Professional Documents

Culture Documents

Underground coalescence separator

Uploaded by

Karthikeyan SankarrajanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underground coalescence separator

Uploaded by

Karthikeyan SankarrajanCopyright:

Available Formats

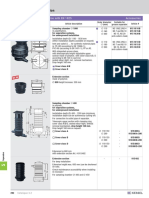

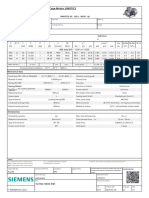

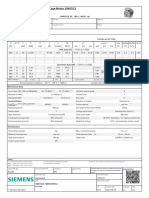

Coalescence separator

for underground installation

Coalescence separator NS 3 - NS 15

Illustration Article description NS Total volume Article #

Suitable for filling stations Coalescence separator NS 3 - NS 15, class I 1 NS 3 1800 99 503.10B EX

with high-performance filling pumps, according to EN 858, made of polymer NS 6 4300 99 706.30B EX

E10 and biodiesel fuels NS 6 5800 99 706.80B EX

For underground installation,

installation depth D = ..... mm NS 10 2600 99 710.15B EX

With integrated sludge trap and self-actuated closure NS 10 4300 99 710.30B EX

lock, calibrated for light liquid with densities between NS 10 5800 99 710.80B EX

0.85 to 0.95 g/cm3. NS 15 5800 99 715.80B EX

With removable coalescence filter.

2 NS 3 1800 99 503.10D EX

Upper sections made of polymer, continuous height

and level adjustment, tiltable to 5°, with covers NS 6 4300 99 706.30D EX

according to EN 124 in cast iron, including removal NS 6 5800 99 706.80D EX

mechanism, private vehicle traffic proof, class B NS 10 2600 99 710.15D EX

(depth of earth coverage DEC 700 to 1800 mm), NS 10 4300 99 710.30D EX

traffic proof for heavy duty vehicles, class D (depth of NS 10 5800 99 710.80D EX

earth coverage DEC 700 to 1500 mm and additional NS 15 5800 99 715.80D EX

concrete slab provided on-site), certified statics,

Inlet and outlet Ø ... for synthetic material pipes in:

PE-HD (according to EN 12666-1);

PVC pipe (according to EN 1401-1); PP or AS.

Choose separator size and article number from table

below. Contact KESSEL for separator sizing support

if required.

1 Cover class A/B

2 Cover class D

Certification no. Z-54.3-454 Ø 160: D-DEC = 155 mm

Ø 200: D-DEC = 180 mm

Accessories:

Sampling chamber for underground

DEC**

installation, extension section for

D

UET

deep installation, alarm units for when

쏗

쏗

the maximum oil level is reached

and there is a back-up of water

(required according to EN 858 Part 1),

h2

h1

oil and sludge suction system,

pump station, SonicControl, TeleControl.

L

Installation is possible with groundwater L max B

up to the upper edge of the tank (UET). **DEC = Depth of earth coverage

Class D = 700 mm ≤ DEC ≤ 1500 mm

A load distribution plate must be planned for class D. Class A/B = 700 mm ≤ DEC ≤ 1800 mm

Sludge trap D Oil storage Excess

NS Ø* capacity L B min max h2 h1 capacity level Weight Lmax mm

NS 3 160 1000 l 2390 1200 840 1240 1100 1070 217 l 80 mm 395 kg 2642

NS 6 200 2) 2500 l 1) 2590 1760 850 1230 1630 1600 271 l 100 mm 535 kg 2940

NS 6 200 2) 5000 l 3110 1760 870 1250 1630 1600 356 l 130 mm 610 kg 3460

NS 10 160 1500 l 2910 1200 840 1240 1110 1070 267 l 100 mm 440 kg 3162

NS 10 200 2) 2500 l 1) 2590 1760 850 1230 1630 1600 271 l 100 mm 535 kg 2940

Separators

NS 10 200 2) 5000 l 3110 1760 870 1250 1630 1600 356 l 130 mm 610 kg 3460

NS 15 200 5000 l 3110 1760 870 1250 1630 1600 356 l 130 mm 610 kg 3460

1) Comparable sludge trap total volume in accordance with the dimensioning according to EN 858.

5

2) eccentric reduction inlet/outlet to Ø 160 possible on-site, as a consequence the sampling chamber 915880 A/B/D can be used see page 304.

* Ø = Inlet and outlet outer diameter (mm)

Catalogue 3.2 301

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- For Underground Installation: Grease SeparatorsDocument1 pageFor Underground Installation: Grease SeparatorsKarthikeyan SankarrajanNo ratings yet

- Njoguini Estate Sewerline Athi River BQDocument2 pagesNjoguini Estate Sewerline Athi River BQmatunduraNo ratings yet

- Bomba Sumergible ZX (Alimentación)Document2 pagesBomba Sumergible ZX (Alimentación)Paolo MacNo ratings yet

- Typenstatik+NF+V1-V5+EPDM+2021+16 4 21-QR de enDocument15 pagesTypenstatik+NF+V1-V5+EPDM+2021+16 4 21-QR de enRaja ShekarNo ratings yet

- Dry-Type Transformer SpecificationDocument2 pagesDry-Type Transformer Specificationk_arindam1No ratings yet

- Abs Submersible Sewage Pump XFP 80C - 151e (GB)Document2 pagesAbs Submersible Sewage Pump XFP 80C - 151e (GB)Ashraf Gomah Mohamed ElshamandyNo ratings yet

- CW Pipe Thickness Calculation - 80% Vacuum - With RCCDocument39 pagesCW Pipe Thickness Calculation - 80% Vacuum - With RCCAshitava Sen0% (1)

- Cross-Talk Attenuators: D Deessc CR Riippttiio ON N H HO OW W Tto O Sseelleec CTTDocument3 pagesCross-Talk Attenuators: D Deessc CR Riippttiio ON N H HO OW W Tto O Sseelleec CTTFaquruddinNo ratings yet

- Sewage Pump XFP 80C-150EDocument2 pagesSewage Pump XFP 80C-150EJose CastroNo ratings yet

- Sandvik Ds210l VDocument4 pagesSandvik Ds210l Vlorenzo henerNo ratings yet

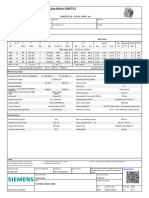

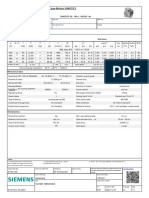

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- 8,800TEU Container Carrier LV Transformer SpecificationDocument21 pages8,800TEU Container Carrier LV Transformer SpecificationSerhiiNo ratings yet

- TechnicalSheet ESDocument1 pageTechnicalSheet ESAndreja GjureskiNo ratings yet

- Fantech - Wall SilencerDocument3 pagesFantech - Wall SilencerEN LeedNo ratings yet

- S Power Heat Pipe Data SheetDocument4 pagesS Power Heat Pipe Data SheetMohammad CholiqNo ratings yet

- Koyo Elevator Co,.LtdDocument4 pagesKoyo Elevator Co,.LtdOussamaNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- HC Atex 2016enDocument6 pagesHC Atex 2016enEmad AkleNo ratings yet

- API 620 DesignDocument27 pagesAPI 620 Designrsubramani100% (2)

- Double-Decking-System For Curtain-SiderDocument6 pagesDouble-Decking-System For Curtain-SiderAldair de Luis MoralesNo ratings yet

- Catalog Ava Air Valve Dok DoakDocument1 pageCatalog Ava Air Valve Dok Doakazlen494No ratings yet

- Fire - X 1620 - ENDocument2 pagesFire - X 1620 - ENFrikkie Le GrangeNo ratings yet

- Valaris DS 14Document2 pagesValaris DS 14LINGGA TRAVELNo ratings yet

- J0231 HV TR - FINAL变压器1Document23 pagesJ0231 HV TR - FINAL变压器1SerhiiNo ratings yet

- Fireproof ROOF Panels Technical InformationDocument4 pagesFireproof ROOF Panels Technical InformationMarko MiticNo ratings yet

- KNF Datasheet N 630-1-2 Ex 03-2022 WebDocument5 pagesKNF Datasheet N 630-1-2 Ex 03-2022 Webssp4ueverNo ratings yet

- IsDocument2 pagesIsvishnumani3011No ratings yet

- WWW - Imp-Ta - Si WWW - Imp-Ta - Si: Control The Stream Control The StreamDocument16 pagesWWW - Imp-Ta - Si WWW - Imp-Ta - Si: Control The Stream Control The StreamCedoNo ratings yet

- TD-ATEX Series: In-Line Mixed Flow Duct Explosion Proof FansDocument4 pagesTD-ATEX Series: In-Line Mixed Flow Duct Explosion Proof FansShahrukh AnsariNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- Check-List of General Building Services: AreasDocument6 pagesCheck-List of General Building Services: AreasJothimanikkam SomasundaramNo ratings yet

- 01 - Agitator Specification - 2001064277 10 R0Document4 pages01 - Agitator Specification - 2001064277 10 R0Erkan TakNo ratings yet

- Efficient submersible pump for wastewater and industrial applicationsDocument2 pagesEfficient submersible pump for wastewater and industrial applicationsdansalsaNo ratings yet

- 1822 Fema Elcis 63Document2 pages1822 Fema Elcis 63Nabil LiveNo ratings yet

- CTC Versao 2018Document9 pagesCTC Versao 2018Santosh kumarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: Ordering Data: 1LE1002-1AB42-2AA4nizarNo ratings yet

- Construction of Theatre in Chulaimbo HospitalDocument18 pagesConstruction of Theatre in Chulaimbo HospitalJoshuaNo ratings yet

- Circulators For Heating and Air Conditioning Systems: ApplicationsDocument18 pagesCirculators For Heating and Air Conditioning Systems: Applicationsresistance-bandsNo ratings yet

- 4000 m3 Storage Tank - Data SheetDocument3 pages4000 m3 Storage Tank - Data SheetSakthi Vel100% (1)

- 191120221906-Price BidDocument3 pages191120221906-Price Bidsatish goreNo ratings yet

- 69FSW 1134Document1 page69FSW 1134dip461No ratings yet

- 1LE1501-1EB43-4JA4 Datasheet enDocument1 page1LE1501-1EB43-4JA4 Datasheet enIbraheem AlfalahatNo ratings yet

- Catalouge 68Document2 pagesCatalouge 68Mais OmarNo ratings yet

- 250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Document3 pages250 ML Stirred Pressure Reactor Autoclaves Datasheet 1669874059Vamshika SutarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZOmair FarooqNo ratings yet

- Rockwool BoardsDocument12 pagesRockwool BoardsMohammed AwwadNo ratings yet

- 06100084EN3 - ZET-Horn 131-141 - SCREENDocument2 pages06100084EN3 - ZET-Horn 131-141 - SCREENenquiryNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- Hudetech Spring IsolatorDocument28 pagesHudetech Spring IsolatorThanh DoNo ratings yet

- Tds Isover TPDocument1 pageTds Isover TPBulent KABADAYINo ratings yet

- Econ Assignment BQDocument26 pagesEcon Assignment BQAnonymous dyEAKLWNo ratings yet

- VRV SYSTEM BILL OF QUANTITYDocument8 pagesVRV SYSTEM BILL OF QUANTITYFluidus EngineeringNo ratings yet

- 20m3 25m3 50m3 60m3 75m3 Elevated Water Reservoirs BoQDocument232 pages20m3 25m3 50m3 60m3 75m3 Elevated Water Reservoirs BoQKim Ryan Pomar100% (1)

- 1le1503 3ab53 4ab4Document2 pages1le1503 3ab53 4ab4Whipman ArduinoNo ratings yet

- Ceiling Concealed Air Conditioner ManualDocument111 pagesCeiling Concealed Air Conditioner ManualWing Hong SamNo ratings yet

- Colortran Mini Soft Lite Spec Sheet 1994Document2 pagesColortran Mini Soft Lite Spec Sheet 1994Alan MastersNo ratings yet

- 1LE1002-1DB43-4FB4 Datasheet enDocument1 page1LE1002-1DB43-4FB4 Datasheet enshashibagewadiNo ratings yet

- Oil Seperator 1 Data SheetDocument4 pagesOil Seperator 1 Data Sheetmohdmmedniyaz786No ratings yet

- 1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enDocument2 pages1MB1533-1EB49-0FB4-Z B43+M4B Datasheet enrianandiyahooNo ratings yet

- Air Flow Velocity in DuctsDocument2 pagesAir Flow Velocity in DuctsKarthikeyan SankarrajanNo ratings yet

- Shaft DesignDocument13 pagesShaft DesignKarthikeyan SankarrajanNo ratings yet

- Machines DesignDocument7 pagesMachines DesignKarthikeyan SankarrajanNo ratings yet

- Stress DesignDocument11 pagesStress DesignKarthikeyan SankarrajanNo ratings yet

- Brake DesignDocument2 pagesBrake DesignKarthikeyan SankarrajanNo ratings yet

- SMACNA - HVAC-Systems-Duct-Design1990 260Document1 pageSMACNA - HVAC-Systems-Duct-Design1990 260Karthikeyan Sankarrajan100% (1)

- Refrigerant Dehumidification Technology: Technical Bulletin 1Document12 pagesRefrigerant Dehumidification Technology: Technical Bulletin 1Karthikeyan SankarrajanNo ratings yet

- Seasonal Energy Efficien..Document6 pagesSeasonal Energy Efficien..Karthikeyan SankarrajanNo ratings yet

- Smacna Duct Fitting Loss TableDocument2 pagesSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

- Sewerage CalculatorDocument5 pagesSewerage CalculatorKarthikeyan SankarrajanNo ratings yet

- Health Facility GuidelinesDocument51 pagesHealth Facility GuidelinesAshok Kumar Pillai100% (1)

- Method statement for testing and commissioningDocument1 pageMethod statement for testing and commissioningKarthikeyan SankarrajanNo ratings yet

- Water Regulations Advisory Scheme Ltd. (Wras) Material ApprovalDocument2 pagesWater Regulations Advisory Scheme Ltd. (Wras) Material ApprovalKarthikeyan SankarrajanNo ratings yet

- F.A.Q. Picv: General Valve QuestionsDocument9 pagesF.A.Q. Picv: General Valve QuestionsKarthikeyan SankarrajanNo ratings yet

- Led Bollard Light: Item Code: EL-S-BOL-LEDDocument1 pageLed Bollard Light: Item Code: EL-S-BOL-LEDKarthikeyan SankarrajanNo ratings yet

- Led Top Pole Light: Item Code: LL-POLETOP-LEDDocument1 pageLed Top Pole Light: Item Code: LL-POLETOP-LEDKarthikeyan SankarrajanNo ratings yet

- IPC Loading UnitsDocument3 pagesIPC Loading UnitsTaqui Mubeen67% (3)

- Part 11. Air-Water System - Chapter 1. Induction Unit SystemDocument1 pagePart 11. Air-Water System - Chapter 1. Induction Unit SystemKarthikeyan SankarrajanNo ratings yet

- 00 HVAC CalcDocument52 pages00 HVAC Calcibson045001256No ratings yet

- Grease Trap TypesDocument1 pageGrease Trap TypesKarthikeyan SankarrajanNo ratings yet

- Fittings - K ValueDocument2 pagesFittings - K ValueKarthikeyan SankarrajanNo ratings yet

- Typical Kv valve sizing chartDocument1 pageTypical Kv valve sizing chartKarthikeyan SankarrajanNo ratings yet

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Document1 pagePart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNo ratings yet

- Lux LevelDocument1 pageLux LevelKarthikeyan SankarrajanNo ratings yet

- Air Duct Design Friction Loss ChartDocument1 pageAir Duct Design Friction Loss ChartKarthikeyan SankarrajanNo ratings yet

- Recommended Duct VelocitiesDocument1 pageRecommended Duct VelocitiesKarthikeyan Sankarrajan100% (1)

- Halton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Document4 pagesHalton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Karthikeyan SankarrajanNo ratings yet

- NTi Audio AppNote XL2 Noise CurvesDocument13 pagesNTi Audio AppNote XL2 Noise CurvesdjossNo ratings yet

- Advances in Remediation-eBookDocument88 pagesAdvances in Remediation-eBookalinerlfNo ratings yet

- Shivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursDocument4 pagesShivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursSHIVAM TAYALNo ratings yet

- Panama Canal Requirements N10-2018Document11 pagesPanama Canal Requirements N10-2018Anca Geanina100% (1)

- Ref Paper 2Document4 pagesRef Paper 2Subhanjali MyneniNo ratings yet

- Conveyor Chain GuideDocument59 pagesConveyor Chain GuideajaykrishnaaNo ratings yet

- Factors Affecting Purchase Intentions in Generation Z Towards Hipster Cafe in Kelantan LOCKEDDocument70 pagesFactors Affecting Purchase Intentions in Generation Z Towards Hipster Cafe in Kelantan LOCKEDlassan199358No ratings yet

- BNF Syntax of Ruby - Less than 40 character title for Ruby BNF syntax documentDocument2 pagesBNF Syntax of Ruby - Less than 40 character title for Ruby BNF syntax documentChristian FerrazNo ratings yet

- Circular Tank Radius CalculationDocument25 pagesCircular Tank Radius CalculationQamar AbbasNo ratings yet

- TNB AR 2022 Corporate StructureDocument2 pagesTNB AR 2022 Corporate StructureZamzuri P AminNo ratings yet

- TM4C129XNCZAD MicrocontrollerDocument2,191 pagesTM4C129XNCZAD Microcontrollermamaligosu1No ratings yet

- COSTECH Accelration of Innovation ImbejuDocument42 pagesCOSTECH Accelration of Innovation Imbejuhamidumajid033No ratings yet

- I) CentrifugesDocument46 pagesI) Centrifugesiahim87No ratings yet

- Safety Training Evaluation Form: Instructor RatingDocument1 pageSafety Training Evaluation Form: Instructor RatingNate JamesNo ratings yet

- Manual Instalaciones Electricas para Centros de ComputoDocument65 pagesManual Instalaciones Electricas para Centros de ComputoJorge Estrada0% (3)

- Industrial HygieneDocument31 pagesIndustrial HygieneGautam SharmaNo ratings yet

- ARL-300 UCM Test Instructions For Hydraulic Lifts - enDocument6 pagesARL-300 UCM Test Instructions For Hydraulic Lifts - enkizonimeisterNo ratings yet

- Battery Testing and MaintenanceDocument23 pagesBattery Testing and MaintenanceMormor Omerta0% (1)

- Introduction To Windows PDFDocument24 pagesIntroduction To Windows PDFRaymoon Twopass DaysNo ratings yet

- Timeline of Programming Languages PDFDocument11 pagesTimeline of Programming Languages PDFMohd Khir ZainunNo ratings yet

- 4c - Expanded - RevisedDocument132 pages4c - Expanded - RevisedMartín Serena75% (4)

- Questionnaire For Future BLICZerDocument1 pageQuestionnaire For Future BLICZerAlejandra GheorghiuNo ratings yet

- Results Part III - Part III-March 2017 - ElectricalDocument3 pagesResults Part III - Part III-March 2017 - ElectricalTharaka MunasingheNo ratings yet

- LogDocument27 pagesLogmilli0chilliNo ratings yet

- Needle System Guide For Old Industrial Singer Sewing MachinesDocument4 pagesNeedle System Guide For Old Industrial Singer Sewing MachinesWilberth FrancoNo ratings yet

- HEN SPF Roof Manual Spray Polyurethane FoamDocument77 pagesHEN SPF Roof Manual Spray Polyurethane FoamDavaakhuu ErdeneeNo ratings yet

- Plotting in AutoCAD - A Complete GuideDocument30 pagesPlotting in AutoCAD - A Complete GuideAdron LimNo ratings yet

- Axial Shortening of Column in Tall Structure.Document9 pagesAxial Shortening of Column in Tall Structure.P.K.Mallick100% (1)

- Julia Warner 2018Document1 pageJulia Warner 2018Julia WarnerNo ratings yet

- Builder's Greywater Guide Branched DrainDocument4 pagesBuilder's Greywater Guide Branched DrainGreen Action Sustainable Technology GroupNo ratings yet