Professional Documents

Culture Documents

Thermodynamics of Refrigeration - English PDF

Uploaded by

Karthikeyan SankarrajanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermodynamics of Refrigeration - English PDF

Uploaded by

Karthikeyan SankarrajanCopyright:

Available Formats

REFRIGERATION THERMODYNAMICS OF THE REFRIGERATION CYCLE

BASIC KNOWLEDGE

THERMODYNAMICS OF THE REFRIGERATION CYCLE

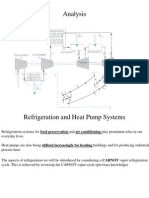

Set-up and function of a compression refrigeration system The refrigerant in a compression refrigeration system flows through a closed cycle with the following four stations: Evaporation A Compression B Condensation C Expansion D The cooling takes place in the evaporator (A). The evaporation takes place at low pressures and temperatures. Here the refrigerant absorbs heat from the environment and thus cools it. The still cold refrigerant steam is aspirated by a compressor (B) and subjected to higher pressure by using mechanical energy. The refrigerant steam heats up due to the compression. The hot refrigerant steam is cooled down in a condenser (C) and condenses while discharging heat to the environment. The liquid pressurised refrigerant is then expanded to the low evaporation pressure in an expansion element (D) and returned to the evaporator. The refrigerant evaporates again and thus completes the circuit. Low pressure L The log p-h diagram for refrigerant Heat absorption during evaporation Cyclic process of a simple compression refrigeration system

Liquid supercooled boiling g temperature p

The refrigeration cycle Heat dissipation during condensation Hig gh pressure For operating media which can have different phases, such as water or refrigerant, the T-s s diagram looks different. It has an area on the left (grey), in which the operating medium is liquid and supercooled. In the centre (blue) there is a mixture of steam and liquid, the wet steam. On the right of it (orange) the operating medium is in pure steam form and superheated. The real refrigeration cycle with its typical phase transitions can also be represented in this T-s s diagram. The cycle has many similarities to the familiar steam power cycle. The major difference is that the cycle is anticlockwise. Thus the processes of evaporation and condensation and expansion and compression (pumping) swap places. The enclosed area (green) corresponds to the compressor work added to the cycle.

Liquid supercooled Compression

Condensation

Gaseous

Expansion n Evaporation Wet steam boiling temperature Gaseous superheated

Compressor power

Liquid

Refrigeration cycle in the T-s diagram

In the log p-h diagram the pressure p is plotted above the enthalpy h. In the centre (blue) is the wet steam area. Here the temperature corresponds to the boiling temperature for the pressure. The wet steam area is surrounded by limit curves with the steam content x=0.0 and x=1.0. To the left of it (grey) the refrigerant is liquid. The temperature is below the boiling temperature for the pressure; the refrigerant is supercooled. On the right (orange) the refrigerant is gaseous and the temperature is above the boiling temperature. The refrigerant is superheated. Every refrigerant has its own log p-h diagram. The log p-h diagram is better suited to represent the refrigeration cycle than the T-s diagram and is therefore used predominantly. Because energies exchanged with the refrigerant modify the enthalpy h of the refrigerant, energy flows can be read directly from the diagram as horizontal lines.

Steam content t tx

Isothermal compression

A cyclic process can be represented very clearly in the T-s s diagram. Here the temperature T of the operating medium is plotted above the entropy s. The area enclosed by the change of state of the operating medium corresponds to the work realised in the cyclic process. The cyclic process with the highest possible efficiency is the Carnot cycle, here the enclosed area is a rectangle. This cycle is often used as a comparison cycle to describe the quality of the cyclic process. The direction of the cyclic process in the T-s s diagram determines whether this is a heat pump cycle (refrigeration cycle) or a work machine cycle (steam power cycle). Refrigeration cycles are anticlockwise and the work represented by the green area is added to the cycle.

Gaseous superheated

log p-h diagram for refrigerant

Isothermal expansion p

Ideal cyclic process (Carnot cycle) of a gaseous medium in the T-s diagram

27

REFRIGERATION THERMODYNAMICS OF THE REFRIGERATION CYCLE

BASIC KNOWLEDGE

THERMODYNAMICS OF THE REFRIGERATION CYCLE

The refrigeration cycle in the log p-h diagram The real refrigeration cycle consists of the following changes of state: 12 polytropic compression on the condensation pressure (for comparison 1 2 isentropic compression) The refrigerant Every cyclic process requires an operating medium which in the refrigeration cycle is the refrigerant. In the refrigeration cycle the refrigerant has the purpose of transporting heat. Here the high absorption of energy during evaporation or discharge of energy during the condensation of a liquid is utilised. To achieve this at the temperatures prevailing in a refrigeration system at well manageable pressures, liquids with a low boiling point, such as different fluorocarbons (FC), ammonia (NH3), carbon dioxide (CO2) or hydrocarbons such as butane or propane, are used as operating medium. The different refrigerants are marked with an R followed by a number. The water often used in technical cycles is not suitable for the refrigeration cycle. At the low temperatures prevailing in a refrigeration system the evaporation pressure is extremely low and there is a risk of the water freezing. The use of CO2 is technically demanding. Due to its low boiling temperature a very high pressure level results. This means that common components from refrigeration technology, such as valves, compressors or heat exchangers, cannot be used. For NH3 there are also special components, because materials containing copper are not resistant against ammonia.

2 2 isobaric cooling, deheating of the superheated steam 2 3 isobaric condensation 3 3 isobaric cooling, supercooling of the liquid

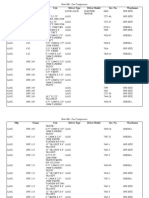

Name 34 isenthalpic expansion to the evaporation pressure FC R134a FC R404a 4 1 isobaric evaporation 1 1 isobaric heating, superheating of the steam FC R407a NH3 R717 The refrigeration cycle in the log p-h diagram Isobutane R600a CO2 R744 Pure substance Mixture Mixture Pure substance Pure substance Pure substance

Boiling temperature Ts = -26C Ts = -47 Ts = -39...-45C Ts = -33C Ts = -12 Ts = -78C

In addition there are also pressure losses in the real refrigeration cycle, which means that evaporation and condensation are not exactly horizontal (isobaric).

Energy considerations in the log p-h diagram The horizontal distances of the key cycle points in the log p-h diagram correspond to the enthalpy differences. In the simple refrigeration cycle without branched off mass flows these result in the energy flows or capacities of the ideal system when multiplied with the refrigerant mass flow. The distances in the log p-h diagram are therefore a direct measure for the energy flows exchanged. The distance 4 1 corresponds to the cooling capacity and is the net capacity of the refrigeration system. The distance 1 2 is the drive power exerted via the compressor. The distance 2 3 corresponds to the heat capacity discharged via the condenser. This is the waste heat of the refrigeration system. From the ratio of the net capacity and the drive power the coefficient of performance COP can be calculated. Energy flows in the refrigeration cycle cooling capacity absorbed compressor drive power heat capacity discharged COP = h1 - h4 h2 - h1 Important for a good operation is the steam pressure curve of the operating medium. It should be gaseous at low pressures and at the desired cooling temperatures and liquid at high pressures and temperatures. The pressure levels should also be easy to manage technically. The diagram shows the steam pressure curve of the well suited FC R134a. Typical freezing temperatures of -26C in the evaporator can be implemented with pressures around 1bar while for condensing only a pressure of 17bar at 60C is required.

Pressure in bar a

Temperature in C

Steam pressure curve of FC R134a

While in pure substances, such as NH3, propane and CO2,, the steam pressure curve is fixed, it can be adapted in FC within wide boundaries to meet requirements by mixing different base grades.

The coefficient of performance can be compared to the efficiency in a work machine.

29

You might also like

- Refrigeration Cycle Efficiency and ComponentsDocument8 pagesRefrigeration Cycle Efficiency and ComponentsJames TheeNo ratings yet

- 00 HVAC CalcDocument52 pages00 HVAC Calcibson045001256No ratings yet

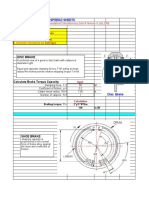

- Stress DesignDocument11 pagesStress DesignKarthikeyan SankarrajanNo ratings yet

- Oundsource Heat Pump SystemsDocument442 pagesOundsource Heat Pump SystemsЕвгений Врублевский90% (10)

- Health Facility GuidelinesDocument51 pagesHealth Facility GuidelinesAshok Kumar Pillai100% (1)

- Part Compressor PDFDocument17 pagesPart Compressor PDFNha TrangNo ratings yet

- Shaft DesignDocument13 pagesShaft DesignKarthikeyan SankarrajanNo ratings yet

- Carrier Transport Air Conditioning Model AirV Rooftop AC Unit For Buses & RV'sDocument62 pagesCarrier Transport Air Conditioning Model AirV Rooftop AC Unit For Buses & RV'sClifton Jamison100% (3)

- HVAC Cooling WaterDocument54 pagesHVAC Cooling WaterShiyamraj Thamodharan100% (1)

- COP of Heat PumpDocument3 pagesCOP of Heat PumpTamoor AliNo ratings yet

- Operasi&Deteksi KerusakanDocument27 pagesOperasi&Deteksi KerusakandennybtgNo ratings yet

- Fraccionamiento y AbsorciónDocument36 pagesFraccionamiento y AbsorciónWilder GanozaNo ratings yet

- Refrigeration CycleDocument8 pagesRefrigeration CycleMohamed HassanainNo ratings yet

- Refrigerant Dehumidification Technology: Technical Bulletin 1Document12 pagesRefrigerant Dehumidification Technology: Technical Bulletin 1Karthikeyan SankarrajanNo ratings yet

- Manual Promass 84fDocument74 pagesManual Promass 84fPedro A. Santana H.No ratings yet

- Methods - ModbusClient - EasyModbusTCP (UDP) and RTU .NET - Modbus TCP and UDP Client and Server For Data Exchange Between PLC andDocument3 pagesMethods - ModbusClient - EasyModbusTCP (UDP) and RTU .NET - Modbus TCP and UDP Client and Server For Data Exchange Between PLC anddirect1No ratings yet

- Process Flow DiagramDocument6 pagesProcess Flow DiagramkoplikNo ratings yet

- Lecture 28 Modeling of GTDocument59 pagesLecture 28 Modeling of GTCindy CarvalhoNo ratings yet

- Vapour Compression Cycle Performance as Refrigerator & Heat PumpDocument7 pagesVapour Compression Cycle Performance as Refrigerator & Heat Pumptatoo1No ratings yet

- Aspen For Chem RXN PART 2Document50 pagesAspen For Chem RXN PART 2hakita86No ratings yet

- Smacna Duct Fitting Loss TableDocument2 pagesSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

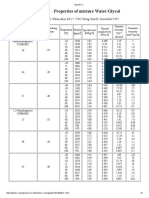

- Table 8 3 1 Properties of Mixture Water/Glycol: Extract From Vdi Warmeatlas DD 17 Vdi Verlag GMBH, Dusseldorf 1991Document2 pagesTable 8 3 1 Properties of Mixture Water/Glycol: Extract From Vdi Warmeatlas DD 17 Vdi Verlag GMBH, Dusseldorf 1991Santiago MolinaNo ratings yet

- Recommended Duct VelocitiesDocument1 pageRecommended Duct VelocitiesKarthikeyan Sankarrajan100% (1)

- Data TTG AcDocument5 pagesData TTG AcMya Diggory SikukangzNo ratings yet

- MWCP 2007 PDFDocument72 pagesMWCP 2007 PDFcesar luis gonzalez rodriguezNo ratings yet

- AC Part 3Document9 pagesAC Part 3Norman Ace AndresNo ratings yet

- Dsa 3431Document8 pagesDsa 3431Jeremy TetoncheNo ratings yet

- Fan & SystemDocument31 pagesFan & SystemAlberto FranciscoNo ratings yet

- IPC Loading UnitsDocument3 pagesIPC Loading UnitsTaqui Mubeen67% (3)

- Diagramas de MollierDocument157 pagesDiagramas de MollierJavier_Ild100% (1)

- Teoria y Principios Eyectores TermocompresoresDocument4 pagesTeoria y Principios Eyectores TermocompresoresJohn Kennedy FernandesNo ratings yet

- F. Huang - Engineering ThermodynamicsDocument52 pagesF. Huang - Engineering ThermodynamicsHectorCabz100% (1)

- Video LabDocument82 pagesVideo LabFabricioMFNo ratings yet

- Bristol ScrollDocument12 pagesBristol ScrollvickersNo ratings yet

- Sprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFDocument3 pagesSprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFsergirojasNo ratings yet

- Review On Heat TransferDocument76 pagesReview On Heat Transferprof_panneer100% (1)

- Air Purger (CPA-10) - Cool PartnersDocument3 pagesAir Purger (CPA-10) - Cool PartnersMohammad AmerNo ratings yet

- Hextran Getting Started GuideDocument56 pagesHextran Getting Started GuideFelix Lara100% (1)

- Lab Manual for Refrigeration and Air ConditioningDocument48 pagesLab Manual for Refrigeration and Air ConditioningcaxxvadgvadgfsNo ratings yet

- 070.610-Iom Rwfii 2017-04 PDFDocument72 pages070.610-Iom Rwfii 2017-04 PDFyoye1968100% (1)

- Hanbook EmbracoDocument98 pagesHanbook EmbracoZETAQ2010No ratings yet

- Dvp-Plc-Program o en 20101119Document618 pagesDvp-Plc-Program o en 20101119Mohammed MagdyNo ratings yet

- Valv - Expans-Regul. HANSEN PDFDocument4 pagesValv - Expans-Regul. HANSEN PDFJuan PanNo ratings yet

- Effective October 2010 Energy EfficientDocument10 pagesEffective October 2010 Energy EfficientAlla Naveen KumarNo ratings yet

- Tabla PsicrometricaDocument18 pagesTabla PsicrometricaRoman ValenciaNo ratings yet

- Iocomp Instrumental Paket PDFDocument72 pagesIocomp Instrumental Paket PDFstari692002No ratings yet

- Pxm20 SiemensDocument76 pagesPxm20 SiemensRamadan RashadNo ratings yet

- PsicrometriaDocument68 pagesPsicrometriaEddy FarfanNo ratings yet

- Fisher® Specification Manager Manual PDFDocument28 pagesFisher® Specification Manager Manual PDFerstendrainNo ratings yet

- Ficha Tecnica Tya4466yds PDFDocument1 pageFicha Tecnica Tya4466yds PDFJorgy Ayala PinedaNo ratings yet

- Pur-15-02 - Air Purger Type PurDocument4 pagesPur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoNo ratings yet

- Elitesoft-Bill Smith - CLTD Vs TFM Vs RtsDocument8 pagesElitesoft-Bill Smith - CLTD Vs TFM Vs RtstzisisNo ratings yet

- Plate Freezer Performance.Document4 pagesPlate Freezer Performance.Behnam AshouriNo ratings yet

- Implementation of Hot Gas Bypass For RefrigerationDocument5 pagesImplementation of Hot Gas Bypass For RefrigerationhurshawNo ratings yet

- Effect of Flash Gas Bypass On Performance of VCR SystemDocument4 pagesEffect of Flash Gas Bypass On Performance of VCR SystemesatjournalsNo ratings yet

- 2500 KW Forced Draft Cooling TowerDocument2 pages2500 KW Forced Draft Cooling Towerleojay24No ratings yet

- Tube Wire Vs Wall Condenser PDFDocument15 pagesTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- 2013 07 04 03 07 51 - Manual t110d - C - eDocument2 pages2013 07 04 03 07 51 - Manual t110d - C - eSamuel Dotou100% (1)

- Food Cooling and FreezingDocument16 pagesFood Cooling and FreezingramonluhrNo ratings yet

- Plate Heat Exchangers-Method of Calculation, Charts and Guidelines For Selecting Plate Heat Exchanger ConfigurationsDocument8 pagesPlate Heat Exchangers-Method of Calculation, Charts and Guidelines For Selecting Plate Heat Exchanger ConfigurationsFrandhoni UtomoNo ratings yet

- Reciprocal CompressorsDocument40 pagesReciprocal CompressorsSathish KasilingamNo ratings yet

- Limpieza de Catdos 03H07200-4-VEN-7813-13-R1 Trans1Document173 pagesLimpieza de Catdos 03H07200-4-VEN-7813-13-R1 Trans1Piero SánchezNo ratings yet

- Stoner Pipeline Simulator BrochureDocument2 pagesStoner Pipeline Simulator BrochurejoselosabeloNo ratings yet

- Air Refrigeration CyclesDocument20 pagesAir Refrigeration CyclesAhmed WazirNo ratings yet

- Copeland Scroll (2014 - 03 - 29 11 - 48 - 13 Utc)Document6 pagesCopeland Scroll (2014 - 03 - 29 11 - 48 - 13 Utc)Jairo GarciaNo ratings yet

- REFRIGERATION EarlyDocument21 pagesREFRIGERATION EarlyIrfan FajriNo ratings yet

- Air Cycle Refrigeration SystemsDocument8 pagesAir Cycle Refrigeration Systemsmesfn derbNo ratings yet

- Chapter 11 Refrigeration CyclesDocument20 pagesChapter 11 Refrigeration Cycleskalite123No ratings yet

- Gas Cycle and Vapour Cycle: Latent HeatDocument49 pagesGas Cycle and Vapour Cycle: Latent HeatCharan Reddy AbbadiNo ratings yet

- IntercoolingDocument13 pagesIntercoolingDerrick Maatla MoadiNo ratings yet

- Carnot Refrigeration Cycle ExplainedDocument11 pagesCarnot Refrigeration Cycle ExplainedZaimNo ratings yet

- Lecture 2. Refrigeration CyclesDocument8 pagesLecture 2. Refrigeration CyclesaddisudagneNo ratings yet

- Machines DesignDocument7 pagesMachines DesignKarthikeyan SankarrajanNo ratings yet

- Brake DesignDocument2 pagesBrake DesignKarthikeyan SankarrajanNo ratings yet

- SMACNA - HVAC-Systems-Duct-Design1990 260Document1 pageSMACNA - HVAC-Systems-Duct-Design1990 260Karthikeyan Sankarrajan100% (1)

- Air Flow Velocity in DuctsDocument2 pagesAir Flow Velocity in DuctsKarthikeyan SankarrajanNo ratings yet

- Seasonal Energy Efficien..Document6 pagesSeasonal Energy Efficien..Karthikeyan SankarrajanNo ratings yet

- Sewerage CalculatorDocument5 pagesSewerage CalculatorKarthikeyan SankarrajanNo ratings yet

- Method statement for testing and commissioningDocument1 pageMethod statement for testing and commissioningKarthikeyan SankarrajanNo ratings yet

- Water Regulations Advisory Scheme Ltd. (Wras) Material ApprovalDocument2 pagesWater Regulations Advisory Scheme Ltd. (Wras) Material ApprovalKarthikeyan SankarrajanNo ratings yet

- F.A.Q. Picv: General Valve QuestionsDocument9 pagesF.A.Q. Picv: General Valve QuestionsKarthikeyan SankarrajanNo ratings yet

- Led Bollard Light: Item Code: EL-S-BOL-LEDDocument1 pageLed Bollard Light: Item Code: EL-S-BOL-LEDKarthikeyan SankarrajanNo ratings yet

- Led Top Pole Light: Item Code: LL-POLETOP-LEDDocument1 pageLed Top Pole Light: Item Code: LL-POLETOP-LEDKarthikeyan SankarrajanNo ratings yet

- Part 11. Air-Water System - Chapter 1. Induction Unit SystemDocument1 pagePart 11. Air-Water System - Chapter 1. Induction Unit SystemKarthikeyan SankarrajanNo ratings yet

- Grease Trap TypesDocument1 pageGrease Trap TypesKarthikeyan SankarrajanNo ratings yet

- Fittings - K ValueDocument2 pagesFittings - K ValueKarthikeyan SankarrajanNo ratings yet

- Typical Kv valve sizing chartDocument1 pageTypical Kv valve sizing chartKarthikeyan SankarrajanNo ratings yet

- Underground coalescence separatorDocument1 pageUnderground coalescence separatorKarthikeyan SankarrajanNo ratings yet

- Lux LevelDocument1 pageLux LevelKarthikeyan SankarrajanNo ratings yet

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Document1 pagePart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNo ratings yet

- Air Duct Design Friction Loss ChartDocument1 pageAir Duct Design Friction Loss ChartKarthikeyan SankarrajanNo ratings yet

- For Underground Installation: Grease SeparatorsDocument1 pageFor Underground Installation: Grease SeparatorsKarthikeyan SankarrajanNo ratings yet

- NTi Audio AppNote XL2 Noise CurvesDocument13 pagesNTi Audio AppNote XL2 Noise CurvesdjossNo ratings yet

- Halton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Document4 pagesHalton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Karthikeyan SankarrajanNo ratings yet

- CIAT Melody MTDocument12 pagesCIAT Melody MTInviairNo ratings yet

- Paj - 2 - 5 Ton PDFDocument16 pagesPaj - 2 - 5 Ton PDFvickersNo ratings yet

- RK-2001E2 English TraductionDocument2 pagesRK-2001E2 English TraductionwxcvbnnbvcxwNo ratings yet

- CAR-II - (R) - Constant Airflow Regulator - Prod Specs Tech DataDocument4 pagesCAR-II - (R) - Constant Airflow Regulator - Prod Specs Tech DataSantiago J. ramos jrNo ratings yet

- Mechanical VentilationDocument22 pagesMechanical VentilationesagcojrNo ratings yet

- b2 Drainage Zone A CorrnerDocument1 pageb2 Drainage Zone A CorrnerAsmir MemicNo ratings yet

- Bill of QuantityDocument20 pagesBill of QuantityBerry MarshalNo ratings yet

- M007 Rak MHV DWG Ucst010 CL 00100Document1 pageM007 Rak MHV DWG Ucst010 CL 00100Adnan Attish0% (1)

- XHBQ-D series heat pump performance chartsDocument1 pageXHBQ-D series heat pump performance chartsarminsarajevoNo ratings yet

- Robotics 2Document13 pagesRobotics 2ChipNo ratings yet

- AT Product Data Sheet - VoltAire Systems - Document #CC0117FDocument7 pagesAT Product Data Sheet - VoltAire Systems - Document #CC0117FMarioNo ratings yet

- HVACDocument58 pagesHVACAnonymous 6V5QyM1M3LNo ratings yet

- Grilles & RegistersDocument19 pagesGrilles & RegistersBelal AlrwadiehNo ratings yet

- Mv-08 2nd, 4th, 7th & 8th Floor PlansDocument1 pageMv-08 2nd, 4th, 7th & 8th Floor PlansriyazNo ratings yet

- Duct DesignDocument31 pagesDuct DesignZul HafizzNo ratings yet

- Brochure Model RHSDWDocument4 pagesBrochure Model RHSDWcnbminhNo ratings yet

- Samsung Manual de Serviço PDFDocument118 pagesSamsung Manual de Serviço PDFjoseNo ratings yet

- RLPN060 5 Ton Ruud PDFDocument80 pagesRLPN060 5 Ton Ruud PDFClaudia YanerzNo ratings yet

- Residential Multi Split Databook PDFDocument168 pagesResidential Multi Split Databook PDFsaruthanNo ratings yet

- HVAC Systems ExplainedDocument42 pagesHVAC Systems ExplainedMunirKhanNo ratings yet

- Rino KK - Gas CompressorsDocument20 pagesRino KK - Gas Compressorsgustavofx21No ratings yet

- (BSR 401) Assignment 1 - Case StudyDocument11 pages(BSR 401) Assignment 1 - Case StudySiti NorliyanaNo ratings yet

- The Benefits of Utilizing Series Counterflow Variable Speed Screw ChillersDocument11 pagesThe Benefits of Utilizing Series Counterflow Variable Speed Screw ChillersAntonio LebrunNo ratings yet

- Multi City Comfort and Weather Comparison Tool Technical Manual - V1 PDFDocument6 pagesMulti City Comfort and Weather Comparison Tool Technical Manual - V1 PDFappucool_2007No ratings yet

- Duct Size Duct Size Velocity Duct Loss Pressure Pressure Length Width (Equiv Round) Airflow Velocity Pressure Length Coeff. Loss Per 100ft LossDocument1 pageDuct Size Duct Size Velocity Duct Loss Pressure Pressure Length Width (Equiv Round) Airflow Velocity Pressure Length Coeff. Loss Per 100ft LossAzher ANo ratings yet