Professional Documents

Culture Documents

API 650 Tank Design 1

API 650 Tank Design 1

Uploaded by

maxhoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 650 Tank Design 1

API 650 Tank Design 1

Uploaded by

maxhoCopyright:

Available Formats

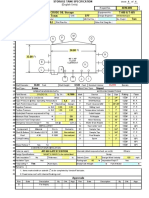

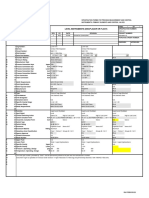

Project No.

J543 11-T-503

Seth A. Duazo No. Req'd :

1 Service : 2 Location : 3 Manufacturer : 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Shell Diameter : 25 Roof Type : 26 P&ID No.

USED LUBE OIL Unit : Al Kharj, Saudi Arabia Model : NMC

Plot Plan No. :

Equipment No. :

11T-503

Mfr Ref. No. :

Design Engineer : Other Ref. Dwg No. :

Two

M G

125.30 46.00 Ft E L

F N1

125.30 Cone

Feet Shell Height :

Ft

H

24" X 36" FLUSH CLEANOUT

E D

N2

J

46.00

Feet

I

Nominal Volume :

101,026

Barrels

Bottom Floor Type: Sp. Gr. : Cyclic psia Design 0.50 2.00

Sloped

NOZZLES/CONNECTIONS Qty 1 2 1 1 0 1 1 0 1 1 2 1 1 1 Size 24" 24" 24"x36" 8" 0 12" 8" 0 4" 4" 3/4" 3/4" 4" 3/4"

OPERATING/DESIGN DATA

LUBE OIL 27 Fluid Stored : 28 This Tank Service is considered:

0.9000

Mark TH1 TH TH2 G H B A K D M F F P D

Service Roof Manway Shell Manway Flush Cleanout MW Stilling Vent Temperature Indicator Outlet Nozzle Fill Nozzle Mixer Manway Water Draw Nozzle Top Center Vent Sample Tap Sample Tap Roof Nozzle Spare

5.5 29 Vapor Pressure @ Max. Operating Temperature 30 Flash Point (Closed Cup) : F Operating

31 Negative Pressure 32 Positive Pressure 33 (Hydro)test Pressure expressed in Psig 34 Minimum Fluid Temperature 35 Maximum Fluid Temperature 36 Emergency Vacuum Design ? 37 38 Component 39 Shell & Bottom 40 Roof 41 Lining/Coating 42 43 Stress Relieve ? 44 45 Code (as appl.): 46 Design Specifications: 47 Tank Insulation ? 48 Insulation Type: 49 Fireproofing ? 50 Remarks 51 52 No Hot No for: CONSTRUCTION/FABRICATION Material A36 A36 No METALLURGY CA, in. 0.0625 0.0313 oz/in.2 psig F F Set @ 0.0.3 0.00 1.00

----25 200

oz/in.2

Remarks Normalized Normalized

Rating 150# 125# 125# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150#

Others: 120 Yes

Face F. F. R. F. R. F. F. F. L. J. API L. J. F. F. R. F. API R. F. F. F. L. J. API API API

API 650 LATEST EDITION

Thickness : Paint Spec. in.

Internals (attach separate sheet, as req'd): Sump Seismic Zone Radiograph 85 EmptyTank Weight

Design Wind Velocity % Inspection Req'd ? Full of Water lb

mph lb

No

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator. 2. Rafter supported type cone roof

Approvals

Rev 0 Date Description J543 By Chk. Appr. Rev Date Description By Chk. Appr.

Rev. No.

Nass Mechanical

STORAGE TANK SPECIFICATION (English Units)

Sheet

1 of 1

API 650 Storage Tank

5/27/2013 Rev: 0

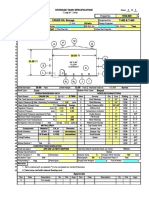

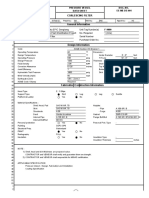

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet Shell Plate Design : 125.30 46.00

38.2 meters 14.0 meters

FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE 0.9 23,200 1.00 24,900 0.1180 20mm 0.569 0.589 0.707 125.30 46.00 1.00 23,200 1.00 24,900 0.1180 18.000 0.632 0.589 0.651 125.30 39.454 1.00 23,200 1.00 24,900 0.0625 16.000 0.540 0.503 0.566 125.30 32.909 1.00 23,200 1.00 24,900 0.0625 13.72 mm 12.78 mm 14.37 mm 16.05 mm 14.95 mm 16.54 mm 14.45 mm 14.95 mm 17.952 mm

SG = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For First Course (Bottom) A36 Plate ;

As per API 5.6.3.2 In US Customary units;

160 Mpa 171 Mpa 3.00 mm

Provided thickness:

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet = H = depth of tank , in feet = SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For Second Course A36 Plate

As per API 5.6.3.2 In US Customary units;

Provided thickness:

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet H = depth of tank , in feet SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For Third Course A36 Plate

As per API 5.6.3.2 In US Customary units;

Provided thickness:

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet H = depth of tank , in feet SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance

Seth A. Duazo Nass Mechanical

Page 2 of 5

FileName: 147916997.xls.ms_office WorkSheet: 11T-503A

API 650 Storage Tank

5/27/2013 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet For Fourth Course A36 Plate

As per API 5.6.3.2 In US Customary units;

125.30 46.00 Provided thickness: 12.000 0.488 0.417 0.480 125.30 26.3632 1.00 21,300 1.00 24,900 0.0625 10mm 0.388 0.332 0.394 125.30 19.754 1.00 21,300 1.00 24,900 0.0625 8mm 0.258 0.245 0.308 125.30 13.194 0.9 21,300 1.00 24,900 0.0625 8mm 0.187 0.160 0.222 125.30 6.63 1 21,300 1.00 24,900 0.0625

38.2 meters 14.0 meters

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet H = depth of tank , in feet SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For Fifth Course A36 Plate

As per API 5.6.3.2 In US Customary units;

12.40 mm 10.60 mm 12.19 mm

Provided thickness:

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet H = depth of tank , in feet SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For Sixth Course A36 Plate

As per API 5.6.3.2 In US Customary units;

9.85 mm 8.43 mm 10.02 mm

Provided thickness:

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet H = depth of tank , in feet SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance For Seventh Course A36 Plate

As per API 5.6.3.2 In US Customary units;

6.56 mm 6.23 mm 7.82 mm

Provided thickness:

td = 2.6(D)(H -1)(SG)/Sd = tt = 2.6(D)(H-1)/St = td = Minimum shell course thickness plus C.A, in inches = D = Normal tank diameter , in feet H = depth of tank , in feet SG = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress A36 Hydro Test CA = Corrosion Allowance

4.74 mm 4.05 mm 5.64 mm

Seth A. Duazo Nass Mechanical

Page 3 of 5

FileName: 147916997.xls.ms_office WorkSheet: 11T-503A

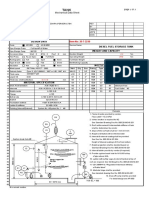

API 650 Storage Tank

5/27/2013 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet BOTTOM PLATE DESIGN:

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.4.1;

125.30 46.00

38.2 meters 14.0 meters

Minimum Nominal Thickness excluding corrosion allowance, Inch Corrosion Allowance for Bottom Plate Required Thickness of Bottom Plate Used bottom plate thickness Minimum Nominal Width, Inch Used bottom plate Width,in ANNULAR BOTTOM PLATE DESIGN:

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.5.2;

0.25 0.125 0.25 0.375 70.866 78.74

6.35 3.18 6.35 10 1800.0 2000.0

mm mm mm mm mm mm

Minimum Annular plate Width shall be =

215 tb ( GH )0.5 or a Minimum of

28.62 23.622

727 mm 600 mm 760 mm

Annular Plate width provided; in

29.92 Where: tb = Annular plate thickness, mm H = maximum Design Liquid level, Meter G = liquid Specific gravity

HENCE, OK.

ROOF PLATE DESIGN: ( Non Frangible roof Tank)

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.10.2.2,

Minimum Nominal Thickness excluding corrosion allowance = Corrosion Allowance for Roof Plate, = Required Thickness of Roof Plate = Used roof plate thickness = SHELL STABILITY CHECK;

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.9.7.1

0.1875 0 0.1875 0.1875

5 0 5 5

mm mm mm mm

The Maximum height for the unstiffined shell shall be calculated as follows: H1 = 600,000*(t)*(((t/D)^3)^0.5)*(120 /V)^2 = , ft 23.82 7.26 Meters Where; H1 = Vertical Distance in ft, betwwen the intermediate wind girder and the top angle of the shell or the top wind girder of an open top tank t = as built thickness, unless otherwise specified of the thinnest shell course (in Inches) D = Nominal Tank height, Ft V = Designed wind speed (3 sec gust)mph

Seth A. Duazo Nass Mechanical

Page 4 of 5

FileName: 147916997.xls.ms_office WorkSheet: 11T-503A

API 650 Storage Tank

5/27/2013 Rev: 0

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

D = Normal tank diameter , in feet H = depth of tank , in feet Equivalent stable height of shell at ' t ' min. HE = sum He He = W( ' t 'min / ' t 'actual)^2.5 As per API 650 11th Ed. 2009 Add. 2 Sect. V.8.1.4 (b) Course Width (M) t' min (mm) 1 1.995 20.00 2 1.995 16.00 3 1.995 15.00 4 2.0 12.00 5 2.0 10.00 6 2.0 8.00 7 2.0 8.00 Minimum Shell Thickness = 8mm Transformed shell height, Maximum height of unstiffined shell= 125.30 46.00

38.2 meters 14.0 meters

Wtr (Meter) 0.202 0.353 0.414 0.726 1.145 2.000 2.000

W' tr 7.26 Meters

6.840

Meters

H1 > Wtr, hence intermediate wind girder is not required

Seth A. Duazo Nass Mechanical

Page 5 of 5

FileName: 147916997.xls.ms_office WorkSheet: 11T-503A

You might also like

- MNPS Proposed BudgetDocument24 pagesMNPS Proposed BudgetPaige WindsorNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (30)

- Data Sheet - Storage-Tank-Specification PDFDocument1 pageData Sheet - Storage-Tank-Specification PDFKimberly Conley100% (2)

- A&D High Tech - Team 2Document9 pagesA&D High Tech - Team 2Alexis ParedesNo ratings yet

- Tank Anchorage (Overturning Stability)Document3 pagesTank Anchorage (Overturning Stability)robertantoreni100% (2)

- Tank Anchorage (Overturning Stability)Document3 pagesTank Anchorage (Overturning Stability)robertantoreni100% (2)

- Electronic Ticket Receipt, October 11 For ARTATES MERLAMINA MSDocument2 pagesElectronic Ticket Receipt, October 11 For ARTATES MERLAMINA MSRamilArtatesNo ratings yet

- API 650 Tank Design Ver 1Document18 pagesAPI 650 Tank Design Ver 1Helena Martins100% (1)

- Tank DesignDocument8 pagesTank DesignAhmed El Hawari100% (1)

- Storage Tank CALC Api 650Document10 pagesStorage Tank CALC Api 650kuselanml100% (3)

- API 650 Tank Design 1foot MethodDocument4 pagesAPI 650 Tank Design 1foot Methodjakjak67% (3)

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- Calculation API 650Document78 pagesCalculation API 650jamil93% (14)

- Calculation - ASME VIII Div.1Document10 pagesCalculation - ASME VIII Div.1bargez100% (1)

- API 650 Tank DesignDocument8 pagesAPI 650 Tank DesignJorge Rodriguez HerreraNo ratings yet

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Diagrama Motor c9Document2 pagesDiagrama Motor c9Juan Pablo Leon Ruales83% (6)

- Chapter 8: Designing For Heating and CoolingDocument11 pagesChapter 8: Designing For Heating and CoolingmegaspiceNo ratings yet

- RH340Document8 pagesRH340ericNo ratings yet

- API 650 Tank Design 5Document44 pagesAPI 650 Tank Design 5Inamullah Khan93% (14)

- Tank CalculationsDocument1 pageTank CalculationsJp Rao67% (3)

- B ABJ 5000 2 API 650 Calculation ReportDocument46 pagesB ABJ 5000 2 API 650 Calculation ReportSalamaNo ratings yet

- API 650 Tank CalculationDocument30 pagesAPI 650 Tank Calculationsachin8389100% (2)

- Storage Tank Design CalculationDocument12 pagesStorage Tank Design Calculationhtutswe80% (15)

- Pressure Vessel Design (Faiz Zelin)Document1 pagePressure Vessel Design (Faiz Zelin)moonstar_dme100% (3)

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDrina2393No ratings yet

- AMETank PDFDocument6 pagesAMETank PDFMadan Yadav50% (2)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsGuliberto AndradesNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationbhavanamadhuri itapu100% (1)

- Fire Water Tank Foundation - DesignDocument7 pagesFire Water Tank Foundation - DesignAnonymous IF7Pu4eS100% (1)

- Tank Design 1Document1 pageTank Design 1RamadanNo ratings yet

- API 650 Tank DesignDocument1 pageAPI 650 Tank Designanto3harrish3fdoNo ratings yet

- Storage Tank 50KL.Document1 pageStorage Tank 50KL.RajdeepsinhNo ratings yet

- Api 650 Tank Design Calculationxls Energy andDocument8 pagesApi 650 Tank Design Calculationxls Energy andjalil ahmedNo ratings yet

- API 650 Tank Design Calculationxls Energy and CompressDocument8 pagesAPI 650 Tank Design Calculationxls Energy and CompressTech ManagerNo ratings yet

- API 650 Tank Design Calculationxls Energy and CompressDocument8 pagesAPI 650 Tank Design Calculationxls Energy and Compressجيلالي نفوسيNo ratings yet

- Memoria - Tanque N 1° La2326cDocument98 pagesMemoria - Tanque N 1° La2326cmile457100% (1)

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- P 102 A B - Rev 0.00Document3 pagesP 102 A B - Rev 0.00dineshsirasatNo ratings yet

- Tower-Process-Data-Sheet - Ex (Version 1)Document1 pageTower-Process-Data-Sheet - Ex (Version 1)Abraham Burgos CelisNo ratings yet

- Reactor HOJA DE DATOSDocument4 pagesReactor HOJA DE DATOSRodrigo GraciaNo ratings yet

- Control Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Document2 pagesControl Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Mateus EliasNo ratings yet

- Datasheet-Process CompressorDocument1 pageDatasheet-Process CompressorZaw Htet WinNo ratings yet

- Hoja de Datos Tanque de AlmacenamientoDocument8 pagesHoja de Datos Tanque de AlmacenamientoRodrigo Gracia100% (1)

- AZ Safety Pressure Valve (Design)Document2 pagesAZ Safety Pressure Valve (Design)ZangNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Pulau Indah Power Plant SDN BHD: Data Sheet For Manual Simplex StrainerDocument4 pagesPulau Indah Power Plant SDN BHD: Data Sheet For Manual Simplex StrainerJung Kyung WooNo ratings yet

- Drum PDSDocument1 pageDrum PDScavidan20055No ratings yet

- Tosaca: CX 45-21 RFQ PSVDocument2 pagesTosaca: CX 45-21 RFQ PSVichi ezzahraNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Drum PDSDocument1 pageDrum PDScavidan20055No ratings yet

- TK-133023 (COATING MATERIAL MIXING TANK) - 3+ú ÔDocument1 pageTK-133023 (COATING MATERIAL MIXING TANK) - 3+ú ÔDarkvaderNo ratings yet

- 3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Document1 page3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Cristobal CherigoNo ratings yet

- Mechanical DesignDocument11 pagesMechanical DesignVilas AndhaleNo ratings yet

- Contoh SoalDocument13 pagesContoh Soalmarkus andikaNo ratings yet

- Pemex Exploracion Y Produccion Level Instruments (Discplacer or Float) Akal B5-BDocument1 pagePemex Exploracion Y Produccion Level Instruments (Discplacer or Float) Akal B5-BIgnacia Ramon JaimeNo ratings yet

- Daily Purchase Equipment ItemDocument1 pageDaily Purchase Equipment ItemAD KhanNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- XXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDocument8 pagesXXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDương HoàngNo ratings yet

- Revision Index: EngenhariaDocument2 pagesRevision Index: EngenhariaBruno AlfanoNo ratings yet

- Customer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormDocument2 pagesCustomer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormGustavo GarciaNo ratings yet

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- FIXED TUBESHEET RULES According To UHX-13 Using MathcadDocument20 pagesFIXED TUBESHEET RULES According To UHX-13 Using MathcadrobertantoreniNo ratings yet

- E.3.2 - MDMT Using MathcadDocument2 pagesE.3.2 - MDMT Using MathcadrobertantoreniNo ratings yet

- API 650 15ft Dia Tank FoundationDocument1 pageAPI 650 15ft Dia Tank FoundationrobertantoreniNo ratings yet

- E4.3.5 - Elliptical Head Div-1 & 2 Using MathcadDocument5 pagesE4.3.5 - Elliptical Head Div-1 & 2 Using MathcadrobertantoreniNo ratings yet

- Tank Standards and Part 4 SP001 InspectionsDocument24 pagesTank Standards and Part 4 SP001 Inspectionsrobertantoreni100% (1)

- Crue Oil 7500bbl API 650 DatasheetDocument16 pagesCrue Oil 7500bbl API 650 DatasheetrobertantoreniNo ratings yet

- Pipe Schedule ChartDocument1 pagePipe Schedule ChartrobertantoreniNo ratings yet

- Silo Design Report-1Document17 pagesSilo Design Report-1robertantoreniNo ratings yet

- TECHNICAL DESIGN-Calculation Report-Clinker SiloDocument128 pagesTECHNICAL DESIGN-Calculation Report-Clinker SiloNam Ngô DuyNo ratings yet

- License Manager Update Windows FirewallDocument6 pagesLicense Manager Update Windows FirewallrobertantoreniNo ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Bolt SelectionDocument44 pagesBolt SelectionrobertantoreniNo ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Excel Tool VBA Password RecoveryDocument1 pageExcel Tool VBA Password RecoveryrobertantoreniNo ratings yet

- Mango Materials PaperDocument8 pagesMango Materials PaperSierra Law100% (1)

- H2 Literature P3 - Who's Afraid of Virginia Woolf - (WAVW - Woolf) IntroductionDocument16 pagesH2 Literature P3 - Who's Afraid of Virginia Woolf - (WAVW - Woolf) Introductionmandy min100% (1)

- Announcement 01 Oct PDFDocument2 pagesAnnouncement 01 Oct PDFgaurav chauhanNo ratings yet

- Cultivation of Two Species of Mushroom Found in Anambra State, South Eastern, Nigeria and Their Potentials For Bioremediation of Trace Metals Polluted SoilDocument12 pagesCultivation of Two Species of Mushroom Found in Anambra State, South Eastern, Nigeria and Their Potentials For Bioremediation of Trace Metals Polluted SoilEditor IJTSRDNo ratings yet

- A Rich Life With Less Stuff by The Minimalists: Before You WatchDocument5 pagesA Rich Life With Less Stuff by The Minimalists: Before You WatchFelipe AndradeNo ratings yet

- Handbook of Mechanical Engineering CalculationsDocument15 pagesHandbook of Mechanical Engineering CalculationsBkhari Haran100% (1)

- NEA's Ra Today, Issue 4, July 3, 2021Document31 pagesNEA's Ra Today, Issue 4, July 3, 2021Los Angeles Daily NewsNo ratings yet

- 3010182428unit Run Canteen (Urc) Manual PDFDocument206 pages3010182428unit Run Canteen (Urc) Manual PDFShyam Prabhu50% (2)

- IP Ref List-MOST RECENT-8-2-13Document30 pagesIP Ref List-MOST RECENT-8-2-13BlaireNo ratings yet

- OMNI S Service Manual - Rev4 - Grips (Manual de Servicio RevisiDocument274 pagesOMNI S Service Manual - Rev4 - Grips (Manual de Servicio RevisiDario Briceño100% (1)

- Black Swan Group 11 PDFDocument15 pagesBlack Swan Group 11 PDFTrAmI SiMiNo ratings yet

- Competency Based Learning MaterialsDocument72 pagesCompetency Based Learning MaterialsLynde MaputolNo ratings yet

- Settling Parties' Motion To Approve Settlement AgreementDocument93 pagesSettling Parties' Motion To Approve Settlement AgreementL. A. PatersonNo ratings yet

- P-413 Technical Data SheetDocument5 pagesP-413 Technical Data SheetdennisjuntakNo ratings yet

- Vegan+Egg+Replacement+BAKERpaper FinalDocument7 pagesVegan+Egg+Replacement+BAKERpaper FinalSQF PractitionerNo ratings yet

- Chapter 2Document43 pagesChapter 2Puvaneswary SegharanNo ratings yet

- Prework QuestionsDocument6 pagesPrework Questionsapi-648757084No ratings yet

- 10 Câu Wordform Olympic 30Document2 pages10 Câu Wordform Olympic 30Hai Anh100% (2)

- Information Data SheetDocument39 pagesInformation Data SheetSaud DhopawnkarNo ratings yet

- Ib Chemistry Answers S3Document14 pagesIb Chemistry Answers S3Carlos JesúsNo ratings yet

- ETFO Internal Memo On New CurriculumDocument2 pagesETFO Internal Memo On New CurriculumCityNewsTorontoNo ratings yet

- Security Roadmap Guide Brochure - OnlineDocument14 pagesSecurity Roadmap Guide Brochure - OnlineEnrique CornielleNo ratings yet

- '02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinDocument5 pages'02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinElvin Domingo100% (1)

- Module 2 SolutionDocument2 pagesModule 2 SolutionLJ Valdez100% (1)