyDocument3 pagesSuspended Load Safetymy_agautamNo ratings yet

- Harvard Business School Kone The MonoSpace Launch in Germany (R)Document3 pagesHarvard Business School Kone The MonoSpace Launch in Germany (R)pijathiNo ratings yet

- Safety AlertDocument1 pageSafety Alertindrak1978No ratings yet

- Banksman ResponsibilitiesDocument2 pagesBanksman ResponsibilitiesAnil CNo ratings yet

- RB - HSE Daily Observation Report Dated 04.11.2021Document3 pagesRB - HSE Daily Observation Report Dated 04.11.2021Idris AdeniranNo ratings yet

- Office - Safety - Training-Trident Hydrojetting Philippines Inc.Document40 pagesOffice - Safety - Training-Trident Hydrojetting Philippines Inc.Dlraje DlrajeNo ratings yet

- Jsa Excavation For Water Filling PitDocument5 pagesJsa Excavation For Water Filling PitDelta akathehuskyNo ratings yet

- SFPSG-Rescue Persons From MEWPsDocument10 pagesSFPSG-Rescue Persons From MEWPsLyle KorytarNo ratings yet

- Safety Alert - EnglishDocument1 pageSafety Alert - Englishjamilhse7759100% (1)

- Safety Alert: Safe Driving During Rainy WeatherDocument1 pageSafety Alert: Safe Driving During Rainy WeatherRanjan PradhanNo ratings yet

- Safety Induction TrainingDocument62 pagesSafety Induction TrainingshoaibNo ratings yet

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocument1 pageScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNo ratings yet

- EHS Handbook FINAL 2013-12-11Document8 pagesEHS Handbook FINAL 2013-12-11Erica LindseyNo ratings yet

- Employee Incident Report Form 1 1Document3 pagesEmployee Incident Report Form 1 1api-459048769100% (1)

- Safety Alert: Incident SummaryDocument1 pageSafety Alert: Incident SummaryAnonymous 3eHGEDbx100% (1)

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Risk Assessment New Site Lifting Operations 07-06-2015Document3 pagesRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLNo ratings yet

- Emergency Response Team: Reporting Flow ChartDocument1 pageEmergency Response Team: Reporting Flow Chartmohamadhakim.19789No ratings yet

- TBT Manual HandlingDocument1 pageTBT Manual HandlingNishadh NishNo ratings yet

- Safety AlertDocument1 pageSafety Alertjithin shankarNo ratings yet

- EHS Alert 010 - Concrete Placing Boom OperationDocument1 pageEHS Alert 010 - Concrete Placing Boom OperationAbdulKatherNo ratings yet

- Legion Ella Risk AssessmentDocument6 pagesLegion Ella Risk AssessmentnemcoutiNo ratings yet

- Hse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationDocument61 pagesHse Induction: Welcome To UMM AL HAYMAN-W 300/132/11 KV SubstationJinadNo ratings yet

- Fall ProtectionDocument71 pagesFall ProtectionFairuz AthallahNo ratings yet

- Miles - PPE Management Plan 2018Document14 pagesMiles - PPE Management Plan 2018Anold MedardNo ratings yet

- HSE-CDS-003 Safe Operating SpecificationDocument16 pagesHSE-CDS-003 Safe Operating SpecificationRoza AzaleaNo ratings yet

- Ev04 - Behavioral Based Safety Training SlidesDocument21 pagesEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNo ratings yet

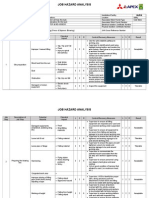

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATETamNo ratings yet

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNo ratings yet

- Lifting Operations Risk Assessment Crane Risk AssessmentDocument13 pagesLifting Operations Risk Assessment Crane Risk Assessment9853318441No ratings yet

- Hirarc Training IADC EqivalentDocument45 pagesHirarc Training IADC EqivalentNorman AinomugishaNo ratings yet

- Generic TRA For Mobile Elevating Work PlatformDocument4 pagesGeneric TRA For Mobile Elevating Work PlatformKhawaja Arslan Ahmed100% (1)

- Safety ObservationDocument48 pagesSafety Observationpooloo70100% (1)

- Toolbox Talks Lifting Safety EnglishDocument1 pageToolbox Talks Lifting Safety EnglishkimlynroseNo ratings yet

- Standard Operating Procedure: Vehicle FuelingDocument1 pageStandard Operating Procedure: Vehicle FuelingAnees EkNo ratings yet

- Workingatheights 110623224858 Phpapp02Document21 pagesWorkingatheights 110623224858 Phpapp02naveeduddin2001No ratings yet

- Window Cleaning Safety GuidelineDocument4 pagesWindow Cleaning Safety Guidelinejhunvalencia1203No ratings yet

- Construction Safety Audit PDFDocument5 pagesConstruction Safety Audit PDFAnonymous Q1Y71rNo ratings yet

- Toolbox Talk LiftingDocument1 pageToolbox Talk LiftingShah KhalidNo ratings yet

- Observation Report 3b 2Document4 pagesObservation Report 3b 2Amobi EvidenceNo ratings yet

- Sharing of Industry Best Practice - Straits ConstructionDocument79 pagesSharing of Industry Best Practice - Straits Construction88sanNo ratings yet

- Safety Alert: Incident SummaryDocument1 pageSafety Alert: Incident SummaryAnonymous 3eHGEDbxNo ratings yet

- JSA BOOM TRUCK 197iDocument3 pagesJSA BOOM TRUCK 197iImamul HaqueNo ratings yet

- Working at Height TrainingDocument47 pagesWorking at Height TrainingthinkpadNo ratings yet

- 9.7 Ladder Inspection ChecklistDocument1 page9.7 Ladder Inspection ChecklistArshad MahmoodNo ratings yet

- Hse JsaDocument22 pagesHse JsaAnonymous y1pIqcNo ratings yet

- Emergency Responce Plan and Safety Plan Ram Chandra EnterpriseDocument4 pagesEmergency Responce Plan and Safety Plan Ram Chandra EnterpriseBilal QureshiNo ratings yet

- Mifa Safety Regulations UKDocument2 pagesMifa Safety Regulations UKnqh2009No ratings yet

- Safety Training: Hot WorksDocument66 pagesSafety Training: Hot WorksMuneeb Ur Rehman100% (1)

- Young Persons Risk Assessment V2.0 October 2021Document2 pagesYoung Persons Risk Assessment V2.0 October 2021Lucas SantosNo ratings yet

- Toolbox Talks Defensive Driving EnglishDocument1 pageToolbox Talks Defensive Driving Englishsuhas100% (1)

- Defensive DrivingDocument54 pagesDefensive DrivingFrancis Enriquez TanNo ratings yet

- Adverse Weather PolicyDocument10 pagesAdverse Weather Policyvlad100% (1)

- HSE Bulletin 26 Crane CollapseDocument1 pageHSE Bulletin 26 Crane Collapseajeet kumar singhNo ratings yet

- Jobsite Safety Checklist Long Ver 1Document5 pagesJobsite Safety Checklist Long Ver 1Usman ShahidNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanNo ratings yet

- Vertical Elevator InspectionhydroDocument4 pagesVertical Elevator InspectionhydroEvelyn BozemanNo ratings yet

- 958174D01 - en - O.1 - 958174D01 - en - O.1 Codes de Pannes KCE ComplèteDocument117 pages958174D01 - en - O.1 - 958174D01 - en - O.1 Codes de Pannes KCE ComplètePape SeckNo ratings yet

- GDCR RudaDocument223 pagesGDCR RudaAshutosh Maru100% (1)

- Booklet 17: Installation Instructions For SpiritDocument112 pagesBooklet 17: Installation Instructions For SpiritJaime MarchantNo ratings yet

- Paper Tray Unit (Machine Code: D331) Service Manual: March, 2007 Subject To ChangeDocument29 pagesPaper Tray Unit (Machine Code: D331) Service Manual: March, 2007 Subject To ChangeДмитрий РазуваевNo ratings yet

- FDGFDDocument139 pagesFDGFDTHE DESIGN GROUPNo ratings yet

- Tamesis Manuals Safe Operation of CranesDocument60 pagesTamesis Manuals Safe Operation of CranesaironyxNo ratings yet

- Kone Final Offer - RR Housing (Machine Room Less)Document6 pagesKone Final Offer - RR Housing (Machine Room Less)Manoj KumarNo ratings yet

- SDC Occupant Handbook October 2019Document39 pagesSDC Occupant Handbook October 2019Ian FinchNo ratings yet

- DCD200-3000,2006 Maintenance ManualDocument362 pagesDCD200-3000,2006 Maintenance ManualOmar Ahmed Banawan100% (1)

- Cerpadla PVM Vickers - enDocument120 pagesCerpadla PVM Vickers - encaprit_her_771605No ratings yet

- AEM-UMEN 1 107.rev1Document90 pagesAEM-UMEN 1 107.rev1CLASS ASHENSORNo ratings yet

- Bulk WeighersDocument8 pagesBulk Weigherskingathur26681No ratings yet

- Itcc Design Drawings List FinalDocument53 pagesItcc Design Drawings List FinaluddinnadeemNo ratings yet

- Liftand Escalator Symposium Proceedings 2016Document244 pagesLiftand Escalator Symposium Proceedings 2016bugse100% (1)

- Catalog BlumDocument549 pagesCatalog BlumarhitectbobocNo ratings yet

- Lifts: Building Material and Construction TechnologyDocument18 pagesLifts: Building Material and Construction TechnologyVala Vraj M.No ratings yet

- Cylinder Repair (Mast SN A513, A514, A613, A614, B513BB514) - (02-2014) - Us-EnDocument66 pagesCylinder Repair (Mast SN A513, A514, A613, A614, B513BB514) - (02-2014) - Us-EnErissonNo ratings yet

- 08.4 Building Utilities Mechanical Systems 11 10 2021Document5 pages08.4 Building Utilities Mechanical Systems 11 10 2021Divina Luiza FantonialNo ratings yet

- DOE-STD-1090-2007 Hoisting and Rigging Standard ToCDocument17 pagesDOE-STD-1090-2007 Hoisting and Rigging Standard ToCbenzfliegerNo ratings yet

- General Specification 2017 Edition (With GSLE01-2017) Vs 2017 EditionDocument12 pagesGeneral Specification 2017 Edition (With GSLE01-2017) Vs 2017 EditionsandyNo ratings yet

- Altivar LIFT - 2010 ENDocument2 pagesAltivar LIFT - 2010 ENzkucanNo ratings yet

- Method Statement For Pre-Fabrication and Erection of PipingDocument10 pagesMethod Statement For Pre-Fabrication and Erection of PipingMohamedNo ratings yet

- TH414C GC TH417C GC Cat OmmDocument148 pagesTH414C GC TH417C GC Cat OmmMalinda100% (1)