Professional Documents

Culture Documents

JUKI ddl8700l

Uploaded by

Anwar HidayatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JUKI ddl8700l

Uploaded by

Anwar HidayatCopyright:

Available Formats

DDL-8700L

1-needle, Lockstitch Machine for Leather and Heavy Materials

Standard model of JUKI 1-needle lockstich machine for leather and heavy materials

DDL-8700L

13mm

The machine head was remodeled to achieve an optimumly balanced and highly rigid machine head frame. With its reduced vibration and noise and easy operation of the feed lever at the time of reverse stitching, the machine promises to make sewing work more comfortable. The wider distance from the machine arm to the needle on the front of the machine head, smoothened design of the machine head, larger needle bar stroke (35 mm), and higher lift of the presser foot (13 mm) enable easy handling of heavy material. In addition, the machine is equipped with a handwheel that is larger than normal for easy turning.

The machine has an attachment mounting seat. This make it easier to replace attachments and increases the durability of the machine bed. Furthermore, the machine is equipped with a feed eccentric pin. This enables easy adjustment of the feed dog inclination and feed timing(phase), thereby offering improved maintainability.

The stitch length can be adjusted to a maximum of 7mm(both in normal feed and reverse feed directions). The highly reliable and durable feed mechanism ensures accurate and consistent stitch length with no errors in the case of long stitching pitches.

Feed eccentric pin

The machine runs at higher sewing speeds than any other lockstitch machine intended for heavy materials anywhere in the world, reaching, up to 4,000sti/min for stitch length of less than 5mm and 3,500sti/min for stitch length of up to 7mm. The result is dramatically increased productivity.

Stitch dial

By adopting the locus best suited to the sewing of leather and heavy materials, the machine smoothly feeds heavy materials without stitch gathering even on multilayered portions. The machine also uses a fluorocarbon resin presser foot that offers sharp-curve sewing capability to prevent from scratch on the material. The hook, gauge, and thread take-up lever are all exclusively designed for the DDL-8700L to enhance its ability to produce beautiful well-tensed seams. The design ensures consistent sewing in difficult processes such as the sewing of heavy multilayered portions of the material with no stitch gathering or thread breakage.

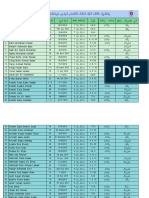

MODEL NAME Max. sewing speed Max. stitch length Needle bar stroke Lift of the presser foot

DDL-8700L 4,000sti/min (for stitch length less than 5mm) 3,500sti/min (for stitch length up to 7mm) 7mm(normal/reverse feed) 35mm By hand: 5.5mm, By knee: 13mm DB1(#21)#16#23 or DP5 Fluorocarbon resin presser foot 3-row Automatic-lubricating full-rotary hook Automatic JUKI Machine Oil No.7 (equivalent to ISO VG7) 28kg

sti/min stands for Stiches per Minute

Embossed JUKI mark

Needle (at the time of delivery) Presser foot Feed dog

CM001

Juki Corporation operates an environmental management system to promote and conduct the following as the company engages in the research, development, design, sales, distribution,and maintenance of industrial sewing machines, household sewing machines, industrial robots, etc., and in the provision of sales and maintenance services for data entry systems: (1) The development of products and engineering processes that are safe to the environment (2) Green procurement and green purchasing (3) Energy conservation (reduction in carbon-dioxide emissions) (4) Resource saving (reduction of papers purchased, etc.) (5) Reduction and recycling of waste (6) Improvement of logistics efficiency (modal shift and improvement of packaging, packing, etc.)

Hook Lubrication Lubricating oil Weight of the machine head

To order, please contact your nearest JUKI distributer.

SEWING MACHINERY BUSINESS UNIT

2-11-1, TSURUMAKI, TAMA-SHI, TOKYO 206-8551, JAPAN PHONE : (81) 42-357-2254 FAX : (81) 42-357-2274 http://www.juki.com

Specifications and appearance are subject to change without prior notice for improvement. Read the instruction manual before putting the machine into service to ensure safety. This catalogue prints with environment-friendly soy ink on recycle paper.

OCTOBER, 2011 Printed in Japan(A)

You might also like

- Turnaround ManagementDocument16 pagesTurnaround Managementpaisa321No ratings yet

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterRating: 4 out of 5 stars4/5 (3)

- Spica 3.2 PDFDocument55 pagesSpica 3.2 PDFKavi k83% (6)

- 118 - Puma 240Document24 pages118 - Puma 240TombongNo ratings yet

- OTE Outotec HIGmills Eng WebDocument4 pagesOTE Outotec HIGmills Eng WebjadetorresNo ratings yet

- Faccin Eng Web PDFDocument40 pagesFaccin Eng Web PDFIstván SzékelyNo ratings yet

- You Are The Light of The WorldDocument2 pagesYou Are The Light of The WorldKathleen Lantry100% (1)

- Vibrating Screen DesignDocument12 pagesVibrating Screen DesignAinur Rohman100% (2)

- Hammer MillsDocument56 pagesHammer MillskokiskoNo ratings yet

- Starmada House RulesDocument2 pagesStarmada House Ruleshvwilson62No ratings yet

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterNo ratings yet

- Shoe Machinery Unit II & IIIDocument106 pagesShoe Machinery Unit II & IIIashutosh100% (1)

- Sifter RS 3 EDocument4 pagesSifter RS 3 EjunnelNo ratings yet

- Notes (Part 1) : Accounting Policies, Changes in Estimates and ErrorsDocument13 pagesNotes (Part 1) : Accounting Policies, Changes in Estimates and ErrorsPaula Bautista100% (2)

- Brochure Hammer Mill Granulex DFZP FB19230 enDocument6 pagesBrochure Hammer Mill Granulex DFZP FB19230 enmuhammadnainNo ratings yet

- DDL-8100eB: This Sewing Machine Has Been Designed With A New ConceptDocument1 pageDDL-8100eB: This Sewing Machine Has Been Designed With A New Conceptsudheer15No ratings yet

- Single Needle Lock StitchDocument2 pagesSingle Needle Lock StitchSilky Prajapati100% (2)

- Rectas DDL 8700DOS TRESDocument2 pagesRectas DDL 8700DOS TRESElvis Aguilar JulcaNo ratings yet

- Juki DDL 8700LDocument2 pagesJuki DDL 8700LJose Antonio Rojas BautistaNo ratings yet

- Juki LZ-271 LZ-391N Catalogo PDFDocument2 pagesJuki LZ-271 LZ-391N Catalogo PDFEko RusmantoNo ratings yet

- JUKI - DDL8100eDocument0 pagesJUKI - DDL8100ejfilinich_1No ratings yet

- Cut Off Machines EnglishDocument8 pagesCut Off Machines EnglishMelissa SanchezNo ratings yet

- MF 7800Document4 pagesMF 7800Md Sahadat UllahNo ratings yet

- Juk I General Machines CatalogueDocument40 pagesJuk I General Machines CatalogueKokić MirzaNo ratings yet

- Loaia Star Linger MachineryDocument30 pagesLoaia Star Linger MachinerySaif MastoiNo ratings yet

- Juki ms1261Document6 pagesJuki ms1261Piyush SinghNo ratings yet

- Juki MH 380Document4 pagesJuki MH 380jongaeckNo ratings yet

- AMS - 224EN SeriesDocument8 pagesAMS - 224EN SeriesJose Antonio Rojas BautistaNo ratings yet

- Technical Specifications of Cutting and Spreading MachinesDocument49 pagesTechnical Specifications of Cutting and Spreading MachinesIndranil Saha50% (4)

- SP 162 Cer Leaflet enDocument4 pagesSP 162 Cer Leaflet enDelibash WholucyNo ratings yet

- Milling Equipment: Product DetailsDocument9 pagesMilling Equipment: Product DetailsPepy PeachNo ratings yet

- JUKIDocument2 pagesJUKIRajib RaihanNo ratings yet

- Spme IIDocument73 pagesSpme IIAnshuman PandeyNo ratings yet

- 3 Ply Carton Machine QuotationDocument14 pages3 Ply Carton Machine QuotationautocareyeNo ratings yet

- Various Type of Fabric Cutting Machines: Anirban Sikder Yogesh KadianDocument19 pagesVarious Type of Fabric Cutting Machines: Anirban Sikder Yogesh KadianYogesh KadianNo ratings yet

- Cutting EdgeDocument8 pagesCutting EdgeVictoria TechiNo ratings yet

- AA MJAE - Volume 33 - Issue 1 - Pages 123-150Document28 pagesAA MJAE - Volume 33 - Issue 1 - Pages 123-150Joseph DatonouNo ratings yet

- Ams 224 eDocument8 pagesAms 224 eUnggul NasrullohNo ratings yet

- Recent Developments in Spinning, Weaving and Wet Processing Industry - Textile LearnerDocument10 pagesRecent Developments in Spinning, Weaving and Wet Processing Industry - Textile LearnerVaanazhaganNo ratings yet

- Nitta Belt PolyDocument16 pagesNitta Belt PolyVictor MoralesNo ratings yet

- Flatbed and Rotary DieDocument10 pagesFlatbed and Rotary DieAliArababadi100% (2)

- Recent Development of Modern Spinning and WeavingDocument20 pagesRecent Development of Modern Spinning and WeavingsuganNo ratings yet

- Sai Extrumech Alias Sai EngineeringDocument18 pagesSai Extrumech Alias Sai EngineeringsaiextrumechNo ratings yet

- Juki DLN-9010Document4 pagesJuki DLN-9010Jose Antonio Rojas BautistaNo ratings yet

- Button Hole MachineDocument4 pagesButton Hole MachineHarun ar RashidNo ratings yet

- Juki DDL-5550 Single Needle Lockstitch MachineDocument3 pagesJuki DDL-5550 Single Needle Lockstitch MachineAbu Anas100% (1)

- Linearschwingsieb enDocument12 pagesLinearschwingsieb enBrunoNo ratings yet

- Waste Sorting SolutionDocument8 pagesWaste Sorting SolutionLi GaryNo ratings yet

- Spreading and Cutting MachinaryDocument21 pagesSpreading and Cutting Machinarypsyish100% (1)

- Double Jersey Circular Knitting Machine by TerrotDocument17 pagesDouble Jersey Circular Knitting Machine by TerrotMd Ahmmad Ullah100% (1)

- Spreading and Cutting Equipments: Spme-IiDocument23 pagesSpreading and Cutting Equipments: Spme-IiNeetek SahayNo ratings yet

- (38-48) Performance Evaluation of Locally Fabricated Slipping Machine For Natural Rubber Wood ProcessingDocument12 pages(38-48) Performance Evaluation of Locally Fabricated Slipping Machine For Natural Rubber Wood ProcessingAlexander DeckerNo ratings yet

- Designing and Fabrication of Multipurpose Tool Post For Lathe MachineDocument3 pagesDesigning and Fabrication of Multipurpose Tool Post For Lathe MachineRahul ShrivastavaNo ratings yet

- Latest Technologies and Developments in Spinning, Weaving, and ProcessingDocument8 pagesLatest Technologies and Developments in Spinning, Weaving, and Processingkhushi savlaNo ratings yet

- Unity Pwoer Point-2Document61 pagesUnity Pwoer Point-2Jai SankerNo ratings yet

- Textiles - Nonwovens: BeltingDocument8 pagesTextiles - Nonwovens: BeltingSariyyaHeydarovaNo ratings yet

- Orient Paper MillsDocument17 pagesOrient Paper MillsEr Mohneesh0% (1)

- Product Information Ryobi 750GE SeriesDocument8 pagesProduct Information Ryobi 750GE SeriesnzeeNo ratings yet

- Juki Mo6100dDocument6 pagesJuki Mo6100djongaeckNo ratings yet

- Catalog Kafo Ka40 PDFDocument8 pagesCatalog Kafo Ka40 PDFFrederik HenderwanzaNo ratings yet

- Contents IMN June 08Document3 pagesContents IMN June 08Dirgantara Noor InsandamudaNo ratings yet

- Thread Trimming Machine in Garment ManufacturingDocument26 pagesThread Trimming Machine in Garment ManufacturingMansi ChandNo ratings yet

- 2m EPS Block Production LineDocument10 pages2m EPS Block Production LineBoulos NassarNo ratings yet

- Remalle Mo 6900gjDocument4 pagesRemalle Mo 6900gjElvis Aguilar JulcaNo ratings yet

- Erema Coax Instalatie Reciclare PlasticDocument4 pagesErema Coax Instalatie Reciclare PlasticSilviu PetreNo ratings yet

- Gandhi An Exemplary LeaderDocument3 pagesGandhi An Exemplary LeaderpatcynNo ratings yet

- NIST SP 800-53ar5-1Document5 pagesNIST SP 800-53ar5-1Guillermo Valdès100% (1)

- Specpro.09.Salazar vs. Court of First Instance of Laguna and Rivera, 64 Phil. 785 (1937)Document12 pagesSpecpro.09.Salazar vs. Court of First Instance of Laguna and Rivera, 64 Phil. 785 (1937)John Paul VillaflorNo ratings yet

- Shop Decjuba White DressDocument1 pageShop Decjuba White DresslovelyNo ratings yet

- Brunon BradDocument2 pagesBrunon BradAdamNo ratings yet

- Letter To Singaravelu by M N Roy 1925Document1 pageLetter To Singaravelu by M N Roy 1925Avinash BhaleNo ratings yet

- The Key To The Magic of The Psalms by Pater Amadeus 2.0Document16 pagesThe Key To The Magic of The Psalms by Pater Amadeus 2.0evitaveigasNo ratings yet

- Coursework Assignment: Graduate Job ImpactDocument13 pagesCoursework Assignment: Graduate Job ImpactmirwaisNo ratings yet

- eLTE5.0 DBS3900 Product Description (3GPP)Document37 pageseLTE5.0 DBS3900 Product Description (3GPP)Wisut MorthaiNo ratings yet

- Eicher HR PoliciesDocument23 pagesEicher HR PoliciesNakul100% (2)

- Vayigash BookletDocument35 pagesVayigash BookletSalvador Orihuela ReyesNo ratings yet

- How To Write A Driving School Business Plan: Executive SummaryDocument3 pagesHow To Write A Driving School Business Plan: Executive SummaryLucas Reigner KallyNo ratings yet

- Integrative Assessment OutputDocument2 pagesIntegrative Assessment OutputRonnie TambalNo ratings yet

- Who Is He? Where Is He? What Does He Do?Document3 pagesWho Is He? Where Is He? What Does He Do?David Alexander Pacheco Morales100% (1)

- Internship Report Mca Audit Report InternshipDocument33 pagesInternship Report Mca Audit Report InternshipJohnNo ratings yet

- Dda 2020Document32 pagesDda 2020GetGuidanceNo ratings yet

- 4-Cortina-Conill - 2016-Ethics of VulnerabilityDocument21 pages4-Cortina-Conill - 2016-Ethics of VulnerabilityJuan ApcarianNo ratings yet

- The Approach of Nigerian Courts To InterDocument19 pagesThe Approach of Nigerian Courts To InterMak YabuNo ratings yet

- 2015 3d Secure WhitepaperDocument7 pages2015 3d Secure WhitepapersafsdfNo ratings yet

- Financial Report: The Coca Cola Company: Ews/2021-10-27 - Coca - Cola - Reports - Continued - Momentum - and - Strong - 1040 PDFDocument3 pagesFinancial Report: The Coca Cola Company: Ews/2021-10-27 - Coca - Cola - Reports - Continued - Momentum - and - Strong - 1040 PDFDominic MuliNo ratings yet

- CKA CKAD Candidate Handbook v1.10Document28 pagesCKA CKAD Candidate Handbook v1.10Chiran RavaniNo ratings yet

- Open Quruan 2023 ListDocument6 pagesOpen Quruan 2023 ListMohamed LaamirNo ratings yet

- Organizational Behavior: Chapter 6: Understanding Work TeamDocument6 pagesOrganizational Behavior: Chapter 6: Understanding Work TeamCatherineNo ratings yet

- HelpDocument5 pagesHelpMd Tushar Abdullah 024 ANo ratings yet

- "Working Capital Management": Master of CommerceDocument4 pages"Working Capital Management": Master of Commercekunal bankheleNo ratings yet